Production method of polyester film having furandicarboxylic acid unit

A manufacturing method and technology of polyester film, applied to chemical instruments and methods, household utensils, packaged food, etc., to achieve excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

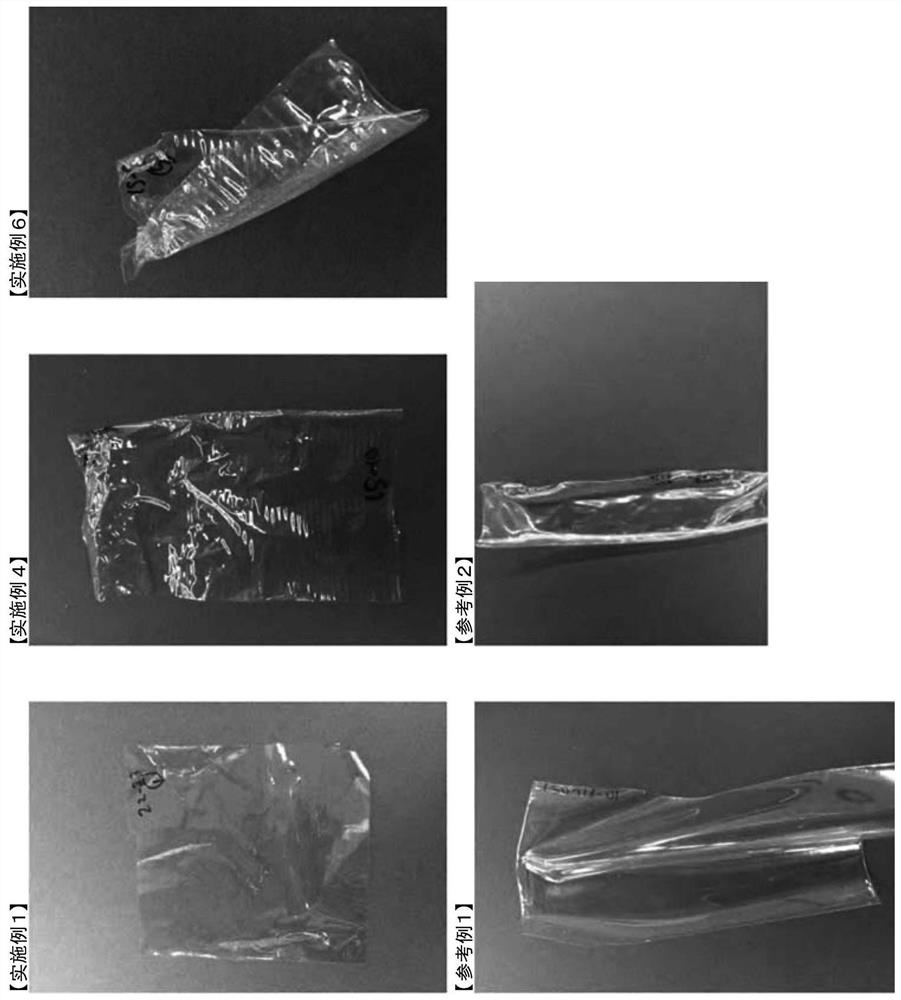

Examples

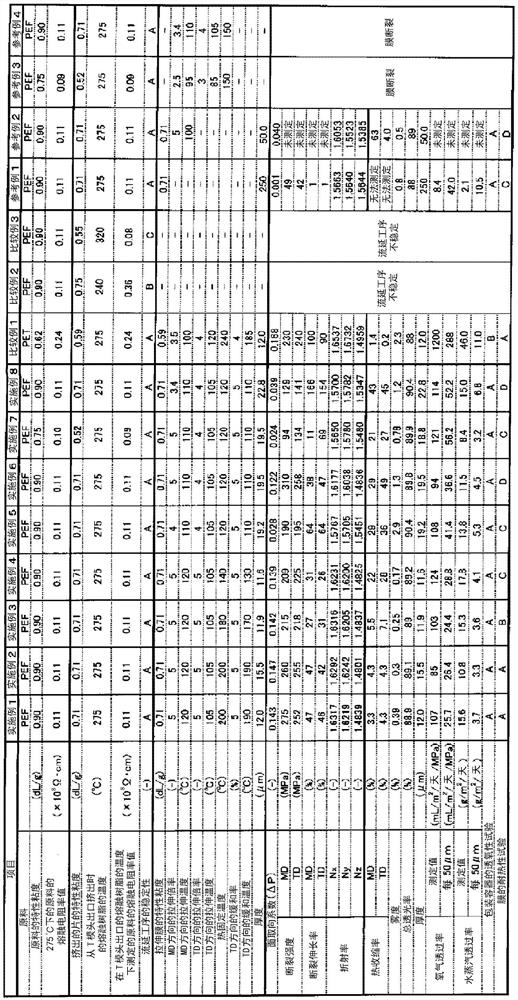

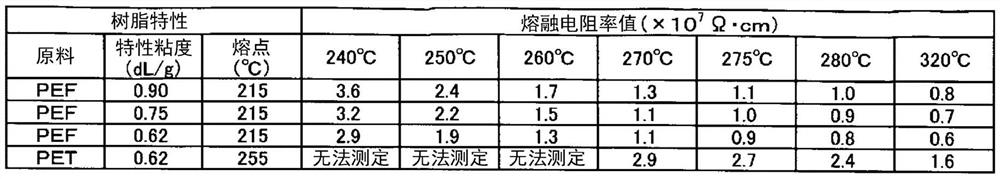

Embodiment 1

[0171] As a raw material, an intrinsic viscosity of 0.90 dL / g, a melting point of 215°C, and a melting resistivity value of 1.1×10 when heated and melted at 275°C were used. 7 Ω·cm Polyethylene 2,5-furandicarboxylate manufactured by Avantium Corporation. After drying under reduced pressure (1 Torr) at 100° C. for 24 hours to make the moisture content 100 ppm or less, it was supplied to a twin-screw extruder (screw diameter 30 mm, L / D=25). Regarding the raw material supplied to the twin-screw extruder, the resin temperature from the melting section of the extruder to the kneading section, the polymer piping (the pipe for the melted raw material), and the gear pump was set to 270°C, and thereafter The polymer piping (pipe for the melted raw material) was set at 275°C, and it was melt-extruded into a sheet form from a T die (pipe). The temperature of the extruded molten resin sheet was 275°C.

[0172] Then, the extruded resin was cast on a cooling drum having a surface temperat...

Embodiment 2

[0176] A film was obtained by the same method as described in Example 1 except that the thickness of the unstretched film was 300 μm. The physical properties of the obtained film are shown in Table 1.

Embodiment 3~6

[0178] A film was obtained by the same method as described in Example 1, except that the film-forming conditions were changed as shown in Table 1. The physical properties of the obtained film are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat shrinkage ratio | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com