A closed-loop control method and system for cement raw meal batching

A closed-loop control, cement raw meal technology, applied in general control systems, control/regulation systems, program control, etc., can solve the problems of lag in calculation results, non-uniform stability of raw material composition, etc., to optimize heat consumption, improve coal Counterpoint problem, the effect of improving uniformity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

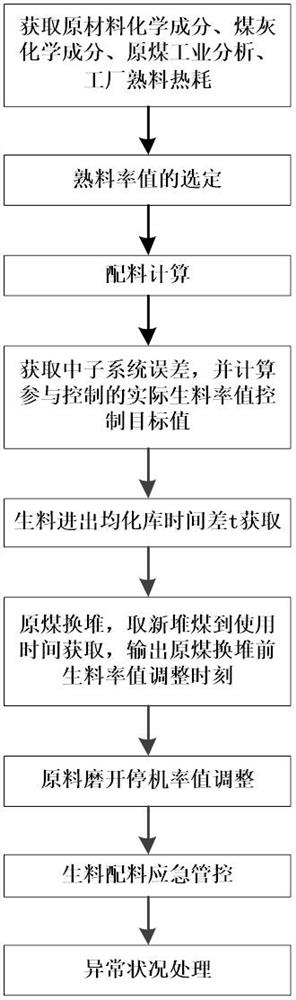

[0076] A cement raw material batching closed-loop control system, including: clinker rate value, clinker heat consumption optimization positioning raw material batching calculation unit, dynamic material warehouse, warehouse consumption balance management and budget unit, raw material batching calculation unit, online Sub-ingredient control unit, fully automated laboratory testing unit, abnormal condition processing unit.

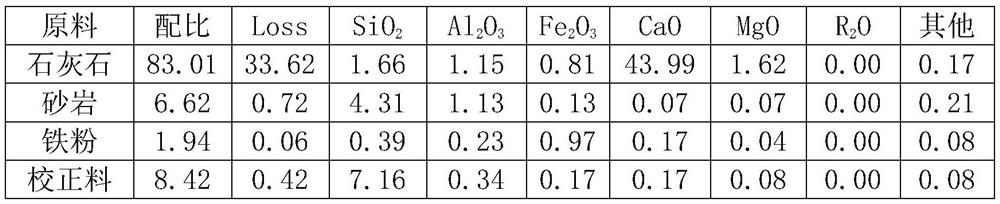

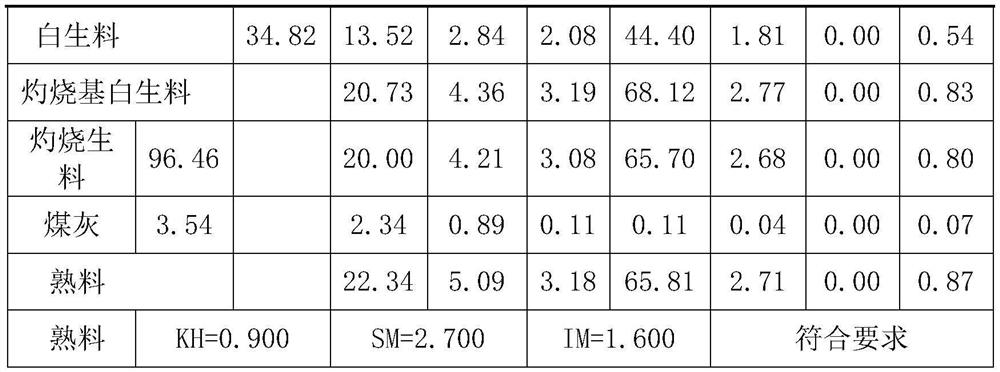

[0077] 1. Clinker rate value, clinker heat consumption optimization positioning raw material batching calculation unit, clinker rate value is selected by algorithm combined with historical clinker calcination temperature and historical clinke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com