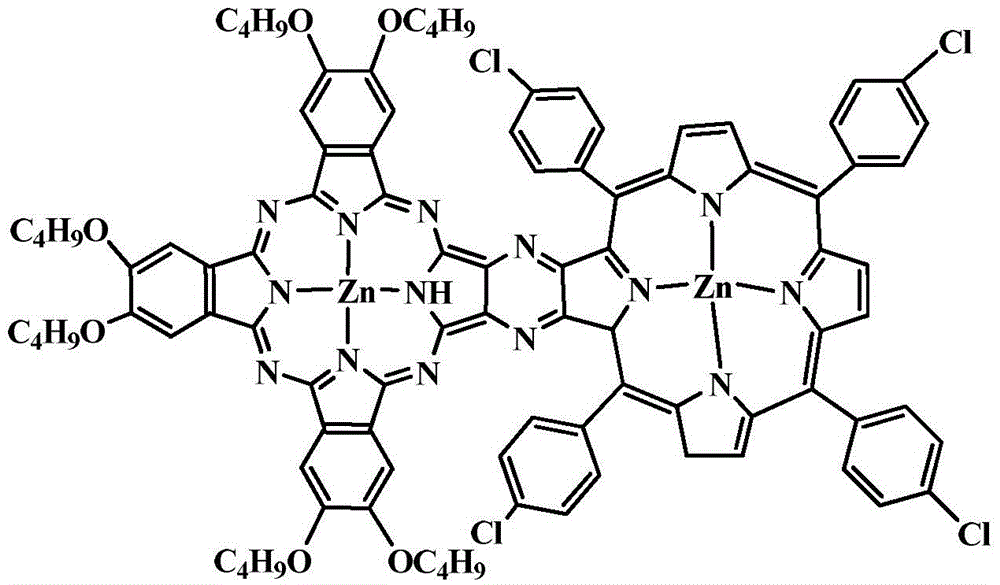

Microcontact printing method using planar conjugated phthalocyanine porphyrin dyad complex

A technology of micro-contact printing and planar conjugation, which is applied in the printing, printing, and printing process of producing special varieties of printed matter. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. The base material polymethyl methacrylate was ultrasonically cleaned with ethanol for 1 hour, and then vacuum-dried at 80°C. use 60 It is irradiated with Co gamma rays, the dose is 100KGy, and the time is 150h. Put 100 g of the irradiated substrate into a three-necked bottle, add 1 g of acrylic acid and 500 ml of distilled water, and react at 80° C. for 1 hour.

[0024] 2. Dissolve 5,10,15,20-p-chlorophenylporphyrin zinc and hexabutoxyphthalocyanine zinc in dichloromethane to obtain 5,10,15,20-p-chlorobenzene with a concentration of 1g / L porphyrin-based zinc hexabutoxyphthalocyanine zinc dichloromethane solution.

[0025] 3. Soak the PDMS stamp in 5, 10, 15, 20-p-chlorophenylporphyrin zinc hexabutoxyphthalocyanine zinc dichloromethane solution for 1 minute, take it out and put it in N 2 Dry in airflow for 30s, cover the PDMS stamp coated with 5,10,15,20-p-chlorophenylporphyrin zinc hexabutoxyphthalocyanine zinc dichloromethane solution on the carboxylation substra...

Embodiment 2

[0028] 1. The base material polymethyl methacrylate was ultrasonically cleaned with ethanol for 1 hour, and then vacuum-dried at 80°C. use 60 It is irradiated with Co gamma rays, the dose is 125KGy, and the time is 160h. Put 100 g of the irradiated substrate into a three-necked bottle, add 1 g of acrylic acid and 500 ml of distilled water, and react at 80° C. for 1 hour.

[0029] 2. Dissolve 5,10,15,20-p-chlorophenylporphyrin zinc and hexabutoxyphthalocyanine zinc with dichloromethane to obtain 5,10,15,20-p-chlorobenzene with a concentration of 5g / L porphyrin-based zinc hexabutoxyphthalocyanine zinc dichloromethane solution.

[0030] 3. Soak the PDMS stamp in 5, 10, 15, 20-p-chlorophenylporphyrin zinc hexabutoxyphthalocyanine zinc dichloromethane solution for 1-2 minutes, take it out and put it in N 2 Dry in airflow for 50s, cover the PDMS stamp coated with 5,10,15,20-p-chlorophenylporphyrin zinc and hexabutoxyphthalocyanine zinc dichloromethane solution on the carboxylatio...

Embodiment 3

[0033] 1. The base material polymethyl methacrylate was ultrasonically cleaned with ethanol for 1 hour, and then vacuum-dried at 80°C. use 60 It is irradiated with Co gamma rays, the dose is 150KGy, and the time is 180h. Put 100 g of the irradiated substrate into a three-necked bottle, add 1 g of acrylic acid and 500 ml of distilled water, and react at 80° C. for 1 hour.

[0034] 2. Dissolve 5,10,15,20-p-chlorophenylporphyrin zinc and hexabutoxyphthalocyanine zinc with dichloromethane to obtain 5,10,15,20-p-chlorobenzene with a concentration of 10g / L porphyrin-based zinc hexabutoxyphthalocyanine zinc dichloromethane solution.

[0035] 3. Soak the PDMS stamp in 5, 10, 15, 20-p-chlorophenylporphyrin zinc hexabutoxyphthalocyanine zinc dichloromethane solution for 1-2 minutes, take it out and put it in N 2 Dry in airflow for 60s, cover the PDMS stamp coated with 5,10,15,20-p-chlorophenylporphyrin zinc and hexabutoxyphthalocyanine zinc dichloromethane solution on the carboxylati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com