Device and method for gas-liquid fluidization exploitation of old goaf slime water

A technology for old gobs and conversion devices, applied in coal gasification, preparation of liquid hydrocarbon mixtures, mining fluids, etc., can solve problems such as waste of coal slime and water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

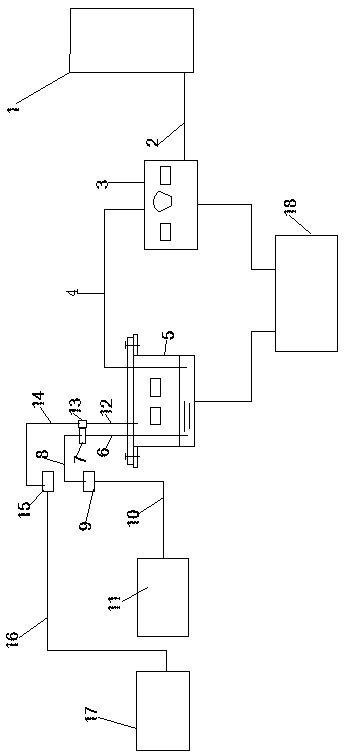

Method used

Image

Examples

Embodiment 1

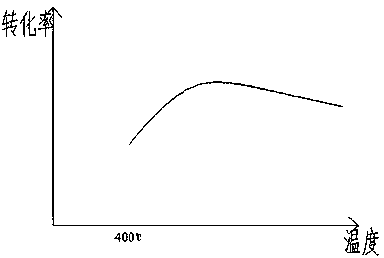

[0056] The above-mentioned equipment for coal slime water-gas-liquid fluidized mining in the old empty area was used to conduct experiments on the conversion efficiency of coal slime at different temperatures. The experimental steps are as follows:

[0057] Step 1: Determine the experimental plan; assume that the experimental pressure is 5 atmospheres, no catalyst is added, and the experimental material comes from the coal slime water in the old empty area whose coal quality is lignite. The temperature is controlled by computer, and multiple experiments are carried out.

[0058] Step 2, sample preparation; sample preparation 0.5 cubic meters of coal slime water.

[0059] Step 3, air tightness inspection; connect the experimental devices in order, generate a certain amount of steam through the heater, and judge the air tightness by observing the value change of the pressure sensor on the slime water-gas liquefaction conversion box. If there is almost no change in the value of ...

Embodiment 2

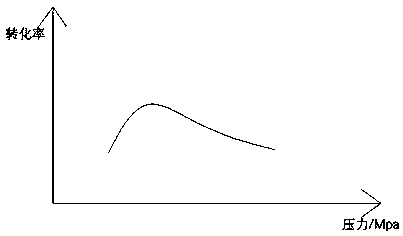

[0071] The above-mentioned device for coal slime water-gas-liquid fluidized mining in the old empty area was used to conduct experiments on the conversion efficiency of coal slime under different pressures. The experimental steps are as follows:

[0072] Step 1: Determine the experimental plan; assume that the experimental temperature is 400°C, no catalyst is added, and the experimental material comes from the coal slime water in the old empty area whose coal quality is lignite. The pressure is controlled by computer, and multiple experiments are carried out.

[0073] Step 2, sample preparation; sample preparation 0.5 cubic meters of coal slime water.

[0074] Step 3, air tightness inspection; connect the experimental devices in order, generate a certain amount of steam through the heater, and judge the air tightness by observing the value change of the pressure sensor on the slime water-gas liquefaction conversion box. If there is almost no change in the value of the pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com