Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64 results about "Polyfuran" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

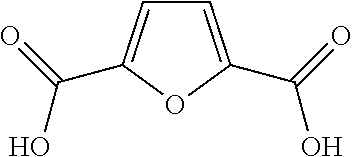

Polyfuran (PFu) is a polymer that consists of multiple furanylene rings. Such materials are of interest for their potential in molecular electronics, although much less studied than polythiophenes and polypyrroles. Polyfuran is distinct from furan resins, a class of non-conjugated polymers. Furan resins are of commercial interest, in contrast to polyfuran.

Method for preparing oligofuran dioctyl phthalate ester by directly esterifying and polymerizing

The invention discloses a method for preparing oligofuran dioctyl phthalate ester by directly esterifying and polymerizing. The method is characterized by comprising the following steps of: under the action of a compound catalyst, undergoing esterification and polymerization reactions on 2,5-furan dioctyl phthalate and low-carbon diatomic alcohol serving as raw materials at the temperature of 130-280 DEG C under the pressure of 2-15 mmHg for 1.5-16 hours; removing excessive low-carbon diatomic alcohol and other impurities by using a vacuum distillation or azeotropic distillation method; and purifying a polymer product with a dissolving-precipitating technology to obtain a high-quality oligofuran dioctyl phthalate ester product. The method has the advantages of high product yield, easinessin separating the product and good application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

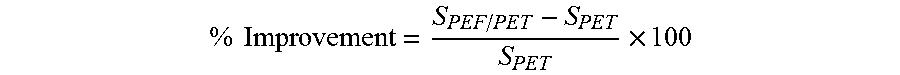

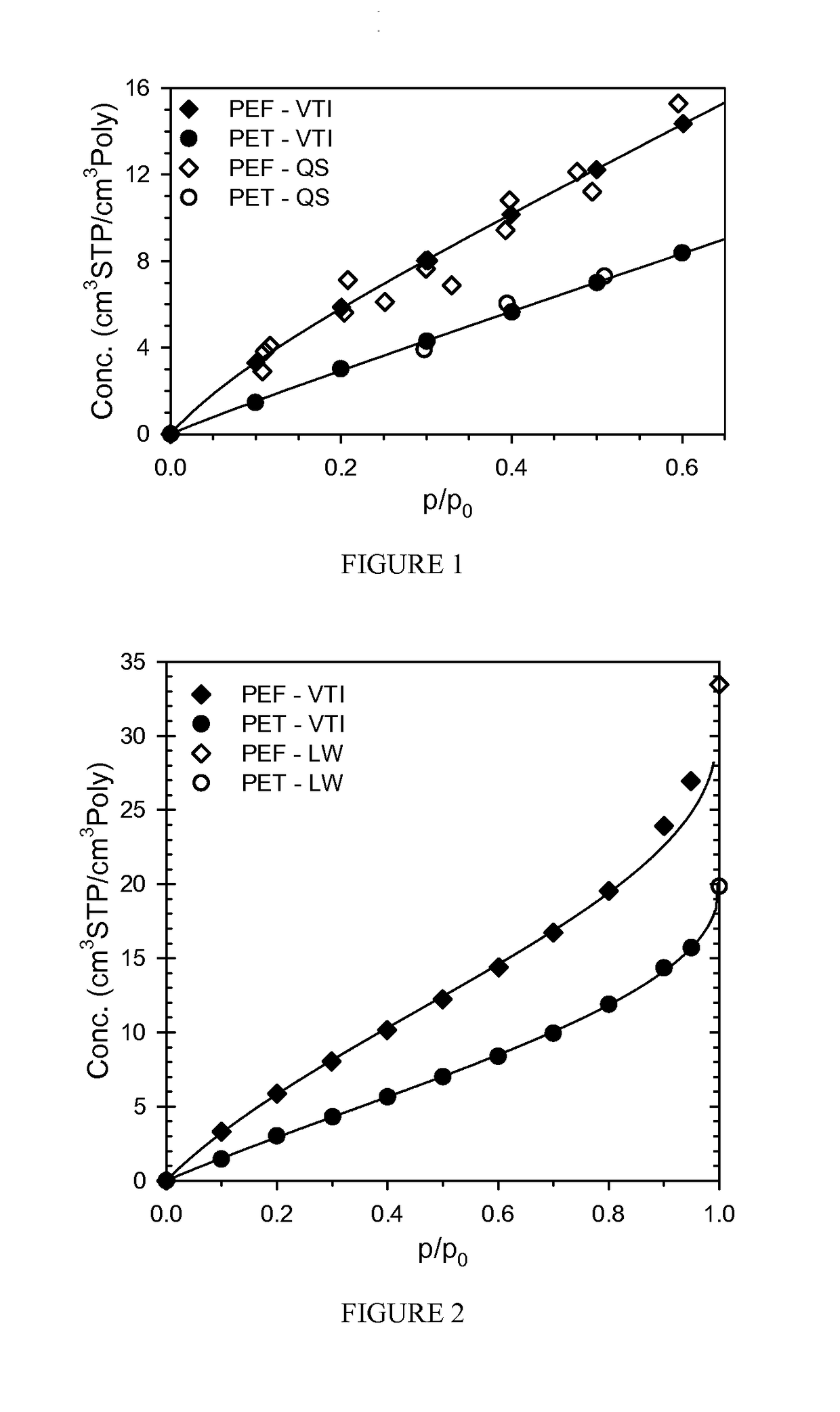

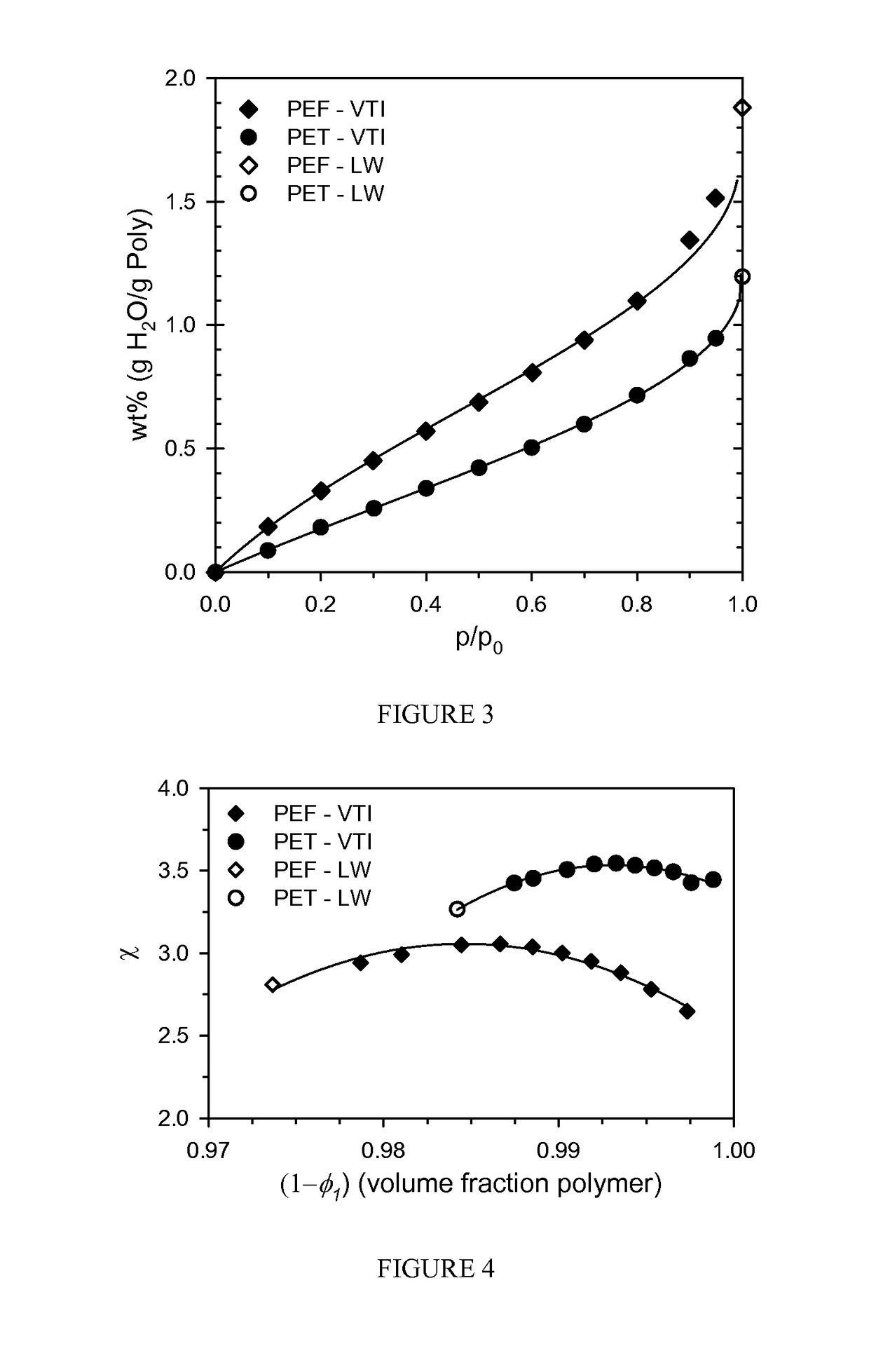

Enhanced barrier performance via blends of poly(ethylene furandicarboxylate) and poly(ethylene terephthalate)

InactiveUS20180141260A1Extended shelf lifeBottlesDomestic articlesPolyethylene terephthalate glycolPolyethylene terephthalate

The disclosure relates to processes for producing lightweight polyethylene terephthalate bottles that retain good barrier properties against the permeation of oxygen, carbon dioxide and / or water vapor. The use of relatively small amounts of polyethylene furandicarboxylate during the formation of the PET bottles can produce a bottle having the required barrier properties and result in the use of less material.

Owner:DUPONT IND BIOSCIENCES USA LLC

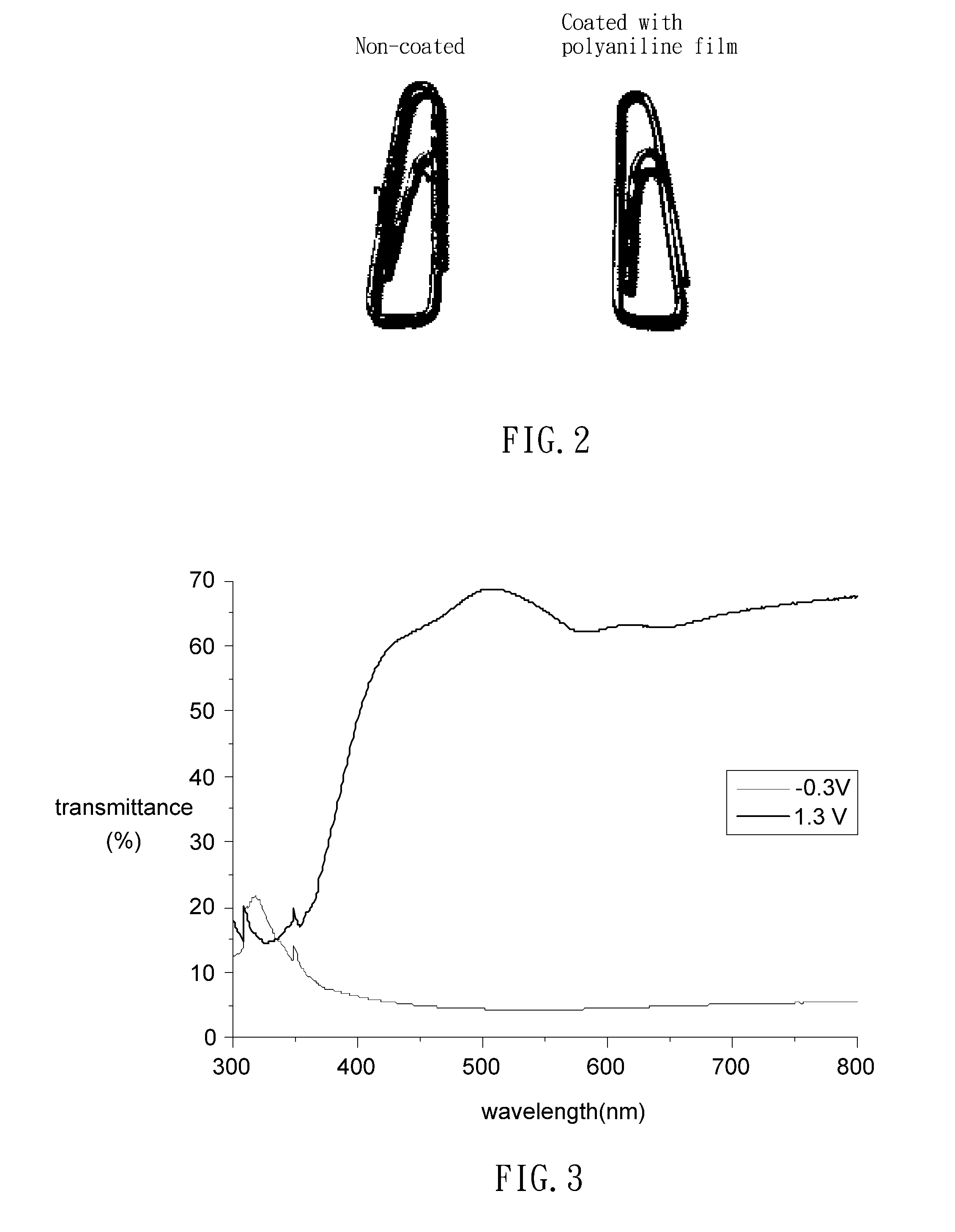

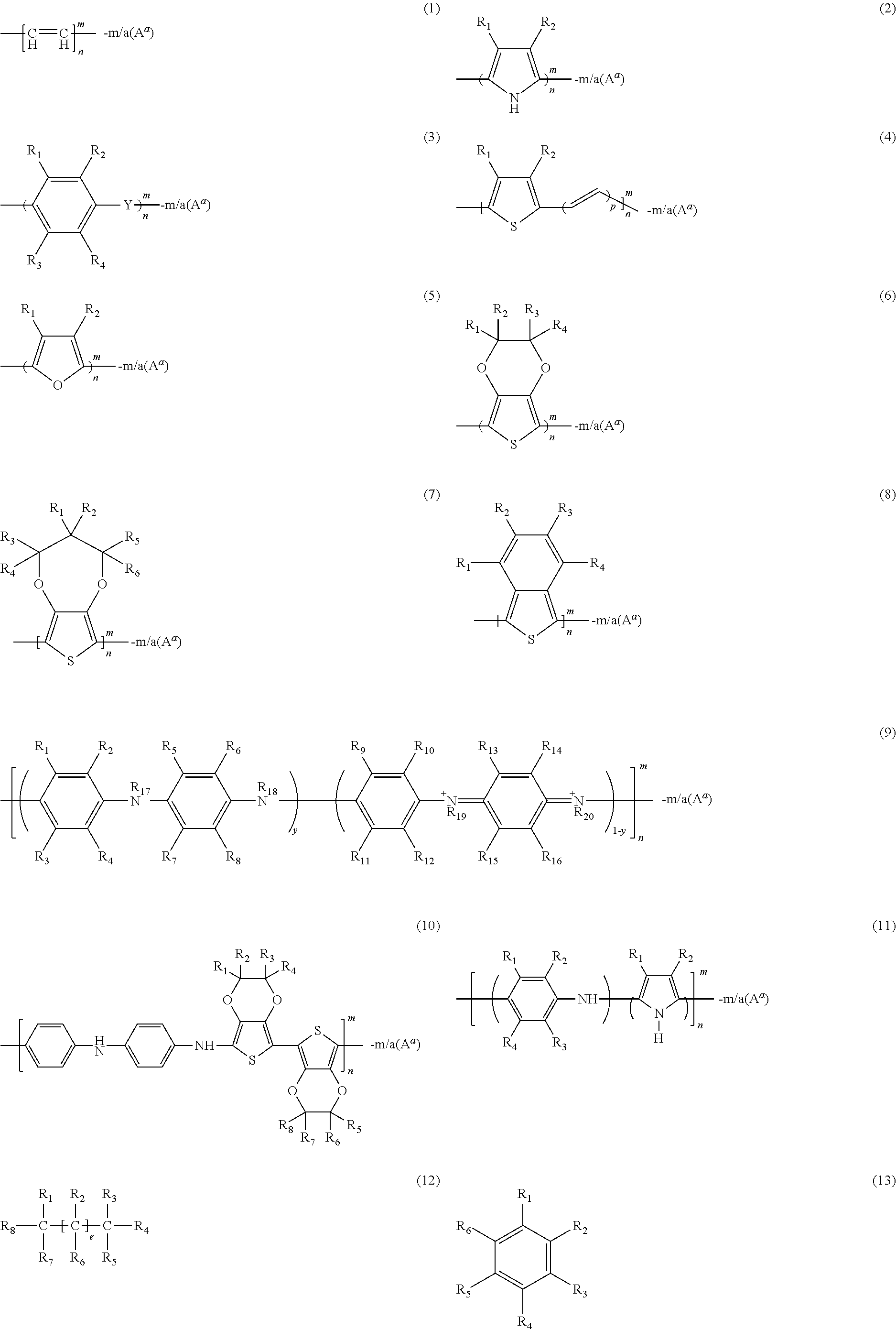

Conductive polymer solution and preparation method thereof

InactiveCN102757611AIncrease concentrationImprove solubilityOrganic conductorsPhotovoltaic energy generationPolymer scienceOrganic solvent

Owner:NAT CENT UNIV

Oxygen barrier plastic material

PendingCN109562609ASynthetic resin layered productsDomestic containersPolymer sciencePolyethylene terephthalate glycol

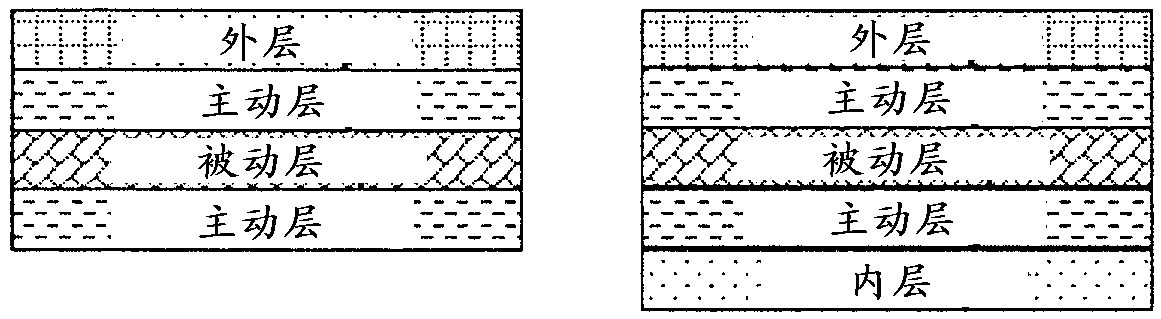

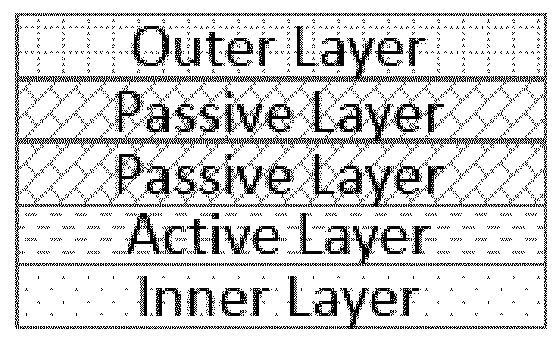

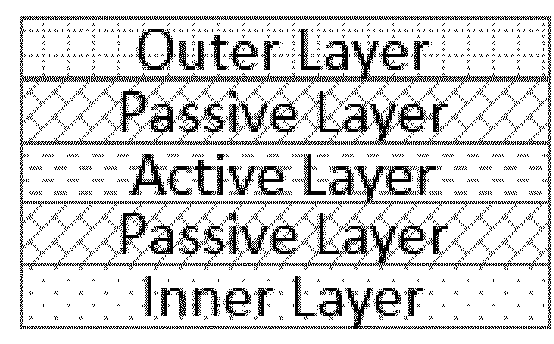

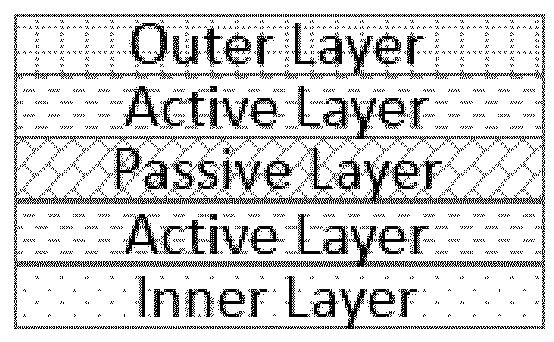

The invention relates to a multilayer packaging film comprising at least three different types of layers (A), (B), and (C): (A) is at least one outer layer, (B) is at least one passive oxygen barrierlayer, (C) is at least one active oxygen scavenging layer, characterized in that - the at least one outer layer (A) is a thermoplastic polymer; - the at least one passive oxygen barrier layer (B) is selected from the group consisting of ethylene vinyl alcohol copolymers, polyvinylchloride, copolymers of polyvinyl chloride, polyvinyl alcohol, polyvinylidene dichloride, copolymers of polyvinylidenedichloride, polyacrylonitrils, copolymers of polyacrylonitrils, polyethylene terephthalate, polyethylene naphthalate, polyethylenefuranoate, polysiloxanes, and polyamides; - the at least one active oxygen scavenging layer (C) comprises a) a plastic material which is a polyolefin, a polyolefin copolymer or a polystyrene, and additives (b) and (c), wherein b) is a polyterpenic resin; and c) is a transition metal catalyst.

Owner:CLARIANT PLASTICS & COATINGS LTD

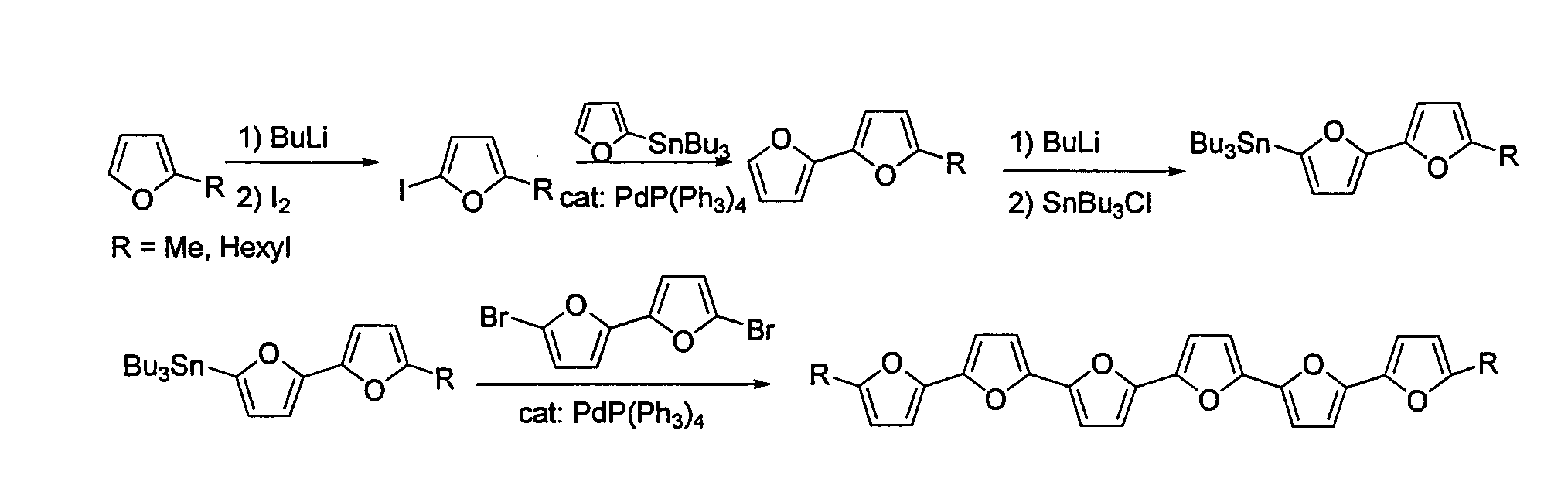

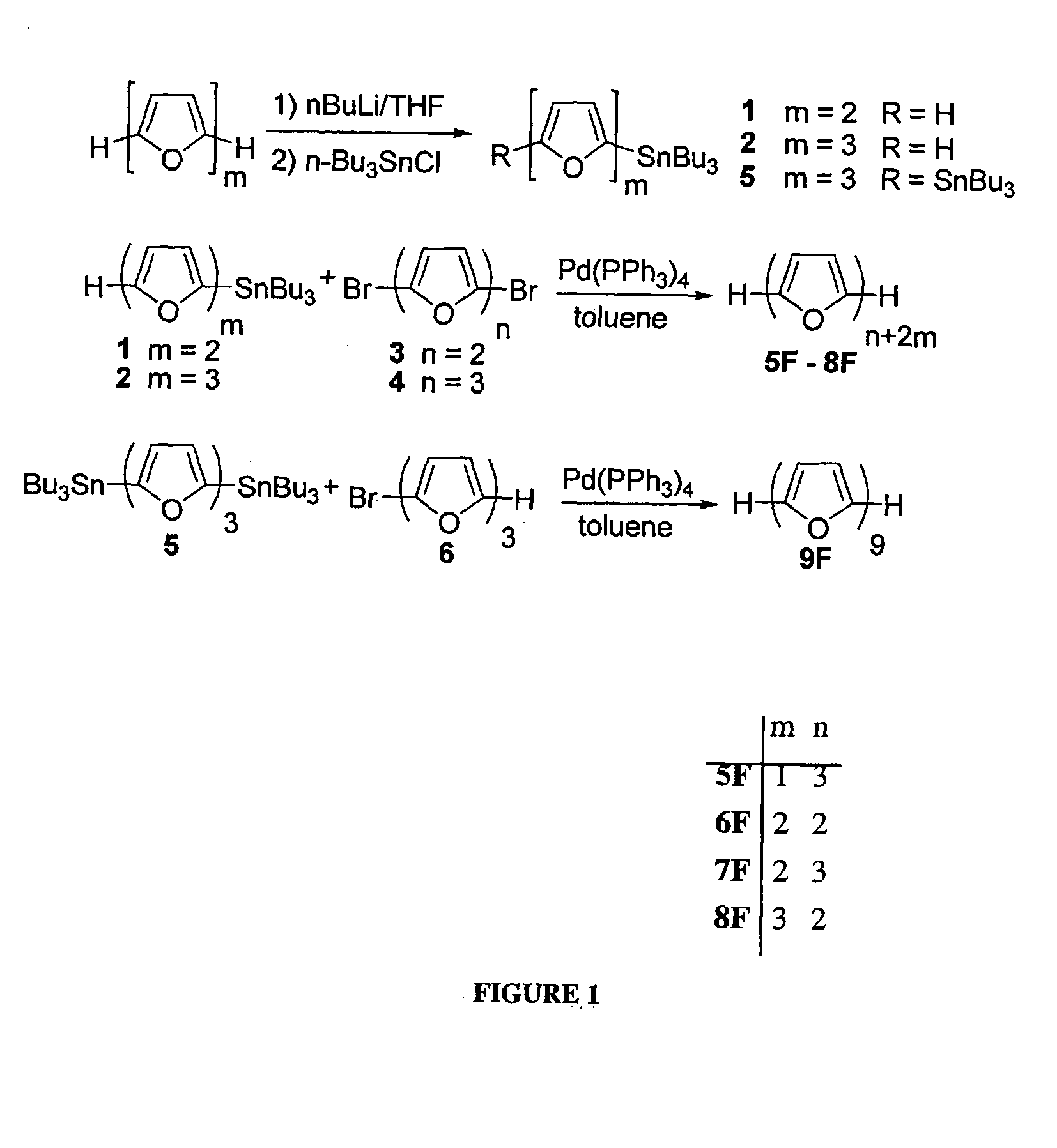

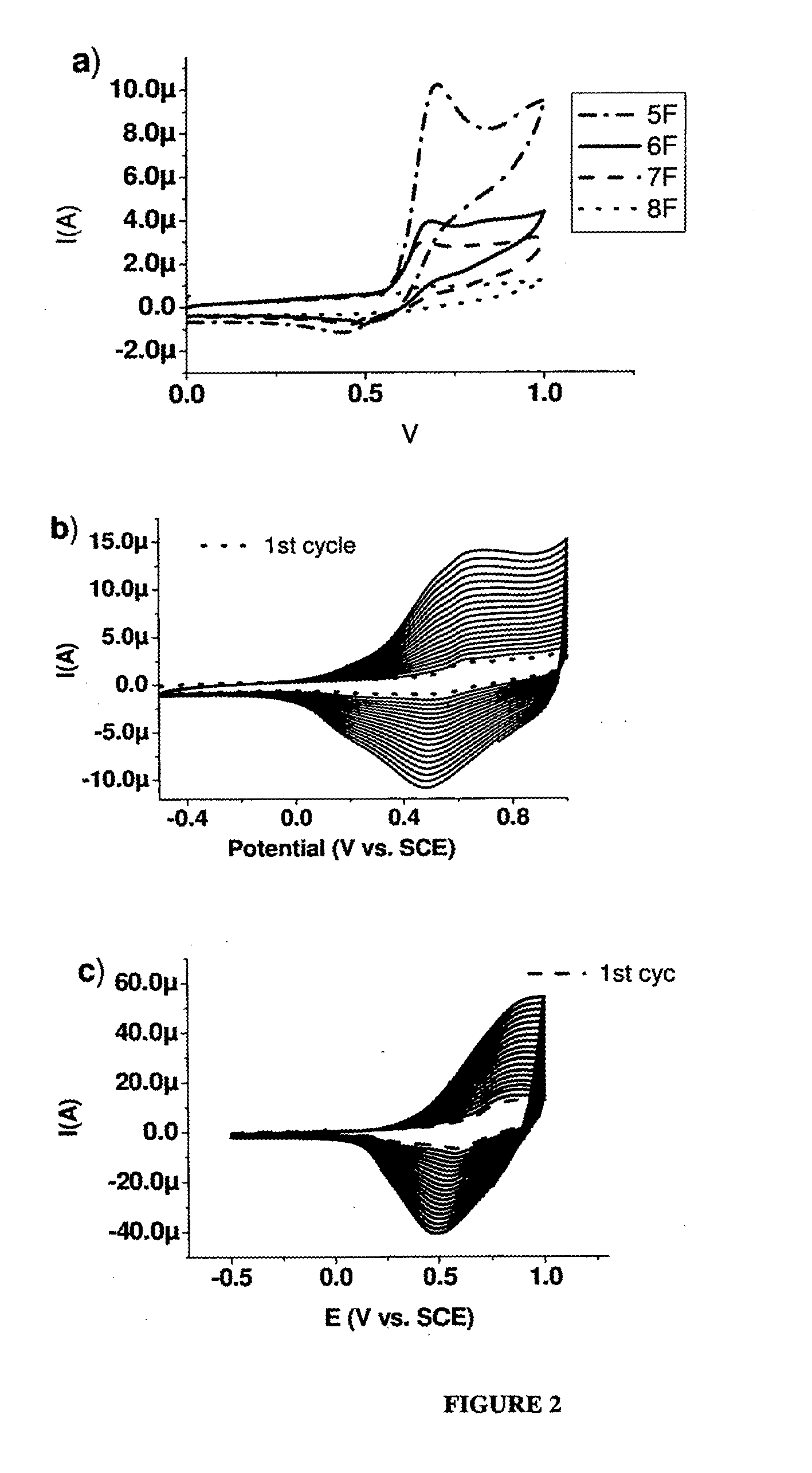

Oligo- and polyfurans, preparation and uses thereof

Owner:YEDA RES & DEV CO LTD

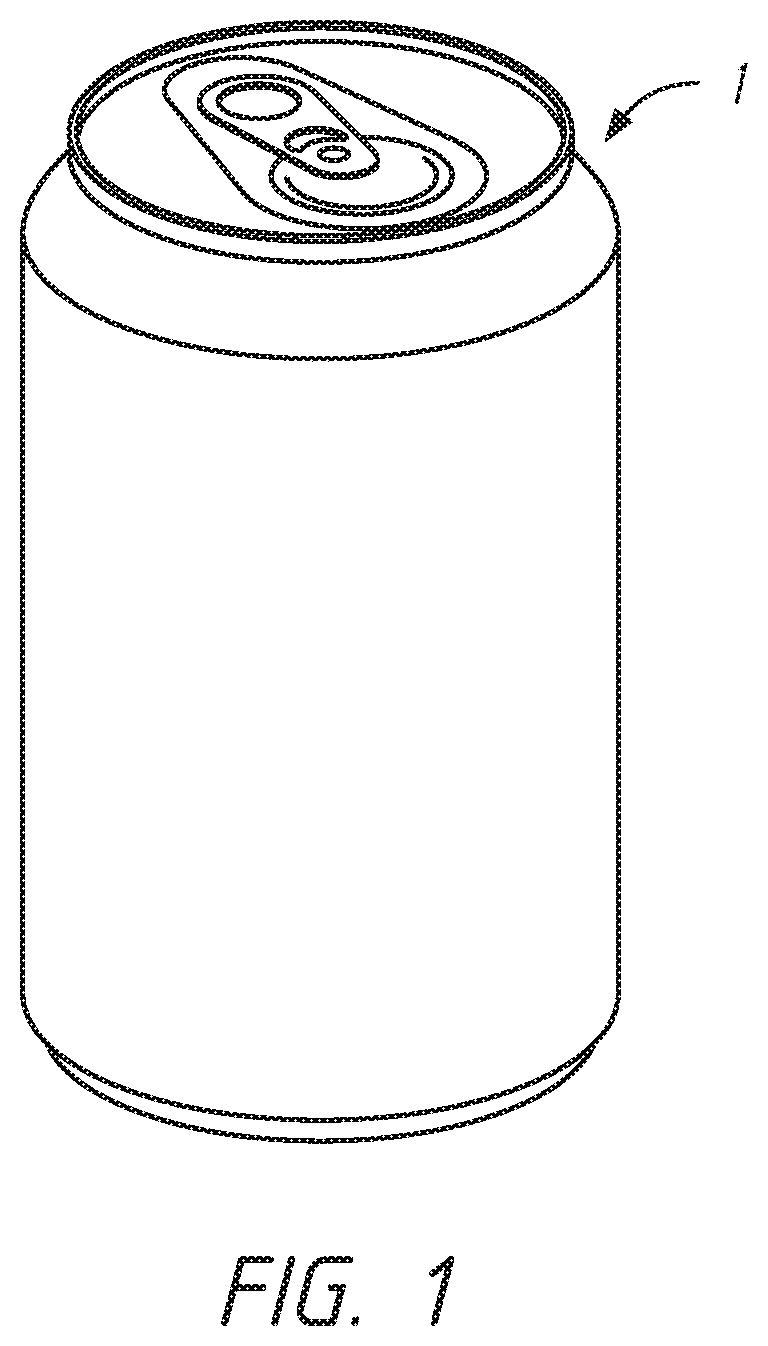

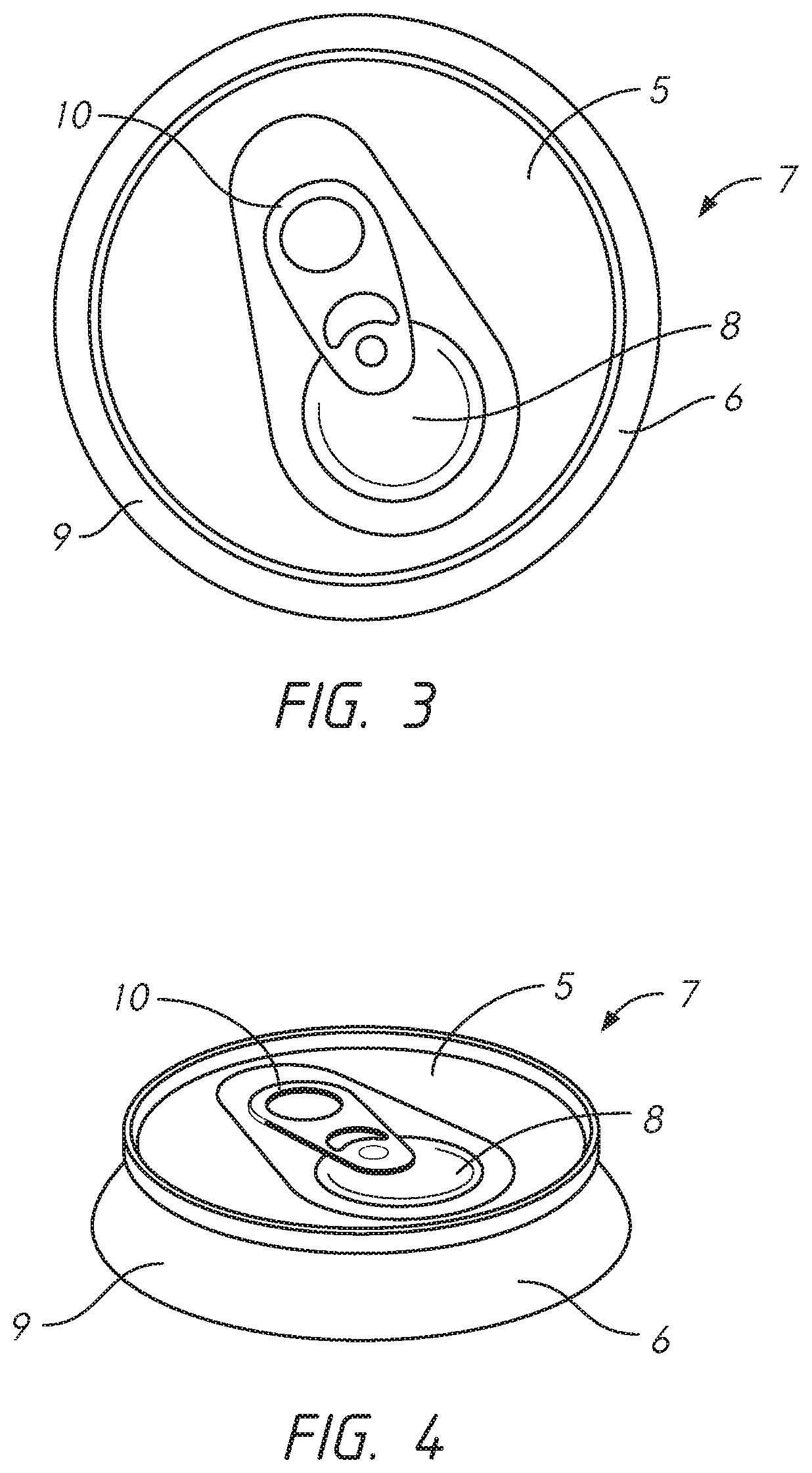

Furan Can

A furan can for containing a product includes a sealed container that contains the product and includes a furan resin selected from the group consisting of: poly (ethylene 2, 5-furan dicarboxylate) (PEF), poly (butylene 2, 5-furan dicarboxylate) (PBF), poly (trim ethylene furan dicarboxylate) (PTF), poly (propylene 2, 5-furandicarboxylate) (PPF), and poly (neopentyl 2, 5-furandicarboxylate) (PNF); and a release mechanism to open the container and access the product. The can may further include a generally cylindrical shell molded to have a sealed bottom and a straight wall that includes the furan resin; and a cap to seal the shell, the cap having the release mechanism and a rim that includes the furan resin; wherein the rim of the cap is bonded to the wall of the shell to releasably seal the product inside the can.

Owner:PATEL AMISHA

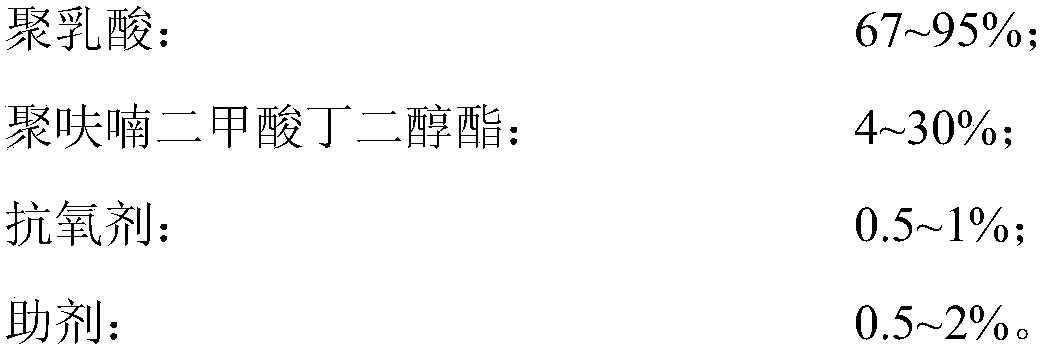

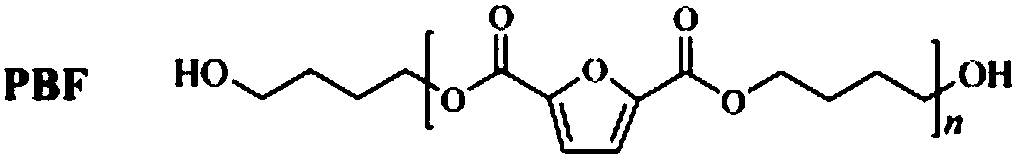

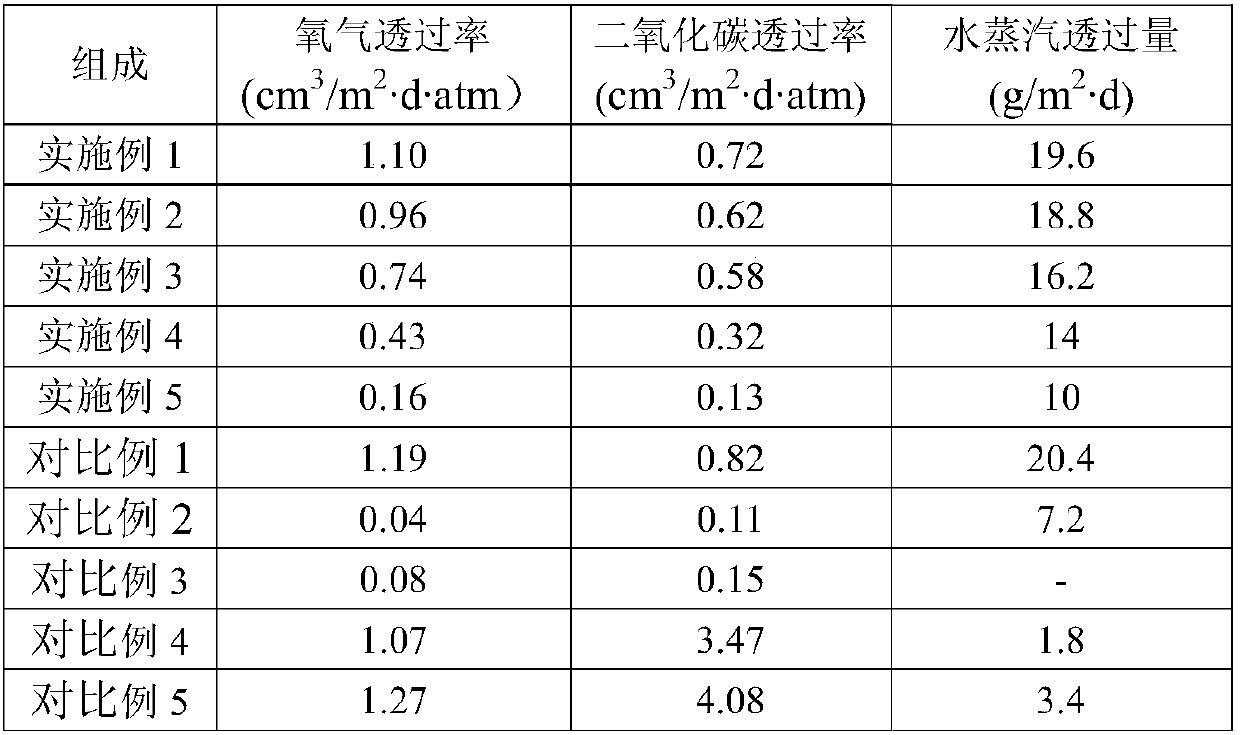

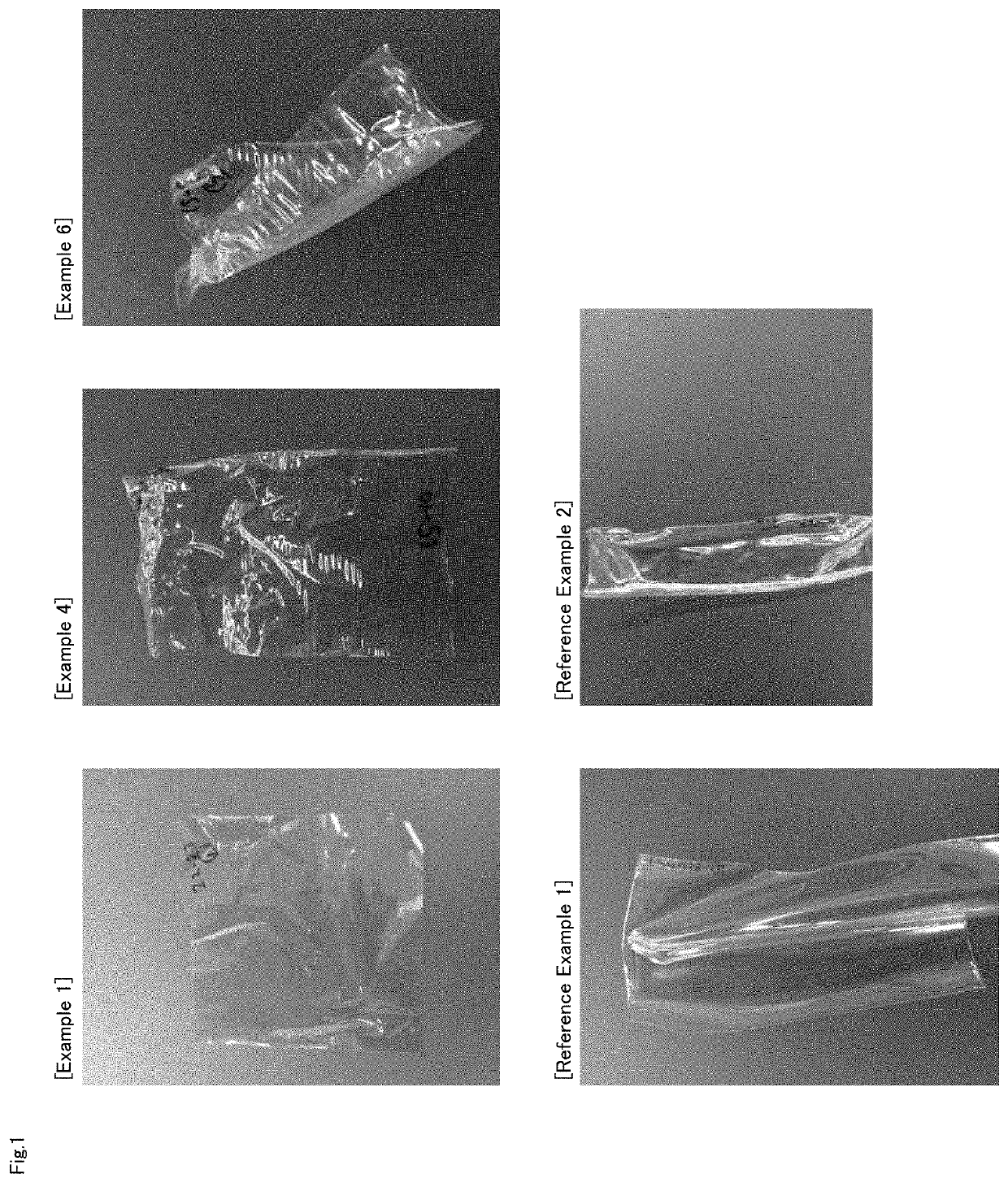

Application of bio-based polyfuran polybutylene terephthalate modified polylactic resin

The invention discloses an application of bio-based polyfuran polybutylene terephthalate modified polylactic resin to preparation of gas barrier materials. The gas permeability of the bio-based polyfuran polybutylene terephthalate modified polylactic resin for oxygen is 0.05-1.10cm<3> / m<2>*d*atm, the gas permeability of the bio-based polyfuran polybutylene terephthalate modified polylactic resin for carbon dioxide is 0.12-0.72cm<3> / m<2>*d*atm, the water vapor permeance of the resin is 7.3-19.6g / m<2>*d, and the resin has excellent gas barrier property, accordingly can be used for fields such aspackaging fields with high requirements for the gas barrier property, and particularly can be used for preparing medicine packaging, beverage bottles, vegetable, fruit and meat preservation boxes, preservative films and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

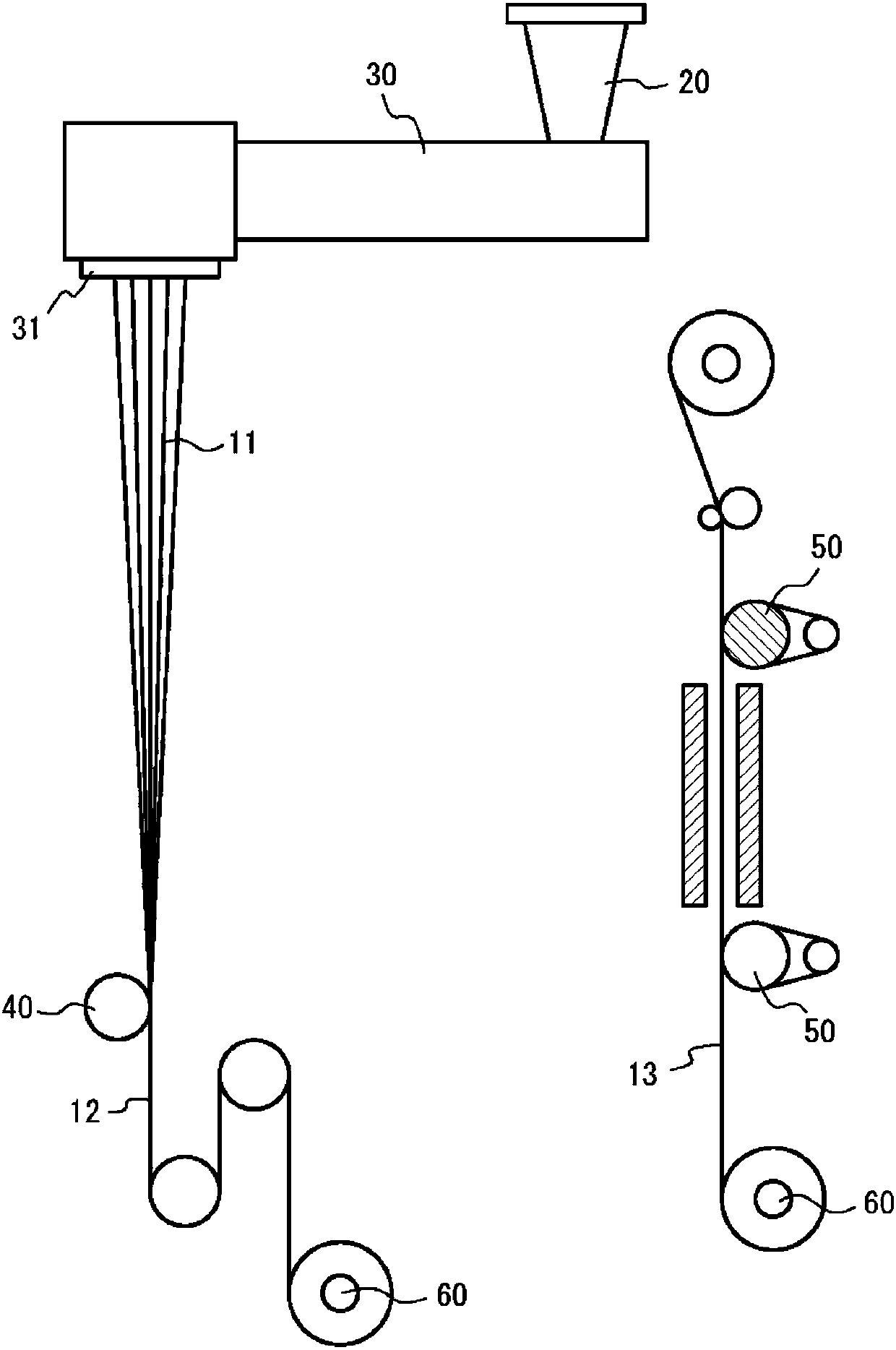

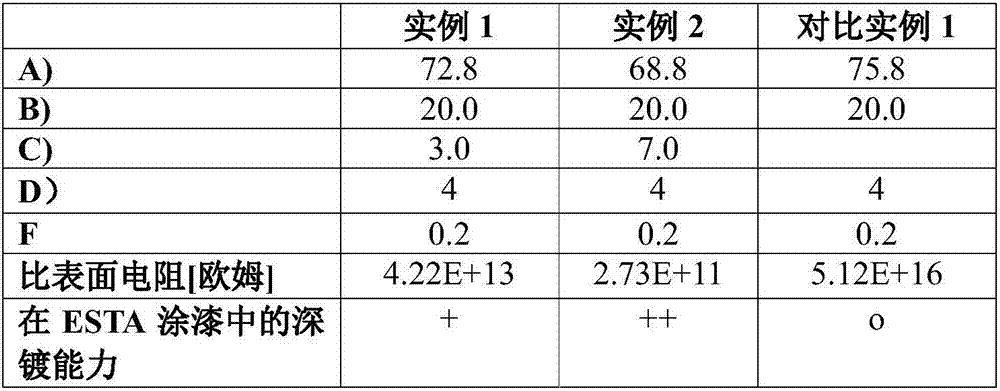

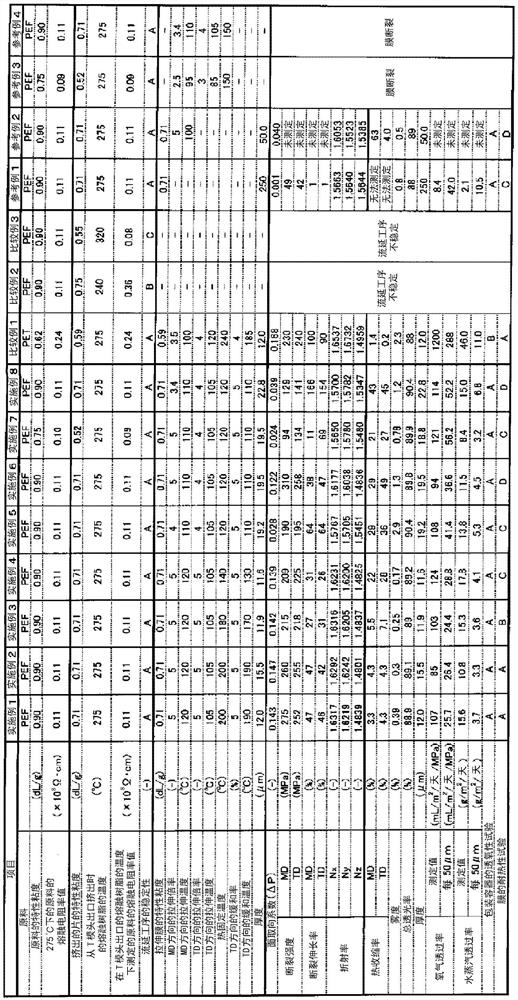

Method for producing polyester film having furandicarboxylate unit

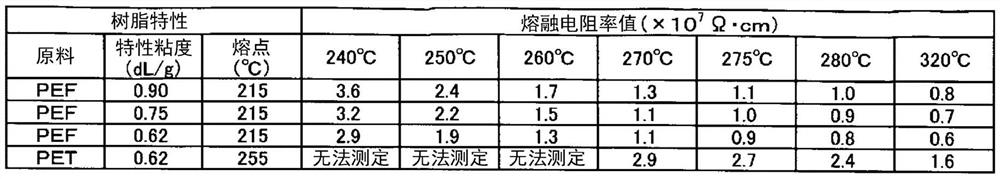

ActiveUS20210016484A1Improve mechanical propertiesGas shielding property extremely higherSynthetic resin layered productsDomestic containersPolymer sciencePolyester resin

It is provided that a method for producing a biaxially oriented polyester film that can be used for industrial and packaging applications. A method for producing a biaxially oriented polyester film, comprising: a step of feeding a polyester resin into an extruder, a step of extruding the molten polyester resin from an extruder to obtain a molten resin sheet at 250 to 310° C., a step of attaching the molten resin sheet closely to a cooling roll by an electrostatic application method to obtain an unstretched sheet, and a step of biaxially stretching the unstretched sheet, wherein the polyester resin fulfills the following (A) to (C): (A) the polyester resin comprises a polyethylene furandicarboxylate resin composed of a furandicarboxylic acid and ethylene glycol; (B) an intrinsic viscosity of the polyester resin is 0.50 dL / g or more; (C) a melt specific resistance value at 250° C. of the polyester resin is 3.0×107 ω·cm or less.

Owner:FURANIX TECH BV +1

Polyester with high glass-transition temperature and low melting point, polyester product, and preparation method and application thereof

ActiveCN112592467AHigh activityHigh glass transition temperatureSynthetic resin layered productsFlat articlesFuranPolycyclic aromatic hydrocarbon

The invention discloses polyester with high glass-transition temperature and low melting point, a polyester product, and preparation methods and applications of the polyester and the polyester product. The preparation method comprises the following steps: copolymerizing bis (hydroxyethoxy) polycyclic aromatic hydrocarbon, first dibasic acid or ester thereof, second dibasic acid or ester thereof and dihydric alcohol to prepare bio-based polyester with high glass-transition temperature and low melting point, wherein the first dibasic acid is furandicarboxylic acid. According to the invention, the dihydroxyethyl polycyclic aromatic hydrocarbon with excellent rigidity and hydroxyl-terminated high activity and the bio-based polyfurandicarboxylate compound are copolymerized, and rigid alicyclicdiol is introduced to further improve the heat resistance of the copolyester, so the finally obtained polyester has excellent heat resistance and processing fluidity at the same time; the glass-transition temperature is 95-160 DEG C, the melt viscosity within the temperature range of 240-260 DEG C is lower than 1,000Pa.S, and the device can be widely applied to stirring cups of wall-breaking foodprocessers, portable juice makers, noodle makers and other equipment, juicing barrels of juice makers, feeding bottle cup bodies and other products.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Bifuran-modified polyesters

Copolyesters such as polyethylene terephthalate (PET) or polyethylene furanoate (PEF) modified with bifuran polyacids such as dimethyl-2,2′-bifuran-5,5′-dicarboxylate (BFE), 2,2′-bifuran-5,5′-dicarboxylic acid (BDA), or bis(2-hydroxyethyl)-2,2′-bifuran-5,5′-dicarboxylate (BHEB), and / or bifuran polyhydroxyls, may have improved properties such as glass transition temperature (Tg), tensile modulus, barrier properties, crystallinity, and / or impact strength. Polyethylene terephthalate-co-bifuranoate (PETBF) has an improved Tg. Also described are polyethylene furanoate-co-bifuranoates (PEFBF).

Owner:EXXONMOBIL CHEM PAT INC +1

Polyethylene 2,5-furandicarboxylate/polyadipate-butylene terephthalate composite material and preparation method thereof

The invention provides a poly(2,5-ethylene glycol furandicarboxylate) / polyadipic acid-polybutylene terephthalate composite material and a preparation method of same, and belongs to the field of composite materials, wherein the composite material includes, by weight, 100 parts of poly(2,5-ethylene glycol furandicarboxylate), 0.01-99.99 parts of polyadipic acid-polybutylene terephthalate, and 0.01-60.00 parts of an additive, which is prepared by modifying a supporter with a silane coupling agent of which a terminal has an isocyanate radical and successively grafting the supporter with poly(2,5-ethylene glycol furandicarboxylate) and polyadipic acid-polybutylene terephthalate. The invention also provides the preparation method of the poly(2,5-ethylene glycol furandicarboxylate) / polyadipic acid-polybutylene terephthalate composite material. The composite material has excellent toughness and high anti-impact strength.

Owner:芜湖万隆新材料有限公司

Process for producing polyester article

The disclosure relates to processes for producing lightweight polyethylene terephthalate articles such as bottles that retain good barrier properties against the permeation of oxygen, carbon dioxide and / or water vapor. The use of relatively small amounts of polytrimethylene furandicarboxylate during the formation of the PET bottles can produce a bottle having the required barrier properties and result in the use of less material.

Owner:DUPONT IND BIOSCIENCES USA LLC

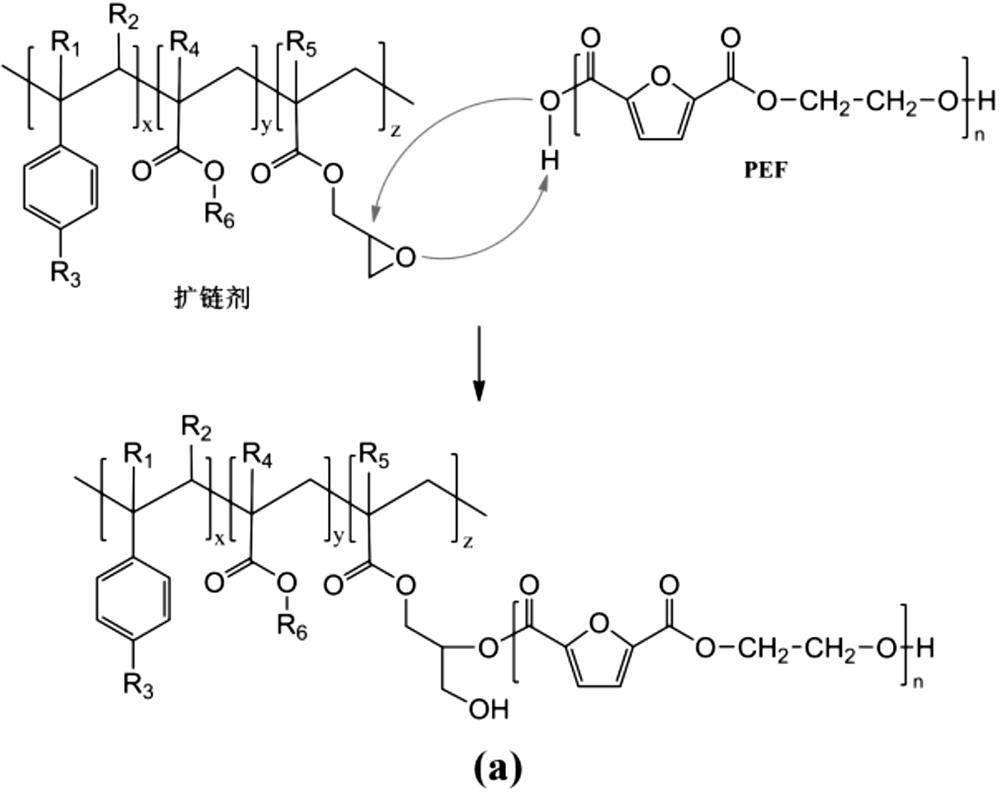

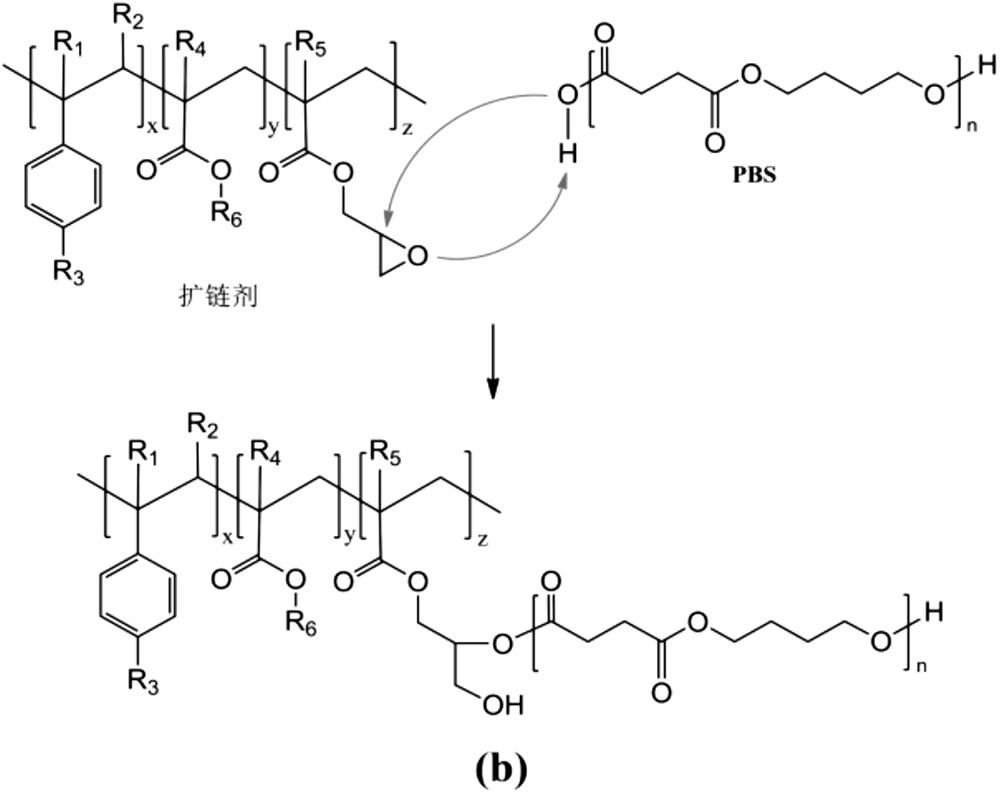

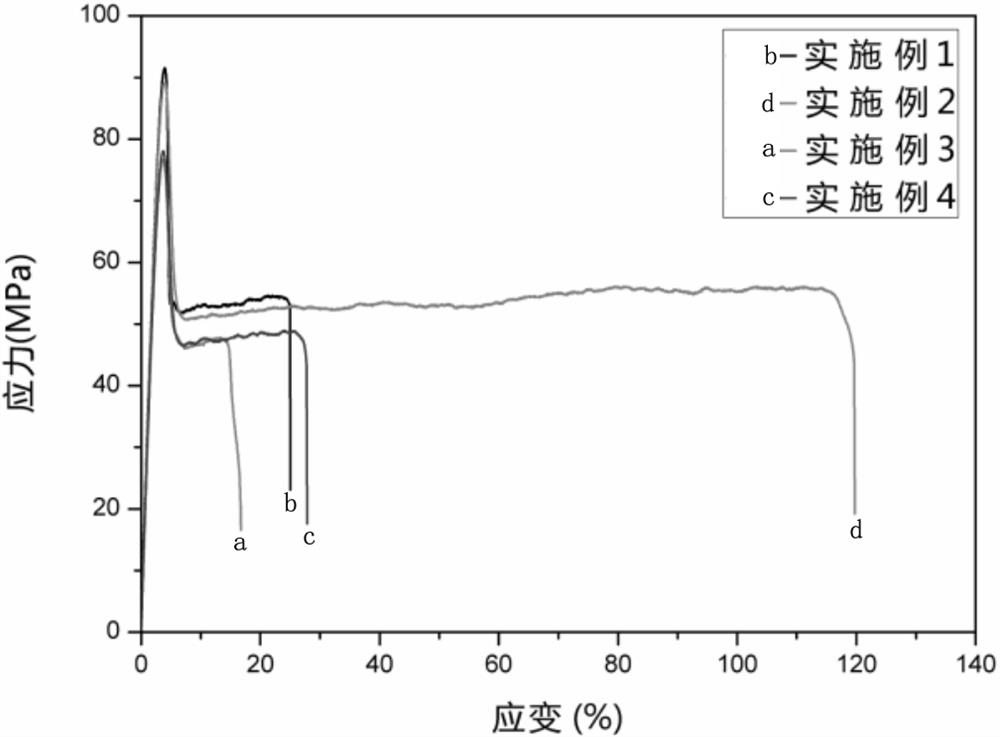

Modified poly(ethylene furandicarboxylate) as well as preparation method and application thereof

The invention relates to modified poly(ethylene furandicarboxylate). The modified poly(ethylene furandicarboxylate) is prepared from the following components in parts by weight: 88 to 96.6 parts of poly(ethylene furandicarboxylate), 3 to 10 parts of poly(butylene succinate), 0.3 to 1 part of chain extender and 0.1 to 1 part of antioxidant. The modified poly(ethylene furandicarboxylate) disclosed by the invention has the characteristics of high strength, high rigidity, good toughness and the like, and keeps excellent gas barrier property. The preparation method of the modified poly(ethylene furandicarboxylate) is simple, and the modified poly(ethylene furandicarboxylate) can be applied to the field of plastic packaging materials with high requirements on gas barrier property.

Owner:宁波昌亚新材料科技股份有限公司

Fiber for tire, rubber/fiber complex, and tire

The objective of the invention in the present application is to provide a fiber for a tire which, when applied to a tire, provides good tire uniformity. This PEF fiber for a tire, which includes a polyethylene-2,5-furandicarboxylate (PEF) yarn, is characterized in that the PEF yarn is obtained by continuously drawing an undrawn yarn, which is formed by melt-spinning a resin composition that includes PEF, without collection, and the storage modulus of the PEF yarn is 1,300 MPa or more.

Owner:BRIDGESTONE CORP +1

Thermoplastic moulding materials

The invention relates to compositions, molding materials producible from the compositions, and to articles of manufacture in turn based on the molding materials, wherein the compositions comprise polyalkylene terephthalate or polyalkylene furanoate, at least one filler or reinforcer, and at least one secondary alkanesulfonate having two alkyl radicals.

Owner:LANXESS DEUTDCHLAND GMBH

A kind of graphene composite cable material and preparation method thereof

ActiveCN106280448BMeet needsMeet industry requirementsInsulated cablesInsulated conductorsHigh pressurePhthalate

The invention discloses a graphene composite cable material and a method for preparing the same. The graphene composite cable material is made of polyimide emulsion, modified montmorillonite, high-density polyethylene, polyfuran dioctyl phthalate glycol ester, silane coupling agents KH-550, sulfur powder, titanium diboride, glass fibers, citrate, graphene, choline alfoscerate, di-(3, 4-dimethyl) benzyl sorbitol, dispersing agents and anti-aging agents. The method includes processes of fitting grinding, spray-drying, acidifying, mixing, ultrasonic treatment, extrusion, stretching, heat setting and the like. The graphene composite cable material and the method have the advantages that requirements of high-voltage and direct-current power transmission cables on the hardness and the toughness of the graphene composite cable material prepared by the aid of the method can be met, the graphene composite cable material is good in environmental protection performance and low in integral cost, accordingly, industrial requirements can be met, and the graphene composite cable material and the method have excellent application prospects.

Owner:湖南三湘电线电缆有限责任公司

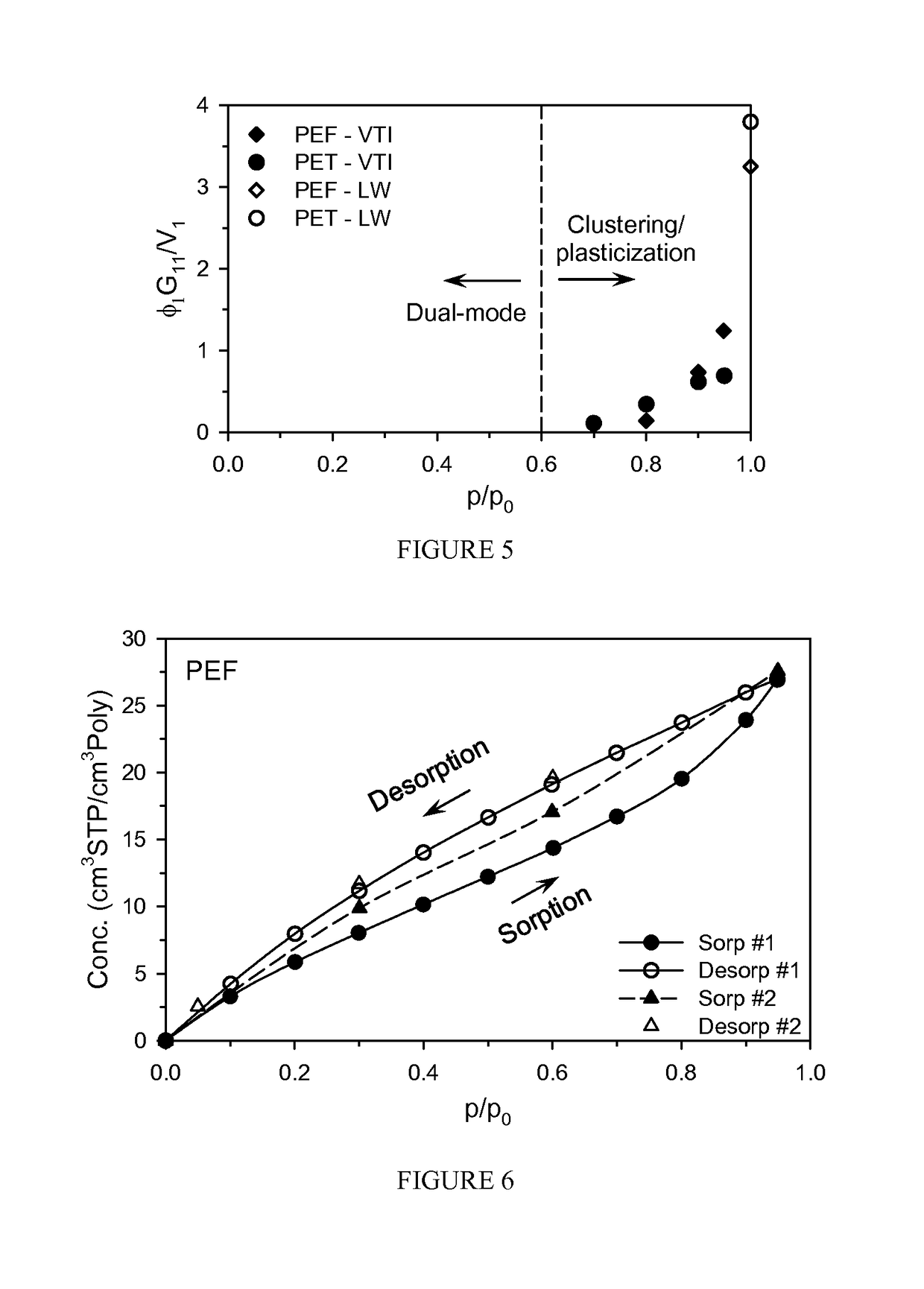

Methods for processing and plasticizing poly(ethylene furanoate) preforms by water sorption

ActiveUS20180154570A1Improve mobilityStretch blow molding processing rangeBottlesDomestic articlesBlow moldingPolyester

This disclosure provides effective methods for expanding the processing window for poly(ethylene furanoate) (PEF) and poly(ethylene furanoate) co-polymer (PEF co-polymer) polyester preforms, such that these preforms can be beneficially used in the fabrication of bottles and containers, including bottles for carbonated soft drinks. The processing window is expanded by, for example, pre-conditioning the PEF or PEF co-polymer preform prior to stretch blow-molding by contacting the PEF or PEF co-polymer preform with water or high (>50%) relative humidity air for a desired time period and at a temperature greater than or equal to ambient temperature, to take advantage of the unique and unexpected properties afforded the preform by water sorption at these temperatures.

Owner:THE COCA-COLA CO

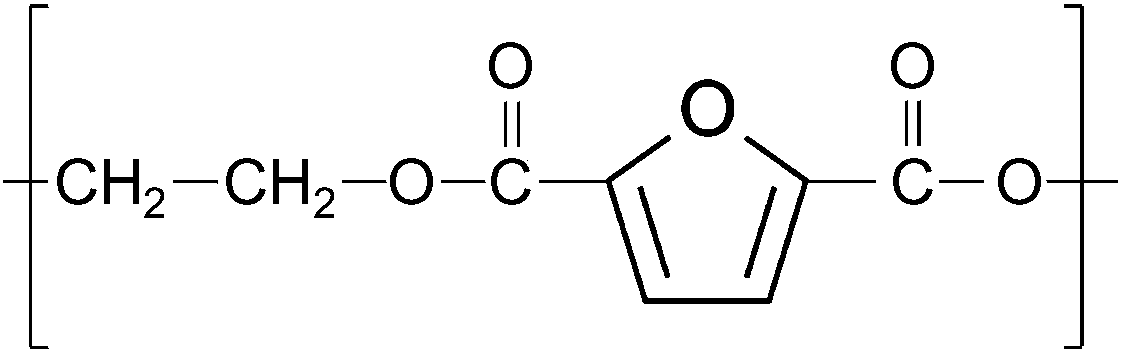

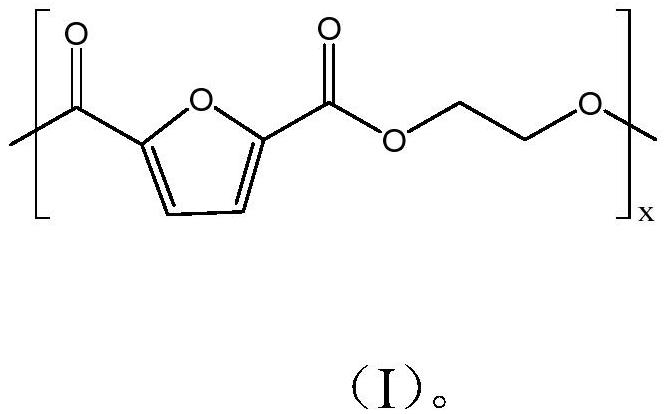

Polymer-based film for dielectric material or energy storage material

PendingCN114752089AHigh dielectric constantHigh tensile strengthThin/thick film capacitorFixed capacitor dielectricDischarge efficiencyPolymer science

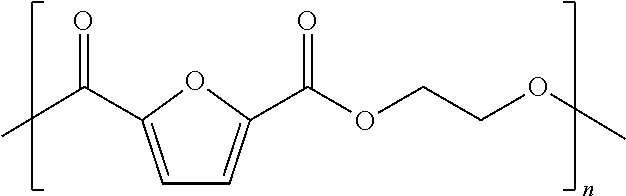

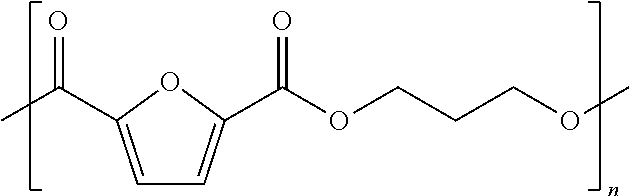

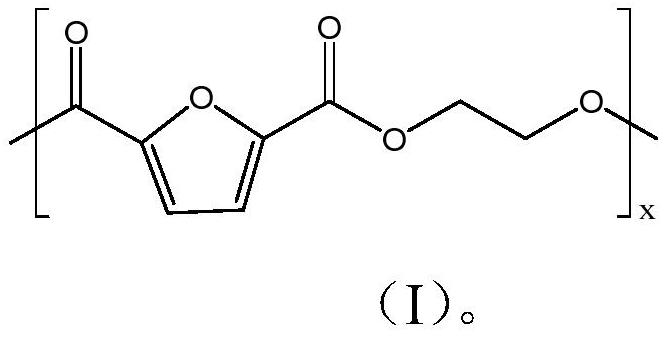

The invention relates to the field of macromolecules and the field of energy, and discloses a polymer-based film for a dielectric material or an energy storage material. The structure of the polyethylene furandicarboxylate is shown as a formula (I). The invention further discloses application of the PEF in the field of dielectrics and application of the PEF in the field of thin-film capacitor energy storage. When the PEF is applied to the field of dielectric materials, the PEF has a high dielectric constant of 5.41 and a low dielectric loss of 0.019. When the PEF is applied to the field of thin film capacitors, the PEF has high discharge energy density and ultrahigh charge-discharge efficiency 96% at 300MV / m, which is higher than that of most polymers. The invention provides a basis for application of a bio-based material in the fields of dielectrics and energy storage.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Reinforcement cord for elastomer products, in particular for vehicle tires, and elastomer product

PendingCN112292485ASave resourcesConsistent product qualityPneumatic tyre reinforcementsArtificial filaments from viscoseElastomerYarn

The invention relates to a reinforcement cord for elastomer products, in particular for vehicle tires, containing at least one yarn made of filaments. The invention additionally relates to an elastomer product which contains at least one reinforcement cord. In order to protect the environment and preserve resources while maintaining a good processing behavior, at least one yarn of the reinforcement cord contains filaments made of polybutylene furandicarboxylate (PBF), wherein the PBF is completely or at least partly made of biomass and / or renewable raw materials.

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

Oxygen Barrier Plastic Material

PendingUS20190210337A1High oxygen permeabilitySynthetic resin layered productsDomestic containersPolymer sciencePolyethylene terephthalate glycol

The invention relates to a multilayer packaging film comprising at least three different types of layers (A), (B), and (C): (A) is at least one outer layer, (B) is at least one passive oxygen barrier layer, (C) is at least one active oxygen scavenging layer, characterized in that —the at least one outer layer (A) is a thermoplastic polymer; —the at least one passive oxygen barrier layer (B) is selected from the group consisting of ethylene vinyl alcohol copolymers, polyvinylchloride, copolymers of polyvinyl chloride, polyvinyl alcohol, polyvinylidene dichloride, copolymers of polyvinylidene dichloride, polyacrylonitrils, copolymers of polyacrylonitrils, polyethylene terephthalate, polyethylene naphthalate, polyethylenefuranoate, polysiloxanes, and polyamides; —the at least one active oxygen scavenging layer (C) comprises a) a plastic material which is a polyolefin, a polyolefin copolymer or a polystyrene, and additives (b) and (c), wherein b) is a polyterpenic resin; and c) is a transition metal catalyst

Owner:CLARIANT PLASTICS & COATINGS LTD

Graphene composite cable material and method for preparing same

ActiveCN106280448AMeet needsMeet industry requirementsInsulated cablesInsulated conductorsPhosphorylcholineHigh pressure

The invention discloses a graphene composite cable material and a method for preparing the same. The graphene composite cable material is made of polyimide emulsion, modified montmorillonite, high-density polyethylene, polyfuran dioctyl phthalate glycol ester, silane coupling agents KH-550, sulfur powder, titanium diboride, glass fibers, citrate, graphene, choline alfoscerate, di-(3, 4-dimethyl) benzyl sorbitol, dispersing agents and anti-aging agents. The method includes processes of fitting grinding, spray-drying, acidifying, mixing, ultrasonic treatment, extrusion, stretching, heat setting and the like. The graphene composite cable material and the method have the advantages that requirements of high-voltage and direct-current power transmission cables on the hardness and the toughness of the graphene composite cable material prepared by the aid of the method can be met, the graphene composite cable material is good in environmental protection performance and low in integral cost, accordingly, industrial requirements can be met, and the graphene composite cable material and the method have excellent application prospects.

Owner:湖南三湘电线电缆有限责任公司

Method for preparing oligofuran dioctyl phthalate ester by directly esterifying and polymerizing

The invention discloses a method for preparing oligofuran dioctyl phthalate ester by directly esterifying and polymerizing. The method is characterized by comprising the following steps of: under the action of a compound catalyst, undergoing esterification and polymerization reactions on 2,5-furan dioctyl phthalate and low-carbon diatomic alcohol serving as raw materials at the temperature of 130-280 DEG C under the pressure of 2-15 mmHg for 1.5-16 hours; removing excessive low-carbon diatomic alcohol and other impurities by using a vacuum distillation or azeotropic distillation method; and purifying a polymer product with a dissolving-precipitating technology to obtain a high-quality oligofuran dioctyl phthalate ester product. The method has the advantages of high product yield, easinessin separating the product and good application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

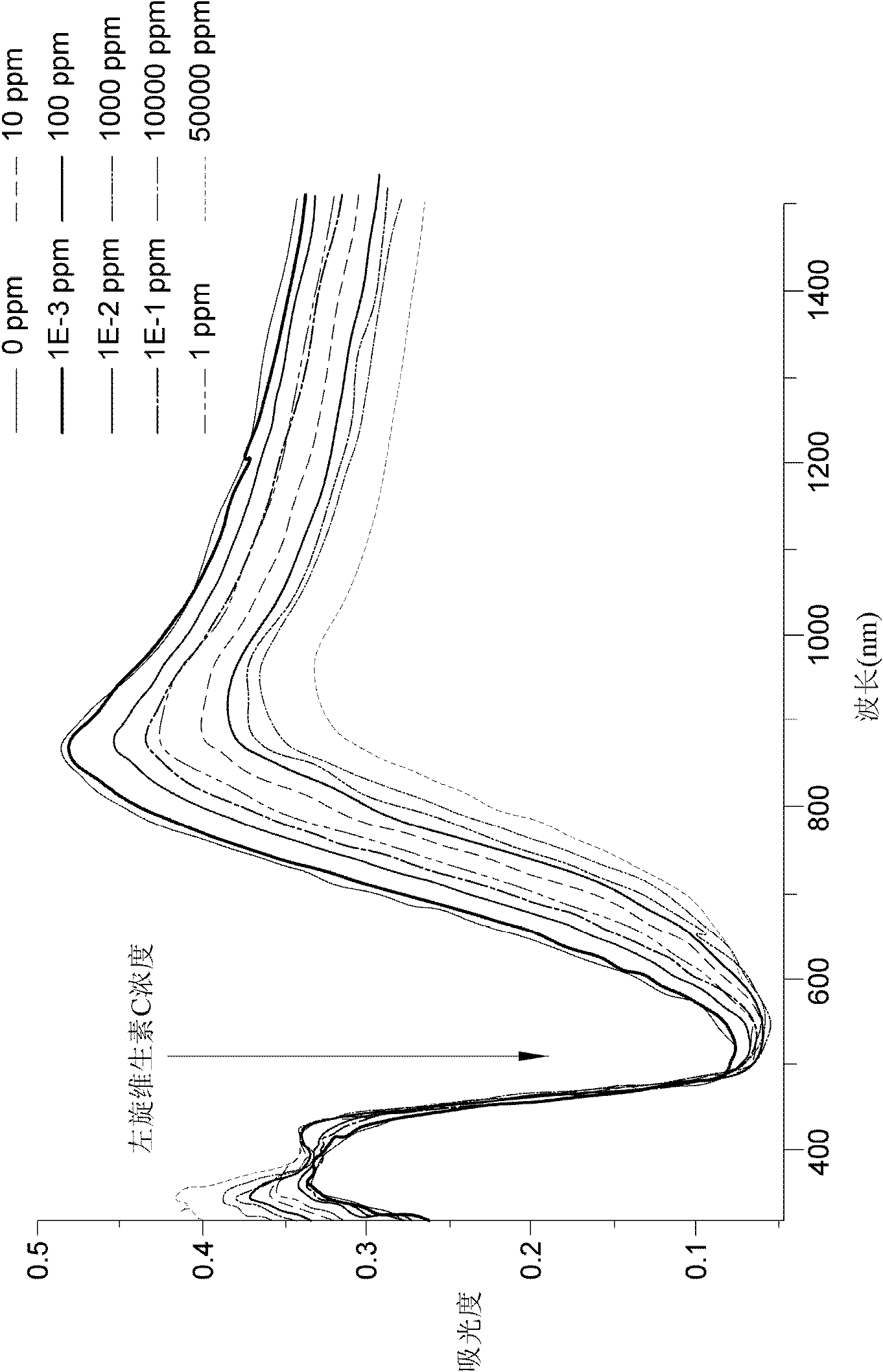

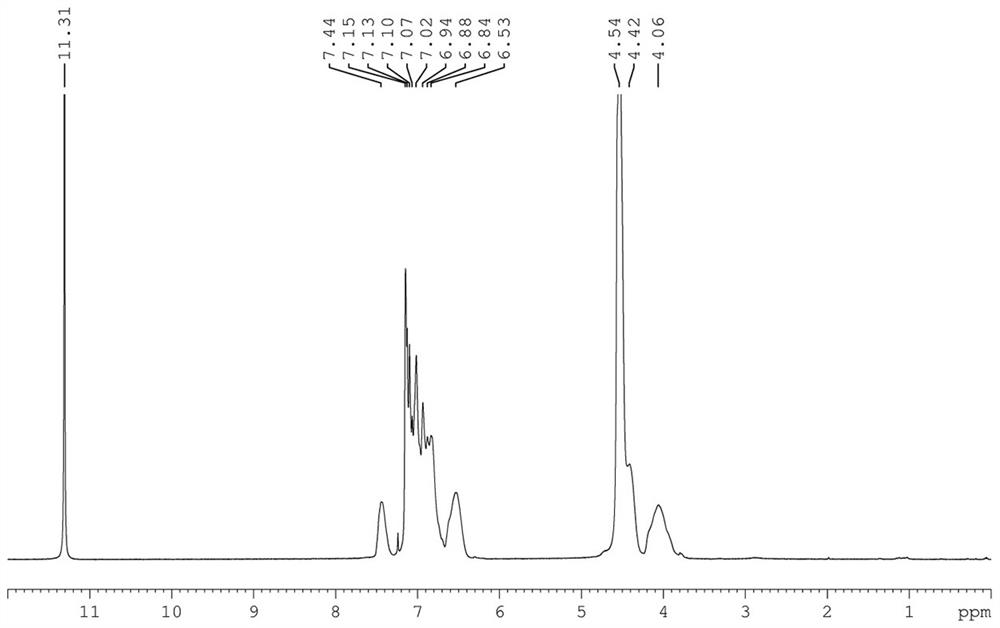

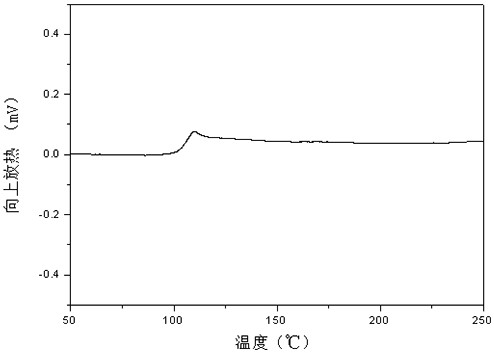

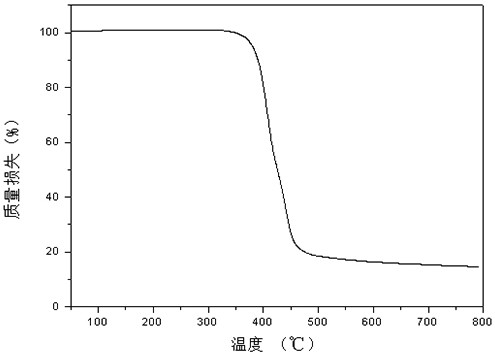

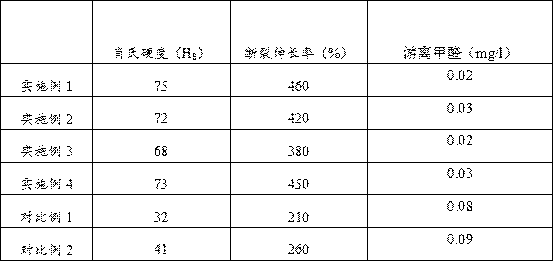

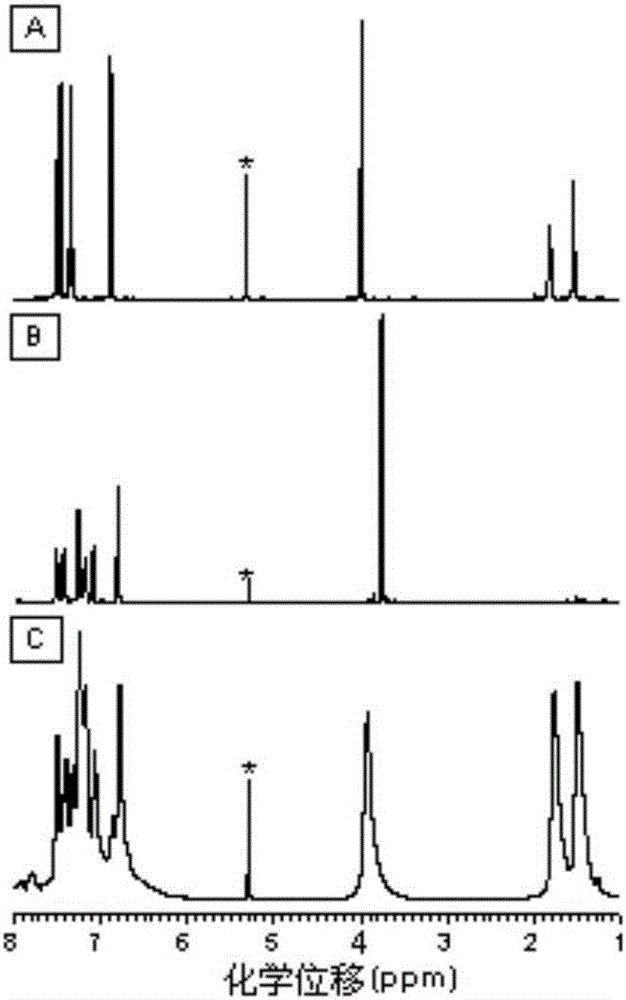

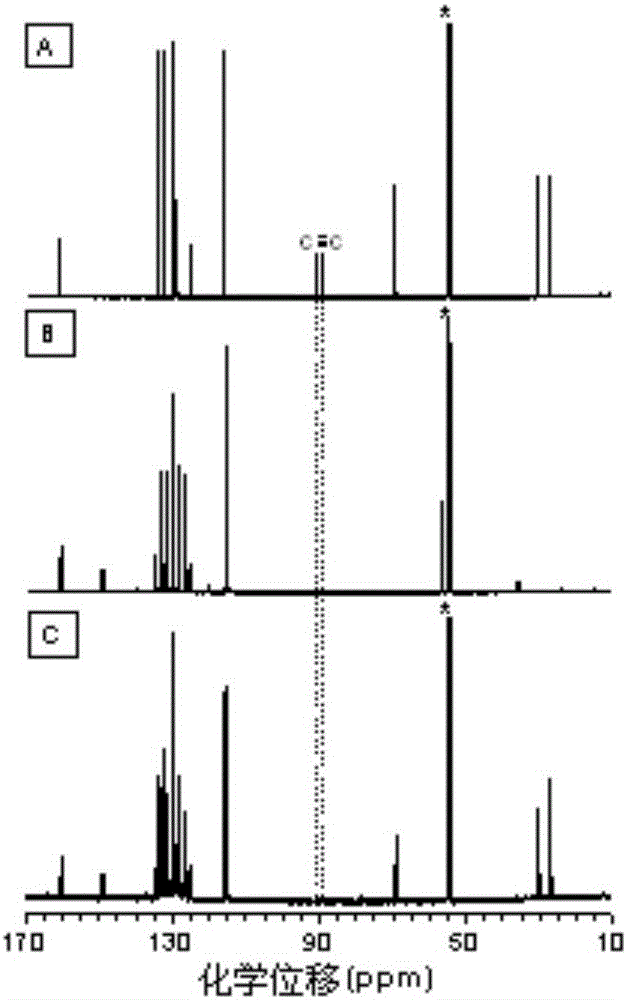

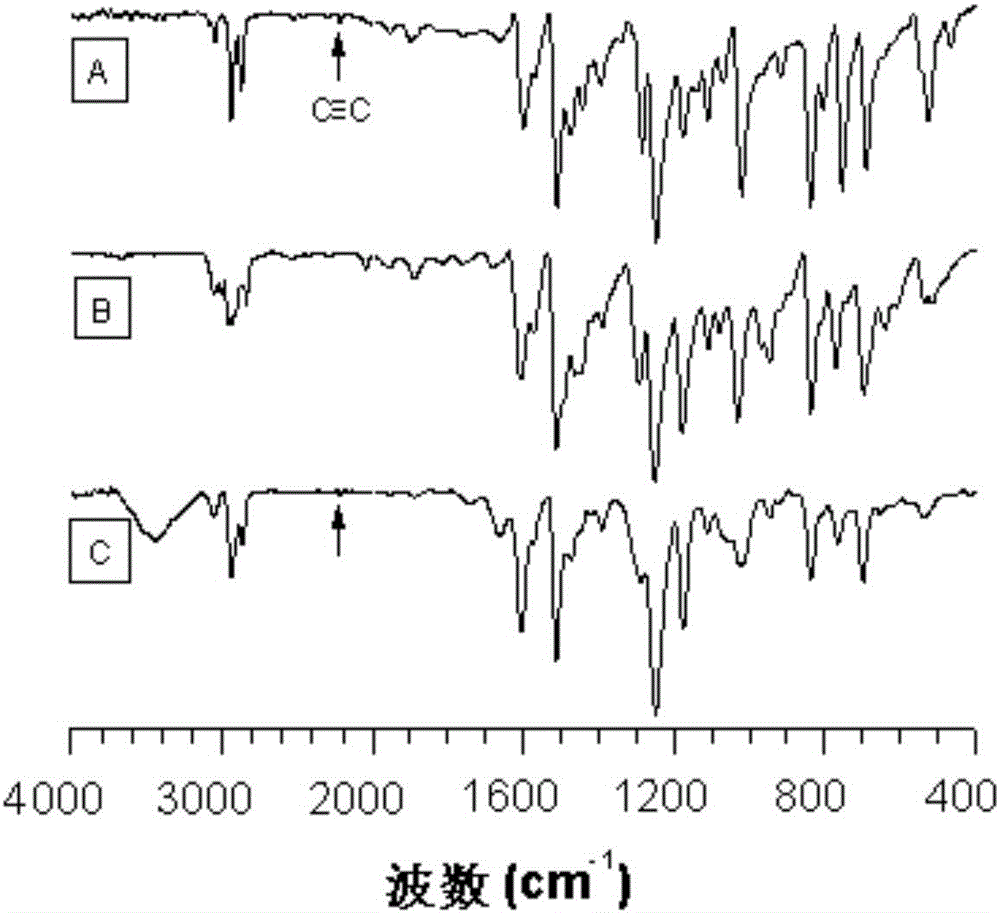

Polyfuran compound and preparation method thereof

The invention belongs to the technical field of organic synthesis and discloses a polyfuran compound and a preparation method thereof. The polyfuran compound has a structural general formula shown as a formula (I). The preparation method includes: in a normal-pressure oxygen environment, enabling bifunctional aryl acetylene monomer and oxygen to be in polymerization reaction in an organic solvent through joint action of a catalyst and a cocatalyst; dissolving a product in the organic solvent; adding into methanol for precipitation; collecting precipitate; drying to constant weight to obtain the polyfuran compound. The preparation method is conducted in the normal-pressure oxygen environment, and oxygen participates in formation of polymer, so that feeding proportion of the monomer does not need to be controlled; the polyfuran compound has high thermostability and excellent processability and has huge application prospect in the field of explosive detection and two-photo absorption due to special photophysical properties.

Owner:SOUTH CHINA UNIV OF TECH

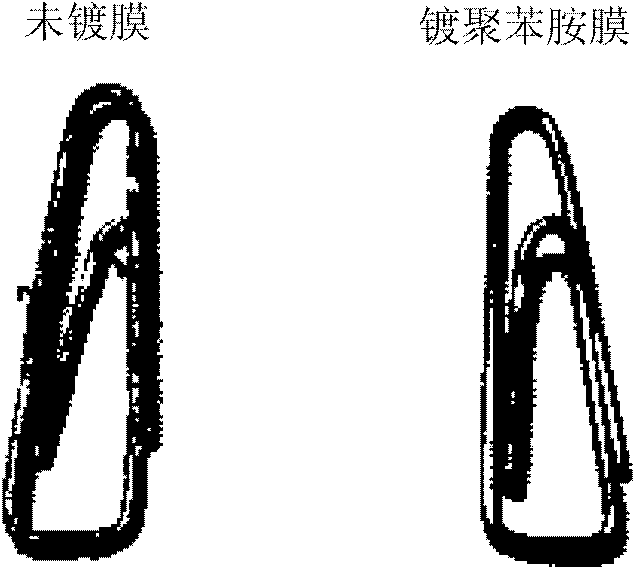

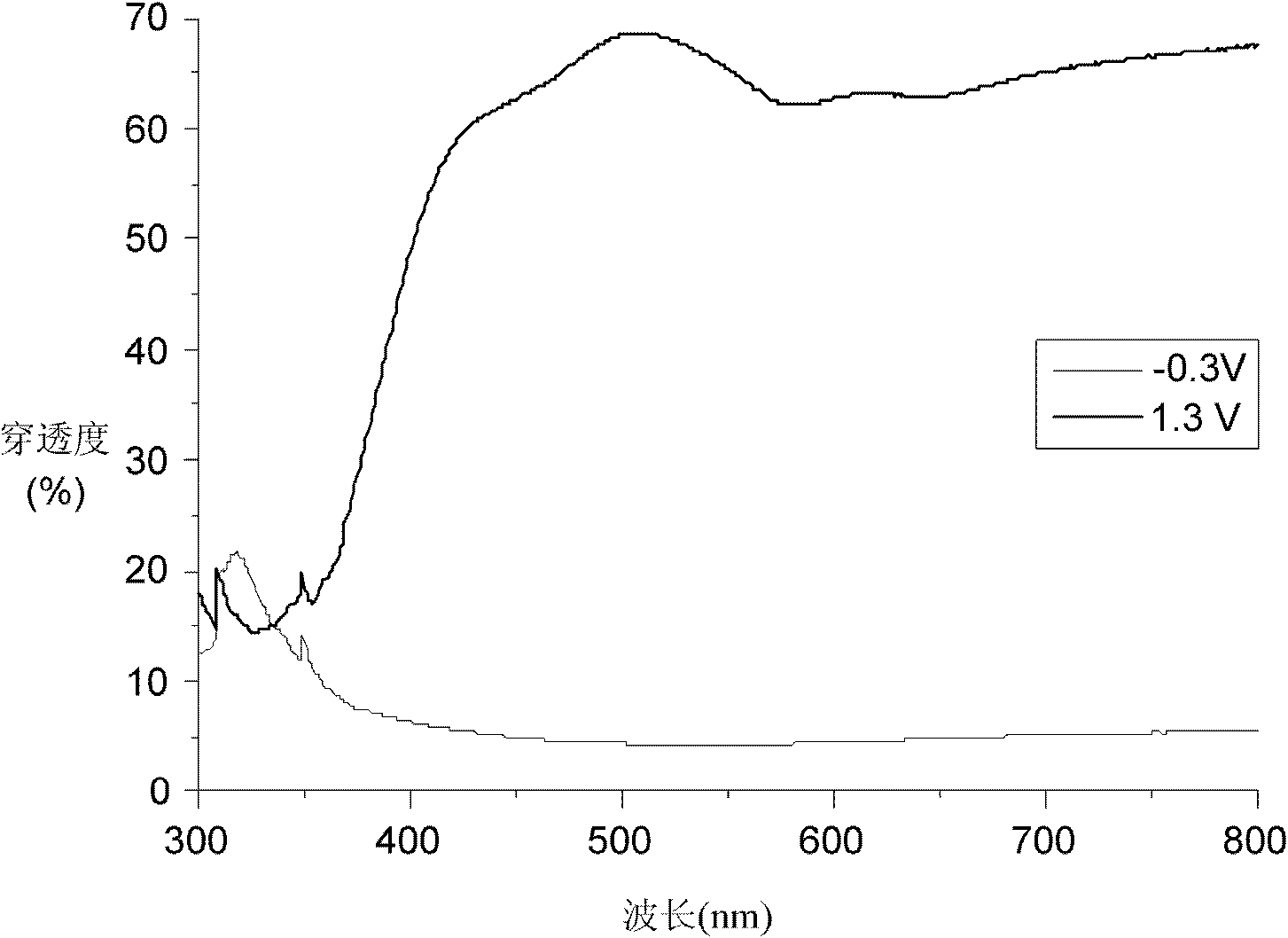

Conductive polymer solution and preparation method thereof

InactiveUS20120273730A1Low boiling pointImprove solubilityConductive materialOrganic conductorsOrganic solventPolymer science

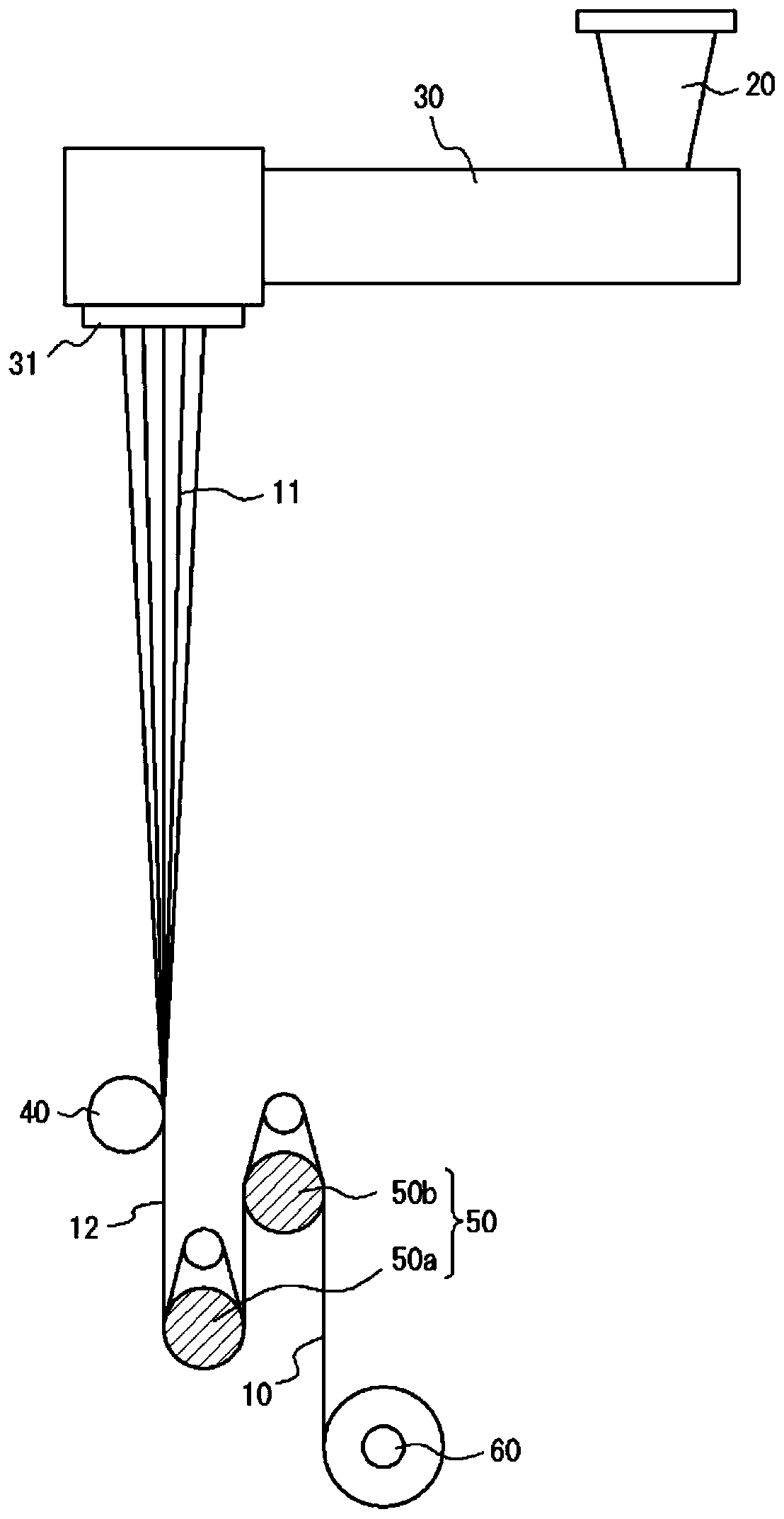

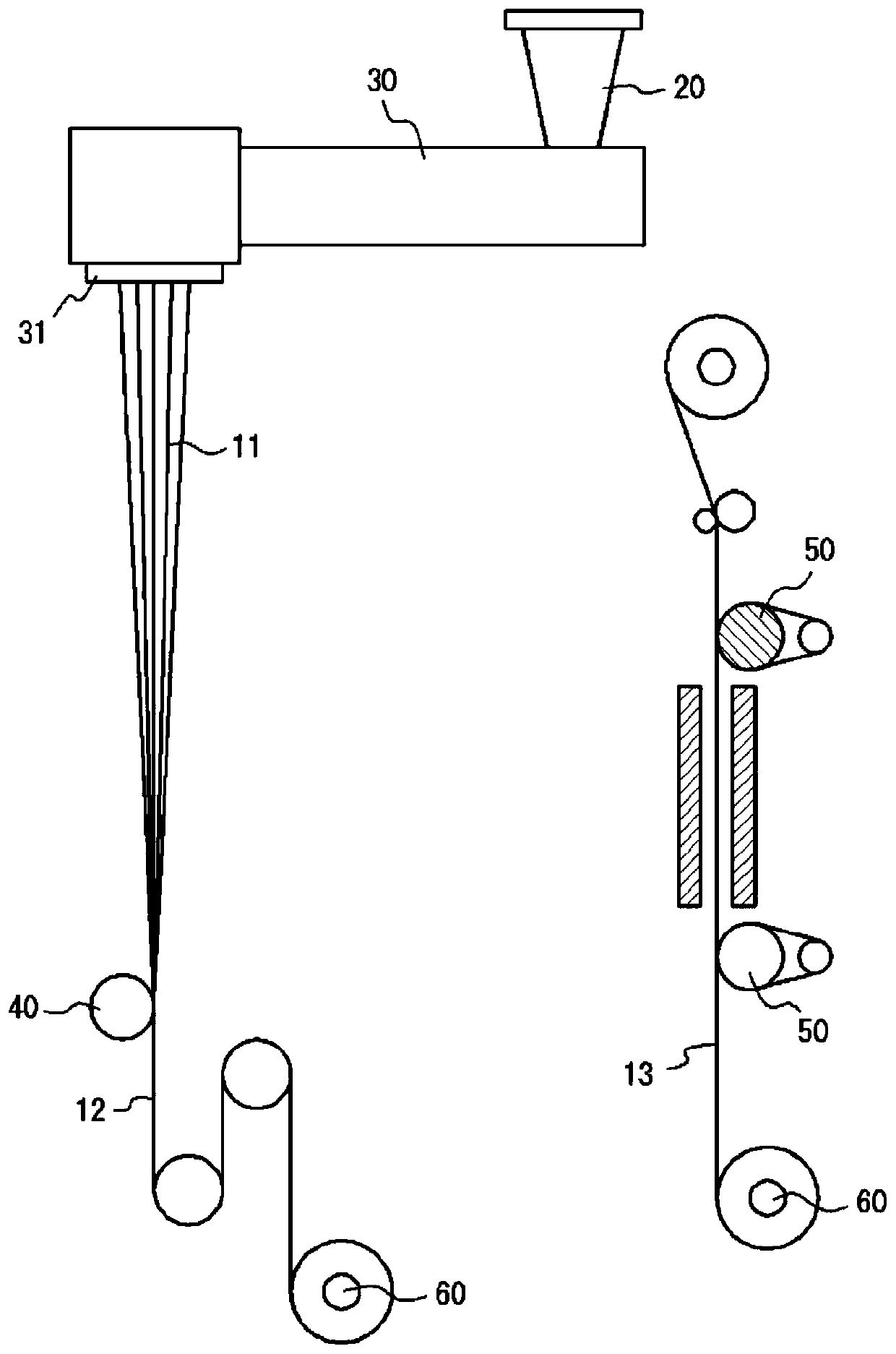

A conductive polymer solution includes one doped conjugated polymer and one organic solvent. The doped conjugated polymer has electrical conductivity, and is selected from the group consisting of polyacetylenes, polypyrroles, polyparaphenylenes, polythiophenes, polyfurans, poly(3,4-ethylenedioxythiophenes), poly(3,4-propylenedioxythiophenes) (PProDOT), polythianaphthenes, polyanilines, and their copolymers, derivatives and combinations. The organic solvent is selected from the group consisting of a fluorinated organic solvent, mixture solvents containing fluorinated organic solvents, and mixture solvents containing fluorinated and non-fluorinated organic solvents. The organic solvent is mixed with the doped conjugated polymer. A preparation method of the conductive polymer solution is also disclosed.

Owner:NAT CENT UNIV

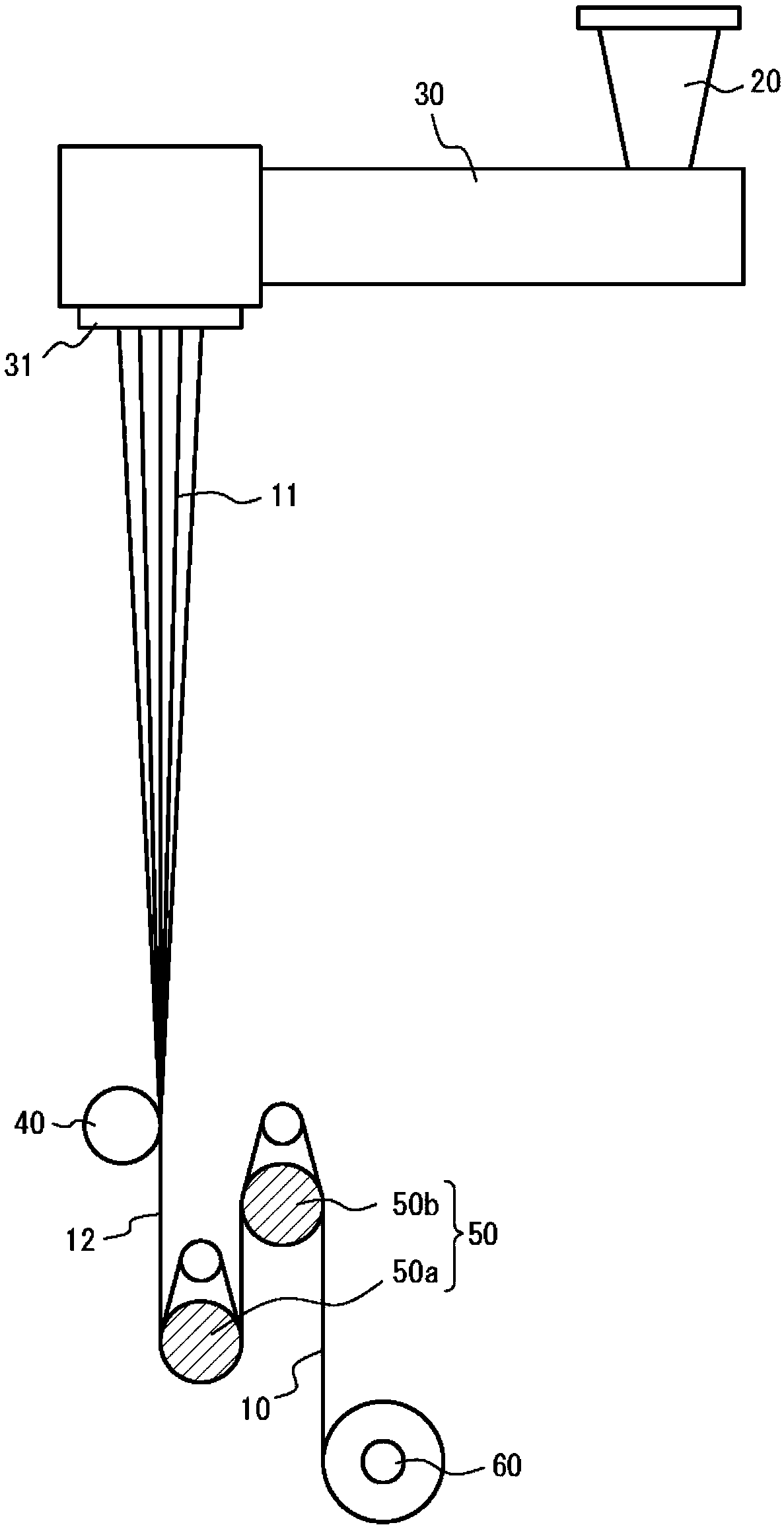

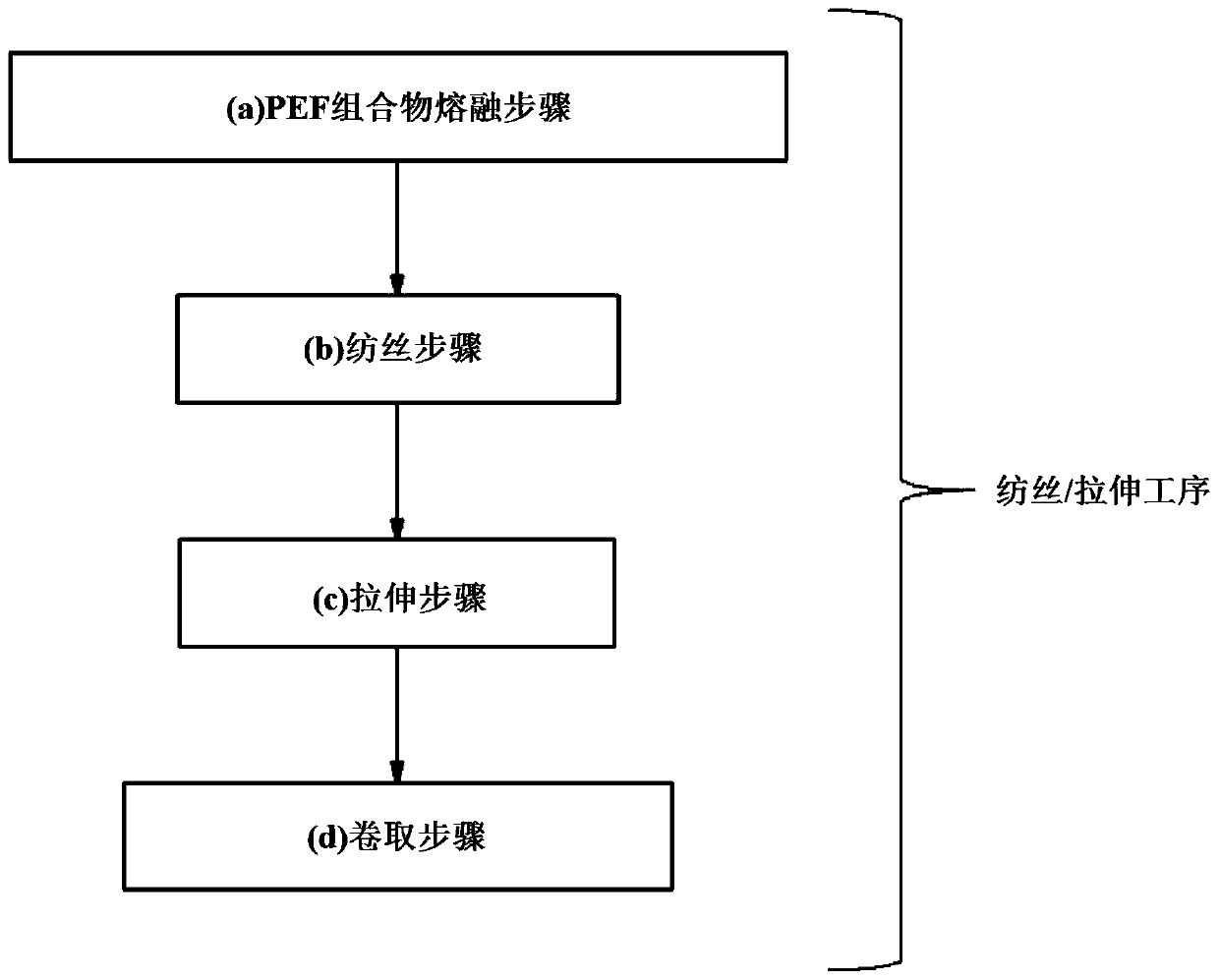

Manufacturing method of pef raw yarn

ActiveCN108026667BEfficient productionHigh storage modulusPneumatic tyre reinforcementsMelt spinning methodsYarnPolymer science

The object of the invention in the present application is to provide a method for producing a raw PEF yarn that can efficiently obtain a raw PEF yarn with a high storage modulus. The method for producing a PEF yarn as a polyethylene 2,5-furandicarboxylate (PEF) raw yarn is characterized in that it is provided with a spinning / stretching step in which the PEF-containing resin composition The undrawn yarn formed by melt spinning is continuously stretched without recovery to obtain the PEF raw yarn, and then the PEF raw yarn is taken up, wherein the take-up speed (T) of the PEF raw yarn is the same as that during the melt spinning. The ratio (T / E) of the speed (E) of extruding the resin composition in a filament shape was 700-2000.

Owner:BRIDGESTONE CORP +1

Process for the production of a solid-state polymerized poly (tetramethylene-2, 5-furan dicarboxylate) polymer and polymer thus produced

Owner:FURANIX TECH BV

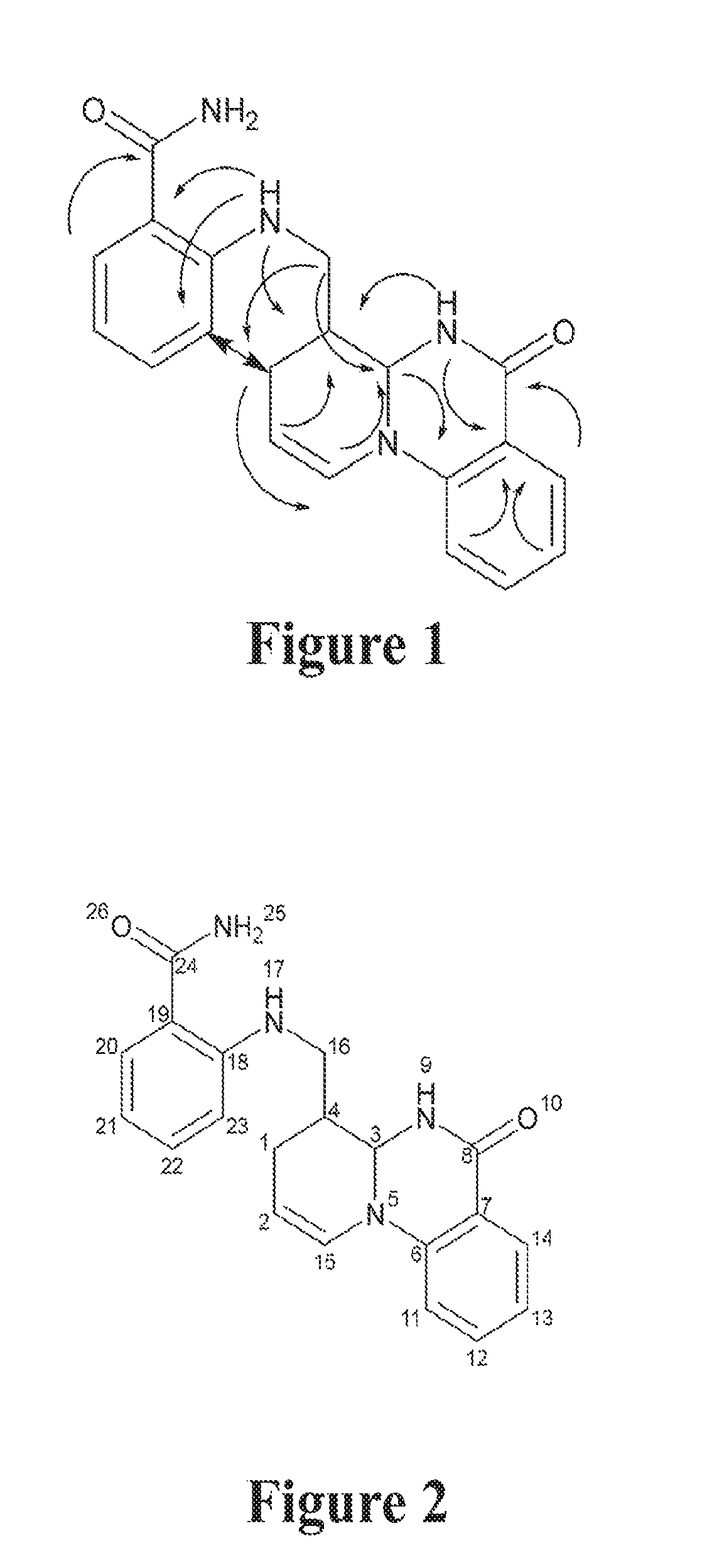

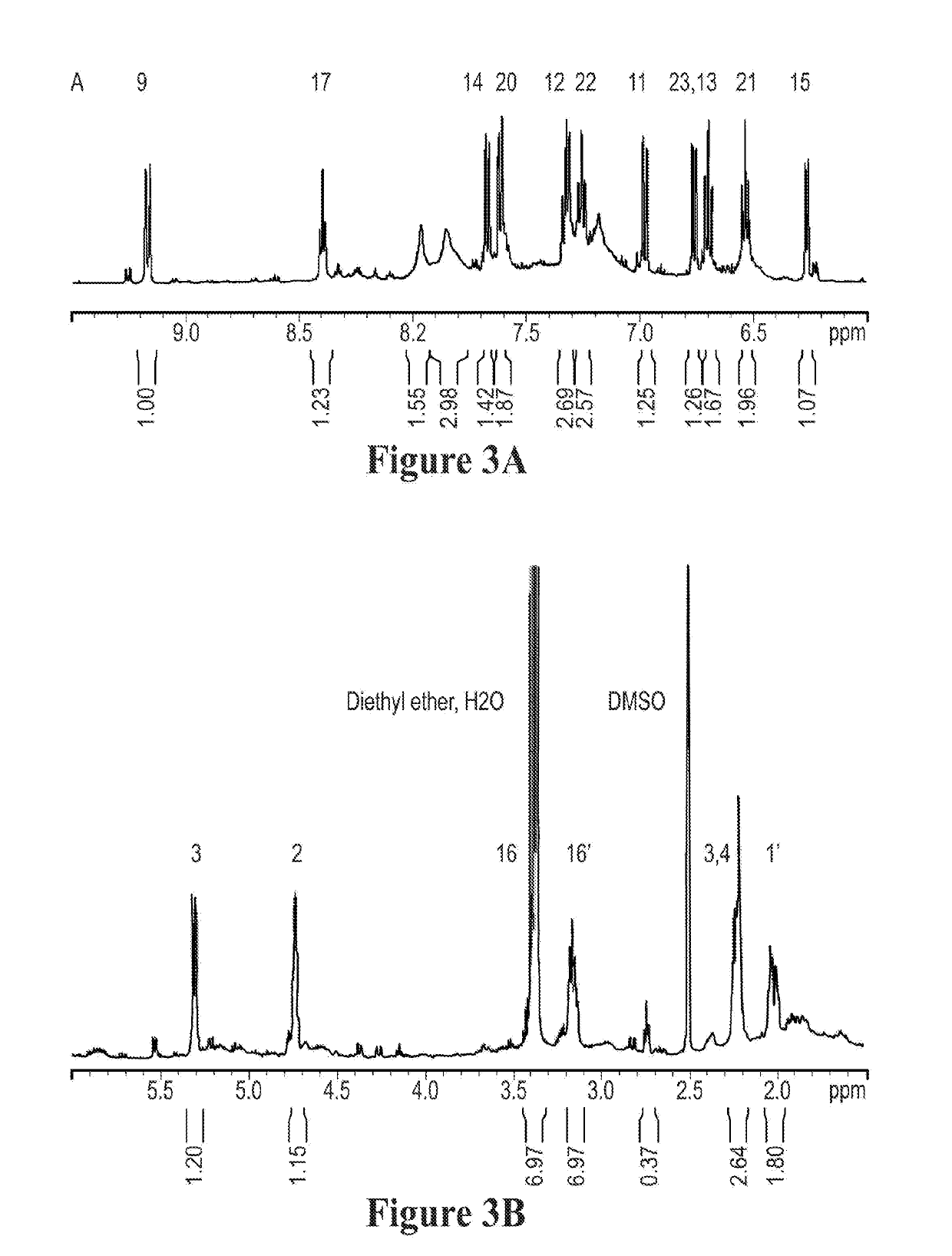

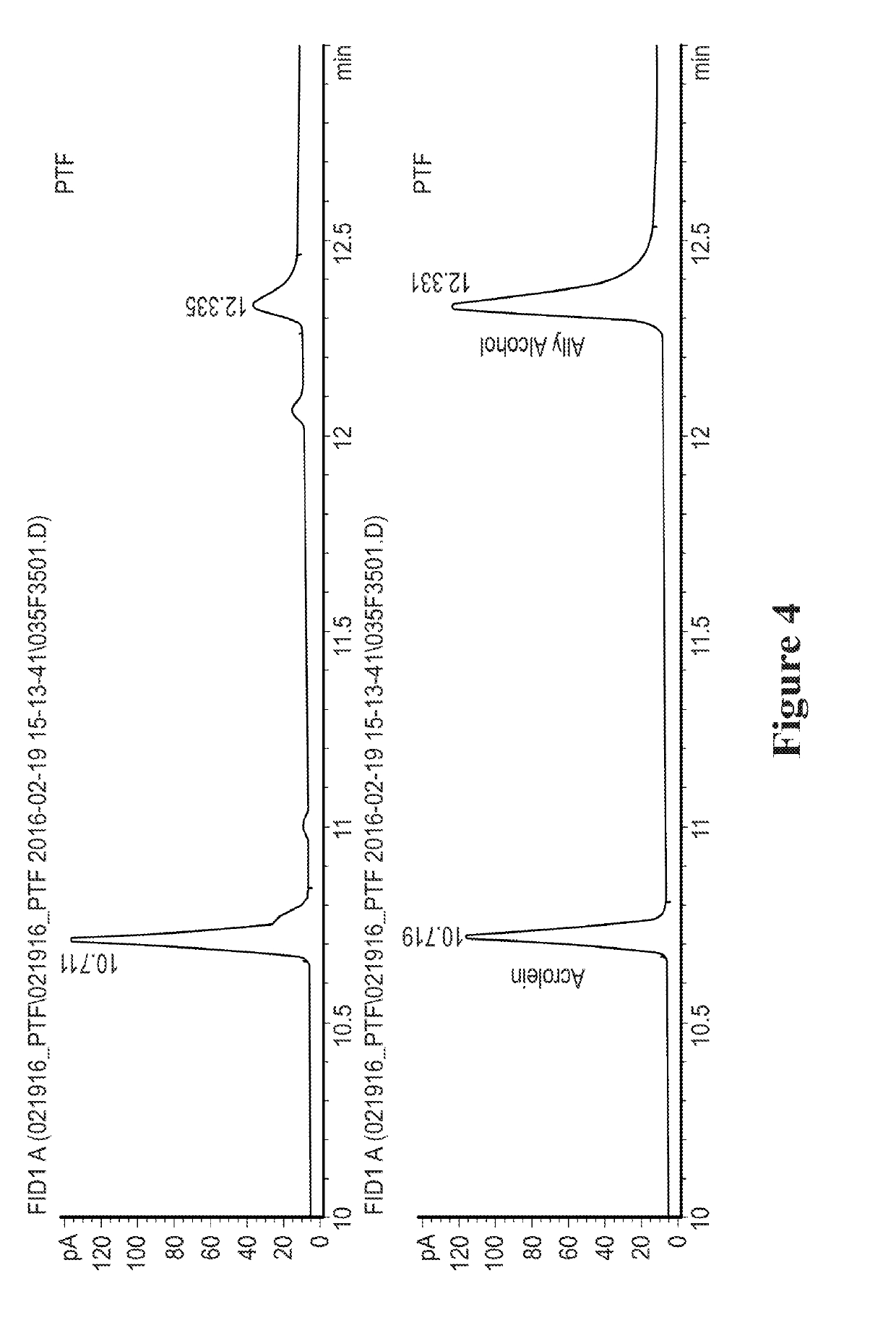

Acrolein scavenging in ptf and other 1,3-propanediol derived polymers

This disclosure provides a process for removing acrolein or allyl alcohol from a polyester composition, the process comprising: combining a polyester composition derived from 1,3-propanediol with an amino amide or a primary amine; wherein the amino amide or the primary amine is combined in sufficient quantities to scavenge acrolein or allyl alcohol produced from degradation of the polyester composition. An analysis of reactions between anthranilamide (AAA) and acrolein demonstrates how amines or amino amides can scavenge acrolein from thermally processed poly(trimethylene terephthalate) and poly(trimethylene furan-2,5-dicarboxylate), and thermodynamic models are presented as guidance for matching targets with scavenging agent.

Owner:THE COCA-COLA CO

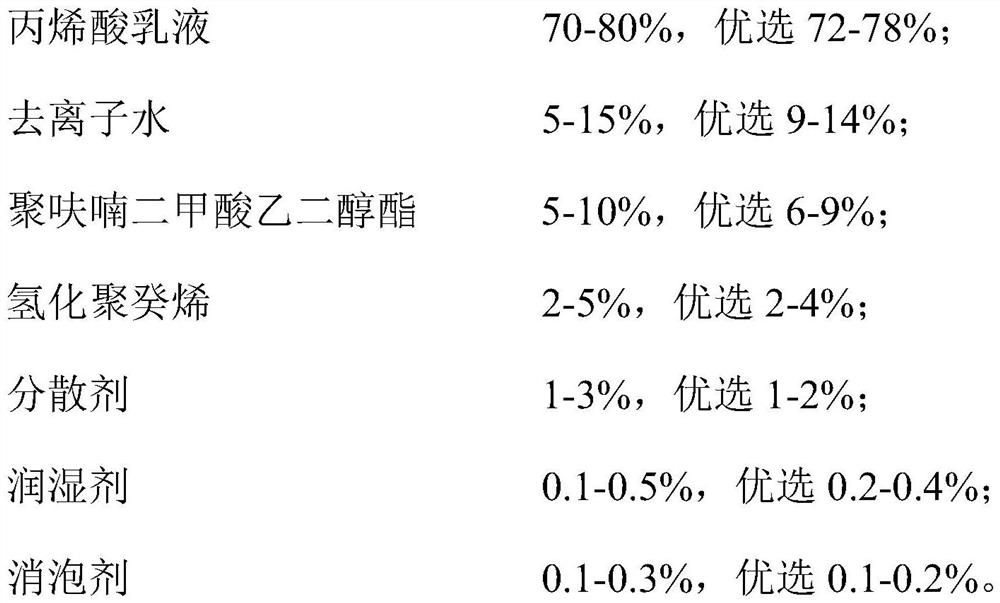

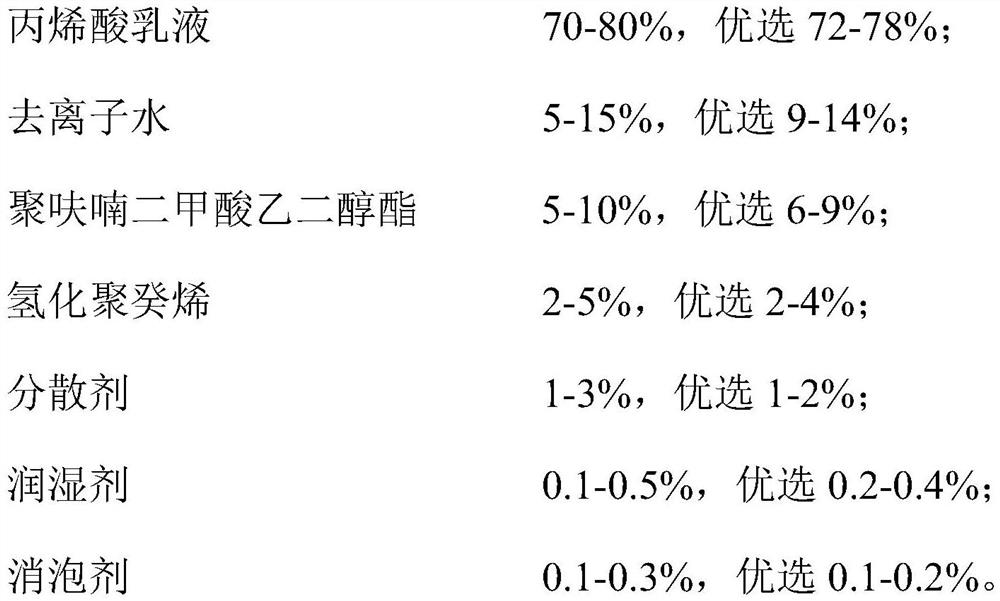

Barrier coating, preparation method thereof and recyclable paper

ActiveCN114350217AImprove barrier propertiesGood film formingNon-fibrous pulp additionPaper coatingFuranPolymer science

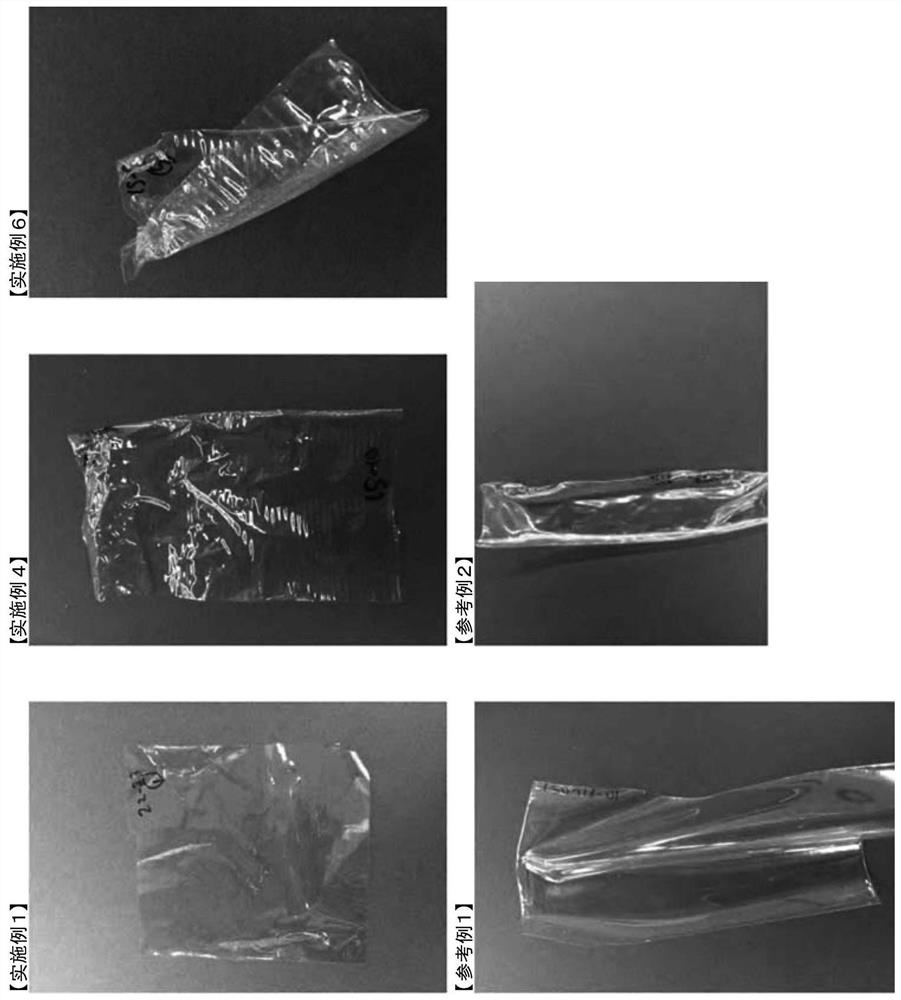

The invention discloses a barrier coating, a preparation method thereof and recyclable paper. The barrier coating is prepared from the following components: acrylic emulsion, deionized water, polyethylene furandicarboxylate, hydrogenated polydecene, a dispersing agent, a wetting agent and a defoaming agent. The intrinsic viscosity of the polyethylene furandicarboxylate is controlled between 0.2 dL / g and 0.4 dL / g. The excellent barrier property and the excellent anti-adhesion property of a single coating can be realized, and meanwhile, the recoverability is realized. The problems that existing materials cannot be recycled and construction is complex are solved.

Owner:WANHUA CHEM GRP CO LTD

Thermoformed article of poly(ethylene 2,5 furandicarboxylate) polyester

Thermoformed article comprising poly(ethylene-2,5-furandicarboxylate) polyester, which polyester has a weight average molecular weight (Mw) of at least 50,000, determined by gel permeation chromatography using polystyrene as standard and which polyester is semicrystalline, is prepared in a process comprising: providing a sheet that comprises poly(ethylene-2,5-furandicarboxylate) polyester, which polyester has a weight average molecular weight (Mw) of at least 50,000, determined by gel permeation chromatography using polystyrene as standard and which polyester is semicrystalline; heating the sheet to a temperature above its glass transition temperature to obtain a pliable sheet; shaping the pliable sheet in a mold to a desired shape to obtain a pliable shaped article; cooling the pliable shaped article; and releasing the thus cooled shaped article from the mold.

Owner:FURANIX TECH BV

Production method of polyester film having furandicarboxylic acid unit

ActiveCN110382602BImprove mechanical propertiesExcellent gas barrier propertiesSynthetic resin layered productsDomestic containersPolymer sciencePolyester resin

The present invention provides a method for producing a biaxially oriented polyester film that can be used in industrial applications and packaging applications. A method for producing a biaxially oriented polyester film, characterized in that it comprises the steps of: feeding a polyester resin into an extruder; extruding the melted polyester resin from the extruder to obtain 250- A step of melting the resin sheet at 310°C; a step of bringing the molten resin sheet into close contact with a cooling roll by an electrostatic application method to obtain an unstretched sheet; and a step of biaxially stretching the above-mentioned unstretched sheet, and the above-mentioned polyester The resin satisfies the following (A) to (C): (A) the above-mentioned polyester resin contains polyethylene furandicarboxylate resin formed by furandicarboxylic acid and ethylene glycol; (B) the intrinsic viscosity of the above-mentioned polyester resin It is more than 0.50dL / g; (C) the melting resistivity value at 250°C of the above-mentioned polyester resin is 3.0×10 7 Ω·cm or less.

Owner:TOYOBO CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com