Equipment for calibrating flow rate characteristic of fuel gas nozzle

A technology of flow characteristics and gas nozzles, which is used in mechanical equipment, combustion engines, internal combustion piston engines, etc., and can solve problems such as imperfection, inability to accurately control gas flow, and inability to accurately measure nozzle gas flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

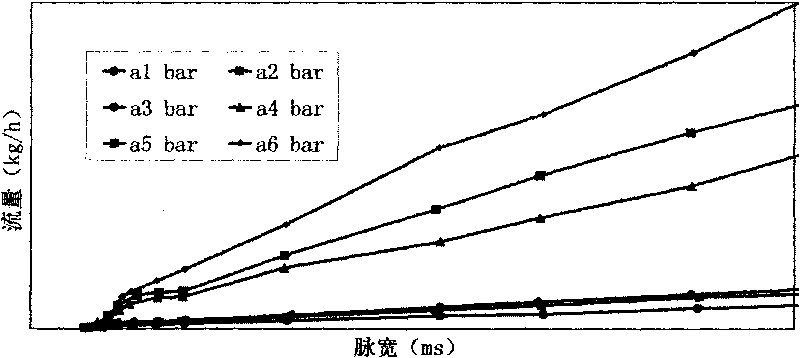

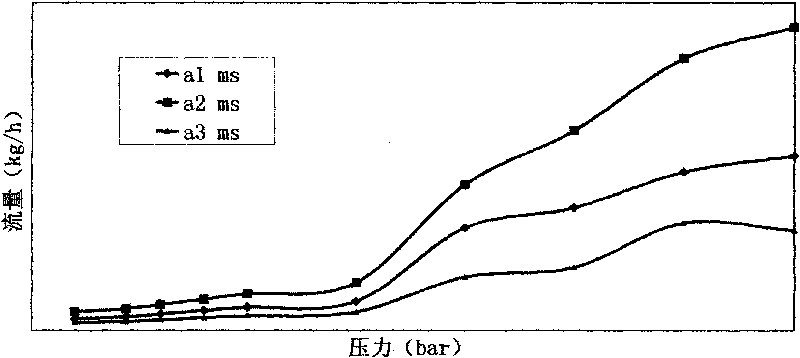

[0021] attached Image 6 , 7 shows a test system and a functional block diagram for calibrating the flow characteristics of a hydrogen nozzle according to an embodiment of the present invention, the system includes a hydrogen source 1 for storing hydrogen, and the high-pressure hydrogen from the hydrogen source 1 is reduced by a pressure reducing valve 2 After being pressurized, it enters the hydrogen plenum 3, and the low-pressure hydrogen flowing out from the hydrogen plenum passes through the hydrogen flow sensor and finally reaches the front end of the hydrogen nozzle 8. The pressure detection and data acquisition device uses the pressure sensor 4a to display the hydrogen pressure value of the stabilizing chamber on the oscilloscope. During the calibration process, the computer 13 compares the hydrogen injection target pressure value with the detection value in real time, and outputs the correction command signal in time to adjust the hydrogen pressure reducing valve. Clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com