Diagnosis and prevention system and method of high temperature corrosion state of boiler water cooled wall

A high-temperature corrosion and state diagnosis technology, which is used in the indication of boiler working conditions, weather resistance/light resistance/corrosion resistance, measurement devices, etc. Corrosion is not easy to detect and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

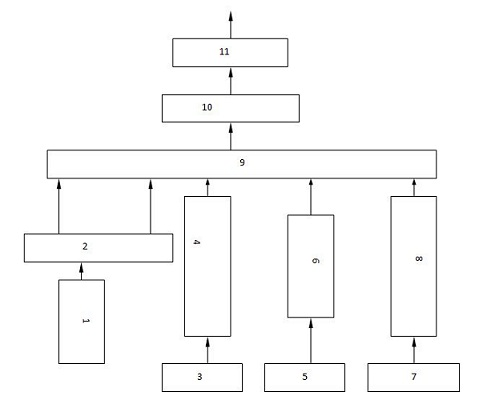

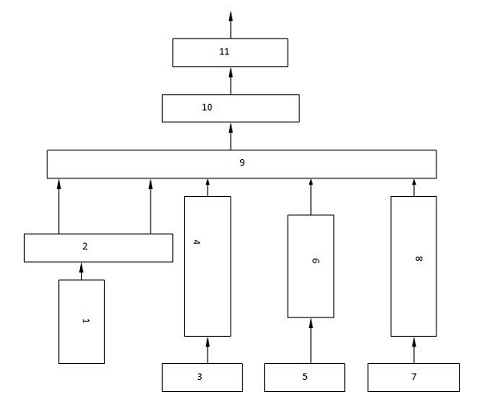

[0046] figure 1 Among them, the high temperature corrosion state diagnosis and prevention system of boiler water wall includes:

[0047] A plurality of temperature sensors 1, which send the collected water wall temperature to the data layer module 9 through the multi-channel A / D conversion acquisition module 2;

[0048] The coal quality sampling module 3 of the furnace coal, which sends the coal quality information into the coal quality analysis module 4, and the coal quality analysis module 4 performs industrial analysis, and then sends the data into the data layer module 9;

[0049] Pulverized coal fineness sampling module 5, this module sends the pulverized coal fineness information of collection into fineness analysis module 6, and this module sends into data layer module 9 after fineness analysis;

[0050] A flue gas sampling module 7, which send...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com