Thermoplastic moulding materials

A product and composition technology, applied in conductive coatings, polyester coatings, coatings, etc., can solve problems such as inappropriate solvents, premature painting, insufficient pretreatment, etc., and achieve lower specific surface area resistance and low surface resistance , High heat resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

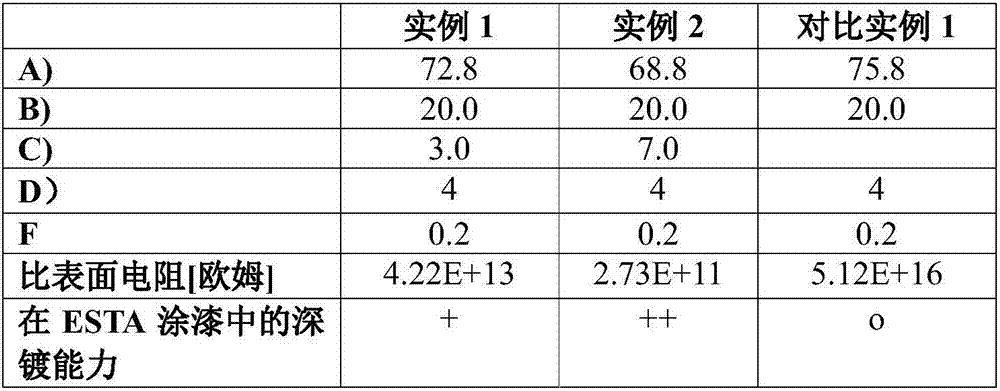

[0153] In order to demonstrate the unexpectedly found properties and the resulting possibilities for painting articles based on the compositions according to the invention, suitable polyester molding materials were initially produced by kneading. For this, the individual components were combined in a twin-screw extruder (ZSK 32 Mega mixer from Coperion Werner & Pfleiderer (Stuttgart, Germany)) at Mix and extrude at a temperature in the range of 260°C to 300°C, cool until pelletizable, and pelletize. After drying (approximately 2 h at 120° C. in a vacuum oven) the pellets were processed to form test samples.

[0154] The test samples reported in Table 1 for the study were injection molded on an injection molding machine at a melting temperature of 260°C and a mold temperature of 80°C.

[0155] -80mm diameter, 4mm thickness round blank

[0156] -Eurosheet: 300mm×15mm×3mm

[0157] Each test was performed on 5 test samples and an average value was determined from the results. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com