Modified poly(ethylene furandicarboxylate) as well as preparation method and application thereof

A technology of polyethylene furandicarboxylate and ethylene furandicarboxylate, applied in the field of modified polyethylene glycol furandicarboxylate, which can solve the problem of high brittleness, PEF strength, rigidity and barrier properties at the same time And other problems, to achieve the effect of high rigidity, conducive to large-scale production and application, and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

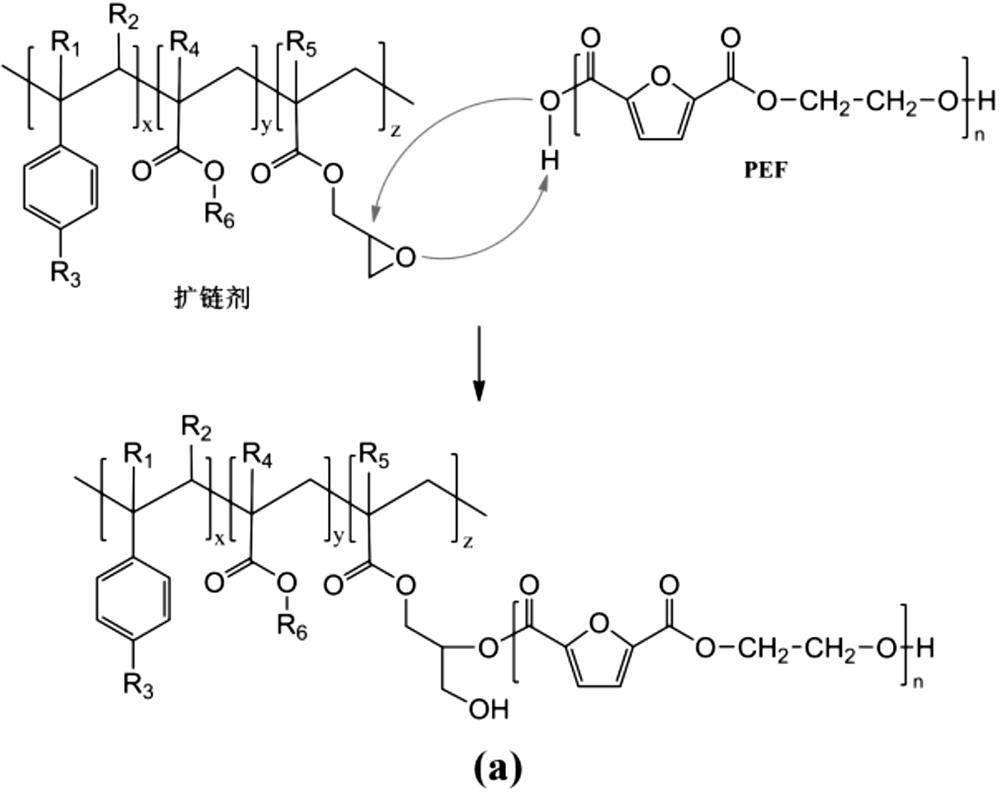

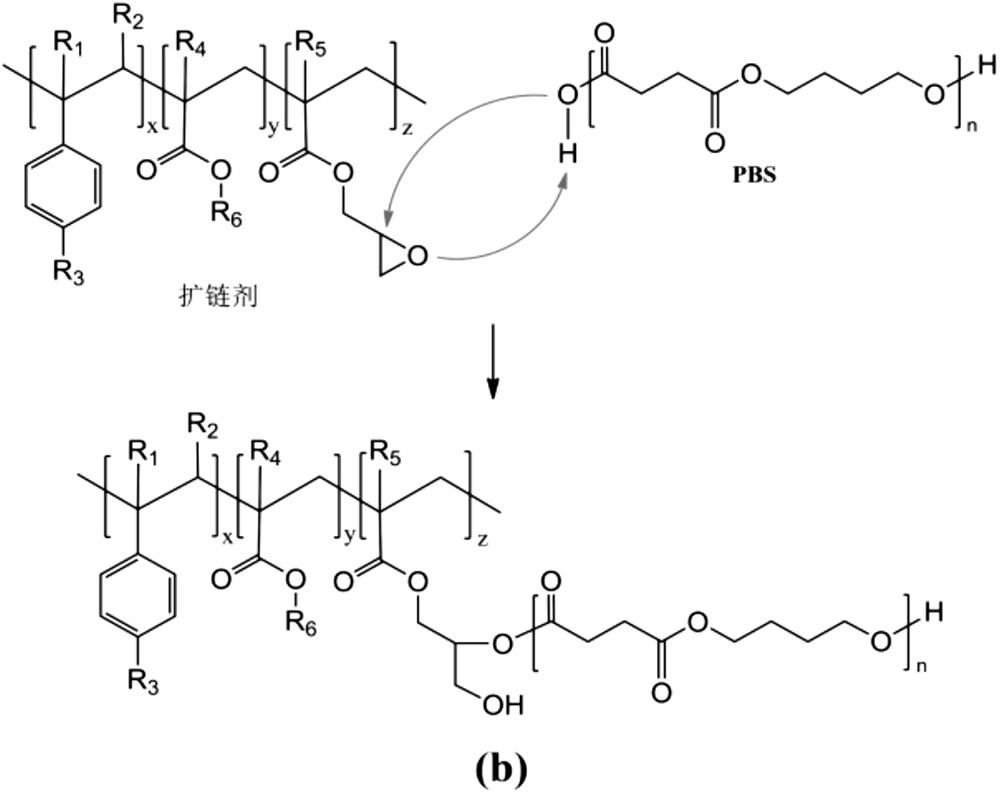

Method used

Image

Examples

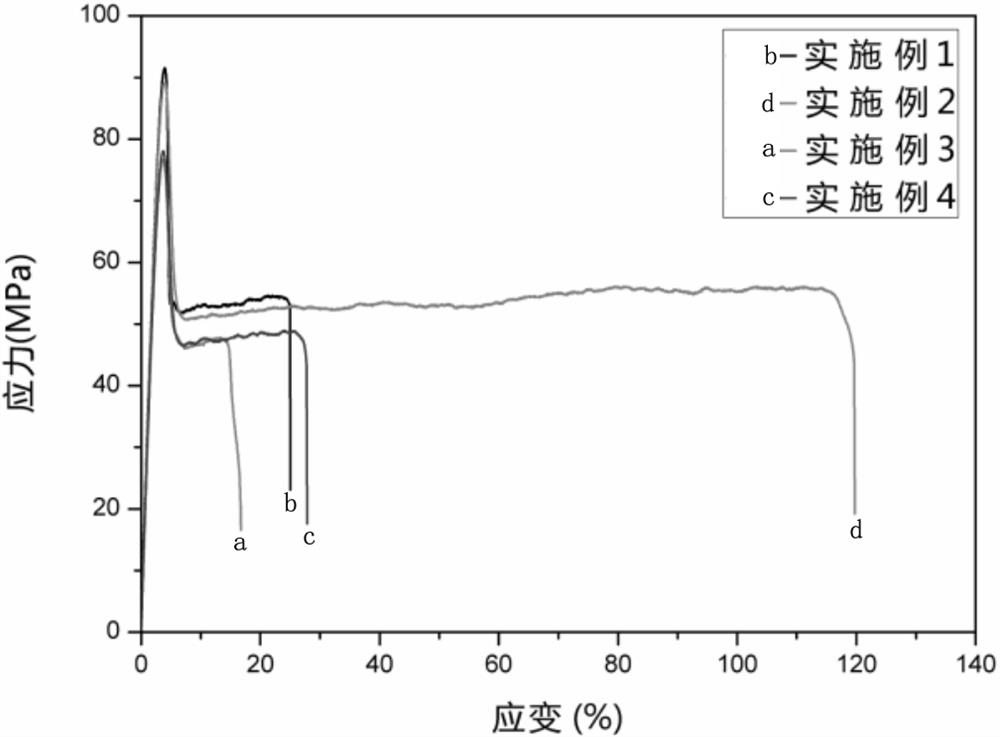

Embodiment 1

[0029] The polyethylene furandicarboxylate and polybutylene succinate were dried in a vacuum oven at 80 °C for 4 h. Take by weighing 93.9 parts of polyethylene furandicarboxylate, 5 parts of polybutylene succinate, 0.5 part of styrene-acrylate-glycidyl acrylate copolymer and 0.6 part of antioxidant (antioxidant 1010 and Antioxidant 168 compounded at a ratio of 1:1), mixed evenly, and then added to a twin-screw extruder for melt blending for 5 minutes and then extruded to pelletize. The melt blending temperature was 230 ° C, and the screw speed was 100 rpm.

Embodiment 2

[0031]The polyethylene furandicarboxylate and polybutylene succinate were dried in a vacuum oven at 80 °C for 4 h. Take by weighing 93.4 parts of polyethylene furandicarboxylate, 5 parts of polybutylene succinate, 1 part of styrene-acrylate-glycidyl acrylate copolymer and 0.6 part of antioxidant (antioxidant 1010 and Antioxidant 168 compounded at 1:1), mixed evenly and added to the rod extruder to melt and blend for 6 minutes, then extrude and pelletize. The melt blending temperature was 230°C and the screw speed was 100rpm.

Embodiment 3

[0033] The polyethylene furandicarboxylate and polybutylene succinate were dried in a vacuum oven at 80 °C for 4 h. Take by weighing 88.9 parts of polyethylene furandicarboxylate, 10 parts of polybutylene succinate, 0.5 part of styrene-acrylate-glycidyl acrylate copolymer and 0.6 part of antioxidant (antioxidant 1010 and Antioxidant 168 compounded at a ratio of 1:1), mixed evenly, and then added to a twin-screw extruder for melt blending for 5 minutes and then extruded to pelletize. The melt blending temperature was 235° C., and the screw speed was 110 rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com