Surface defect automatic detecting device for section bars

An automatic detection device and profile technology, applied in the direction of optical testing flaws/defects, etc., to achieve the effect of high transmission speed requirements, large real-time data transmission volume, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

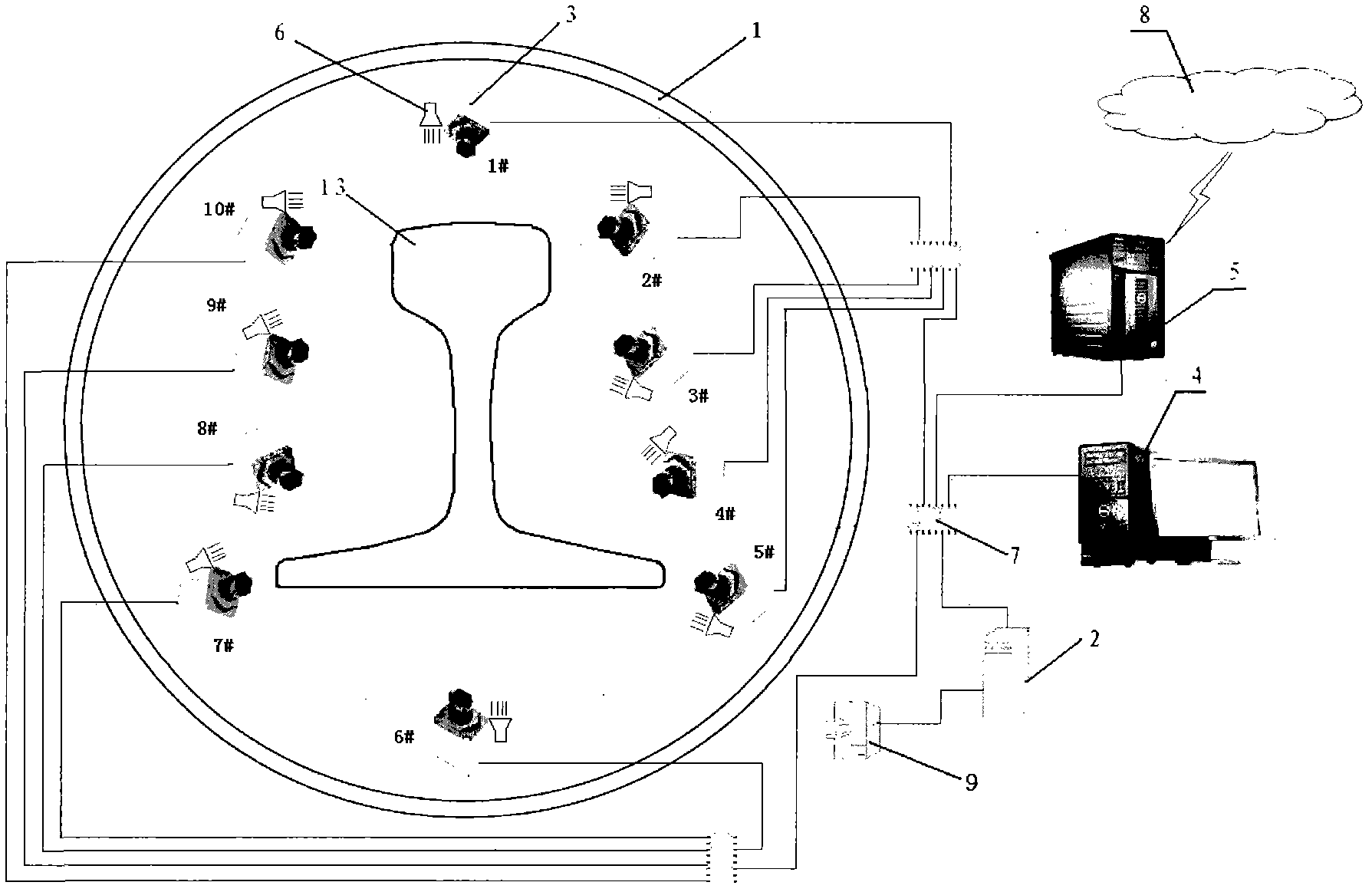

[0024] The device structure of this embodiment, the computer network system hardware structure diagram is as follows figure 1 , figure 2 As shown, it includes a fixing device 1, a control device 2, a camera 3, an image acquisition computer 4, an information processing server 5, an LED light source 6, a local area network 7, a process control network system 8, a spraying device 9, a pinch roller 10, and a conveying roller table 11. Sealing rubber 12, heavy rail 13, compressed air 14, section steel 15.

[0025] After being rolled, the steel billets of the profile rolling mill production line enter the heavy rail processing line or the profile steel finishing line according to the different types of production. Such as figure 1 Shown is the automatic detection device for surface defects installed in the heavy rail processing line of the present invention, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com