Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67 results about "PDMS stamp" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

PDMS stamps are pieces of polydimethylsiloxane (PDMS), a silicone, that have been patterned usually against a master to form a relief pattern used in soft lithography. This PDMS stamp can be used in either its current form as a relief surface for techniques such as microcontact printing or can also be attached to an external source by tubing so that liquid may be passed through channels on its surface. In this second case it will often be laminated to a surface so that chemistry can be performed on that surface producing a pattern of the PDMS stamp on to the surface. Alternatively a PDMS stamp can be laminated to a second piece of PDMS to form a contained device. It is possible to pattern PDMS with nanometre resolution. PDMS stamps can be procured from some commercial sources such as Research Micro Stamps. Many techniques have been developed to modify the basic setups to perform a range of tasks such as assays on small volumes. These kinds of devices are often referred to as microfluidic devices. Because of the small dimensions of these devices flow is laminar not turbulent which can lead to many useful properties; however, this reduces the ability of fluid streams to mix.

Application of zinc phthalocyanine complex as ink in micro-contact printing

InactiveCN102516841BReduce bloatReduce distortionInksOther printing apparatusMicrocontact printingPolyimide substrate

The invention discloses application of a zinc phthalocyanine complex as ink in micro-contact printing. The 2-propyl alcohol solution of 8(Octanohydroxamic)-zinc phthalocyanine serves as micro-contact printing ink; the pattern of a Polydimethylsiloxane (PDMS) seal is transferred to the surface of carboxylation polyethylene terephthalate, polyethylene naphthalate or polyimide substrate; and a delicate metal pattern is obtained on the substrate with a chemical plating method. The application of the zinc phthalocyanine complex as the ink in the micro-contact printing has the beneficial effect that the common phenomena of pattern inflation and pattern torsion in the micro-contact printing can be reduced by the phthalocyanine metal complex ink, and the phthalocyanine metal complex ink has a lowpreparation cost and great potential in the industrial application and is stable.

Owner:GUANGXI TEACHERS EDUCATION UNIV

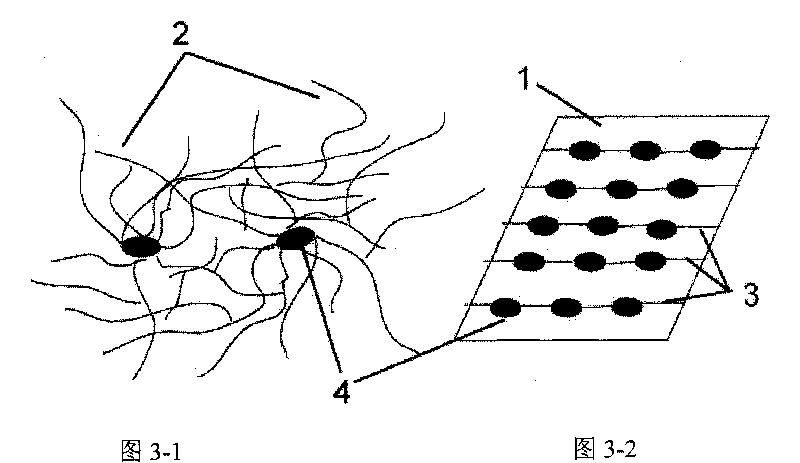

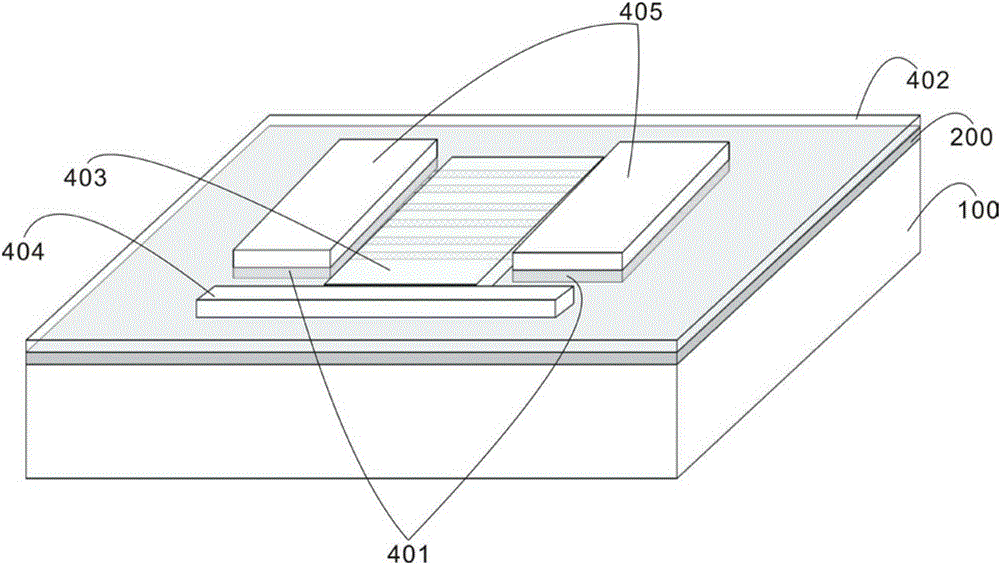

Device for establishing single-cell level connection between neurons and growth connecting method

InactiveCN101748061AConvenience platformConvenient ArrangementTissue cultureTissue/virus culture apparatusBasementEngineering

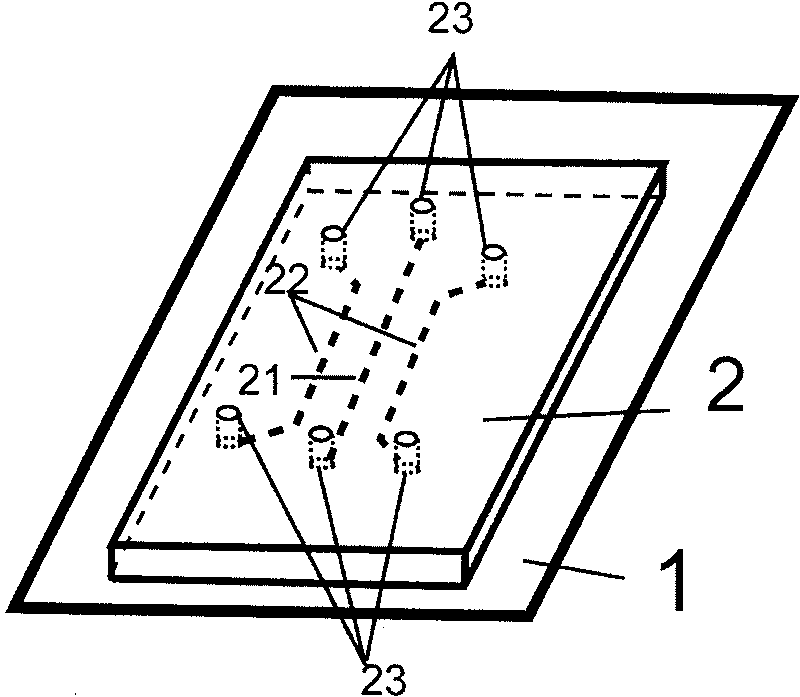

The invention discloses a device and a method for establishing single-cell level connection between neurons; the device comprises a basement whose upper surface is provided with protein band, and the region outside the protein band at the basement is covered by a polyether F127 layer; a PDMS stamp which is covered to the upper surface of the basement and whose lower surface is provided with a micro-groove unit; the micro-groove unit comprises: a linear type intermediate groove and at least one linear type side groove which is arranged at the left side or / and the right side of the intermediate groove, the middle section of the side groove does not intersect with the intermediate groove, and two end sections outside the middle section of the side groove incline to the direction away from the intermediate groove; the groove end is provided with a vertical hole channel; the protein band intersects with the groove without superposition; neurons are sent into the channel and only adhere to the protein band, the neurite directionally grows along the protein band without branching, thereby obtaining single-line connection of neuron single-cell level; the structure is simple, the operation is easy, and the orderly growth of the neurite can be controlled, and the electrical signal transduction between the neurocytes can be precisely studied, furthermore, the invention provides foundation support for manufacturing of bio-sensors.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Application of zinc phthalocyanine complex as ink in micro-contact printing

InactiveCN102516841AReduce bloatReduce distortionInksOther printing apparatusMicrocontact printingPolyimide substrate

The invention discloses application of a zinc phthalocyanine complex as ink in micro-contact printing. The 2-propyl alcohol solution of 8(Octanohydroxamic)-zinc phthalocyanine serves as micro-contact printing ink; the pattern of a Polydimethylsiloxane (PDMS) seal is transferred to the surface of carboxylation polyethylene terephthalate, polyethylene naphthalate or polyimide substrate; and a delicate metal pattern is obtained on the substrate with a chemical plating method. The application of the zinc phthalocyanine complex as the ink in the micro-contact printing has the beneficial effect that the common phenomena of pattern inflation and pattern torsion in the micro-contact printing can be reduced by the phthalocyanine metal complex ink, and the phthalocyanine metal complex ink has a lowpreparation cost and great potential in the industrial application and is stable.

Owner:GUANGXI TEACHERS EDUCATION UNIV

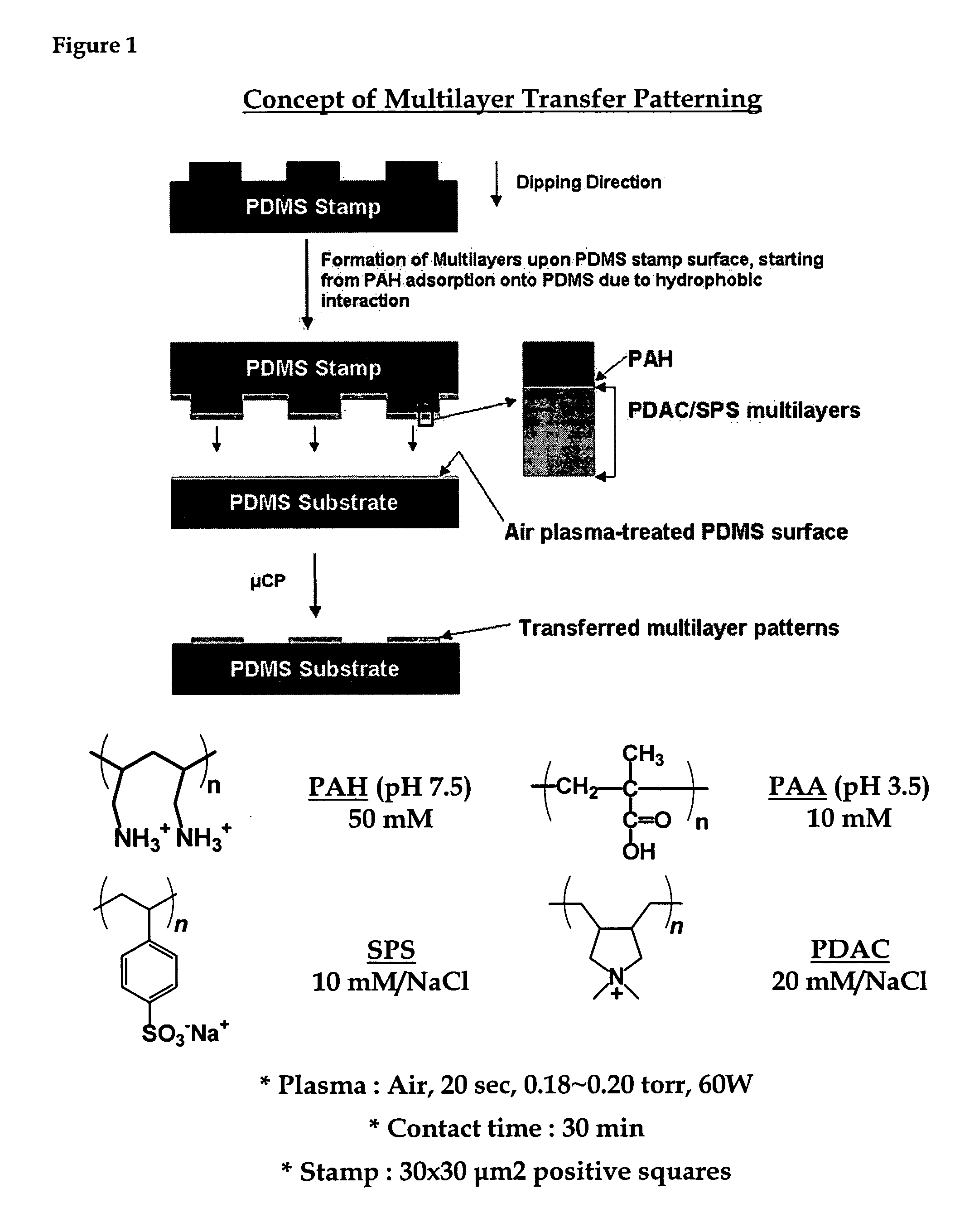

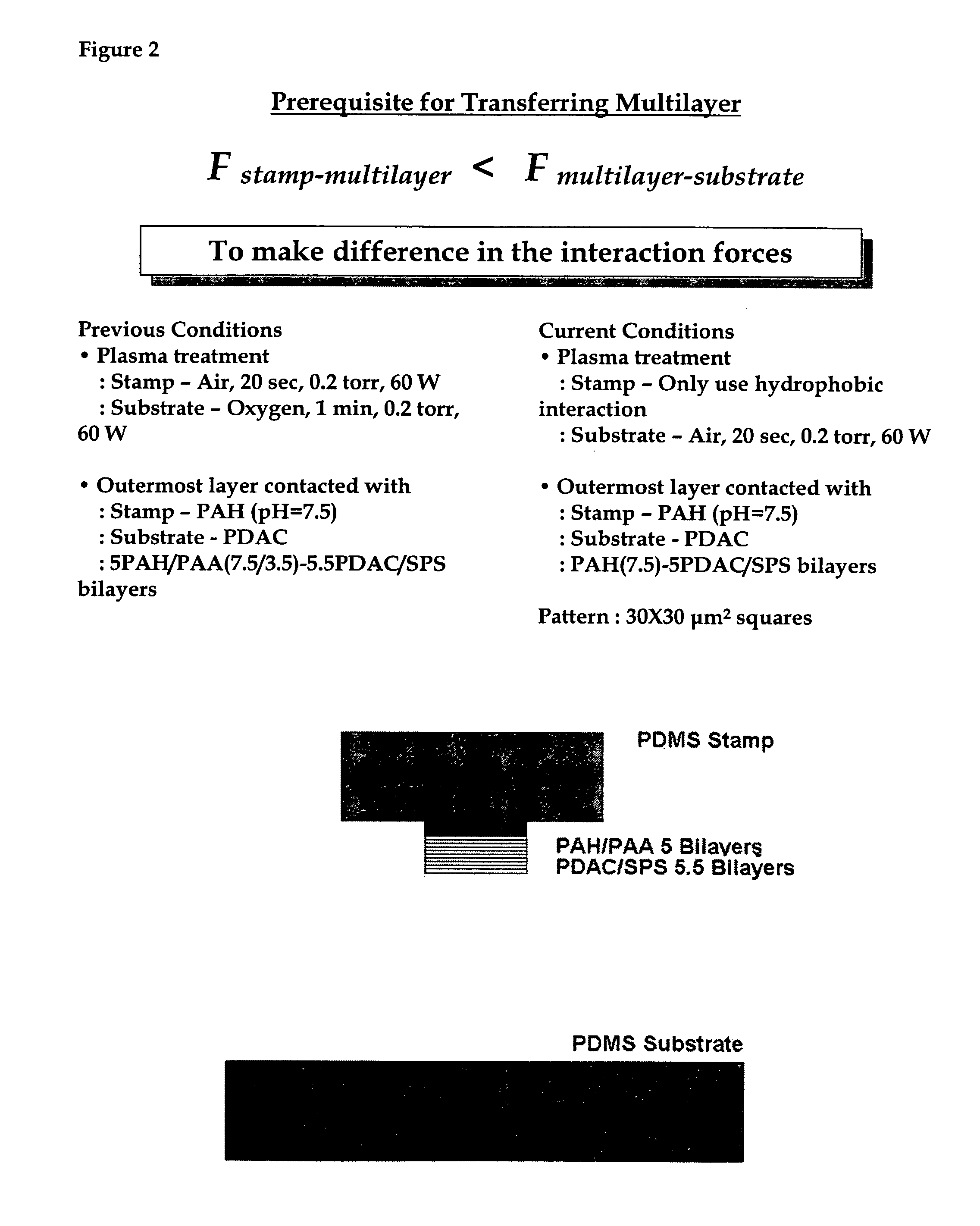

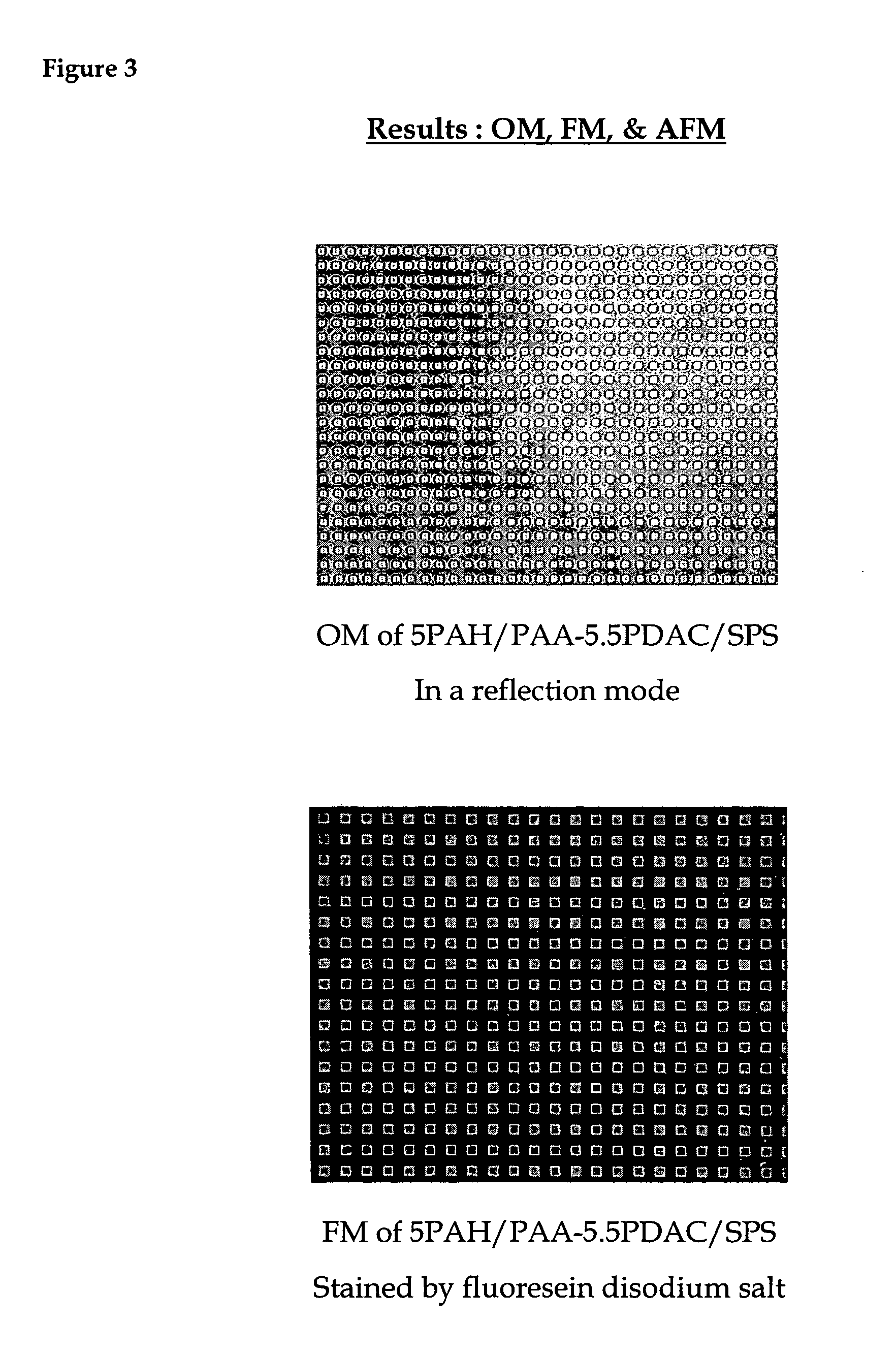

Multilayer transfer patterning using polymer-on-polymer stamping

One aspect of the present invention relates to a method for transferring a patterned polyelectrolyte multilayer from a first surface, e.g., a PDMS stamp, to a second surface, e.g. fabric or a non-woven material, wherein the patterned polyelectrolyte multilayer on the first surface is brought into contact with the second surface in order to transfer the polyelectrolyte multilayer from the first surface to the second surface. Another aspect of the present invention relates to a stamp comprising a surface coated with a polyelectrolyte multilayer suitable for transfer to a substrate using the aforementioned method of transferring patterned multilayers.

Owner:MASSACHUSETTS INST OF TECH

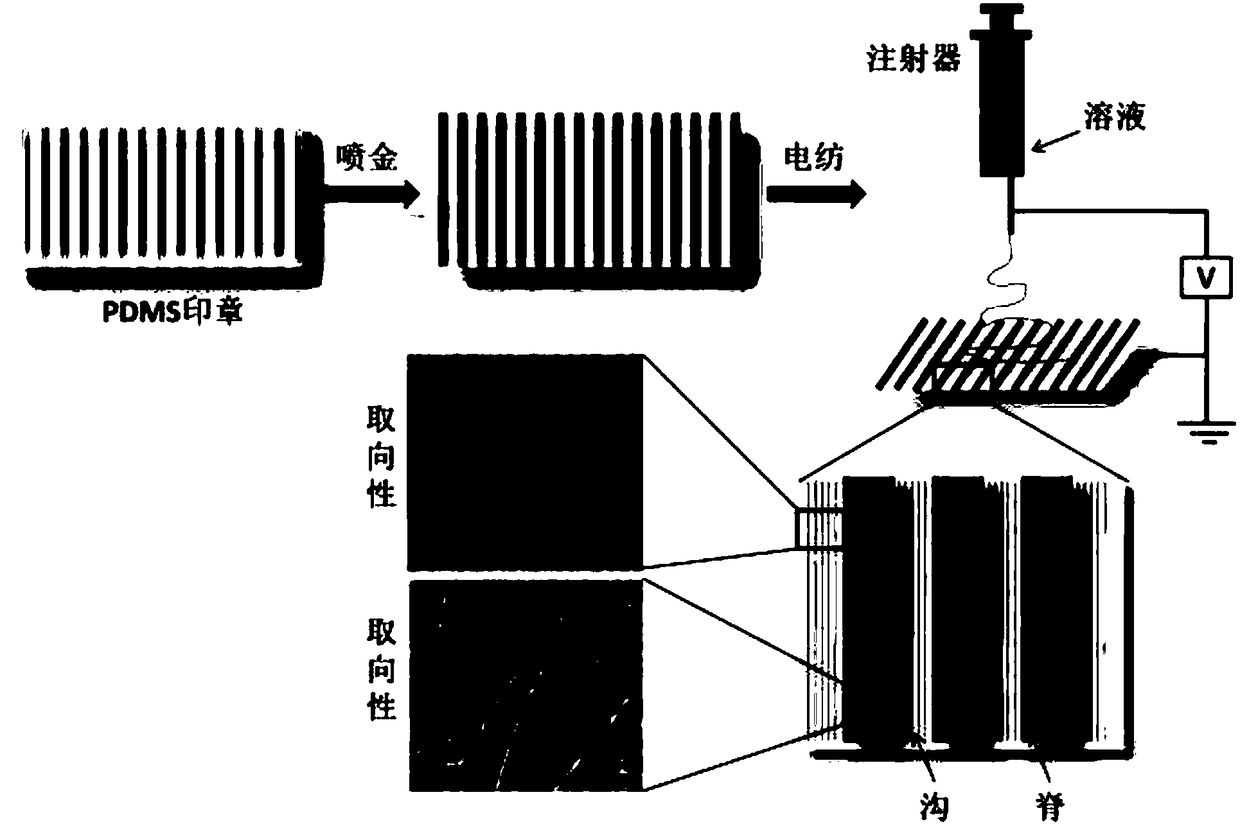

Preparation method for tissue engineering transplant with micro-nano topological geometry structure on surface

InactiveCN108525013ADoes not affect the basic shapeImprove adhesionPharmaceutical delivery mechanismCatheterMicro nanoElectrospinning

A preparation method for a tissue engineering transplant with a micro-nano topological geometry structure on the surface includes 1), preparing a silicone rubber seal with a micro-nano topological (three-dimensional) geometry structure pattern on the surface according to a micro molding method; 2), spraying a metal conducting nano-coating with the thickness of 50-100nm on the surface of the silicone rubber seal according to an ion sputtering method; 3), electrically spinning a natural or composite biological material solution onto the surface of the PDMS seal by an electrospinning technique toform a biological material support; 4), separating the spun biological material support from the PDMS seal to obtain the tissue engineering transplant with the micro-nano topological geometry structure on the surface. The preparation method has the advantages that the micro molding technology and the electrospinning technique are applied jointly, the spun biological material support is separatedfrom the PDMS seal easily, and the preparation method is simple and easy to operate and suitable for mass production.

Owner:NANTONG UNIVERSITY

PDMS elastomer micro-nano processing method based on surface oxidation control transfer printing

InactiveCN105731364AAchieve controllable patterningRealize fine controlDecorative surface effectsChemical vapor deposition coatingElastomerMicro nano

The invention discloses a PDMS elastomer micro-nano processing method based on surface oxidation control transfer printing. The PDMS elastomer micro-nano processing method comprises the following steps: preparing a PDMS film with an adjustable thickness to serve as a transfer printing substrate by using a pouring method or a spin coating method; preparing a PDMS film with a surface microstrucutre to serve as a transfer printing stamp by using a replica casting method; carrying out a surface oxidation treatment on the substrate or the stamp, importing a cohesive energy difference between the PDMS stamp and the planar PDMS substrate to obtain a hard / soft or soft / hard stamp-substrate combination, and simultaneously carrying out a surface activation treatment and a heating treatment on the combination to improve the contact adhesion of the two; taking off the stamp, generating cohesive energy breakage on the soft party during the separation to transfer PDMS ink to the hard party, so as to obtain a PDMS film with complex, precise and controllable concave or convex patterns on the surface. The PDMS elastomer micro-nano processing method disclosed by the method is simple and convenient to operate, low in cost, and is used for avoiding the defects of limited applicable range of other related technology and simple processing patterns.

Owner:TIANJIN UNIV

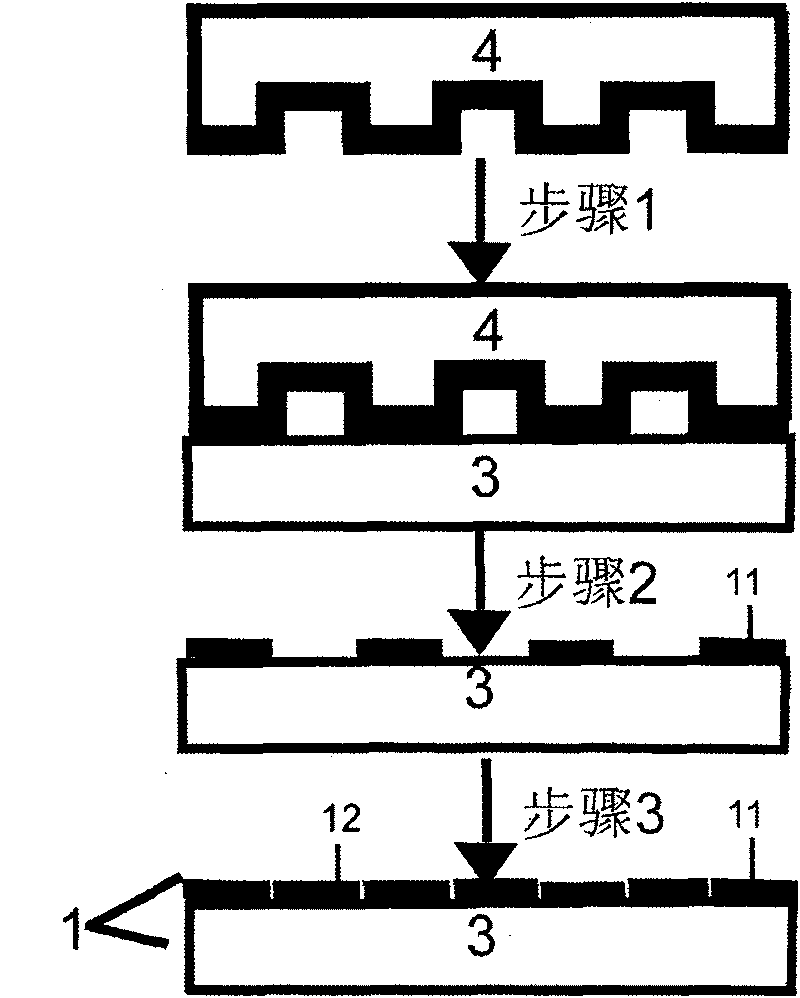

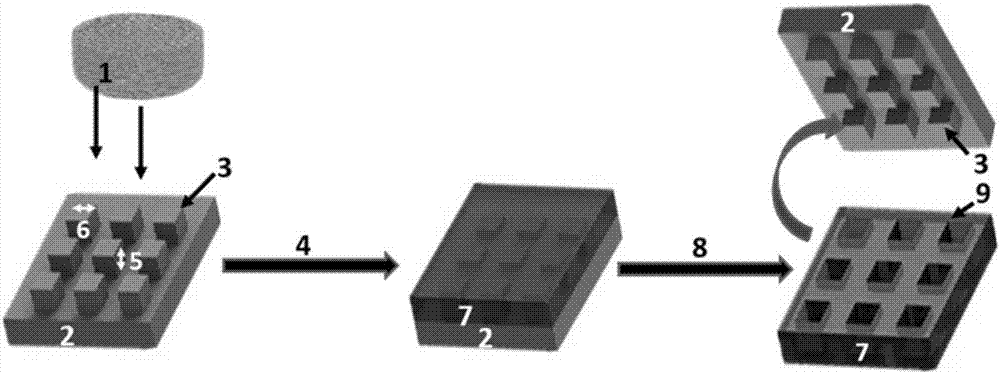

Method for preparing PDMS seal by employing hot-press approach

InactiveCN104281004ABatch processingFast processingPhotomechanical apparatusPolymer scienceUltraviolet

The invention discloses a method for preparing a PDMS seal by employing a hot-press approach, and belongs to the technical field of nano coining. The method comprises the following concrete operation steps: (1) processing a template and processing the template surface; (2) carrying out hot pressing on a polymer by virtue of a template to obtain a polymer mold; and (3) preparing a PDMS seal by virtue of the polymer mold. According to the method, the polymer template is firstly prepared by using the hot pressing method and is taken as an intermediate medium; a mixture of a PDMS performed polymer and a curing agent is spun or cast on a polymer wood plate; and finally the mixture is solidified and demolded. According to the method, the time for preparing the PDMS seal is shortened, and the prepared PDMS seal is high in accuracy and is suitable for being widely applied to the fields such as soft lithography and ultraviolet coining.

Owner:WUXI IMPRINT NANO TECH

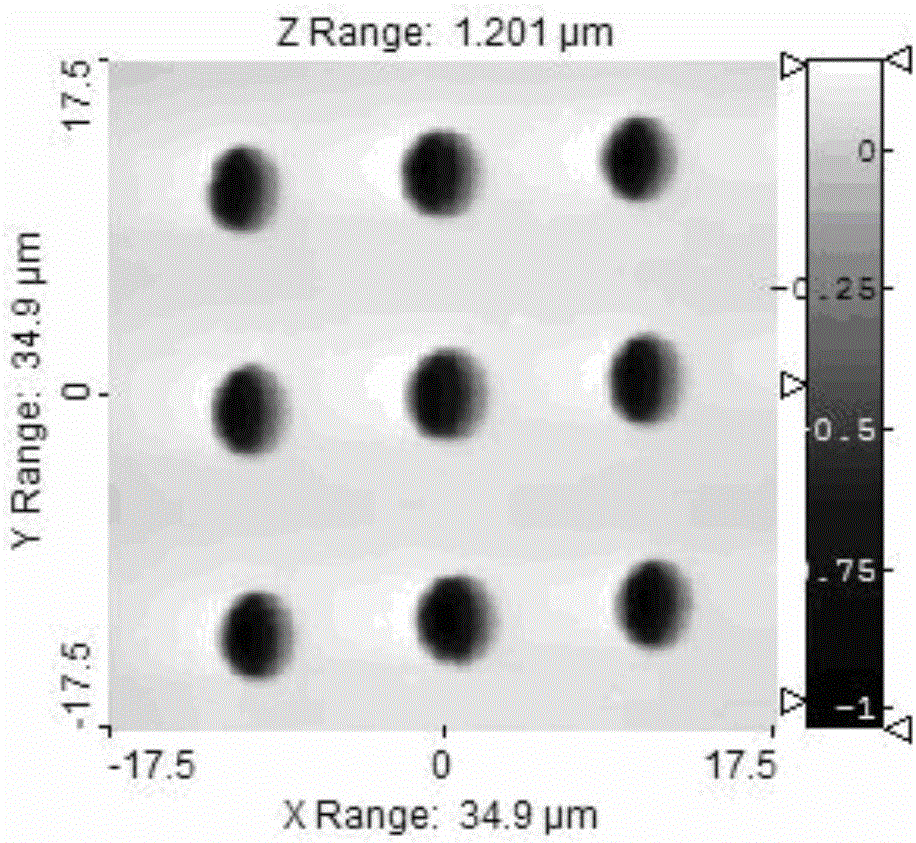

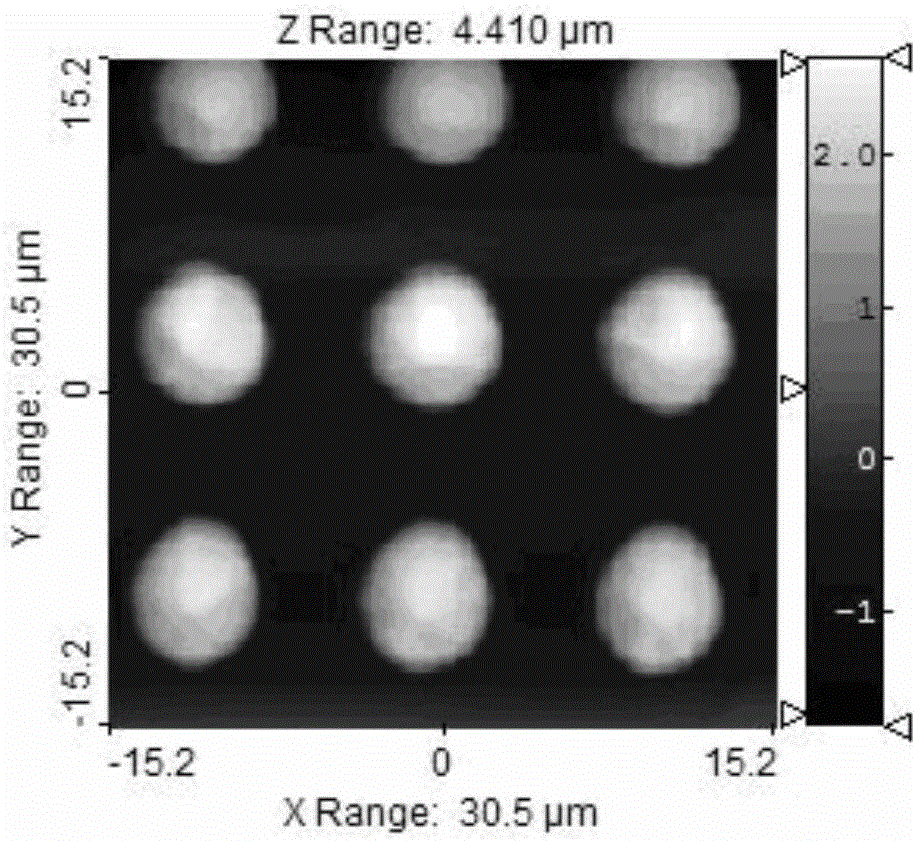

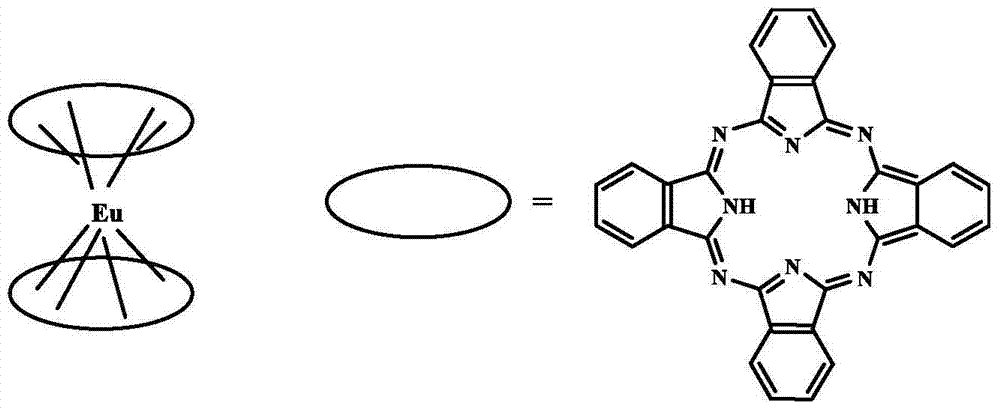

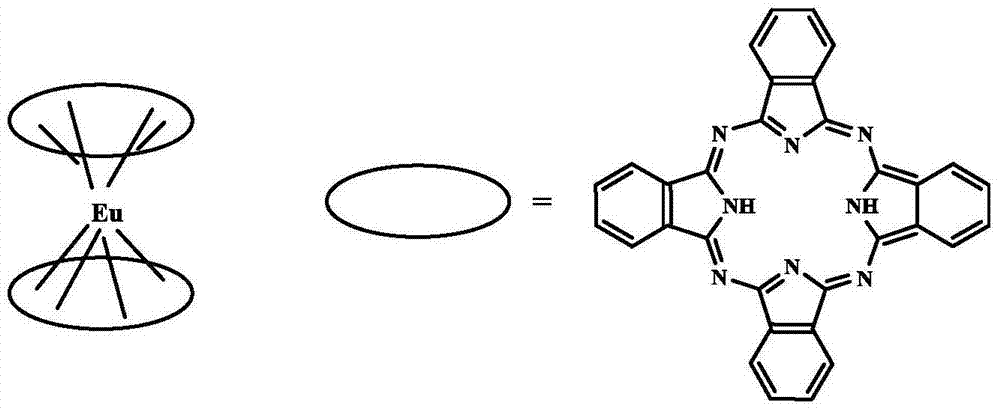

Application of double-layer sandwich-type Eu metal phthalocyanine complex in microcontact printing

ActiveCN104119723AHigh resolutionReduce bloatInksLiquid/solution decomposition chemical coatingMicrocontact printingChemical plating

The invention discloses an application of a double-layer sandwich-type Eu metal phthalocyanine complex in microcontact printing. The double-layer sandwich-type Eu metal phthalocyanine complex is bis(phthalocyanine) complexing Eu, and a metal pattern is obtained on a polytetrafluoroethylene substrate by virtue of a chemical plating method by taking a dichloromethane solution of the bis(phthalocyanine) complexing Eu as a printing agent of microcontact printing and transferring the pattern of a PDMS (Polydimethylsiloxane) seal to a carboxylation polytetrafluoroethylene substrate. According to the application, the fine metal patterns can be obtained by carrying out microcontact printing on the surface of the polytetrafluoroethylene substrate commonly used in an electron industry by taking the dichloromethane solution of the bis(phthalocyanine) complexing Eu as ink, so that the common phenomena of pattern expansion and distortion during the microcontact printing are effectively decreased, and the distinguishability is enhanced.

Owner:WUXI TONGCHUN NEW ENERGY TECH

Device and method for arranging a plurality of cells at same plane and controlling cells

ActiveCN101748060APrecise arrangementPrecise distance controlTissue cultureTissue/virus culture apparatusEngineeringCultured cell

The invention discloses a device and a method for arranging a plurality of cells at the same plane and controlling the cells, comprising: a thin film with micro-hole arrays which is located at the upper surface of a base; a PDMS stamp whose lower surface is provided with a micro-groove unit and is coated on the thin film; the micro-groove unit comprises: an intermediate groove and a left-side groove and a right-side groove which are located at the left side and the right side of the intermediate groove; the middle sections of the left-side groove and the right-side groove are parallel to the intermediate groove; the both end sections except for the middle sections of the left-side groove and the right-side groove slant towards the direction away from the intermediate groove; the end of the groove is provided with a vertical through hole which is communicated with the corresponding groove; the holes of the thin film are all located in the micro-groove of the stamp; and a micro-pipeline is provided with different cell suspensions, the cell grows in the micro-pipeline and adheres to the micro-pipeline; the stamp is removed to realize the co-culture of a plurality of cells at the same plane; and then the thin film is removed to realize the free movement of the plurality of co-cultured cells at the same plane; the method is simple to operate, the used material is cheap, and the invention can be used for high-throughput screening of useful drugs for cells.

Owner:重庆龙翼生物科技有限公司

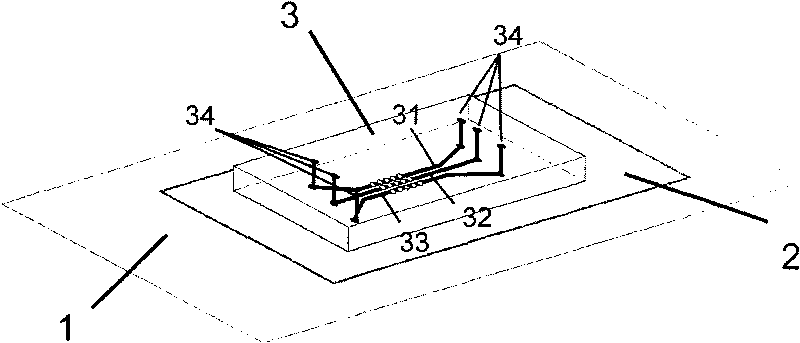

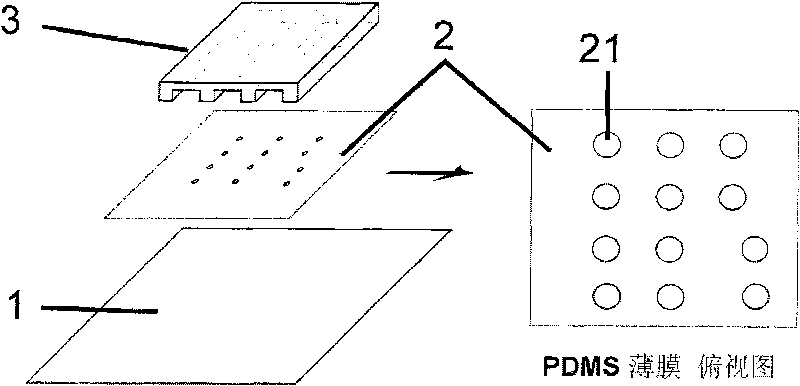

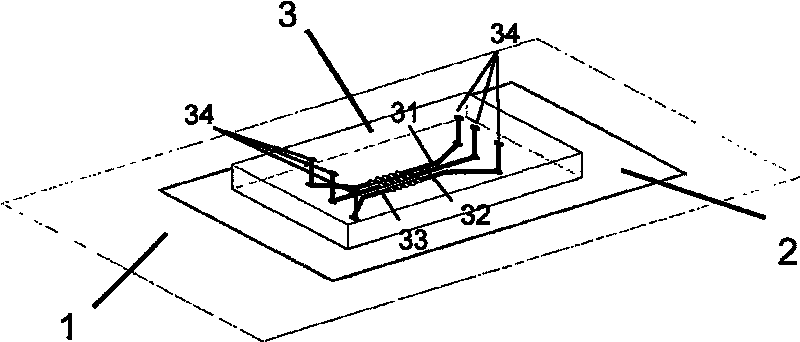

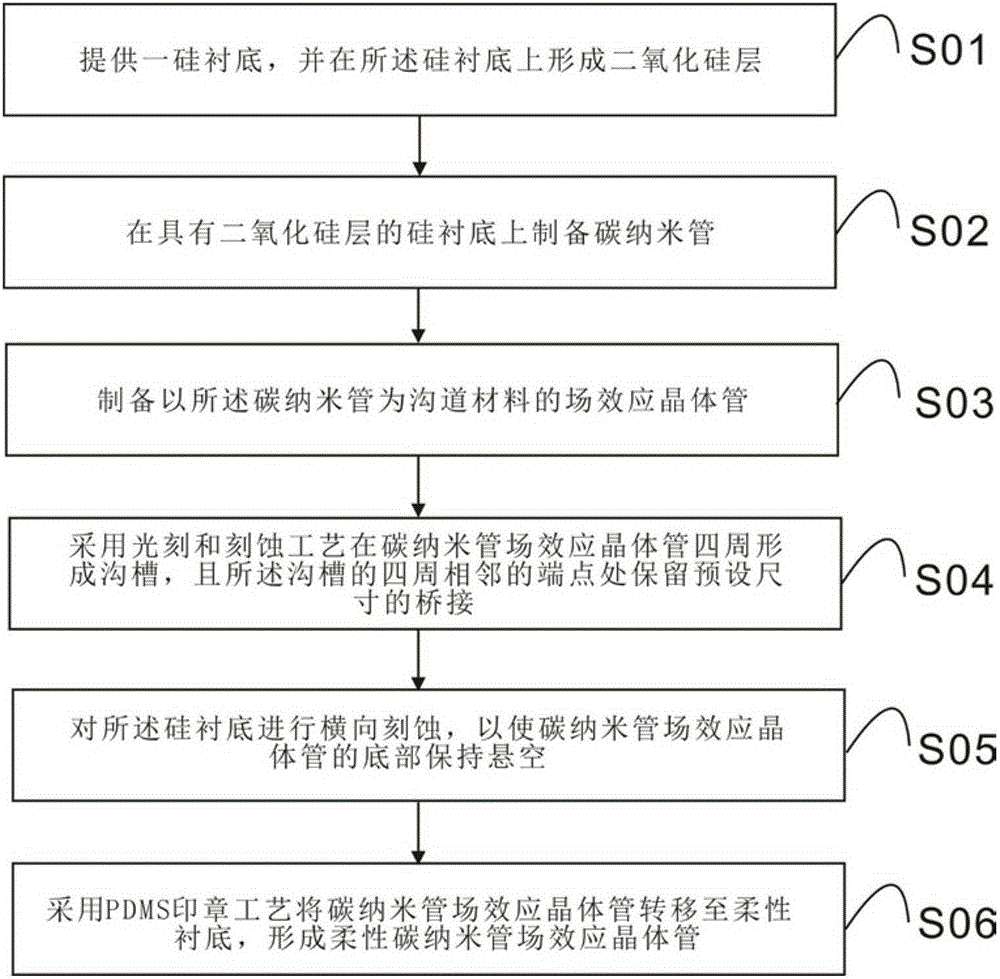

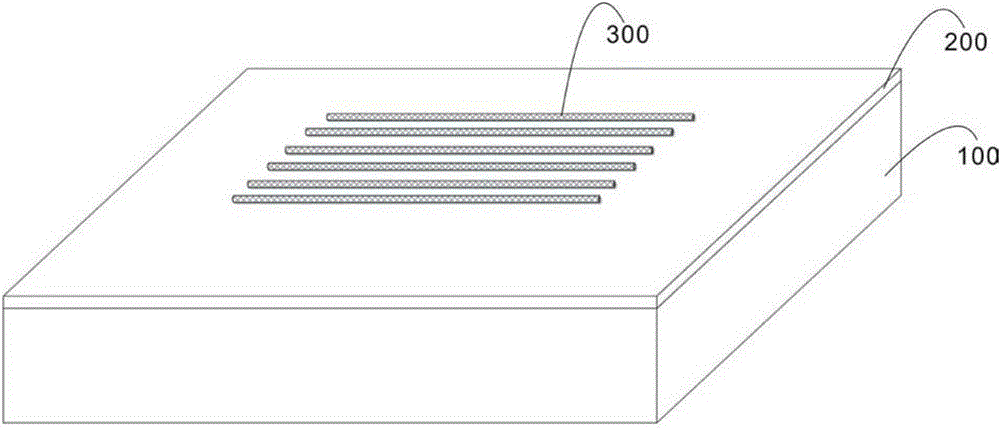

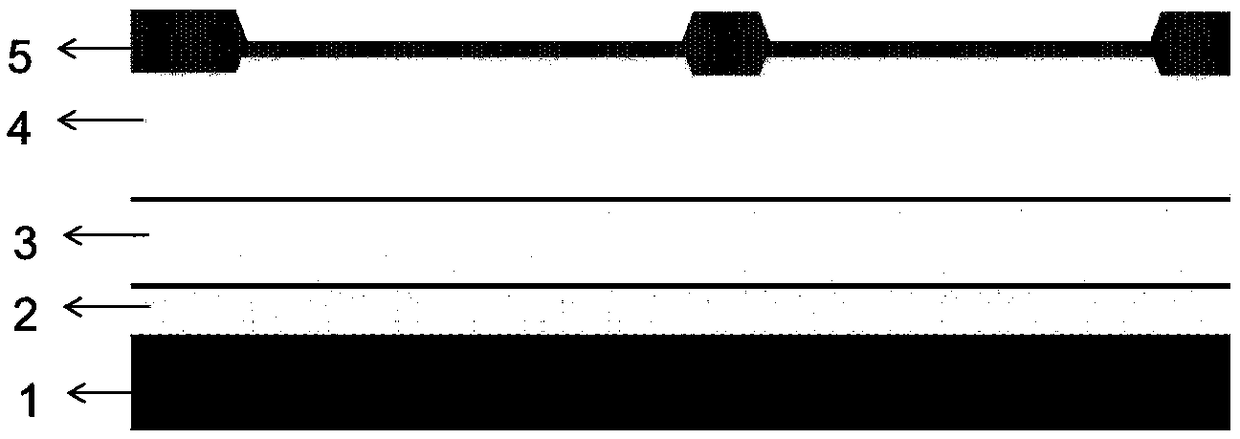

Preparation method for flexible carbon-nanotube field effect transistor

InactiveCN105304499ARealize mass productionBroad market application valueMaterial nanotechnologySemiconductor/solid-state device manufacturingCarbon nano tube field effect transistorOrganic field-effect transistor

The invention discloses a preparation method for a flexible carbon-nanotube field effect transistor, and belongs to the field of semiconductor manufacture. A silicon substrate is provided, and carbon nanotubes are prepared on the silicon substrate; a field effect transistor taking the carbon nanotube as channel materials is prepared; trenches are formed in the periphery of the carbon-nanotube field effect transistor, and bridging of preset size is reserved in the adjacent end points of the trenches; the silicon substrate is etched horizontally, so that the bottom of the carbon-nanotube field effect transistor is suspended; and a PDMS stamping technology is used to transfer the carbon-nanotube field effect transistor to a flexible substrate to form the flexible carbon-nanotube field effect transistor. Mainstream preparation technologies of the high-performance carbon-nanotube transistor are combined, large-scale production of the flexible carbon-nanotube field effect transistors is realized by integrating the flexible packaging technology, and the market and application values of the method are high.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT +1

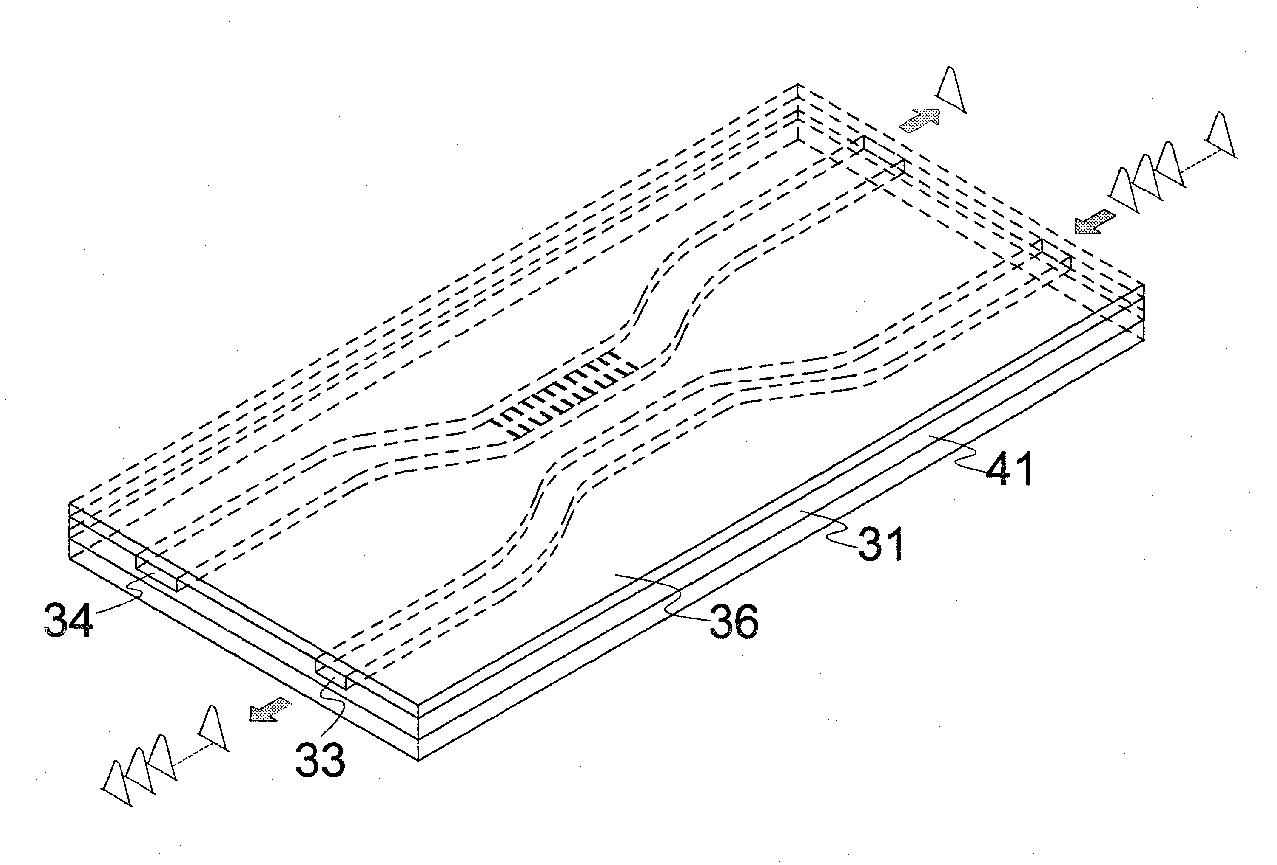

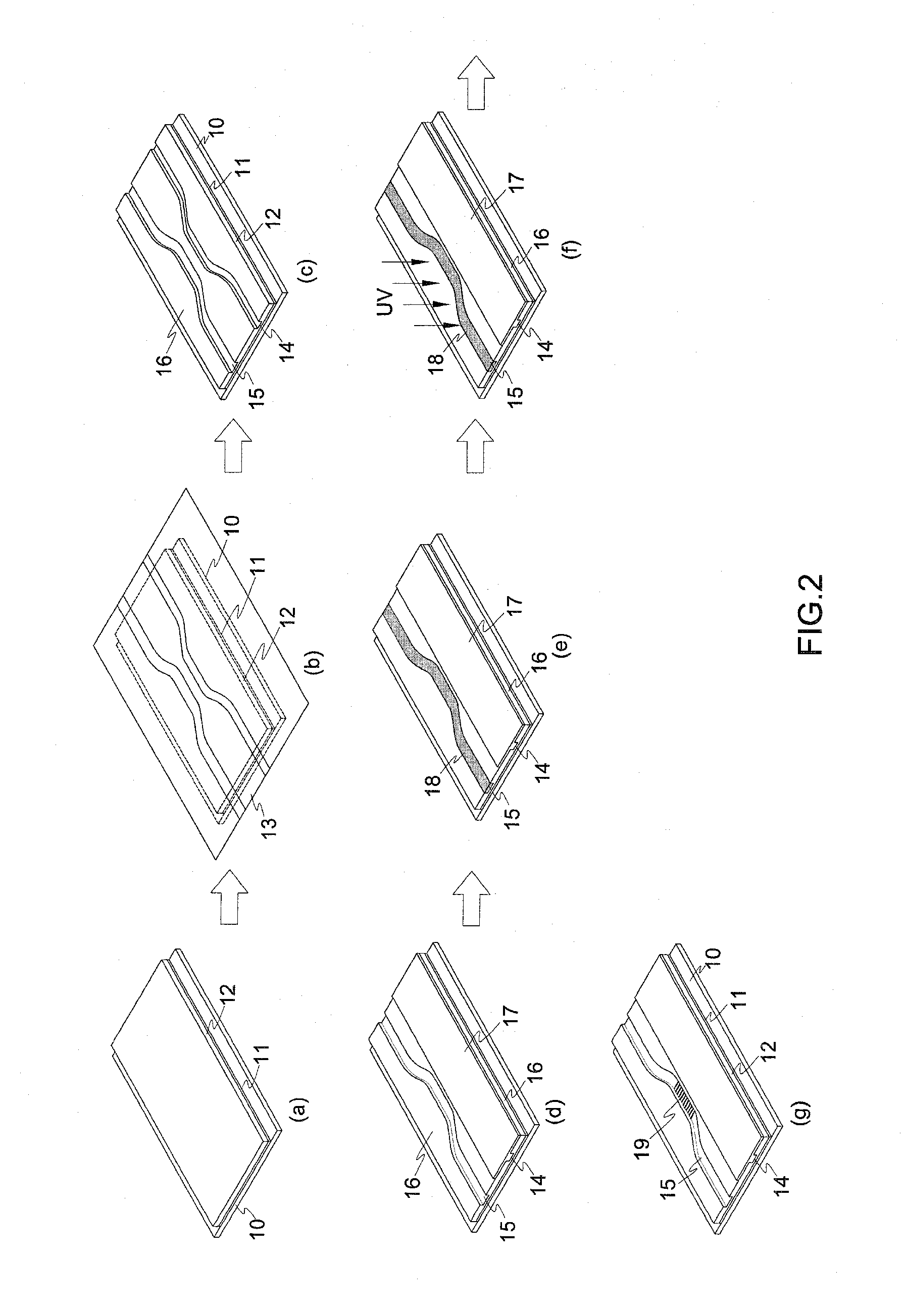

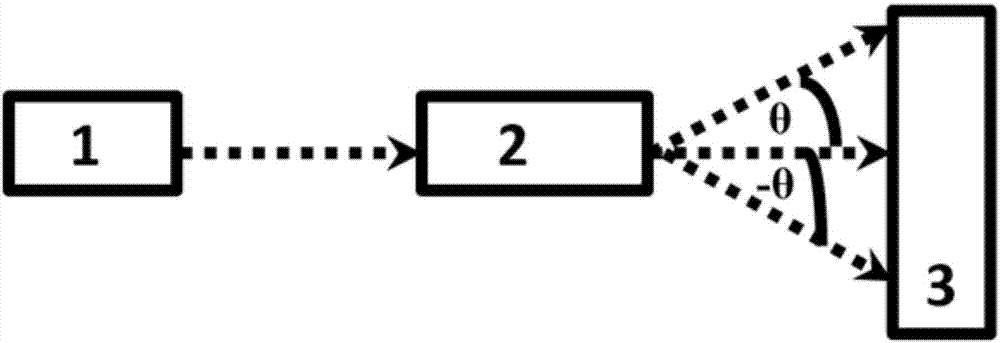

Method of fabrication for an asymmetric bragg coupler-based polymeric wavelength filter with single-grating waveguide

InactiveUS20130129934A1Accurate and reliable processCoatingsOptical waveguide light guideResistWavelength filter

The present invention discloses a method for fabricating polymeric wavelength filter based on an asymmetric Bragg coupler with single-grating waveguide. The asymmetric waveguide coupler is formed firstly on a negative photo-resist mold. PDMS film is injected into the narrow waveguide of the coupler to act as a protection layer. The gratings pattern is exposed on the alternative waveguide and subsequently transferred to PDMS stamp mold. The PDMS stamp mold is used as a stamp to transfer the gratings pattern of the ABC wavelength filter onto UV cured polymer to form the final ABC filter. Whereby, the fabrication process is reliable and accurate, and can offer great potential for mass production of the ABC filter with single-grating waveguide.

Owner:NAT FORMOSA UNIV

Preparation method for realizing graphical ZnO nanowire arrays by micro-contact printing

InactiveCN104030238AClear patternSmall cell sizeNanostructure manufacturePhotomechanical apparatusGraphicsTwo step

The invention discloses a preparation method for micro-sized and graphical ZnO nanowire arrays by adopting two steps of micro-contact printing (MCP) and low-temperature chemical bath deposition (CBD). The preparation method includes: firstly, adopting a sol-gel method to prepare a ZnO seed layer film on conductive glass; transferring TiO2 sol ink to the ZnO seed layer film through elastic polydimethylsiloxane (PDMS) stamps with different graphics to acquire a graphical TiO2 shielding layer film; adopting a chemical bath deposition method to complete select growth of ZnO nanowires in a ZnO seed layer area shielded by the TiO2 film. The preparation method is simple in process, low in cost, large in preparation area and good in repeatability; the three critical techniques in the entire process refer to preparation of the TiO2 sol ink with appropriate viscosity, setting of inkiness of the PDMS stamps and pressure parameter of the printing process and time control of hydrothermal growth of the nanowires.

Owner:XI AN JIAOTONG UNIV

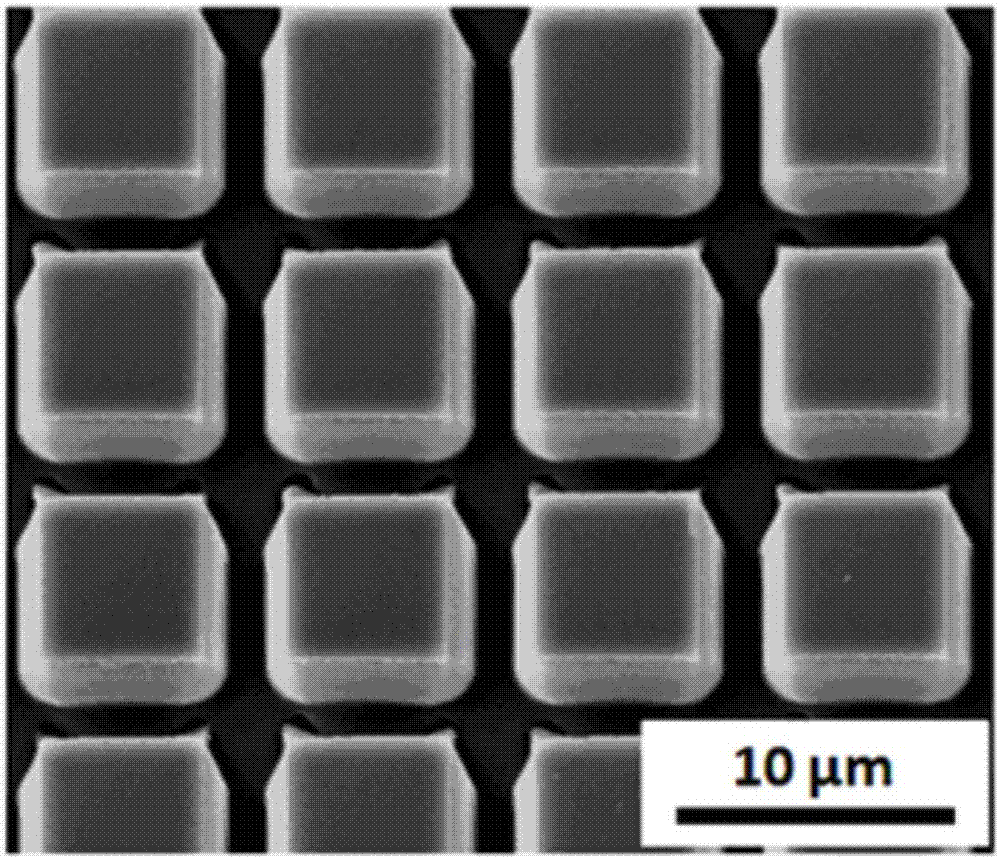

Method of etching surface topography of polydimethylsiloxane (PDMS) by oxygen plasmas

InactiveCN104445052ALow costHigh precisionDecorative surface effectsChemical vapor deposition coatingOxygen plasmaDimethyl siloxane

The invention provides a method of etching the surface topography of polydimethylsiloxane (PDMS) by oxygen plasmas. The method comprises the steps of placing a prepared PDMS stamp in an oxygen plasma atmosphere, and etching the PDMS stamp to obtain a surface microstructure. Moreover, a method of preparing a CD surface microstructure with a regular microstructure is introduced in details. According to the method provided by the invention, the oxygen plasmas are used for etching the PDMS stamp with the surface microstructure, which is obtained by a replica moulding technology, and the height of the microstructure of the PDMS stamp is accurately regulated and controlled by changing the etching time of the oxygen plasmas. The technology is low in cost, high in accuracy, simple and convenient to operate, and wide in application range; the topography height of the PDMS stamp is regulated and controlled by the oxygen plasmas under a condition of no change on the topography of the PDMS stamp; the microstructure prepared by the method provided by the invention has wide application prospects in many fields of optics, microelectronics, sensors, biomedicine and the like.

Owner:TIANJIN UNIV

PDMS elastomer micro-nano processing method based on crosslinking control control transfer printing

InactiveCN105731365AAchieve controllable patterningRealize fine controlDecorative surface effectsChemical vapor deposition coatingElastomerMicro nano

The invention discloses a PDMS elastomer micro-nano processing method based on crosslinking control control transfer printing. The PDMS elastomer micro-nano processing method comprises the following steps: preparing a PDMS film to serve as a transfer printing substrate by using a pouring method; preparing a PDMS film with a surface microstrucutre to serve as a transfer printing stamp by using a replica casting method; importing a cohesive energy (soft / hard) difference between the PDMS stamp and the planar PDMS substrate by different crosslinking agent contents in the process of preparing the substrate and the stamp; and simultaneously carrying out an OP treatment on the prepared substrate and the stamp for 0.5 min, immediately adhering the substrate and the stamp, and carrying out a heating treatment to improve the contact adhesion of the substrate and the stamp, taking off the stamp, generating cohesive energy breakage on the soft party during the separation to transfer PDMS ink to the hard party, so as to obtain a PDMS film with concave or convex patterns on the surface. The PDMS elastomer micro-nano processing method disclosed by the method is simple and convenient to operate, low in cost, and is used for avoiding the defects of limited applicable range of other related technology and simple processing patterns.

Owner:TIANJIN UNIV

Method for preparing patterned agarose stamp

The invention discloses a method for preparing a patterned agarose stamp, wherein the method comprises the steps of fluorinating a polydimethylsiloxane (PDMS) stamp with patterns at room temperature, casting aqueous agarose solution to the fluorinated PDMS stamp with the patterns at room temperature, increasing the temperature to 80 to 90 DEG C, keeping the stamp for a while, taking out the stamp, cooling the stamp to the room temperature and removing solated agarose which is peeled from the PDMS stamp, so as to obtain the agarose stamp with the patterns. The agarose stamp is clear in pattern and large in pattern area and can be preserved for a long time.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

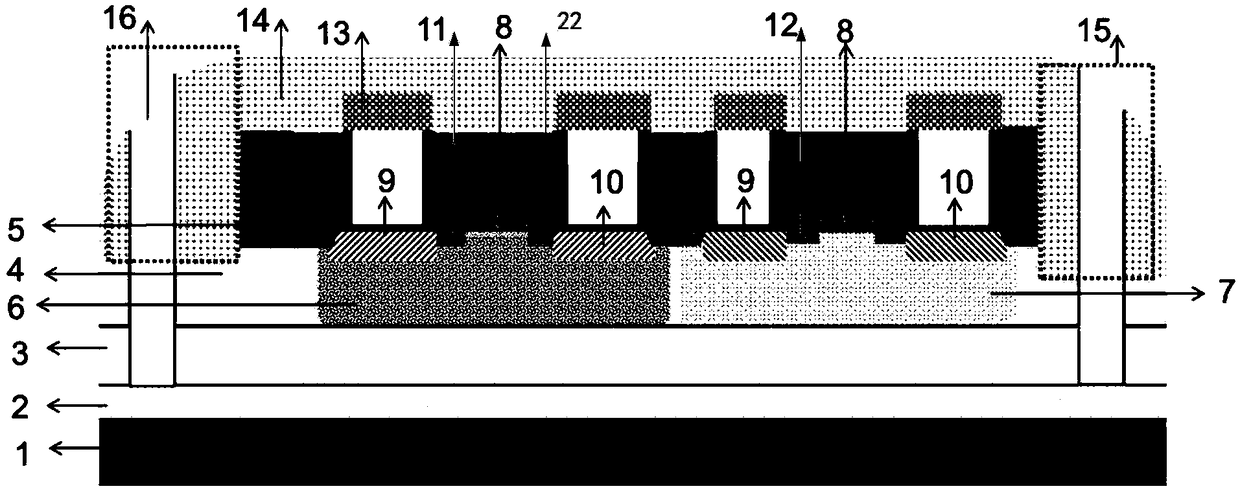

Electronic device based on SOI CMOS, preparation method and peeling method thereof

ActiveCN108962918AThe overall thickness is thinImprove flexibilitySolid-state devicesSemiconductor/solid-state device manufacturingSoi cmosPDMS stamp

The invention provides an electronic device based on an SOI CMOS, a preparation method and a peeling method thereof. The electronic device based on the SOI CMOS is provided with a plurality of peelingtroughs. The peeling troughs penetrate through the electronic device based on the SOI CMOS. Not only is manufacture of the electronic device based on the SOI CMOS facilitated, but also a stress in bending is reduced. Damage of the electronic device based on SOI CMOS is prevented. Through arranging the peeling troughs and arranging the peeling troughs which are trough to an embedded oxide layer, and performing corrosion processing on the embedded oxide layer, corrosion of the embedded oxide layer is realized; and furthermore the electronic device based on the SOI CMOS is disengaged from a substrate. The electronic device based on the SOI CMOS forms a suspended structure through supporting by a support. Manufacturing process difficulty and manufacturing cost are reduced. The electronic device is peeled to a target substrate through a PDMS stamp.

Owner:NO 24 RES INST OF CETC

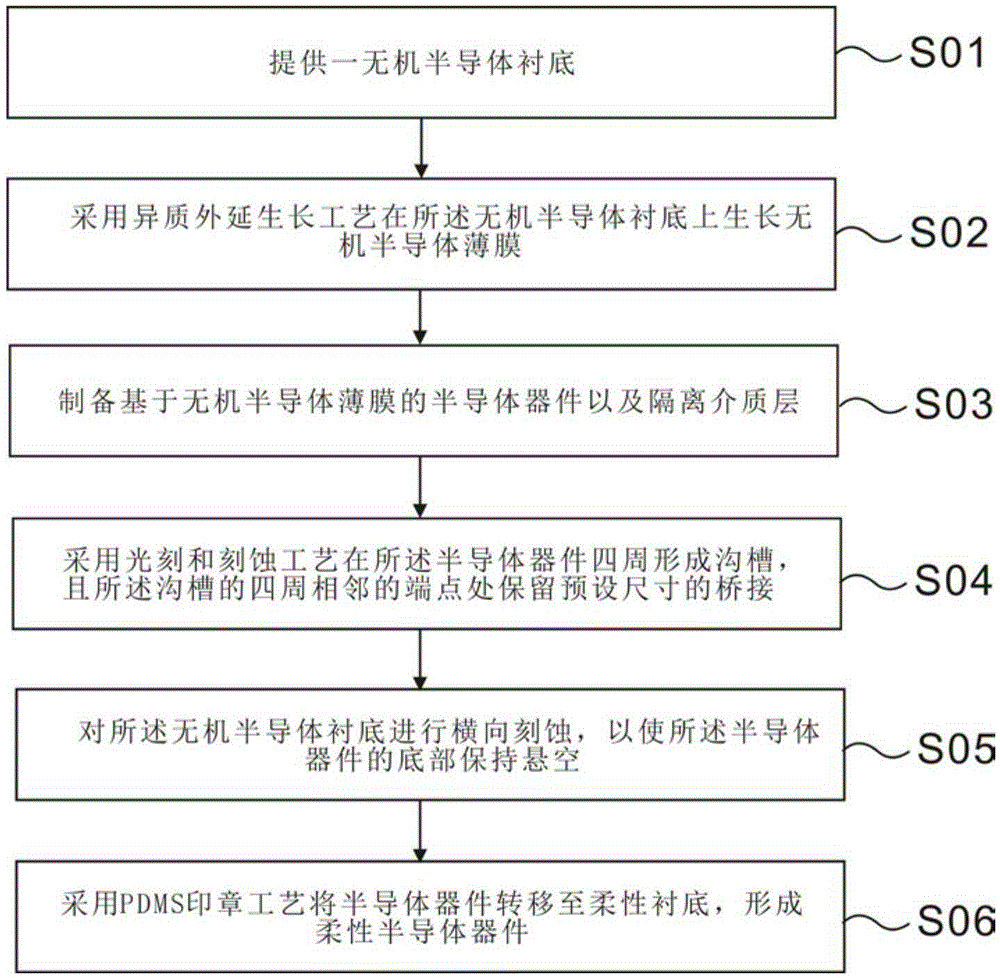

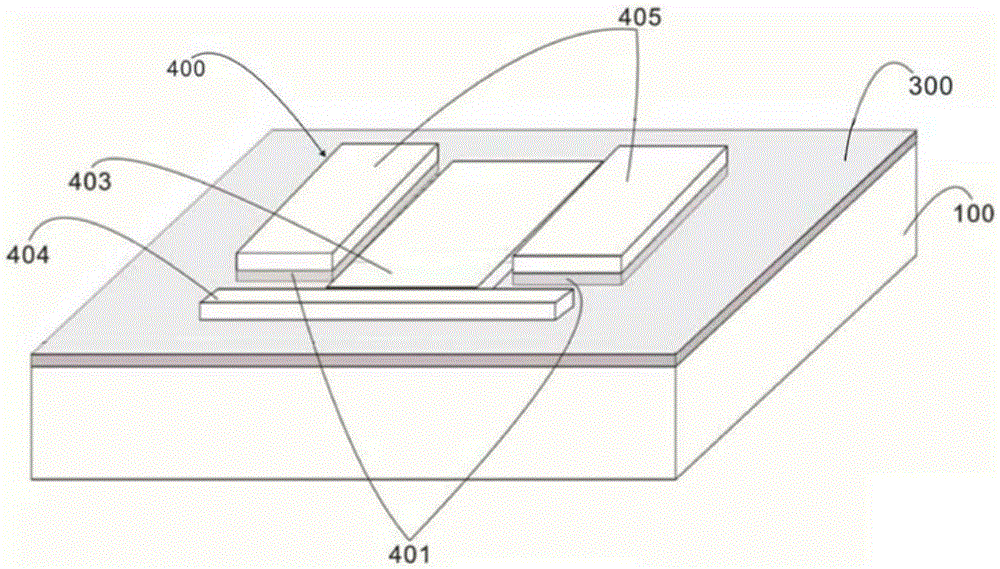

Preparation method of flexible semiconductor device

InactiveCN105355563AGuaranteed performanceRealize mass productionSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor materialsFlexible circuits

The invention belongs to the field of semiconductor manufacture, and discloses a preparation method of a flexible semiconductor device. The method includes: firstly, an inorganic semiconductor film is grown on an inorganic semiconductor substrate, then a semiconductor device based on the inorganic semiconductor film and an isolation medium layer are prepared, a groove is then etched so that the bottom of the semiconductor device maintains suspended, and finally the semiconductor device is transferred to a flexible substrate via a PDMS seal technology. The method is completely compatible with the current mainstream microelectronics technology, and the performance of the device can be effectively guaranteed via the semiconductor device prepared based on inorganic semiconductor materials; besides, the method can be widely applied to the preparation of flexible semiconductor devices of different kinds, such as light emitting diodes (LED) or field effect transistors (FET), the method can even be directly applied to the realization of flexible circuits, batch production of flexible circuit chips can be realized via the integration of the flexible packaging process, and the application values are very important.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT +1

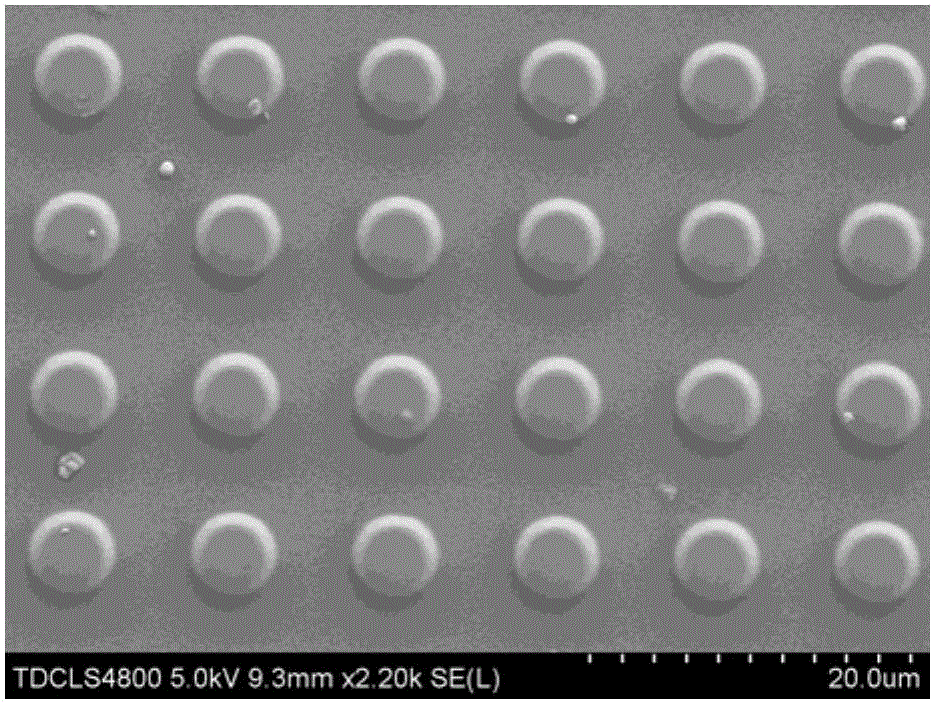

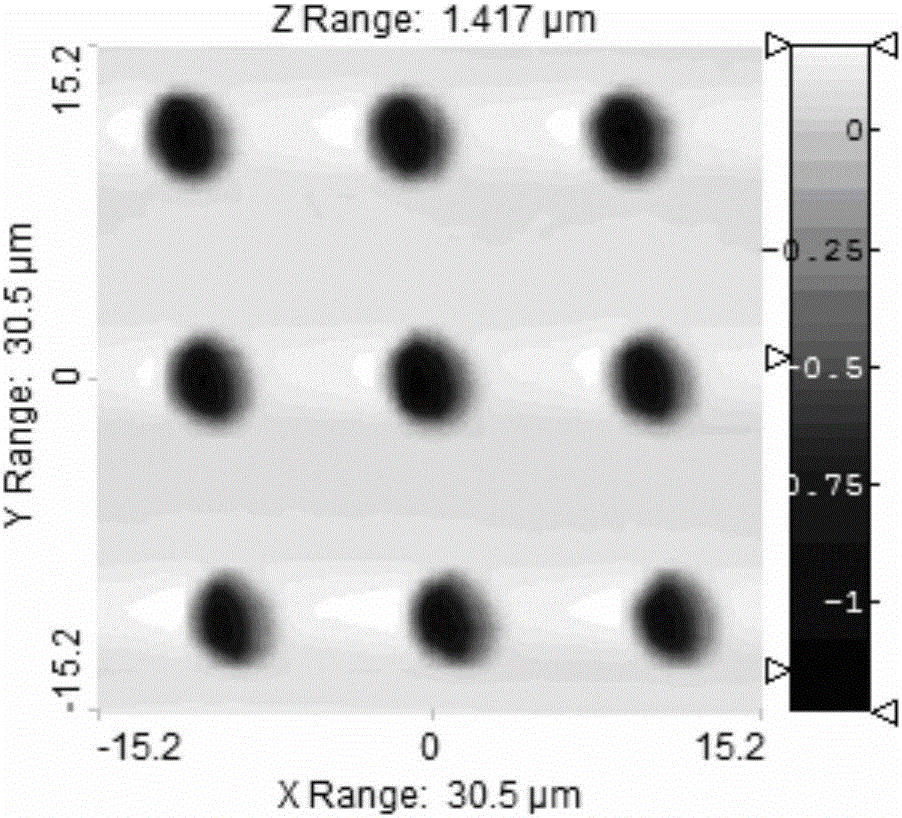

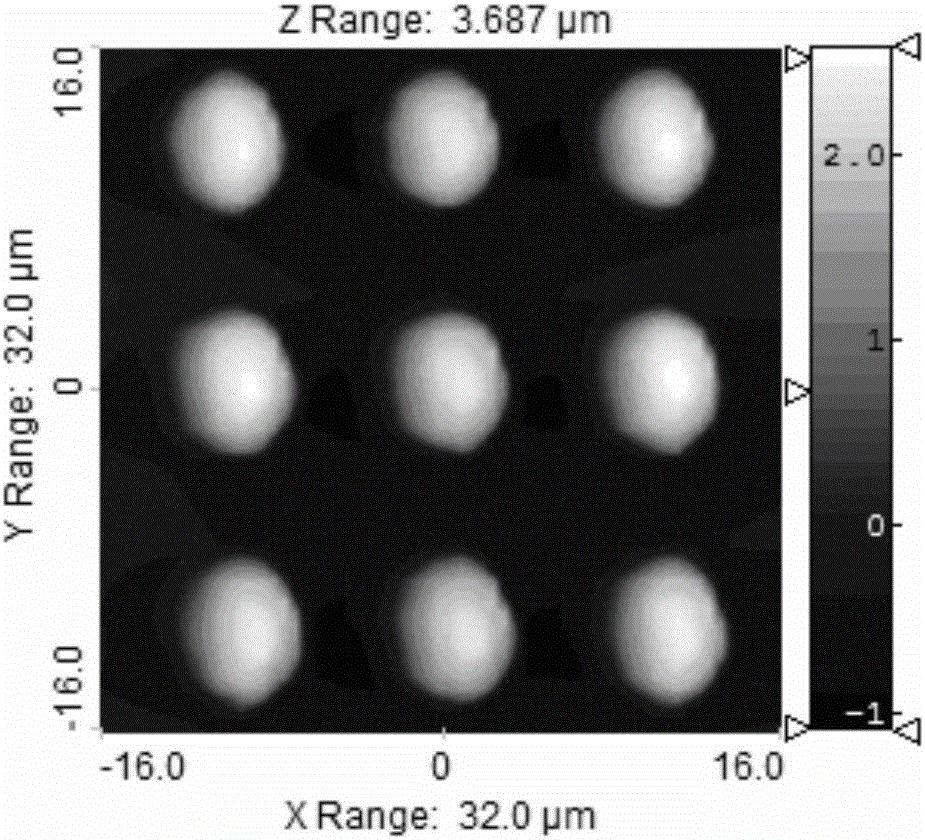

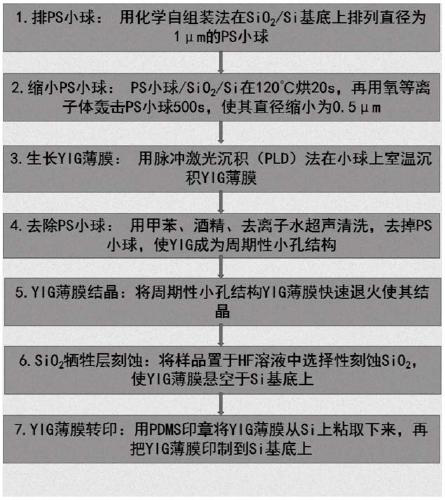

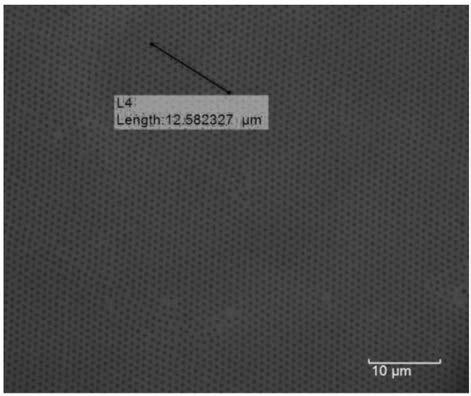

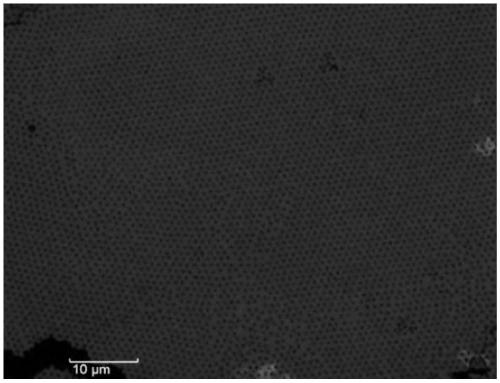

Method for integrating garnet film on silicon at low temperature based on transfer printing

ActiveCN109164603AAddressing high thermal budgetsCan't solveVacuum evaporation coatingSputtering coatingOxygen plasmaRoom temperature

The invention belongs to the field of integrated optics, and in particular relates to a method for integrating a garnet film on silicon at low temperature based on transfer printing. In the method provided by the invention, closely arranging PS globules at six corners of a SiO2 / Si substrate by using a chemical self-assembly method, the PS globules are bombarded by oxygen plasma to reduce the diameter, the magneto-optical garnet film is deposited on the PS globules that are bombarded by the oxygen plasma at room temperature by using a pulse laser deposition method, the PS globules are cleaned with methylbenzene to remove the PS globules and the garnet film on the PS globules, so that the garnet film with holes are reserved on the SiO2 / Si substrate, and finally the etching speed is greatly improved, and the HF corrosion degree of the garnet film is reduced. After etching is completed, the suspended garnet film is taken down by using a PDMS seal, and then printed on the silicon substrate,and thus the low-temperature integration of the garnet film on the silicon substrate is achieved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

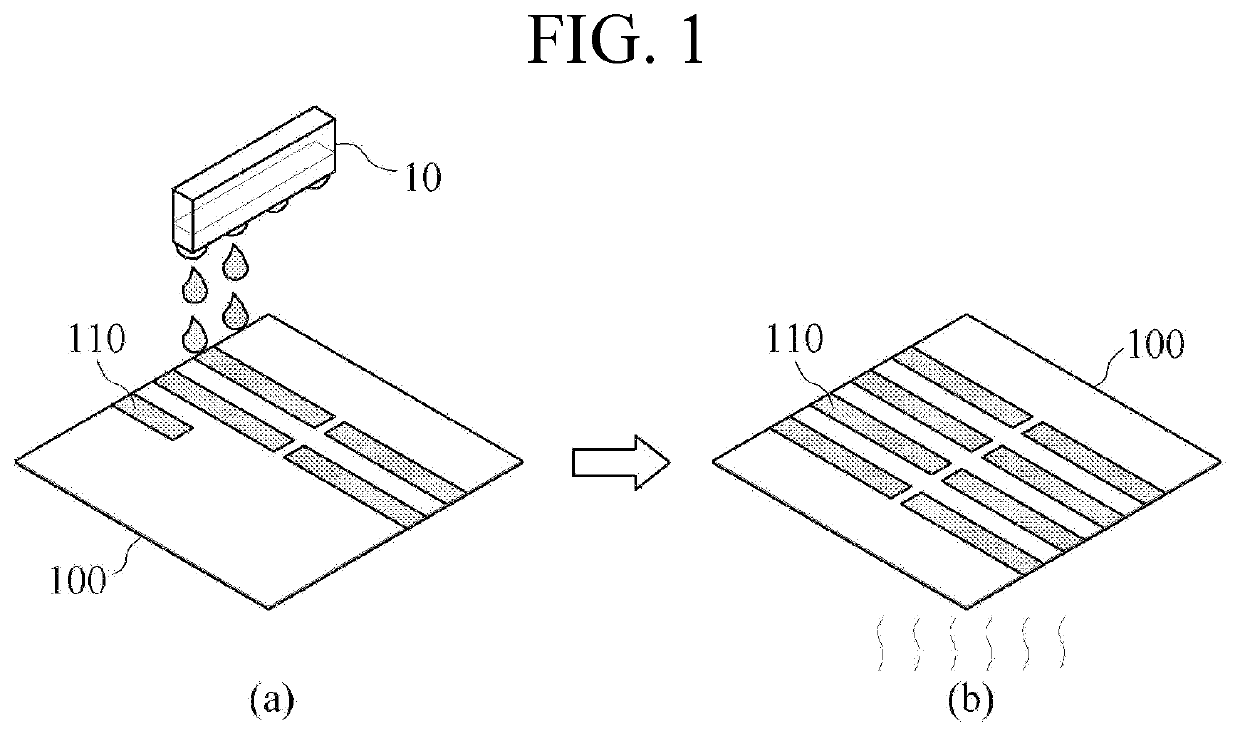

Silver nanowire thin-film patterning method

PendingUS20210272795A1Low costSemiconductor/solid-state device manufacturingTransparent dielectricsConductive polymerThin membrane

Disclosed is a silver nanowire patterning method including patterning an adhesive conductive polymer thin-film on a substrate, fabricating a polydimethylsiloxane (PDMS) stamp coated with a silver nanowire thin-film, and bonding the substrate patterned with the conductive polymer thin-film to the PDMS stamp coated with the silver nanowire thin-film and then separating the two bonded substrates.

Owner:SEOUL NAT UNIV R&DB FOUND

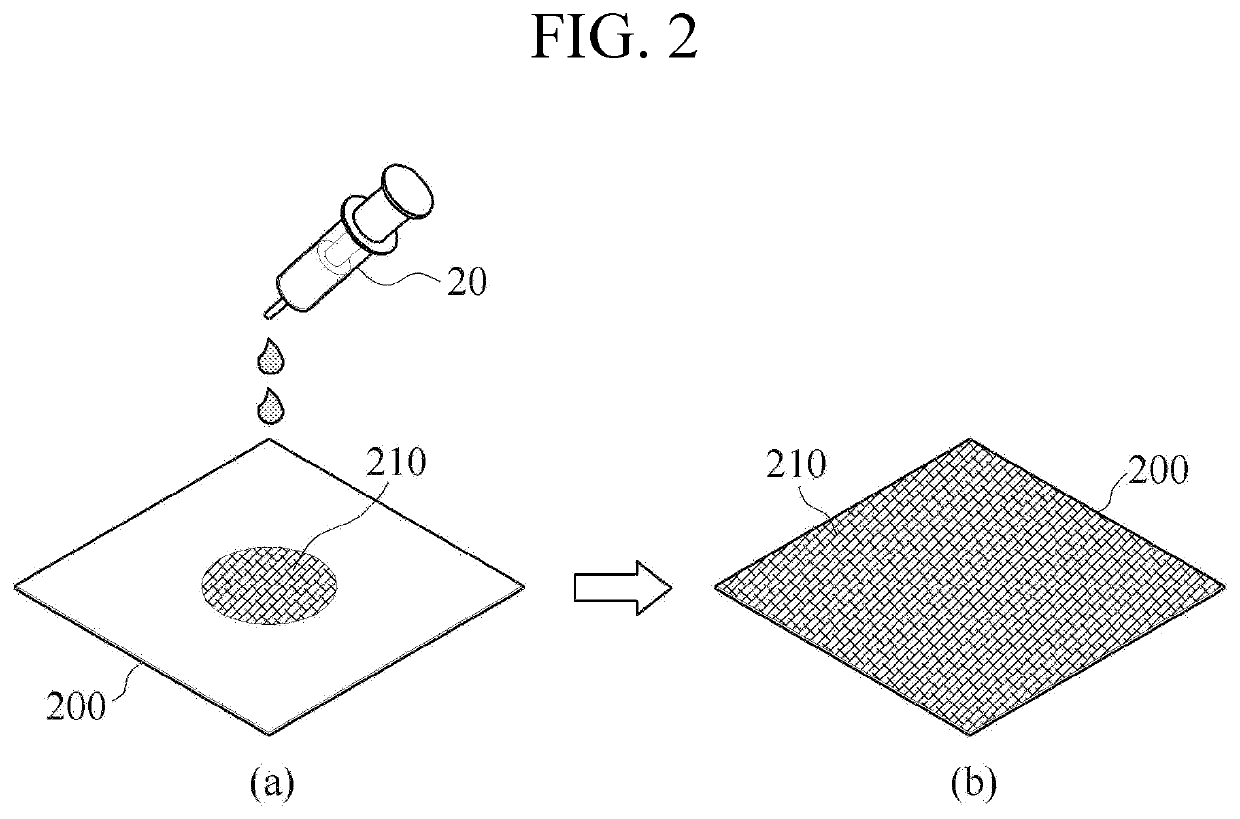

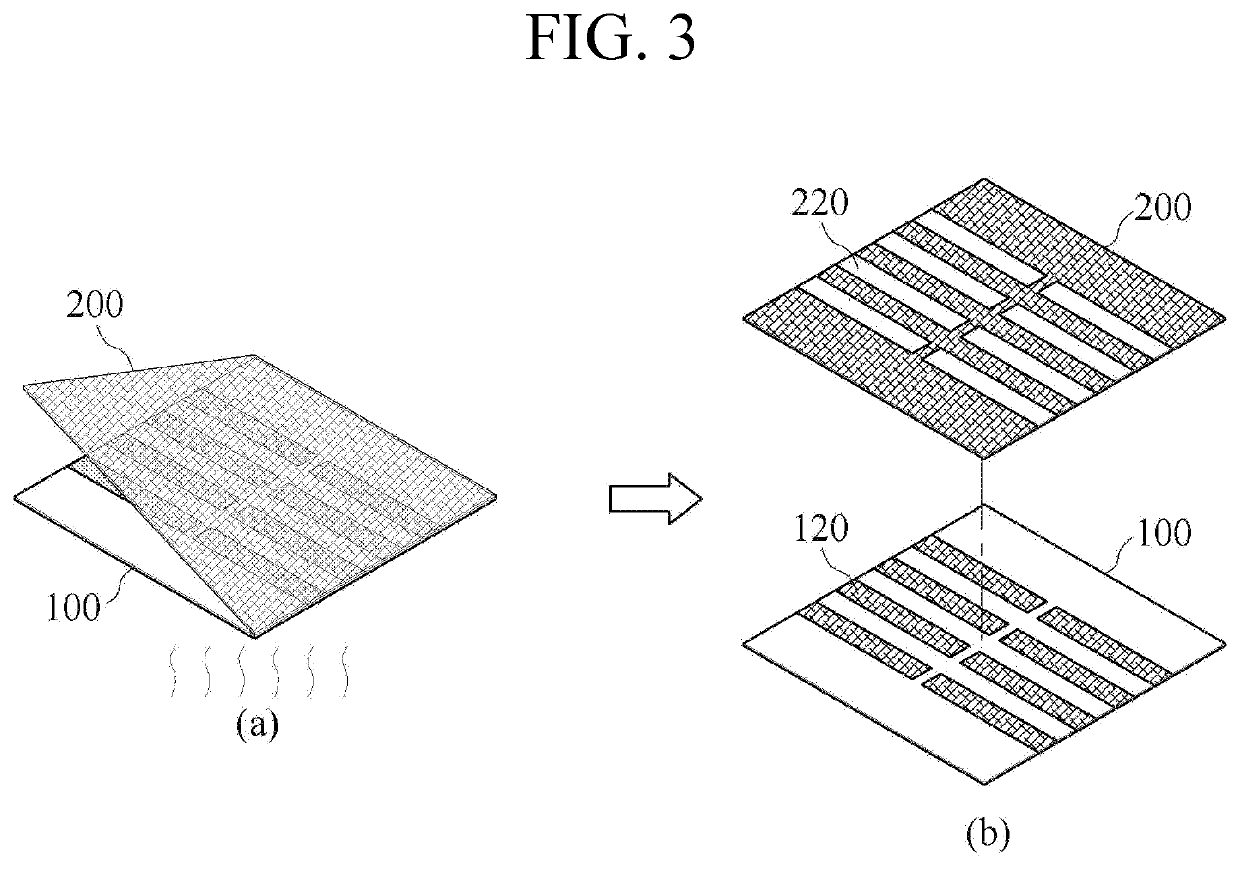

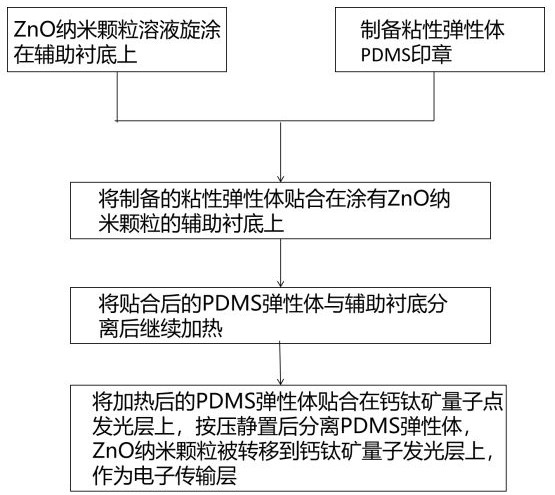

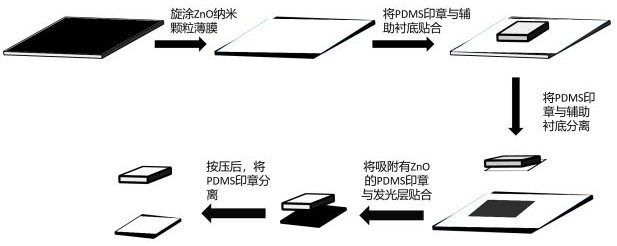

Method for preparing perovskite QLED electron transport layer by transferring ZnO nano-film

ActiveCN112701230AAvoid damageNo pollution in the processSolid-state devicesSemiconductor/solid-state device manufacturingElastomerZno nanoparticles

The invention belongs to the technical field of electron transport layer QLED preparation, and particularly relates to a method for preparing a perovskite QLED electron transport layer by transferring a ZnO nano-film through a dry process. The method comprises the following steps: preparing a layer of ZnO nano-film on an auxiliary substrate, attaching a pre-prepared viscous elastomer PDMS to the ZnO nano-film, adsorbing the ZnO nano-film by utilizing the viscosity of the elastomer PDMS, and separating PDMS / ZnO from the auxiliary substrate; and annealing to weaken the viscosity of the PDMS stamp, attaching PDMS / ZnO to a perovskite quantum dot light-emitting layer, pressing, transferring ZnO nanoparticles to the perovskite layer, and finally separating the PDMS stamp from the ZnO layer. According to the invention, the ZnO nano-film is transferred to the perovskite quantum dot light-emitting layer through the PDMS stamp to be used as an electron transport layer, so that a perfect heterogeneous interface can be constructed, and the perovskite quantum dot light-emitting layer can be prevented from being damaged by a solvent effect in solution addition or a heat effect of a vacuum process.

Owner:FUZHOU UNIV +1

Preparation method and application of polyelectrolyte compound with stress response and patterned micro-nano structure

InactiveCN107219194ASolve productivitySolve Humidity ProblemsScattering properties measurementsNanotechnologyPolyelectrolyteMicro nano

The invention relates to a preparation method and application of a polyelectrolyte compound with a stress response and a patterned micro-nano structure, in particular to a preparation method and application of the polyelectrolyte compound. The invention aims to solve the problems that an existing humidity sensor is expensive, and a compound sensor cannot realize industrial production and is not provided with relative humidity, acidity and other detection indexes. The preparation method comprises the following steps of (1) preparing a patterned PDMS stamp; (2) preparing the polyelectrolyte compound; (3) pressurizing, keeping warm and transferring to obtain the polyelectrolyte compound with the stress response and the patterned micro-nano structure. The polyelectrolyte compound with the stress response and the patterned micro-nano structure is used as an intelligent super perspective material and a stress responsive scattering medium for application, is used for detecting life food quality, and is used for a humidity sensor. According to the preparation method provided by the invention, the polyelectrolyte compound with the stress response and the patterned micro-nano structure can be obtained.

Owner:HARBIN INST OF TECH +1

Method for building PPy (polypyrrole) thin film with multiple forms based on silicon template

The invention discloses a method for building a PPy (polypyrrole) thin film with multiple forms based on a silicon template. The method adopts a preparation process with the following steps of firstly, casting a mixture of a PDMS (polydimethylsiloxane) prepolymer and a crosslinking agent onto the silicon template, heating and curing, so as to obtain a PDMS stamp with the silicon template patterns;then, depositing the PPy thin film with certain thickness at the surface, so as to obtain the PPy thin film which is of a multiple-wrinkle structure. The PPy thin film with different surface forms can be obtained by adjusting the different reaction time; the longer the reaction time is, and the longer the obtained wrinkle cycle is. The method overcomes the defects of complicated preparation process and poor controllability in process, and has the advantages that the operation mode is simple, the conductive polymer has multiple forms, and the defects of complicated operation, high cost, nonuniform patterns, small area and the like in the existing photoetching methods and other patterning methods are overcome.

Owner:TIANJIN UNIV

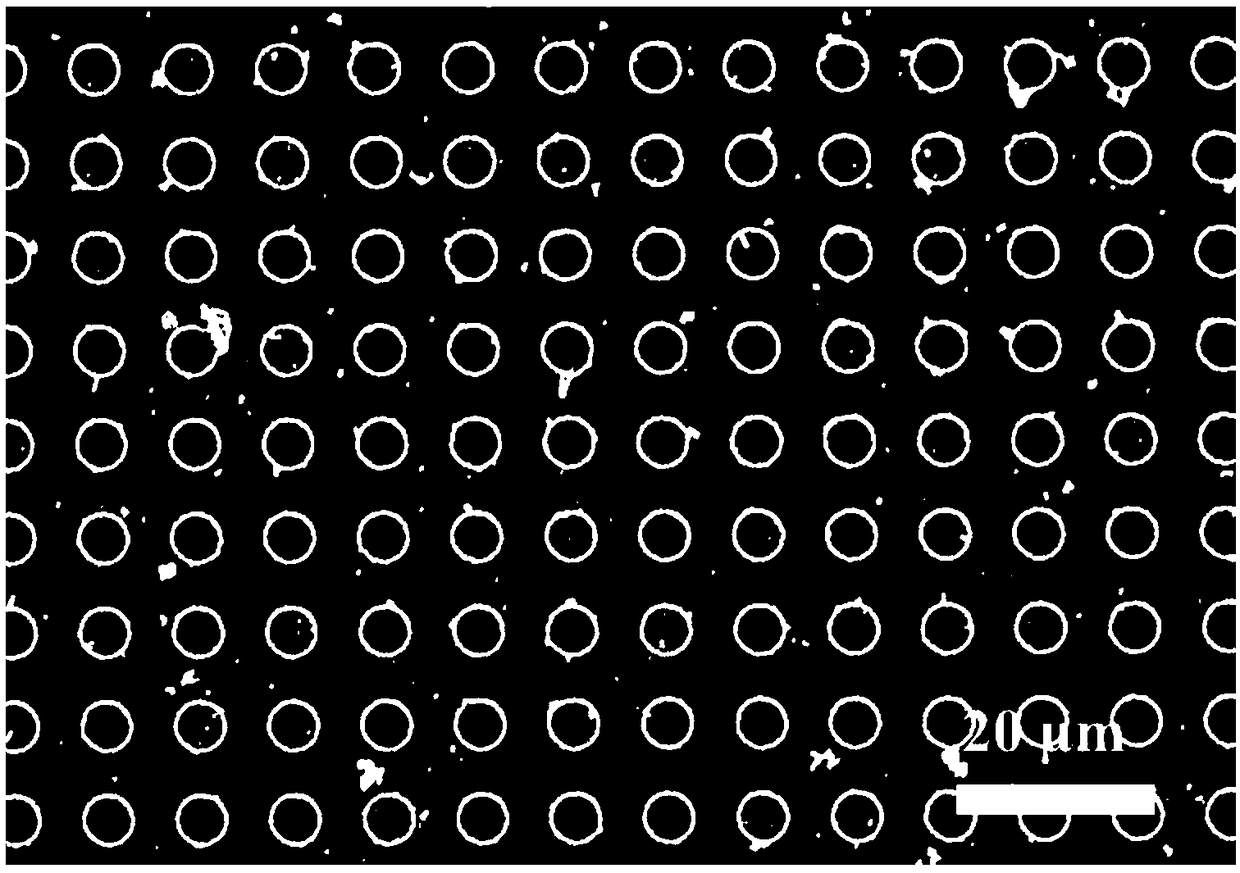

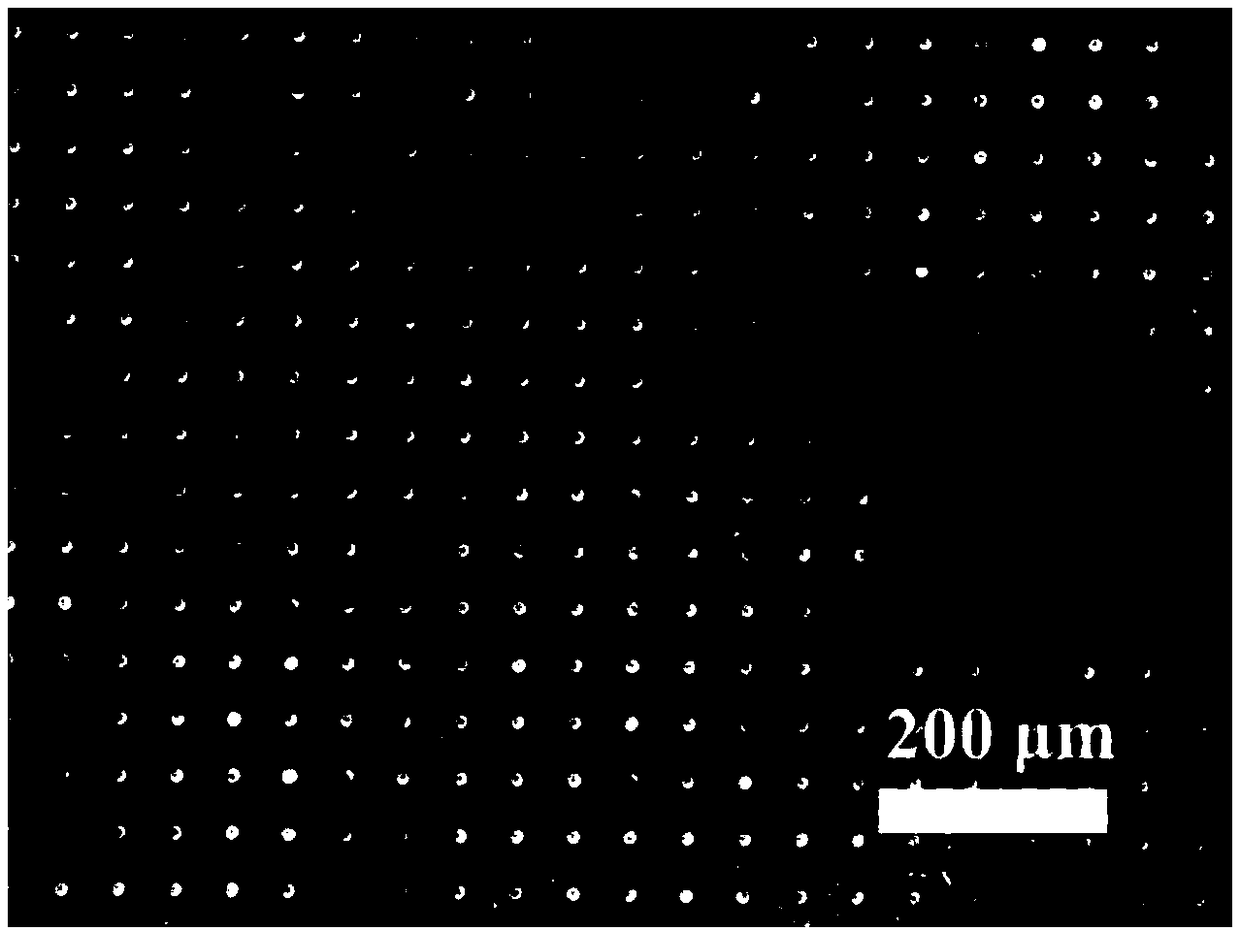

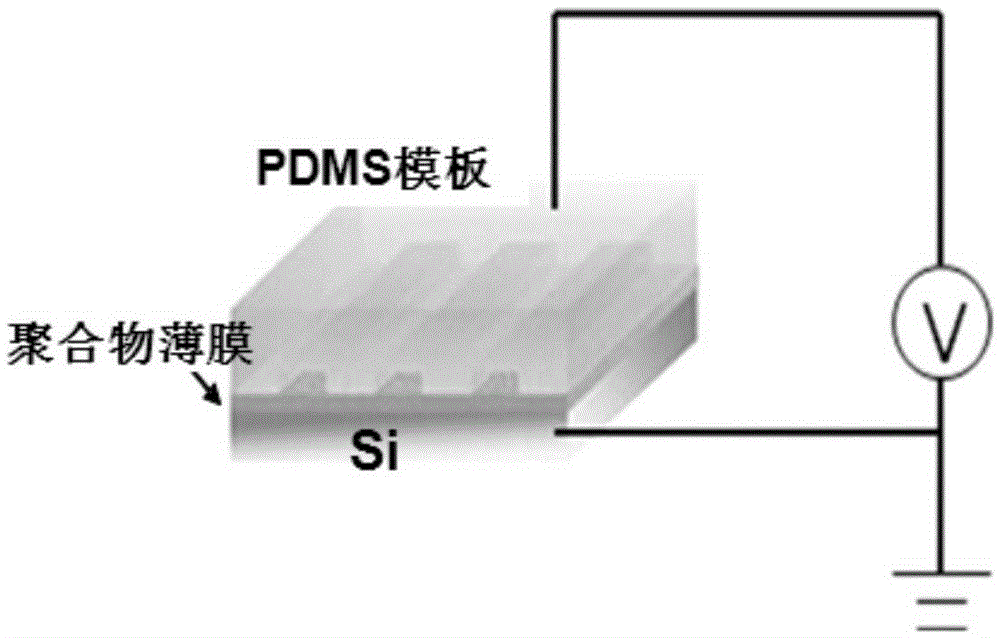

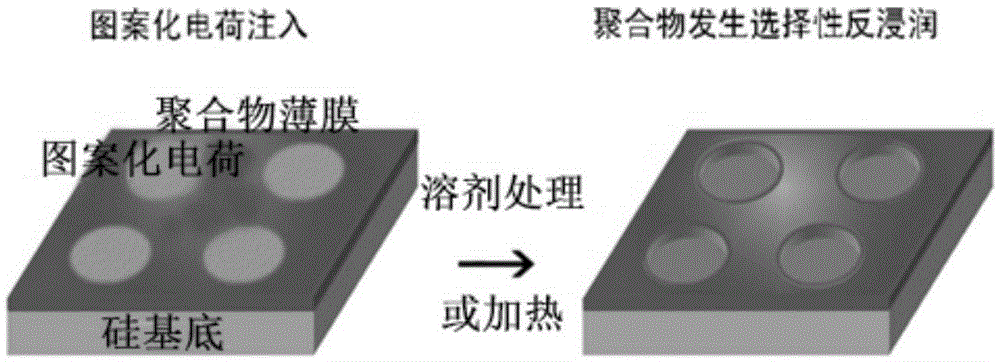

Research method for relaxation phenomenon of polymer via patterned charge mark

The invention discloses a research method for the relaxation phenomenon of a polymer via a patterned charge mark. The method comprises the following steps that 1) a PDMS stamp is used to carry out patterned injection on a polymer film, a charge pattern is formed at the surface of the polymer film, the PDMS stamp includes a PDMS template whose surface includes a micro-nano pattern structure, and both the upper and lower surfaces of the PDMS stamp are plated with metal; and 2) the relaxation phenomenon of the polymer film under the temperature or solvent simulation condition is researched. According to the method provided by the invention, the patterned static charge can serve as a mark in the micro scale, contrast of related parameters of an injection area and a non-injection area in the relaxation process can be observed in real time and measured quantitatively, the method is more visual to observe the dielectric relaxation difference, and experimental and theoretical basis is provided for aging and failure analysis under the electric field effect when the polymer serves as an engineering material.

Owner:RENMIN UNIVERSITY OF CHINA

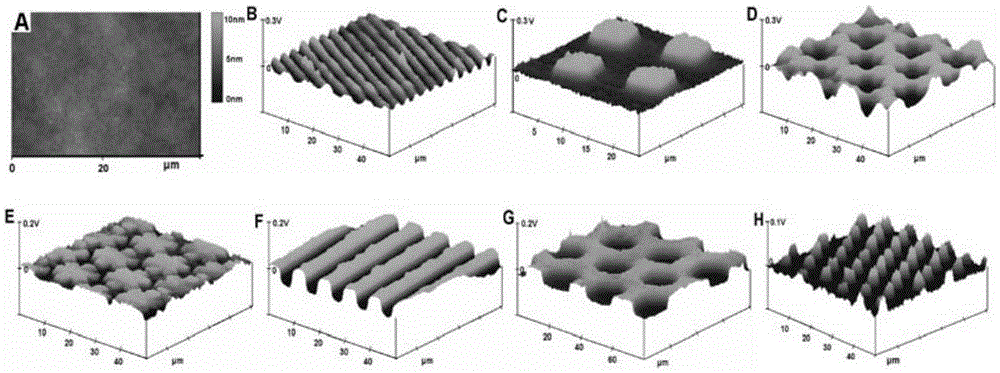

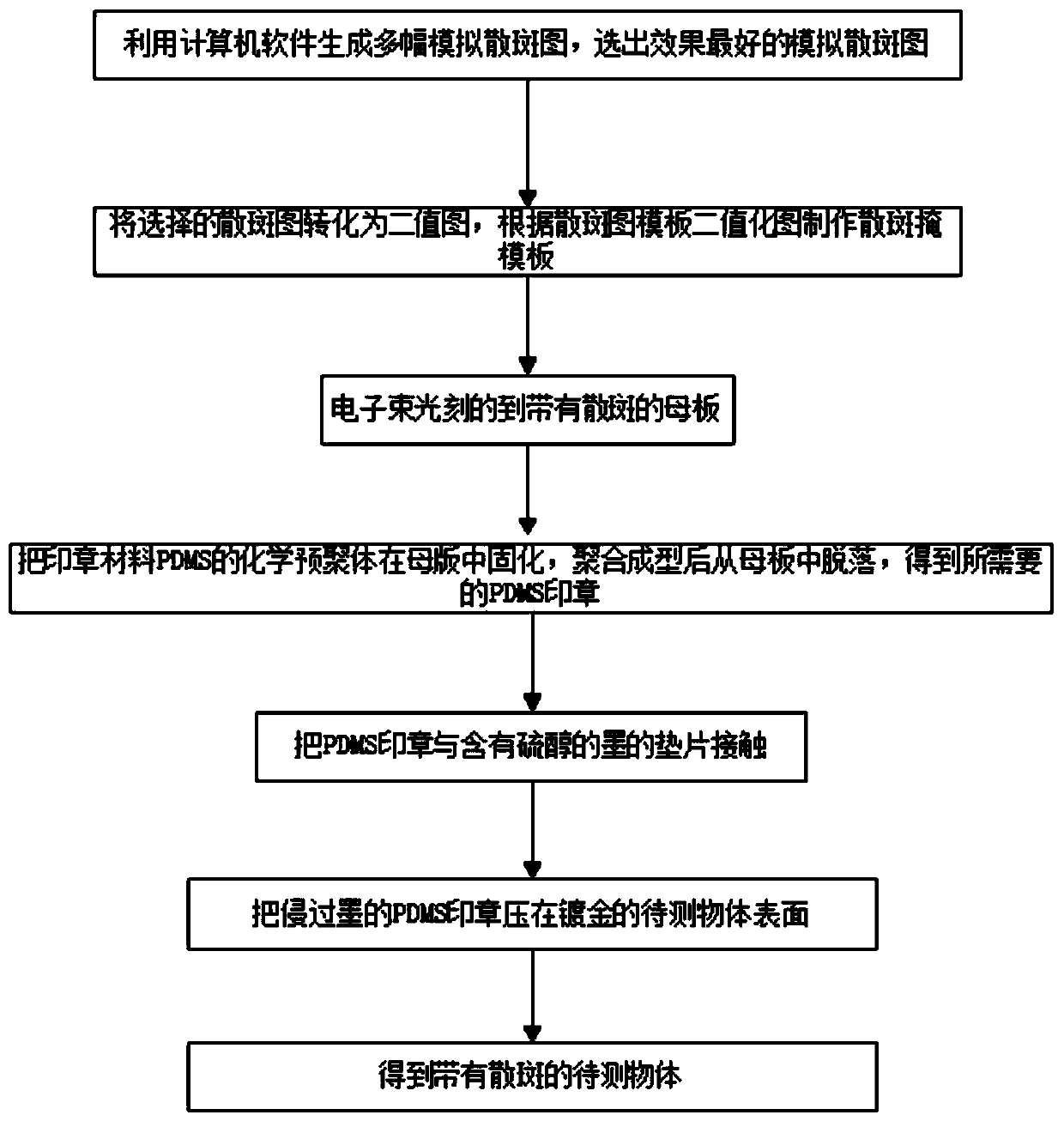

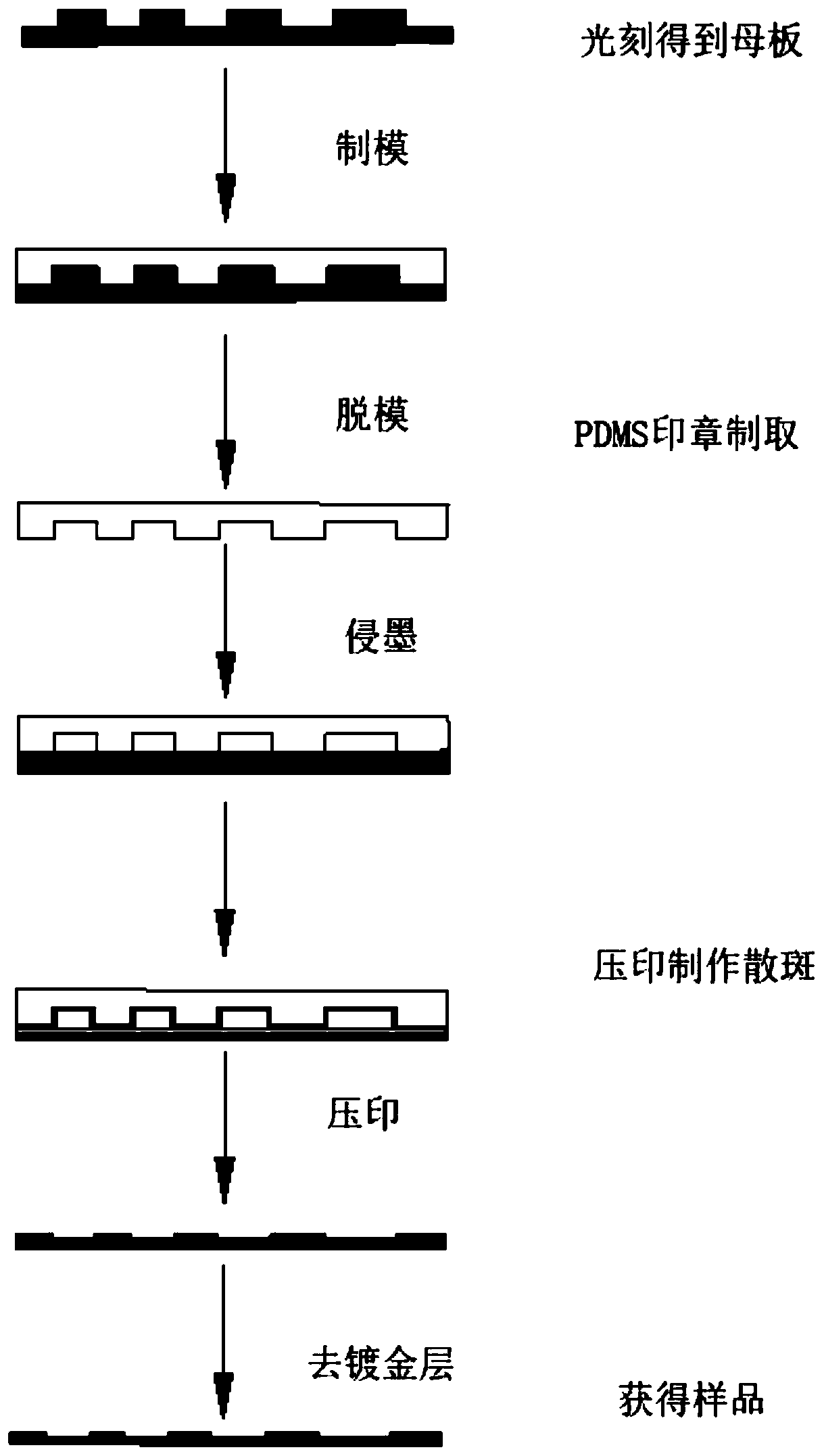

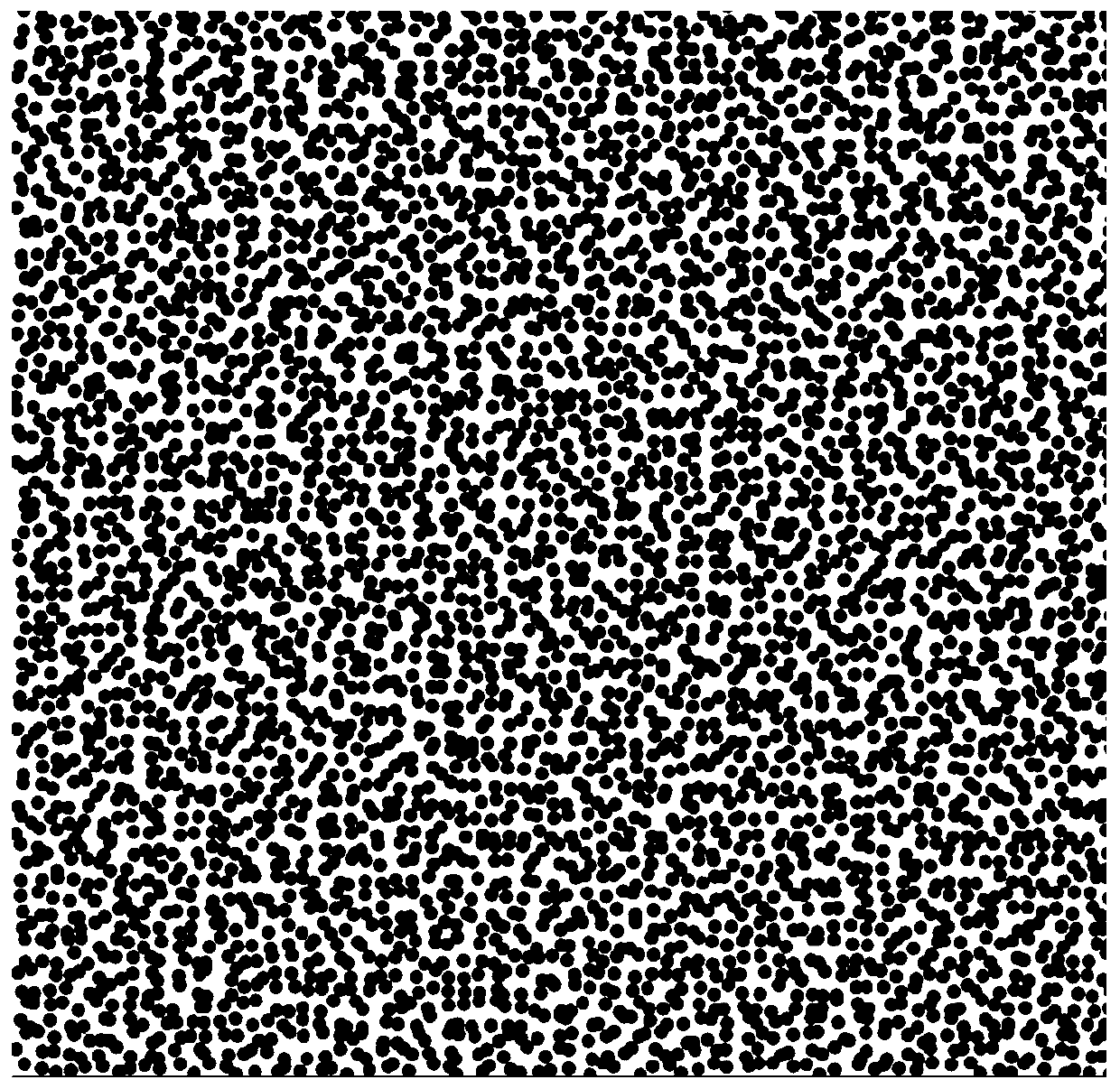

Micro-nano-scale speckle manufacturing method

InactiveCN110618538ASpeckle size highHigh precisionPhotomechanical apparatusOptical elementsMicro nanoSpeckle pattern

The invention designs a micro-nano-scale speckle manufacturing method. The method comprises the steps of generating multiple simulated speckle patterns with different particle sizes and numbers by using computer software, selecting an optimal simulated speckle pattern from the simulated speckle patterns, converting the speckle pattern into a binary pattern, and printing the speckle binary patternon a plastic polymer sheet to be used as a mask; and then obtaining a mother board with speckles through etching, curing the chemical prepolymer of the seal material PDMS in the mother board, droppingoff the chemical prepolymer from the mother board after polymerization molding to obtain a PDMS seal, enabling the PDMS seal to contact a gasket containing ink, and pressing the PDMS seal which has been soaked in the ink on a surface of the gold-plated to-be-detected object to obtain the to-be-detected object with the speckles. The method disclosed by the invention has the advantages of being simple and quick in manufacturing, convenient to operate, low in cost and efficient in batch.

Owner:WUHAN UNIV

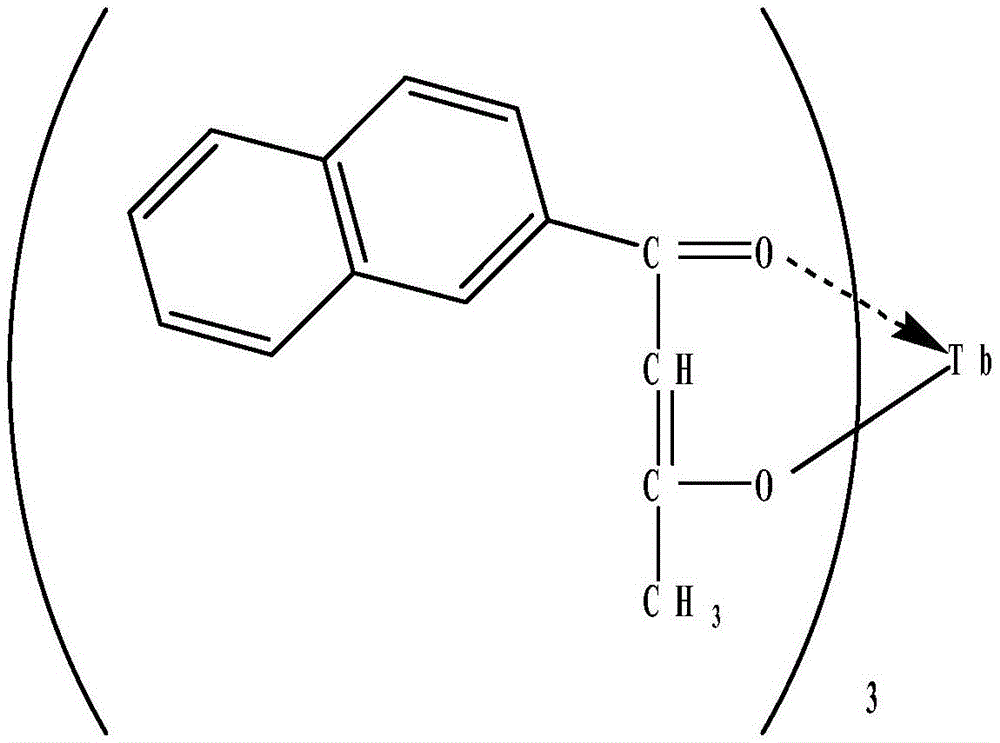

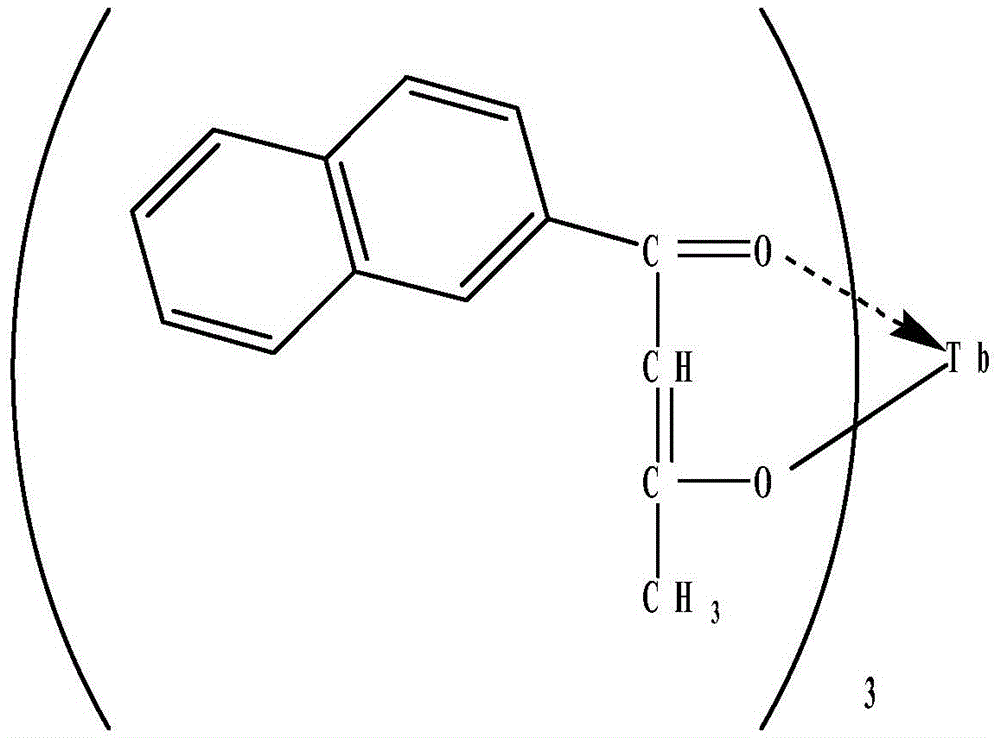

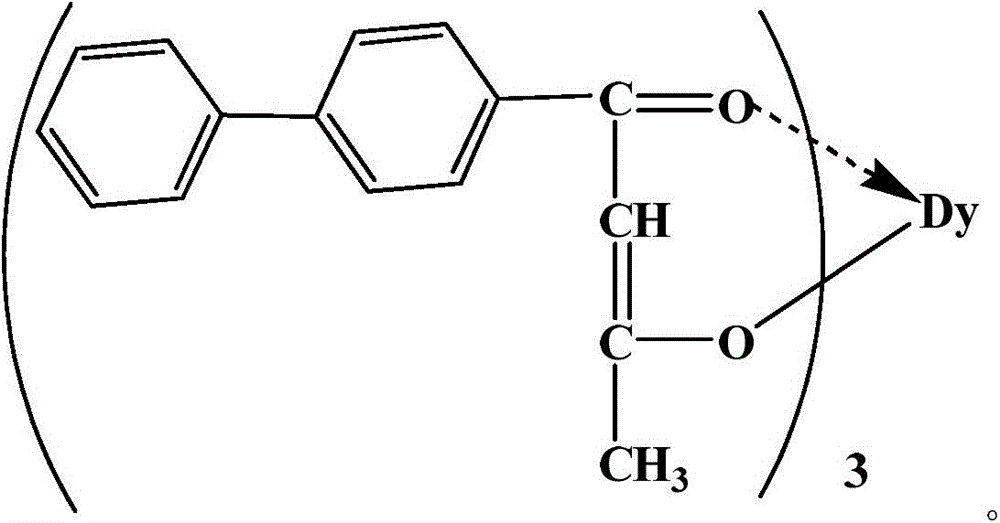

Gamma-cyclodextrin and rare earth Tb complex and application of gamma-cyclodextrin and rare earth Tb complex in microcontact printing technique

ActiveCN105462342AHigh resolutionNarrow redox potentialInksCoatingsMicrocontact printingChemical plating

The invention relates to a rare earth Tb complex and further provides application of a compound solution of the rare earth Tb complex and gamma-cyclodextrin in the microcontact printing technique. The application comprises the steps of dissolving gamma-cyclodextrin into water, so as to obtain a 3g / L-6g / L gamma-cyclodextrin water solution, adding 0.8g of rare earth Tb complex into each liter of the gamma-cyclodextrin water solution, regulating the frequency at 20kHz, carrying out ultrasonic treatment for30-60 minutes by virtue of an ultrasonic instrument, so as to obtain the uniformly-dispersed compound solution of gamma-cyclodextrin and the rare earth Tb complex, soaking a PDMS stamp into the compound solution, covering a carboxylation substrate with the PDMS stamp, and carrying out chemical plating. According to the application, a metal pattern is prepared on polymer substrates frequently used in the electron industry by virtue of microcontact printing ink, and a new thought is provided for the microcontact printing industry.

Owner:ZHEJIANG DONGHE PRINTING PACKAGING CO LTD

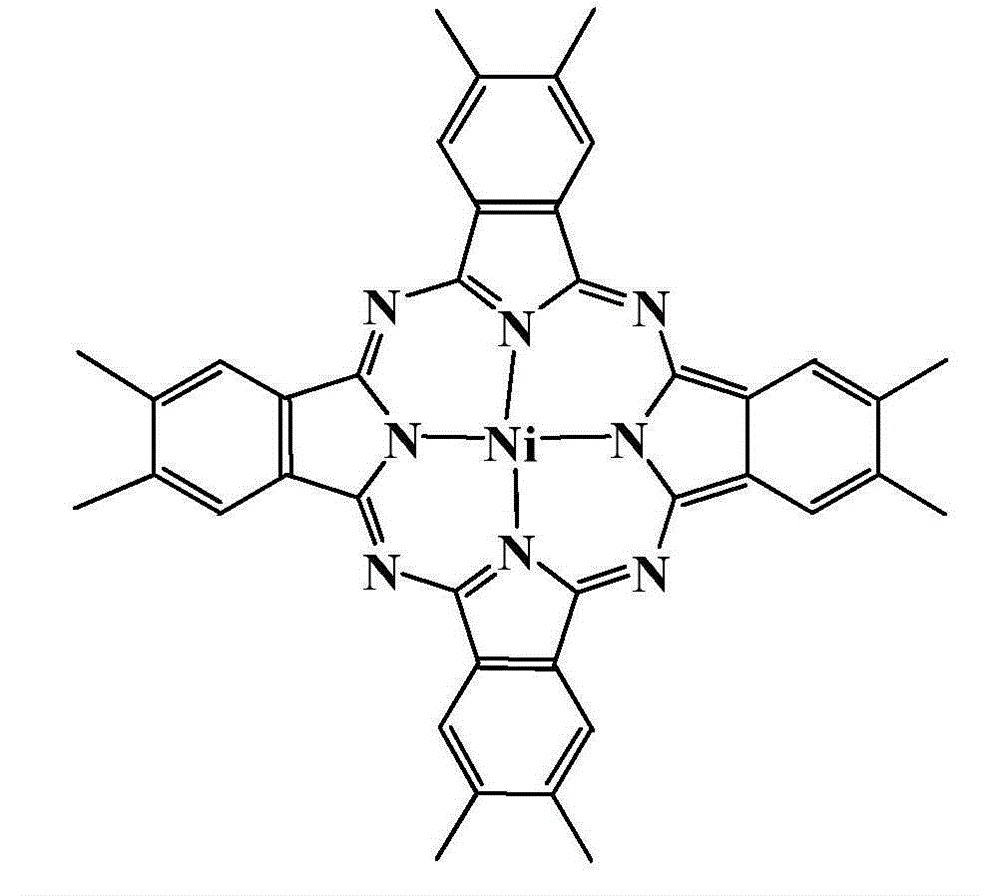

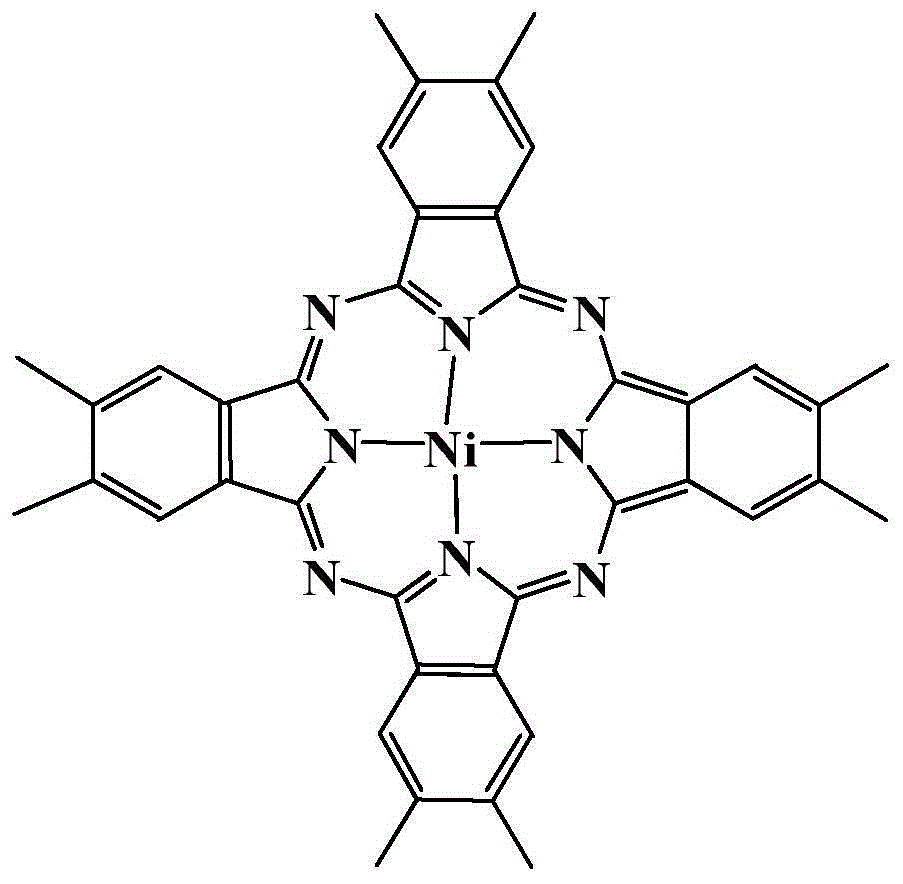

Method for Microcontact Printing of Graphene/Silver Composite Pattern Using Nickel Phthalocyanine Complex

InactiveCN104312264BTightly boundThe method steps are simpleInksMicrocontact printingPolyimide substrate

The invention discloses a method for printing a graphene / silver composite pattern by using a phthalocyanine nickel complex in a micro contact manner. The phthalocyanine nickel complex is prestox phthalocyanine nickel. The method comprises the following steps: by taking a dichloromethane solution of prestox phthalocyanine nickel as a printing agent of the micro contact printing, transferring a pattern of a PDMS seal to a polyimide substrate, further adsorbing and reducing graphene and silver, and finally obtaining delicate metal patterns on the substrate. By using the micro contact printing method, the graphene patterns can be printed on the surface of the polyimide substrate which is frequently used in the electronic industry, and a novel idea is provided for the micro contact printing industry.

Owner:魏颖

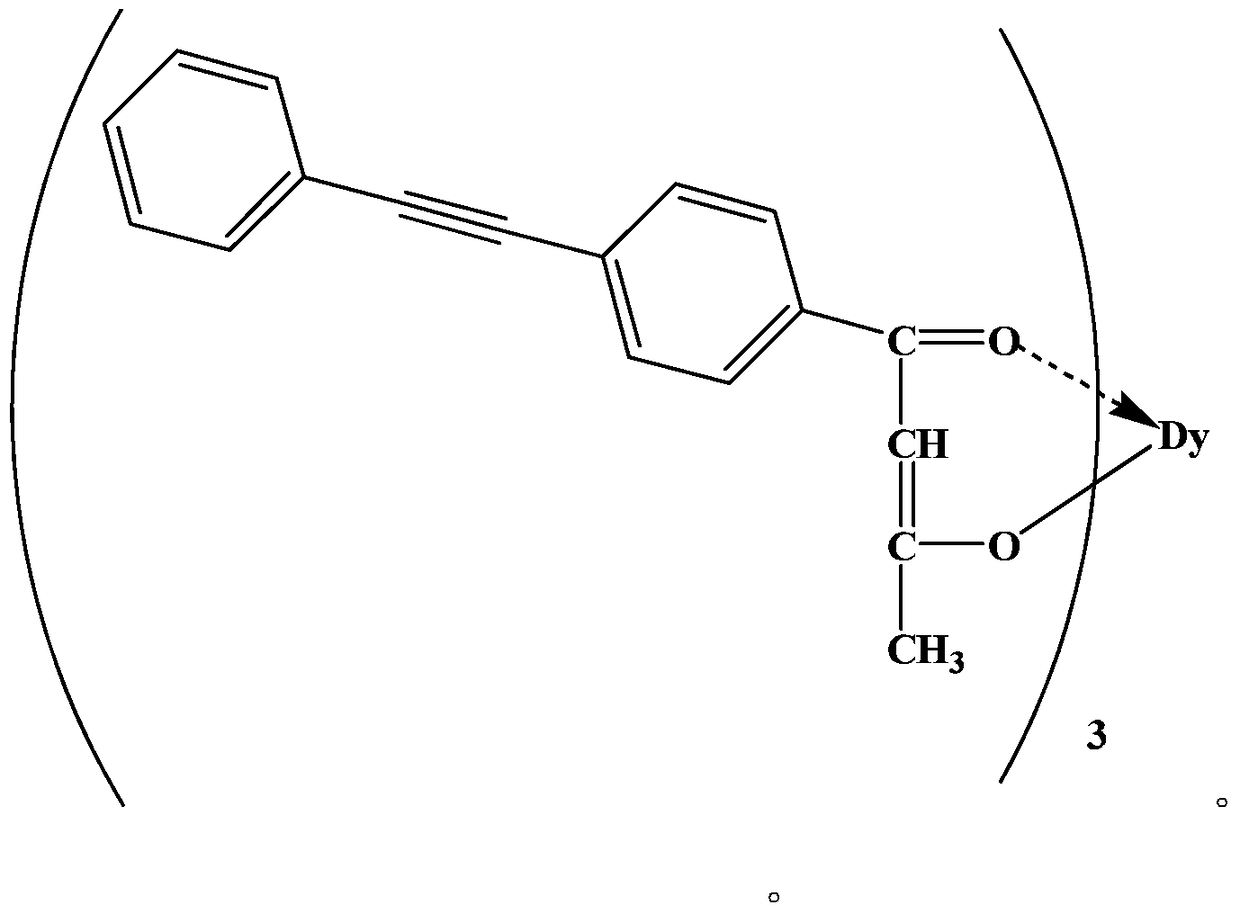

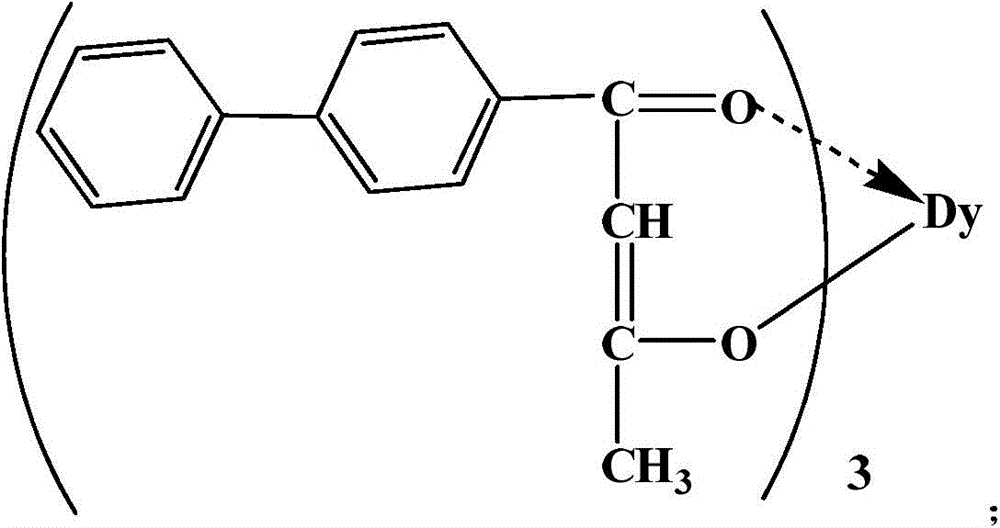

Application of Composite Solution of γ-Cyclodextrin and Rare Earth Dy Complex in Microcontact Printing

ActiveCN105504958BStrong magnetismRaw materials are easy to getInksCoatingsMicrocontact printingChemical plating

The invention discloses application of an alpha-cyclodextrin and rare-earth Dy complex composite solution in micro-contact printing. The alpha-cyclodextrin and rare-earth Dy complex solution serves as a printing agent for micro-contact printing, a pattern of a PDMS stamp is transferred to a carboxylic polyethylene substrate, and then a fine metal pattern is obtained on the substrate by adopting a chemical plating method. The alpha-cyclodextrin and rare-earth Dy complex composite solution serves as micro-contact printing ink to make the metal pattern on the bottom surface of the polyethylene substrate commonly used in the electronic industry, and a new thought is provided for the micro-contact printing industry.

Owner:广西北部湾粮油技术研究有限公司

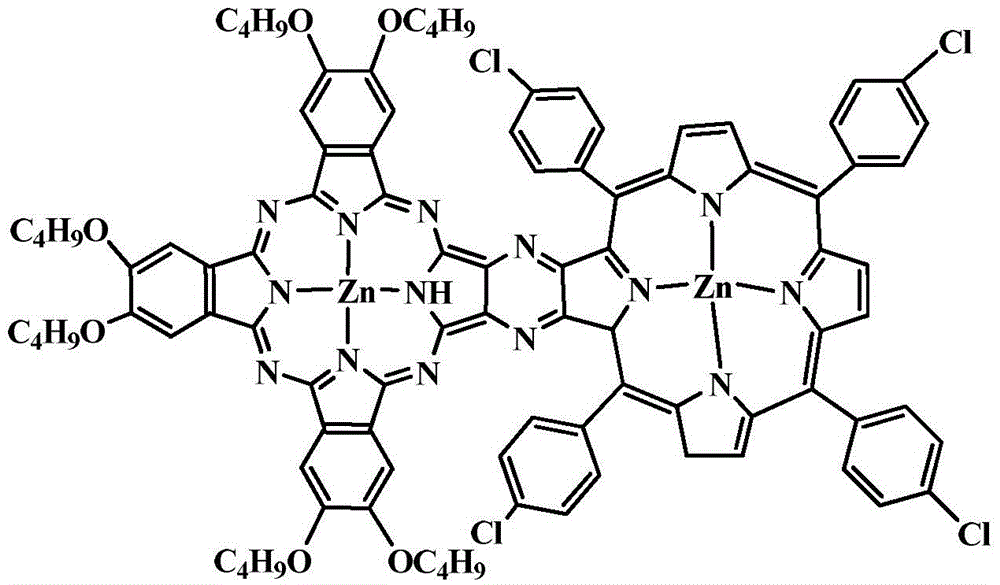

Microcontact printing method using planar conjugated phthalocyanine porphyrin dyad complex

InactiveCN104387836BAggregation tightEasy to adjustPattern printingInksMicrocontact printingPolymethyl methacrylate

The invention discloses a method for carrying out microcontact printing by employing a plane conjugate phthalocyanine-porphyrin coordination compound. The method comprises the following specific steps: with a dichloromethane solution of 5,10,15,20-parachloro-phenyl porphyrin zinc-hexabutoxyphthalocyanine zinc as a printing agent for microcontact printing, transferring a pattern of a PDMS stamp to a polymethyl methacrylate substrate, and adsorbing reduced copper on the substrate to obtain a fine metal pattern. A metal pattern is prepared by taking the dichloromethane solution of 5,10,15,20-parachloro-phenyl porphyrin zinc-hexabutoxyphthalocyanine zinc as microcontact printing ink on the surface of the polymethyl methacrylate substrate which is commonly used in the electron industry, so that the method is available in raw materials, low in cost and stable, and has great potential in industrial application, and a new idea is provided for the microcontact printing industry.

Owner:深圳市润宝印刷科技有限公司

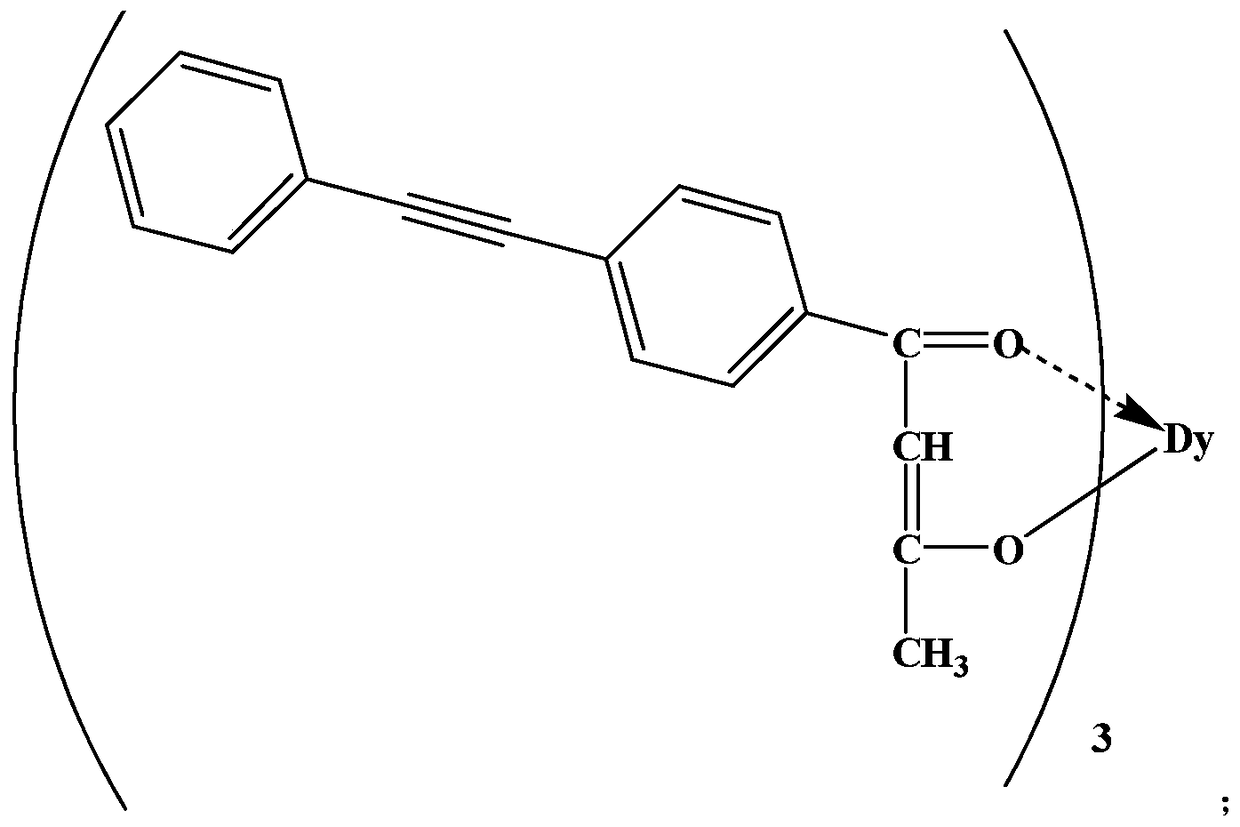

Application of compound solution of beta-cyclodextrin and rare earth Dy complex in microcontact printing

ActiveCN105462343AStrong magnetismRaw materials are easy to getInksCoatingsMicrocontact printingChemical plating

The invention discloses application of a compound solution of beta-cyclodextrin and a rare earth Dy complex in microcontact printing. According to the application, the compound solution of beta-cyclodextrin and the rare earth Dy complex is taken as a printing agent of the microcontact printing, a pattern of a PDMS stamp is transferred to a polyethylene glycol terephthalate substrate, a fine metal pattern is prepared on the polyethylene glycol terephthalate substrate by virtue of a chemical plating method, and a metal pattern is prepared on the polyethylene glycol terephthalate substrate frequently used in the electron industry by taking the compound solution of beta-cyclodextrin and the rare earth Dy complex as microcontact printing ink. According to the application, a new thought is provided for the microcontact printing industry.

Owner:ZHEJIANG DONGHE PRINTING PACKAGING CO LTD

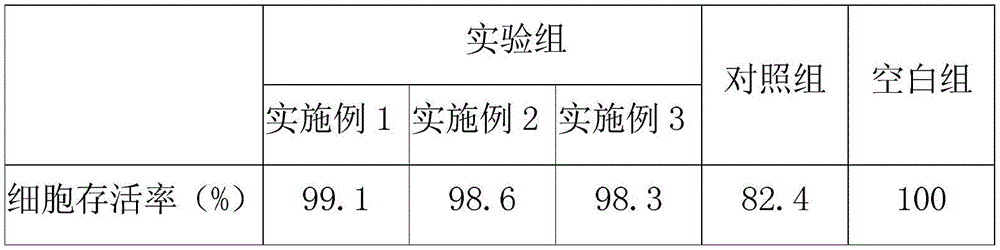

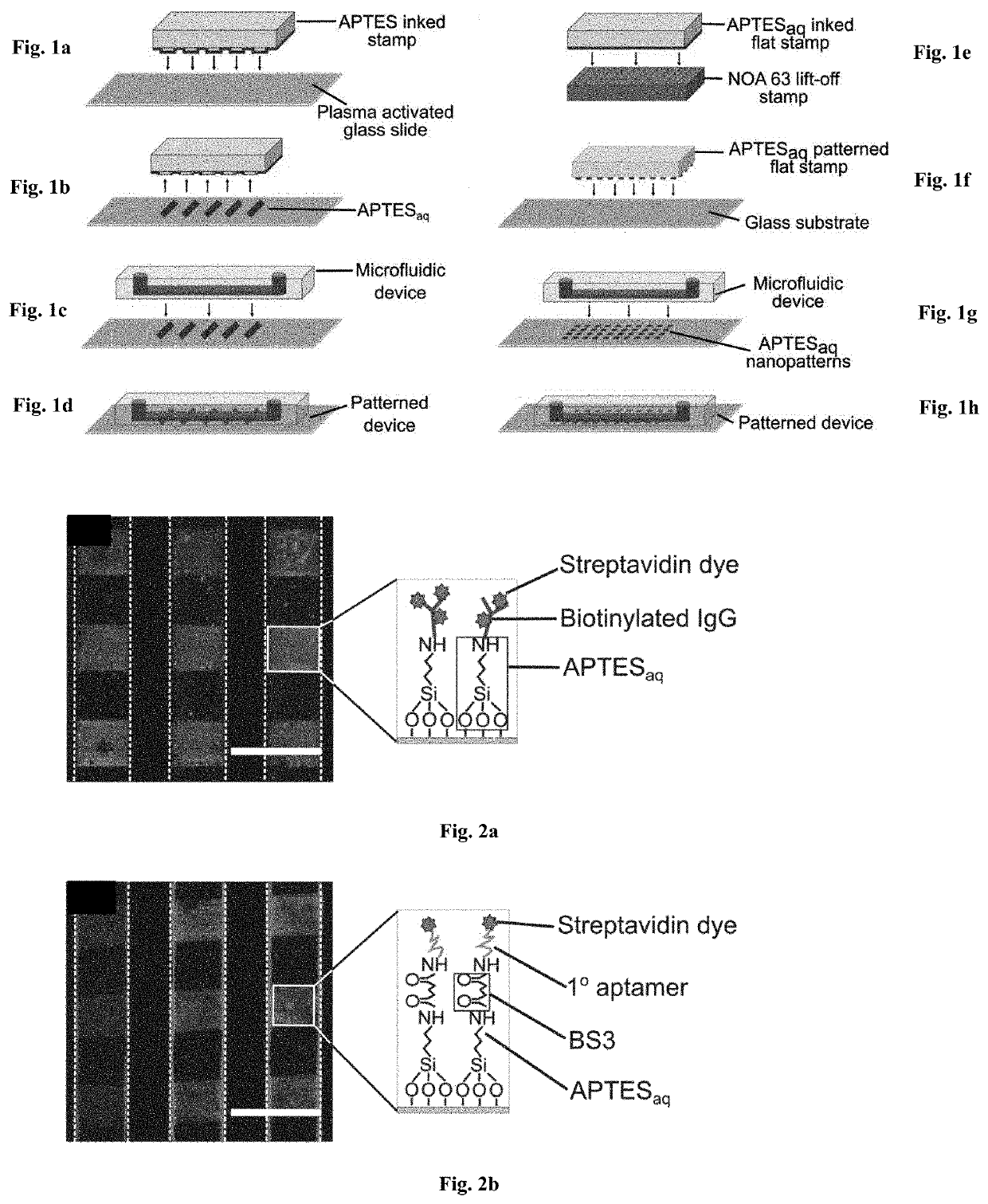

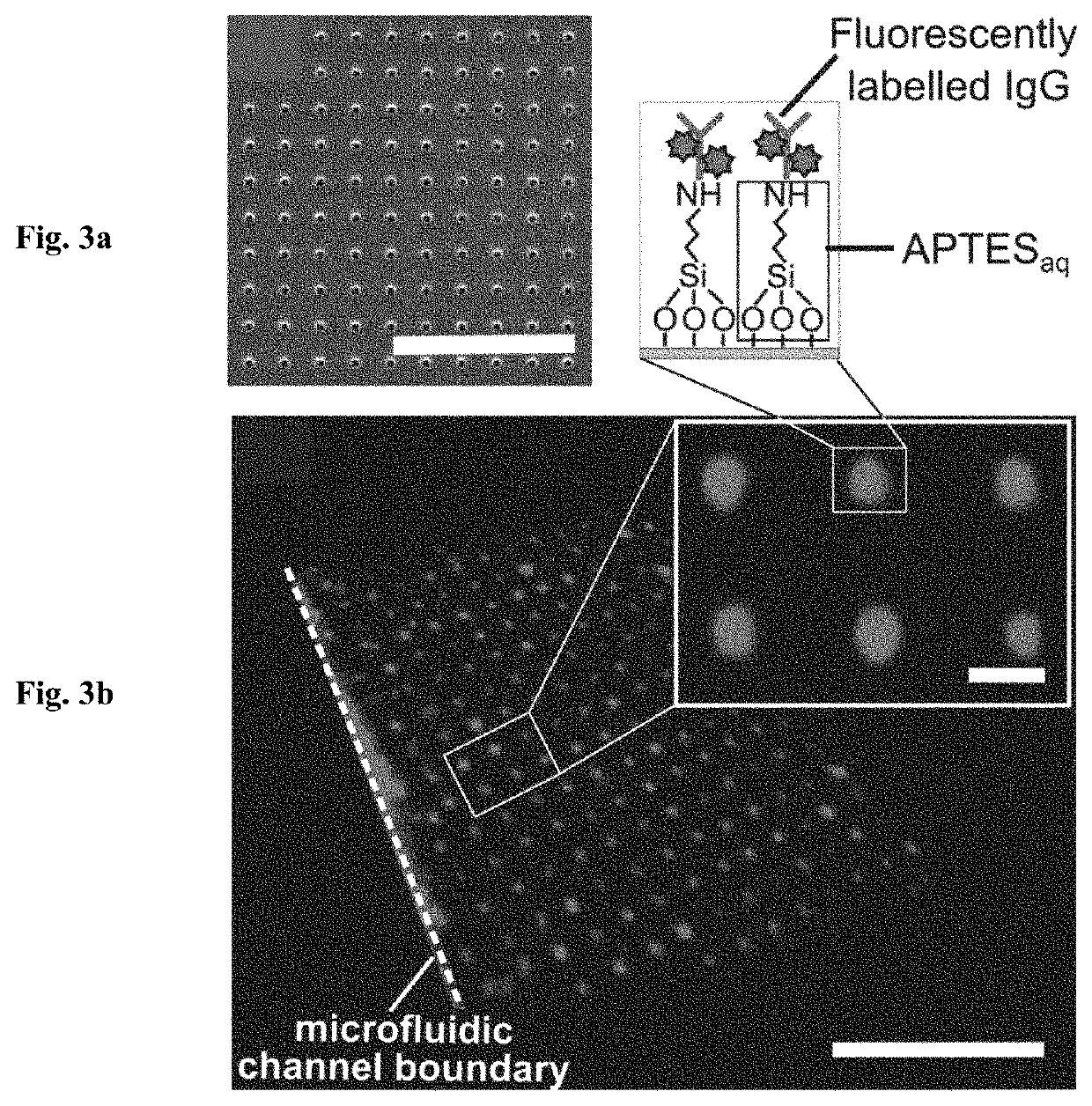

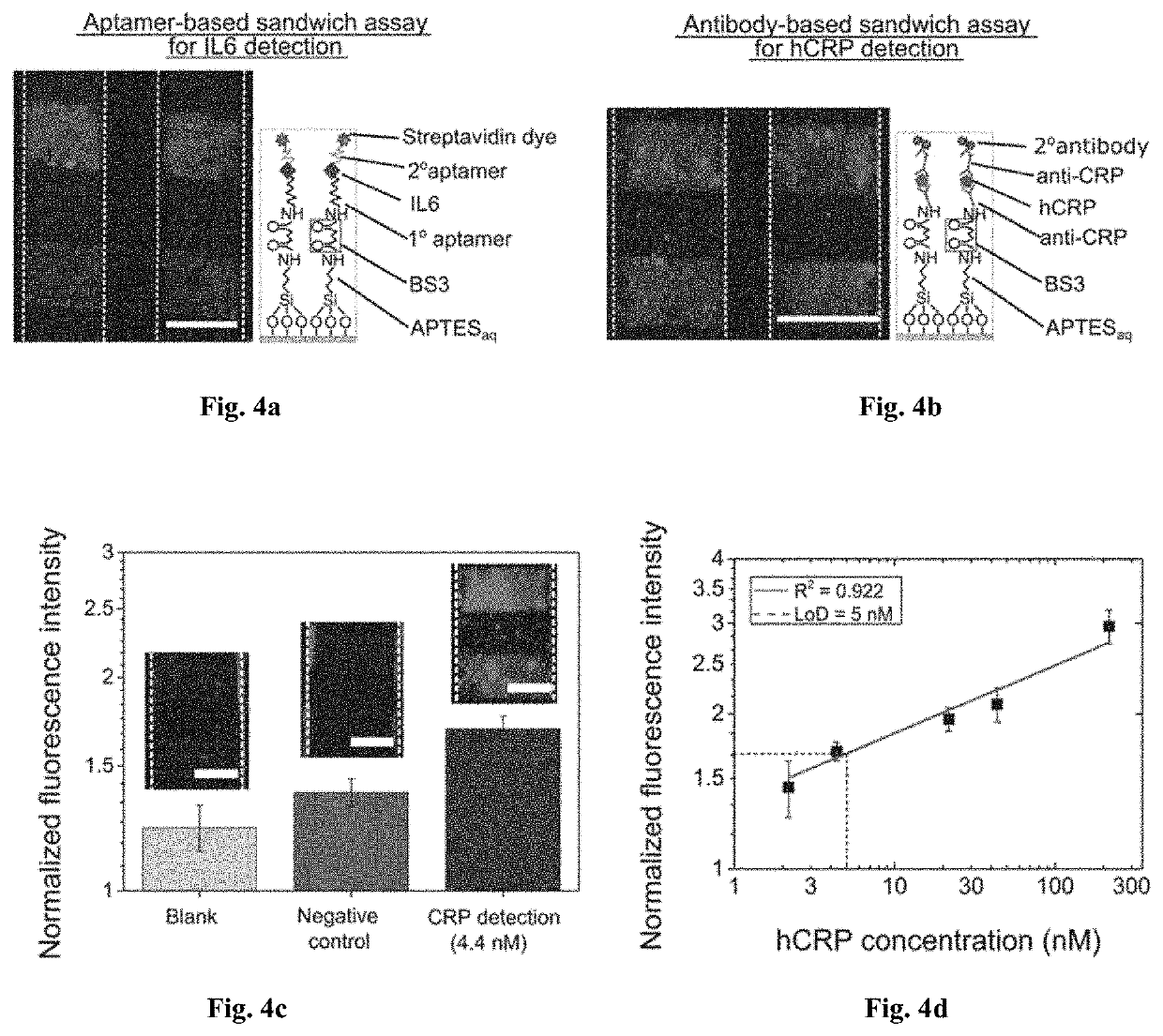

Micro- and nanocontact printing with aminosilanes: patterning surfaces of microfluidic devices for multi- plexed bioassays

InactiveUS20210046476A1Bioreactor/fermenter combinationsBiological substance pretreatmentsMicrocontact printingBiologic Assays

It is an object of the present invention to achieve rapid surface patterning of biomolecules within microfluidic devices with high reproducibility. In this work, we present a new means of creating micro- and nano-patterns of aminosilanes within microfluidic devices via an aqueous based microcontact printing technique. To minimize the diffusion of molecules into the PDMS stamp, we use water as the inking solvent and enforce short incubation and contact times during the printing process to preserve the pre-defined resolution of patterned features. These patterns then serve as the building block to couple multiple biomolecules in solution onto a single surface for subsequent bioassays.

Owner:OKINAWA INST OF SCI & TECH SCHOOL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com