Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

75 results about "Ferric fluoride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iron(III) fluoride, also known as ferric fluoride, are inorganic compounds with the formula FeF 3 (H 2 O)x where x = 0 or 3. They are mainly of interest by researchers, unlike the related iron(III) chlorides. Anhydrous iron(III) fluoride is white, whereas the hydrated forms are light pink.

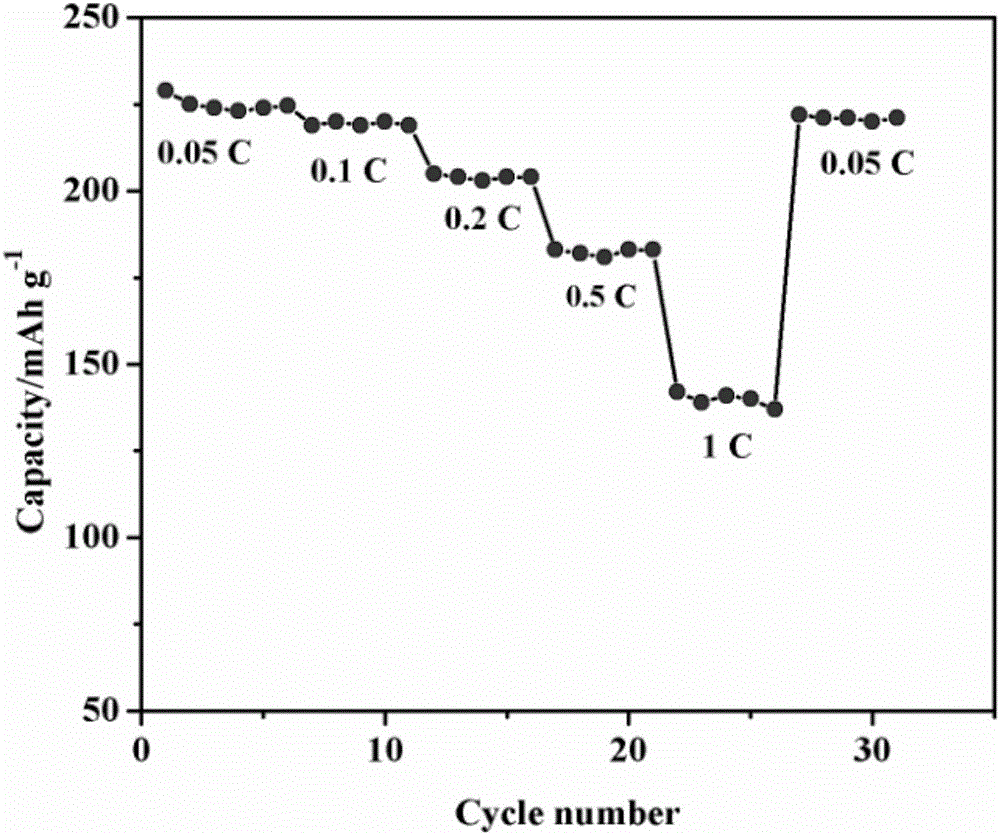

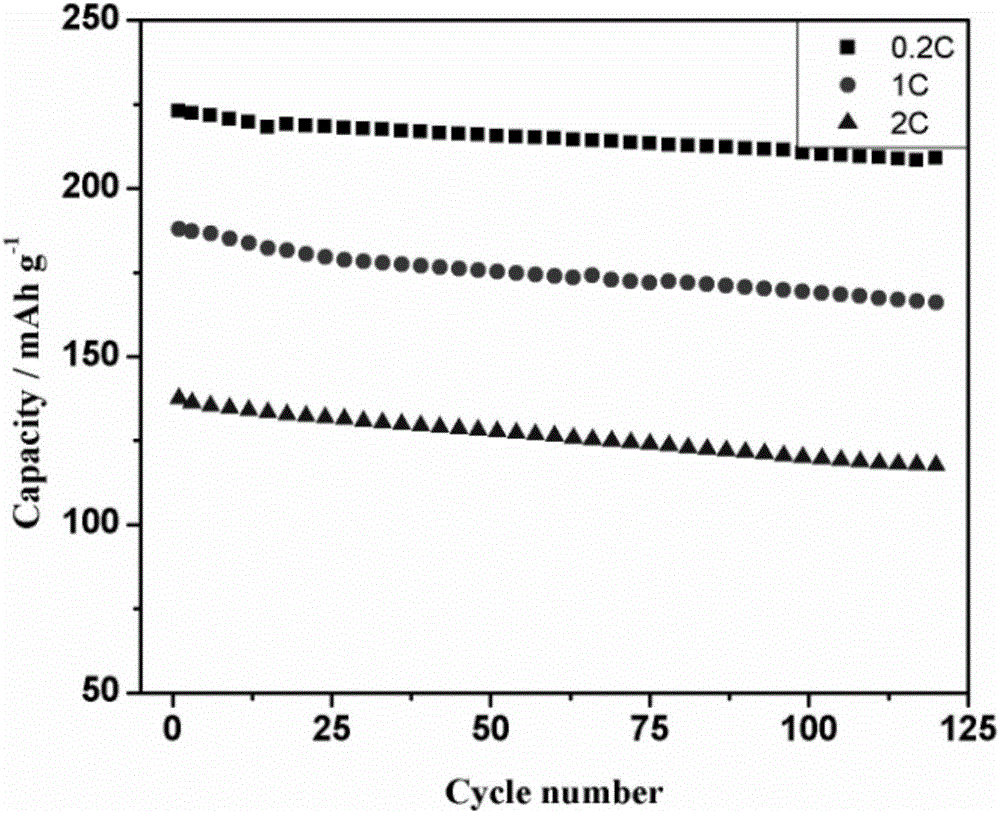

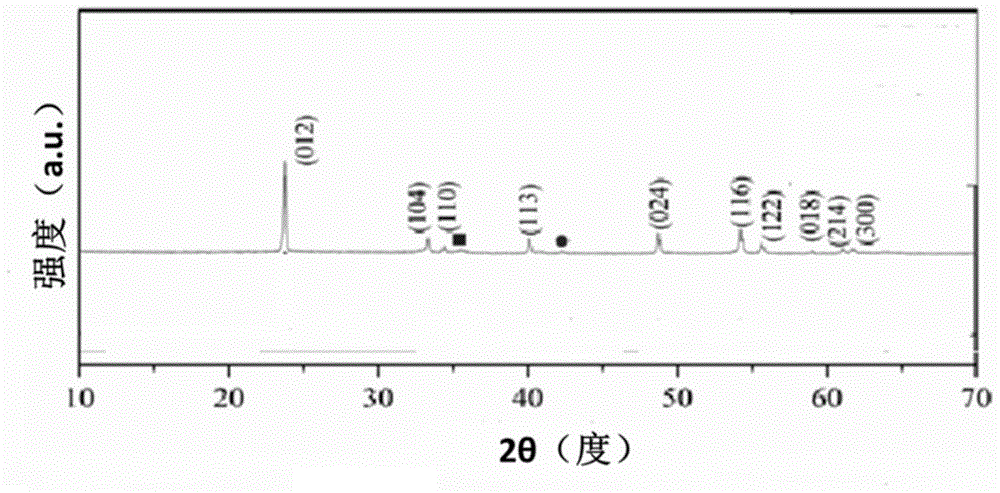

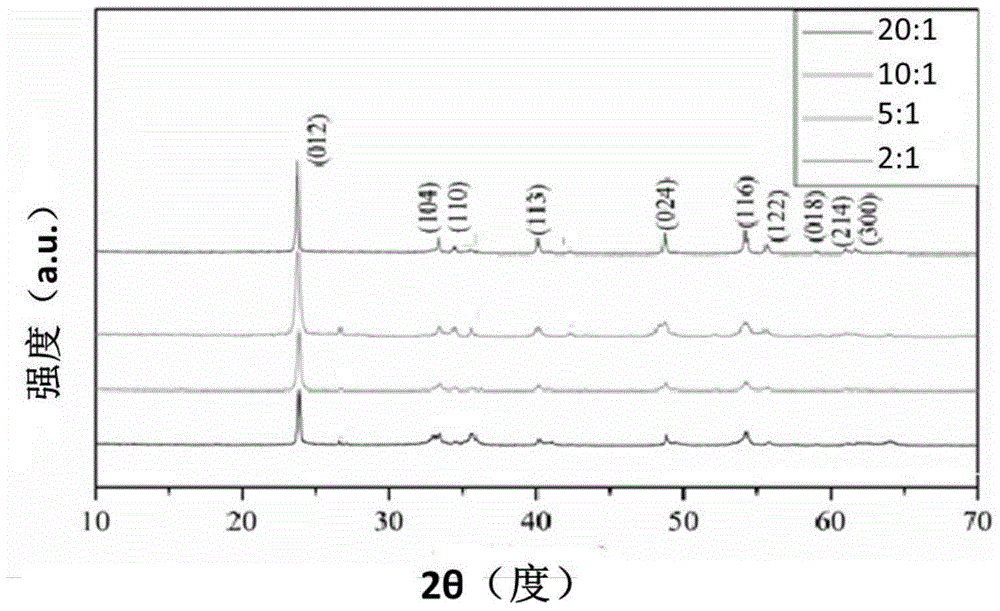

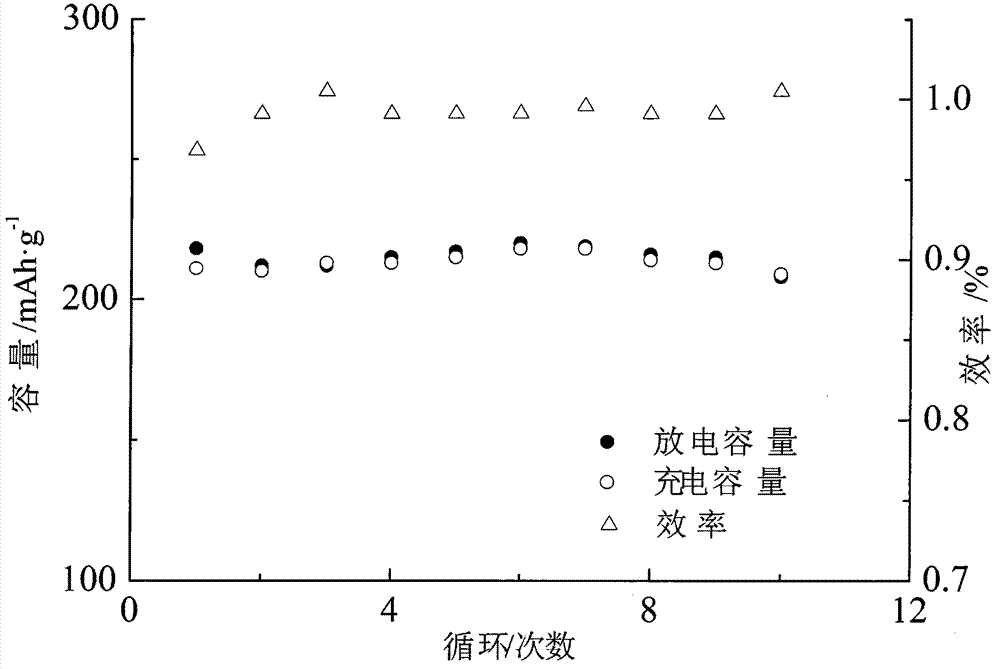

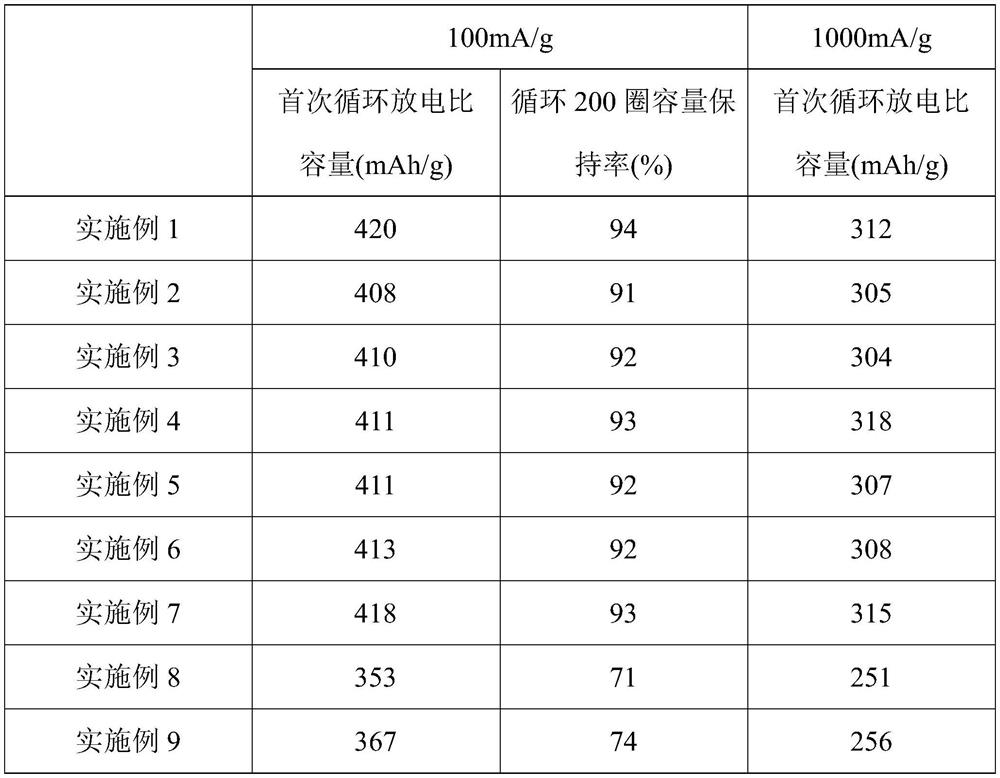

Cobalt-doped carbon-coated ferric fluoride anode material and preparation method thereof

InactiveCN102623707AUniform electrochemical cycle performanceImprove electrochemical cycle performanceCell electrodesHydrogen fluoridePhysical chemistry

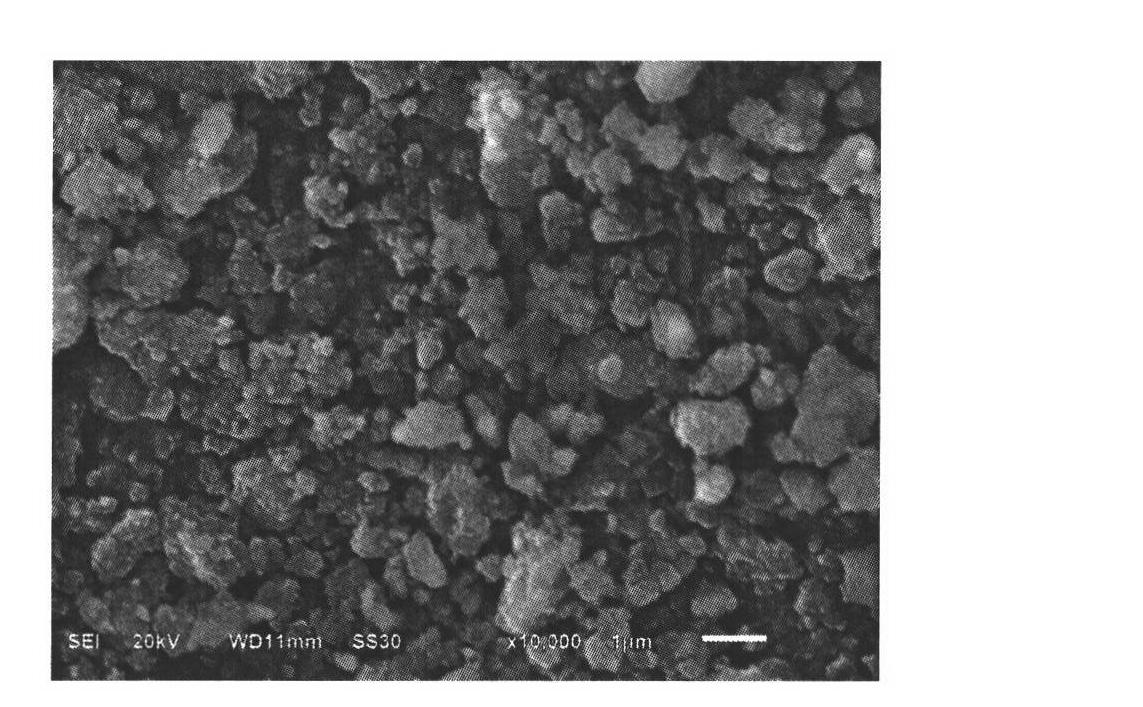

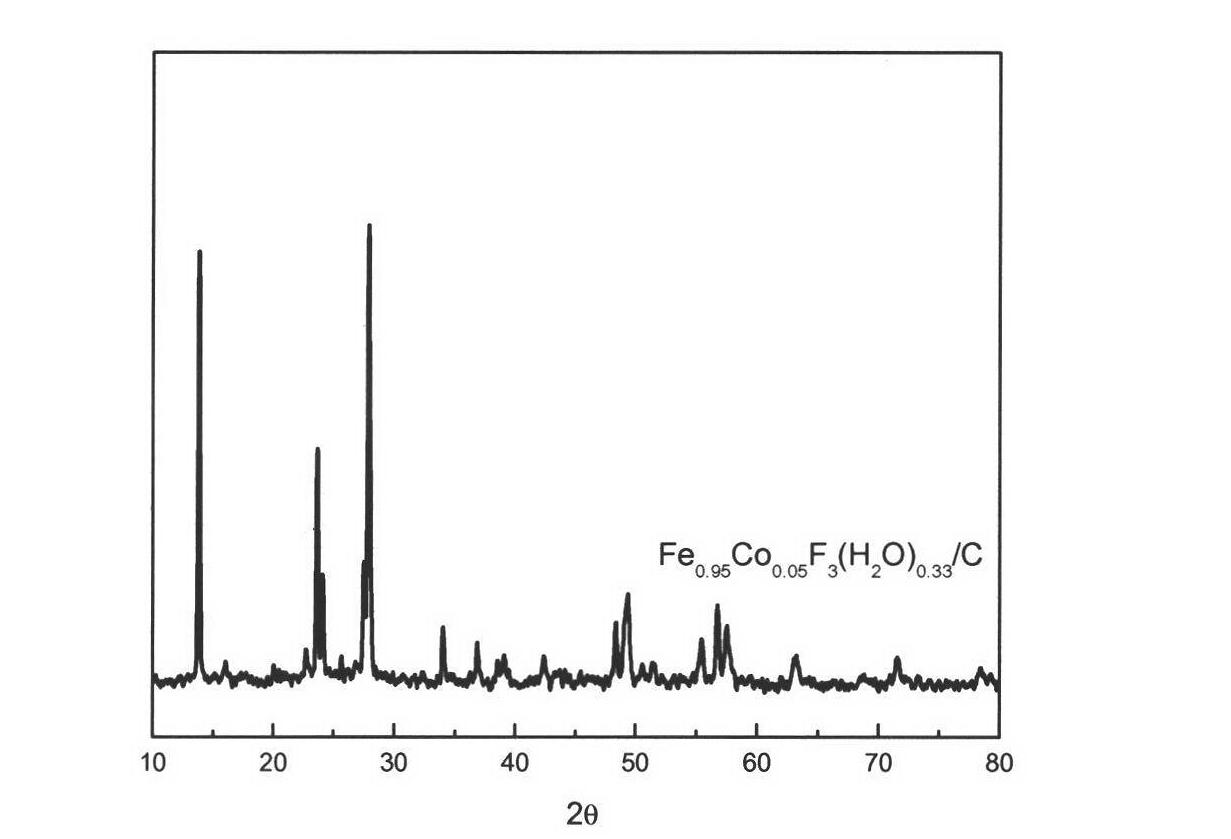

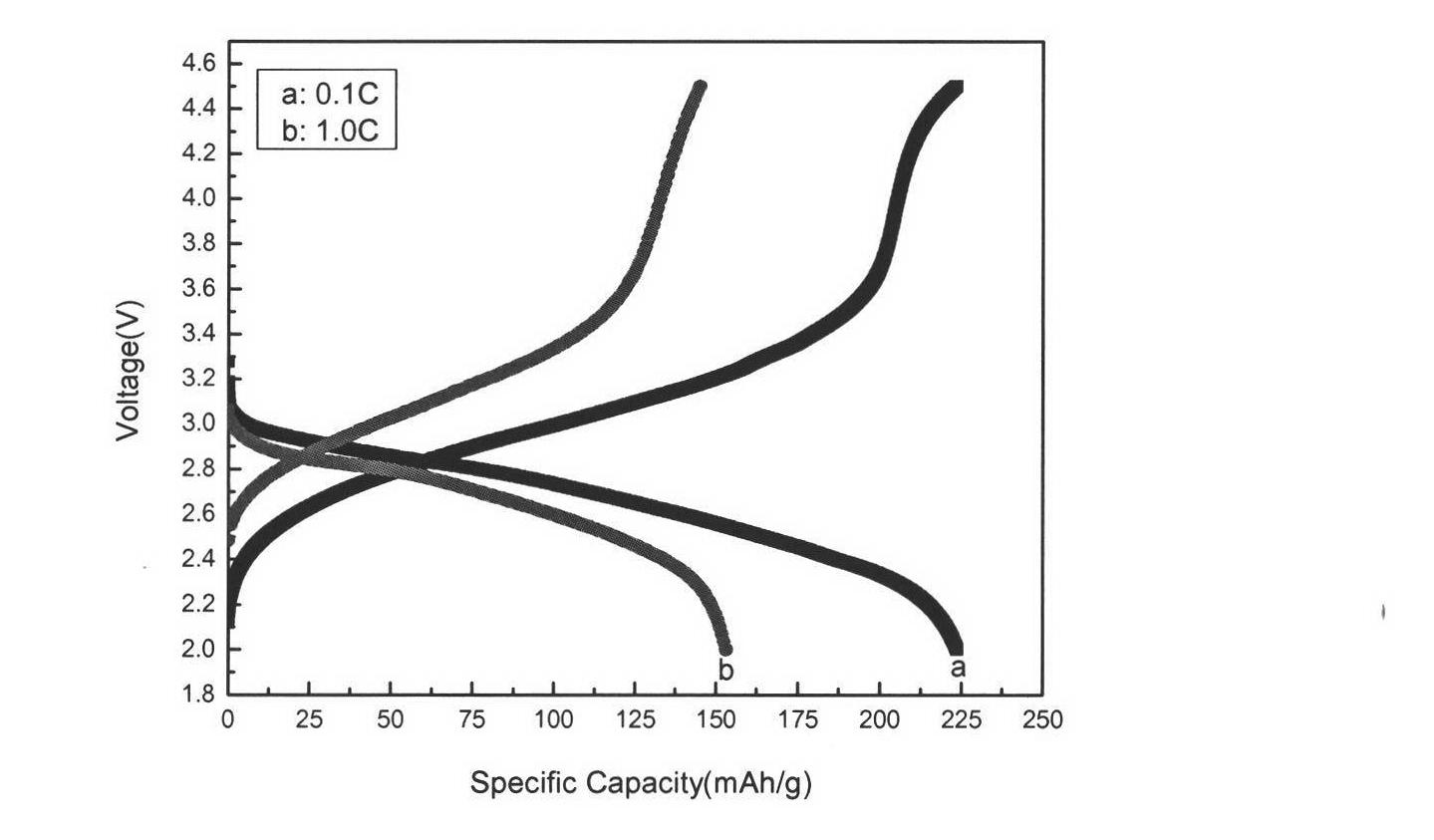

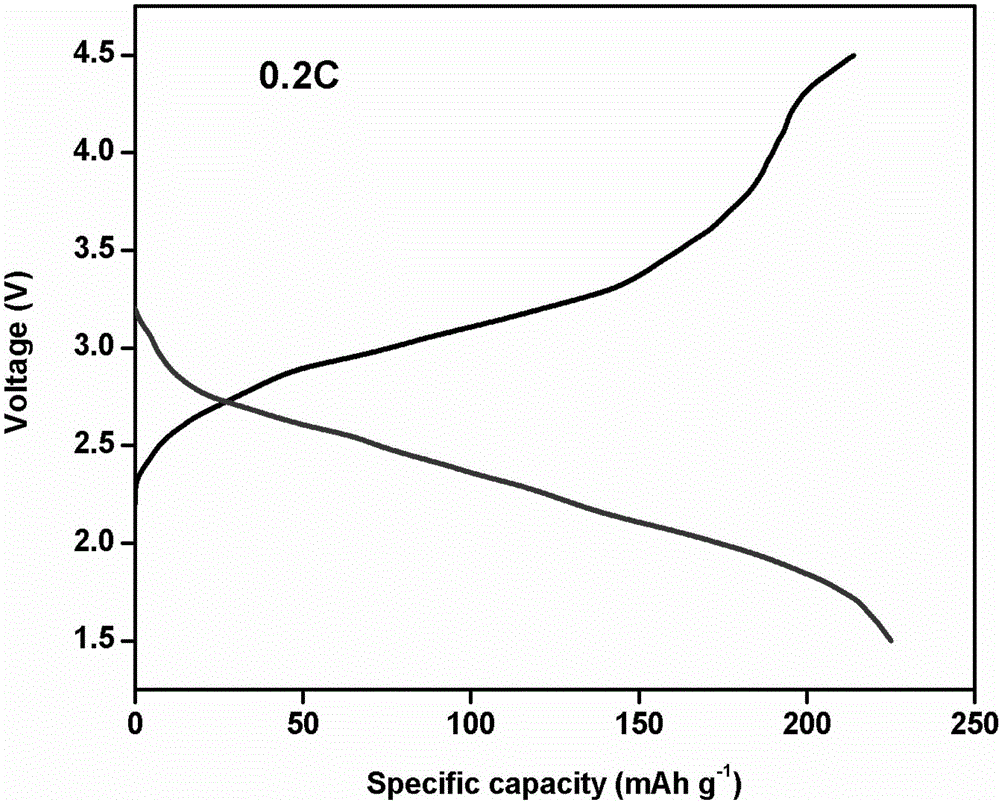

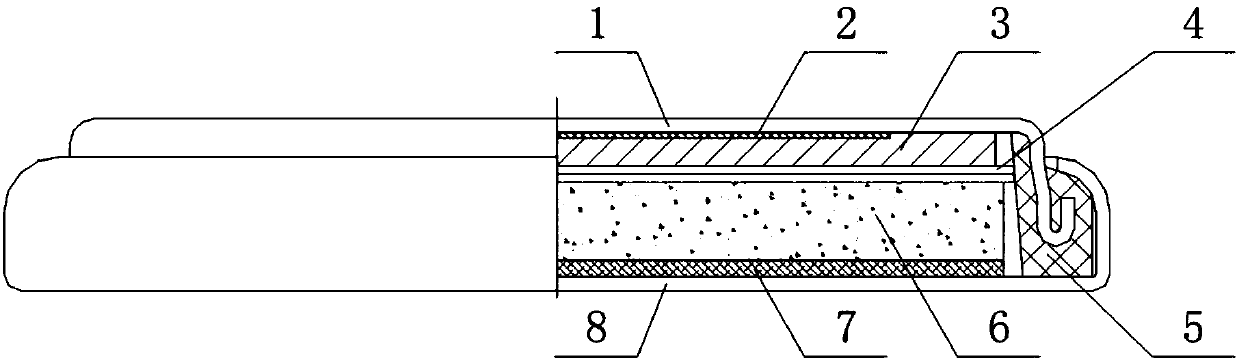

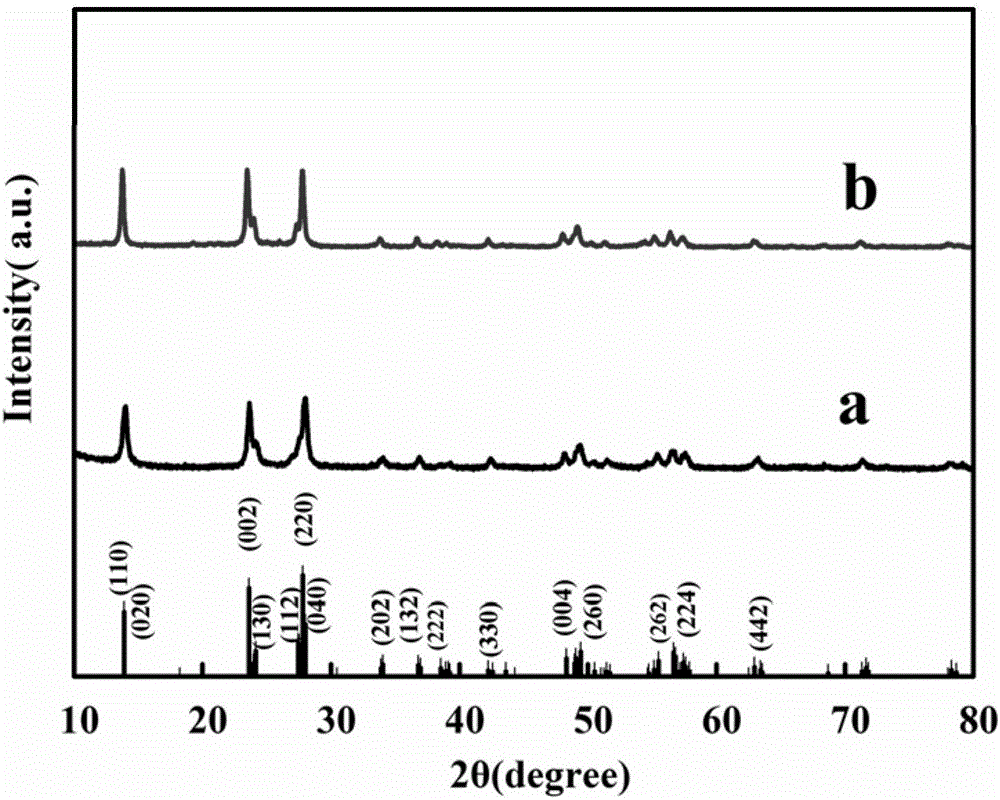

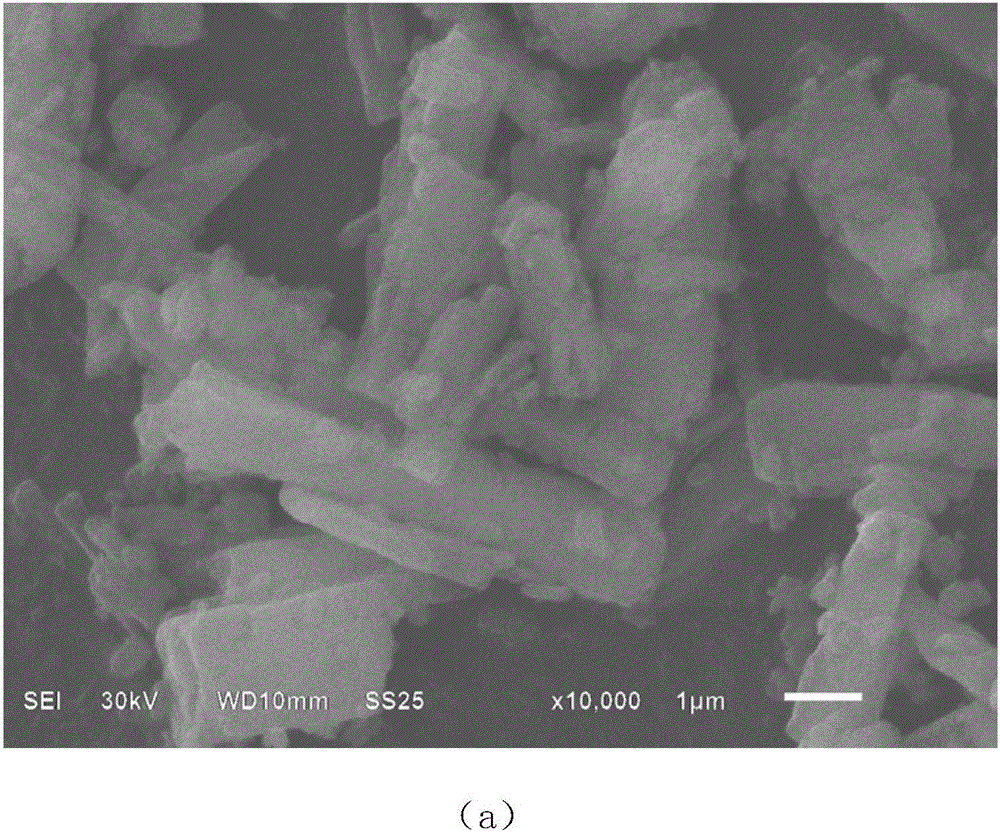

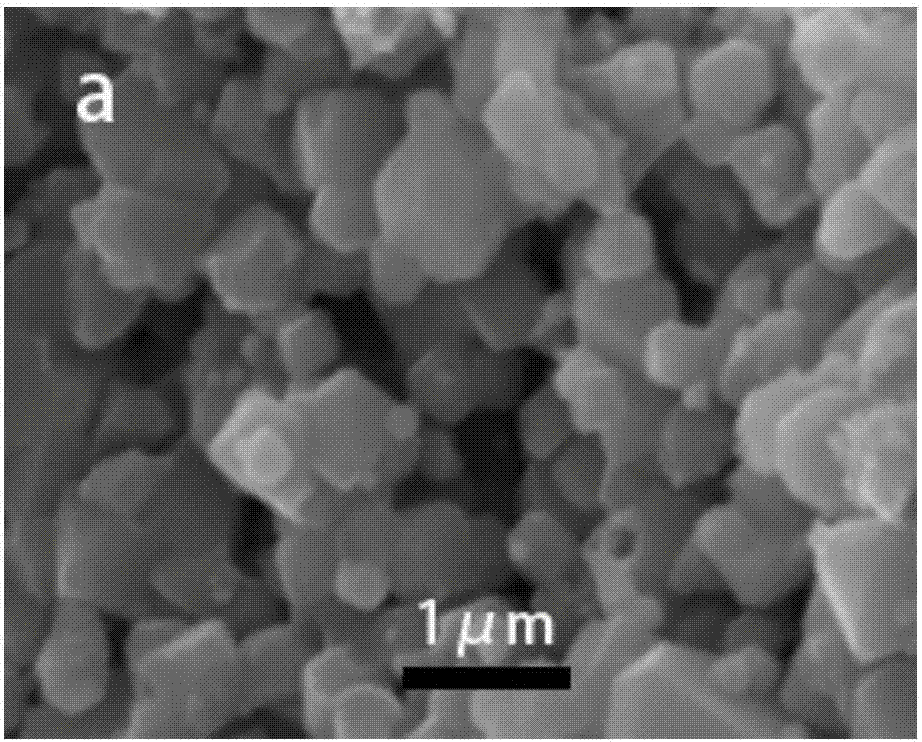

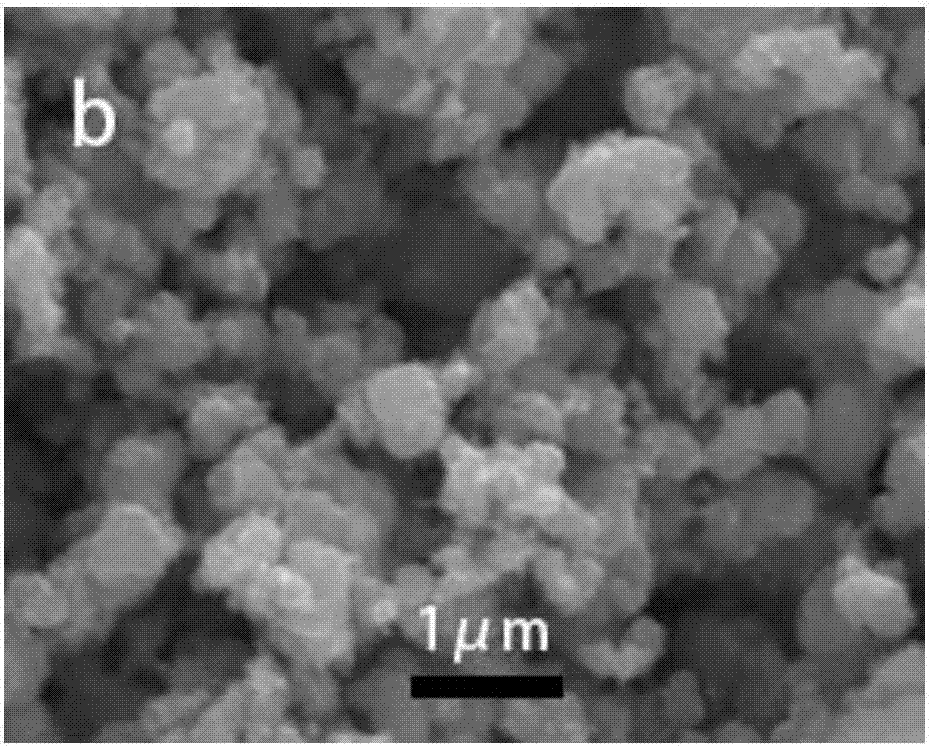

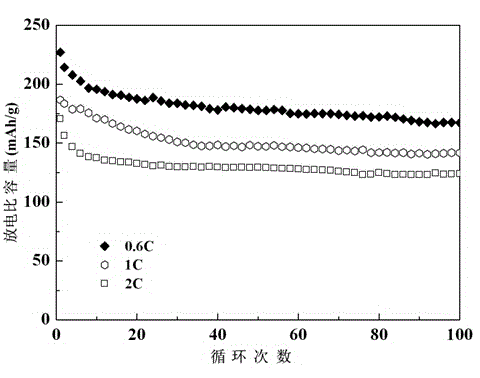

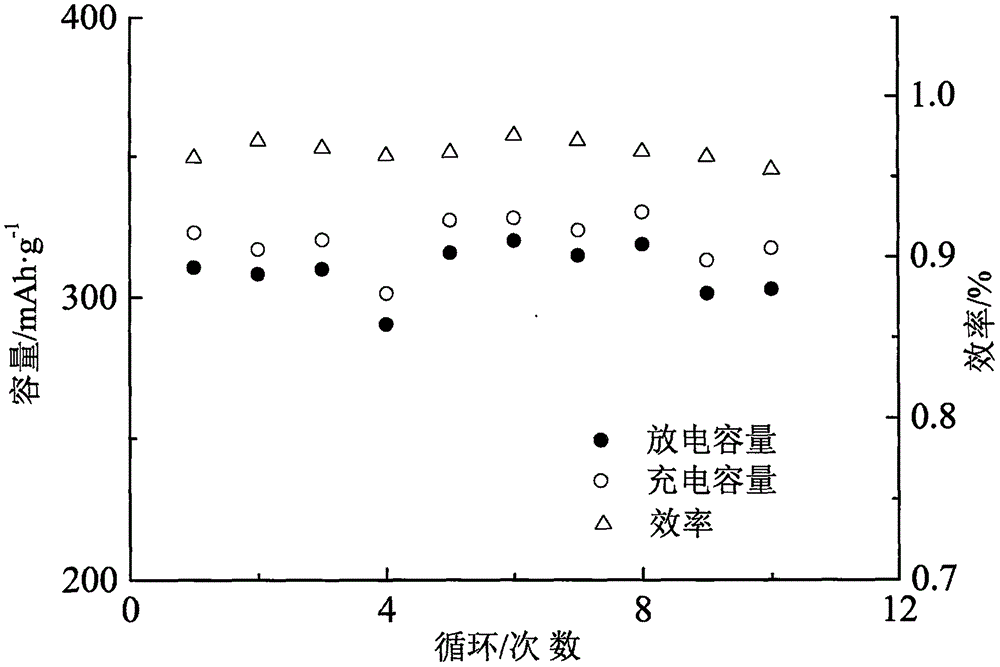

The invention discloses a cobalt-doped carbon-coated ferric fluoride anode material and a preparation method thereof. The chemical formula of the ferric fluoride anode material of the cobalt coated carbon is Fe(1-x)CoxF3(H2O)0.33 / C. The preparation method comprises the steps of adding iron source and cobalt source at the normal temperature into a hydrogen fluoride solution, and stirring the mixture to react in a sealed teflon reactor; continuously stirring the hydrogen fluoride solution to react after the temperature is raised, carrying out sucking and filtering, washing the obtained product with ethanol, drying the obtained product after washing, and carrying out heat treatment in vacuum to obtain cobalt-doped ferric fluoride powder; and pelletizing the cobalt-doped ferric fluoride powder and acetylene black, and carrying out heat treatment in vacuum to obtain the cobalt-doped carbon-coated ferric fluoride anode material. The preparation method disclosed by the invention has the following technical effects that (1) the prepared Fe(1-x)CoxF3(H2O)0.33 / C has a complete orthorhombic system structure, the grain diameter of the ferric fluoride anode material of the cobalt coated carbon is small, and the ferric fluoride anode materials of the cobalt coated carbon are uniformly distributed; (2) the materials of Fe(1-x)CoxF3(H2O)0.33 / C has favorable electrochemical cycling performance; and (3) the preparation method has the advantages of low required temperature and low cost, and is easy to industrially popularize.

Owner:XIANGTAN UNIV

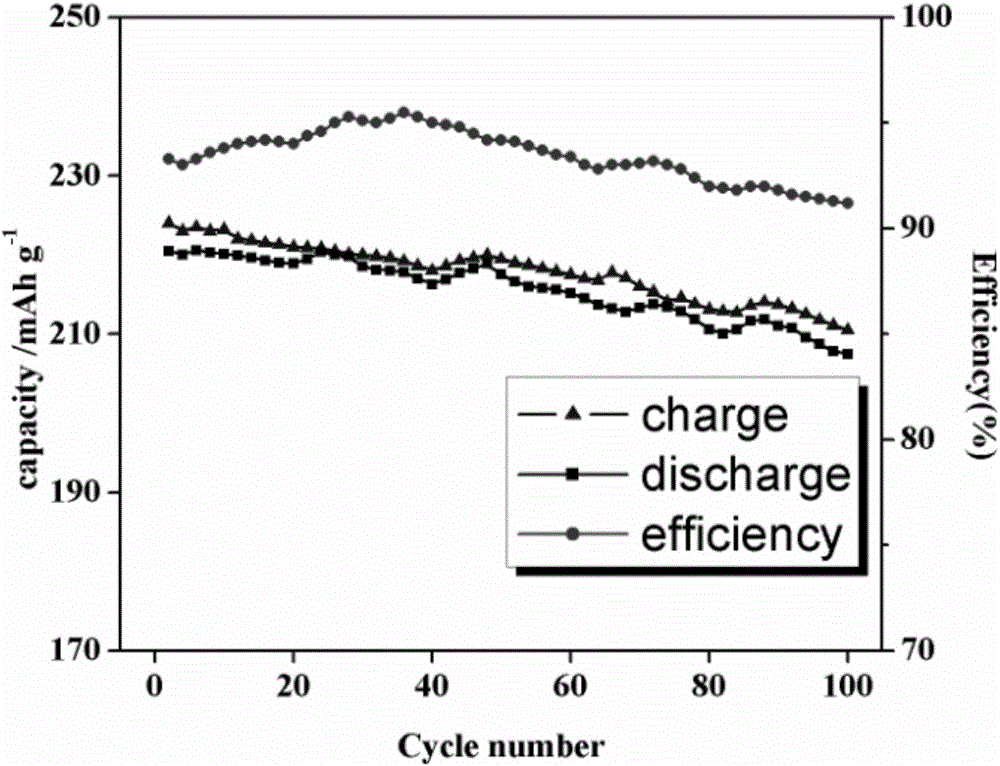

Mixed crystal form ferric fluoride cathode material and preparation method thereof

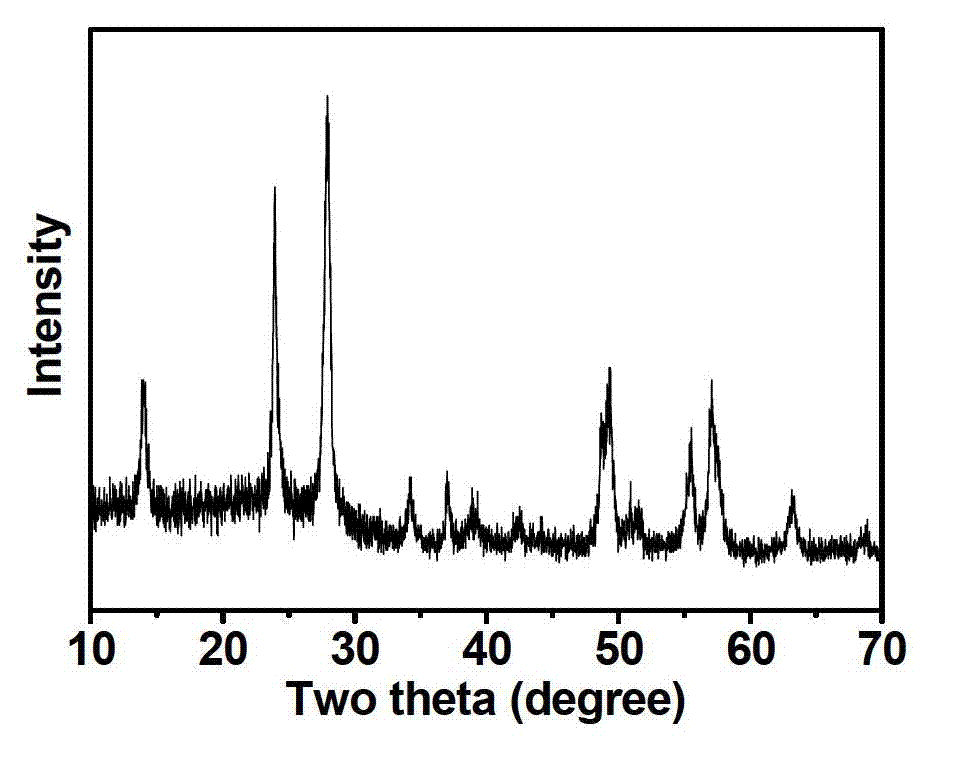

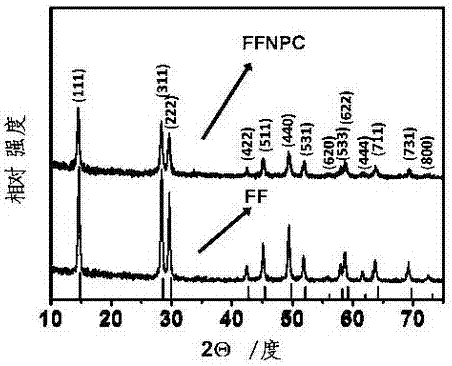

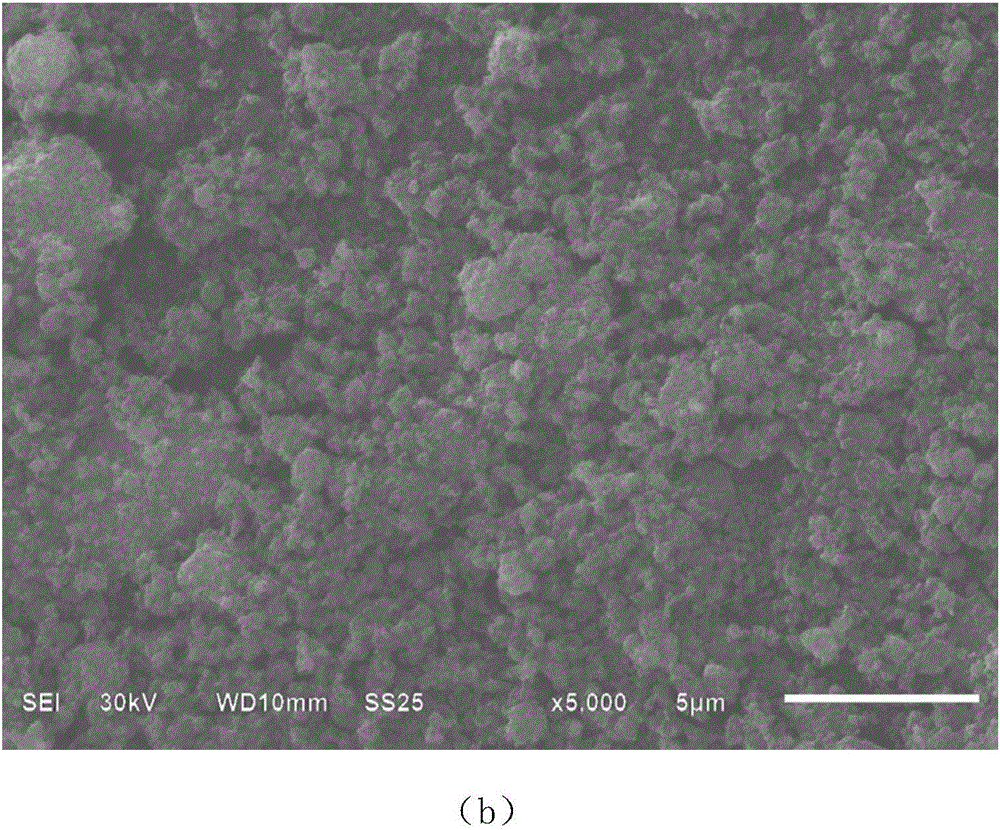

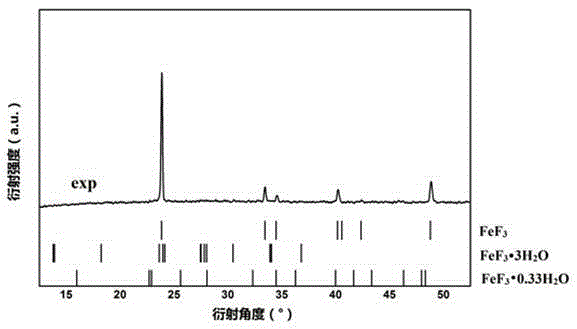

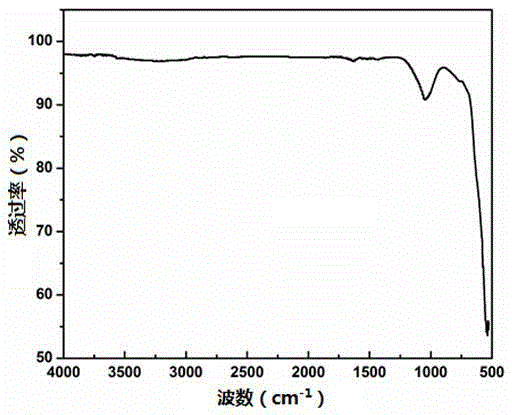

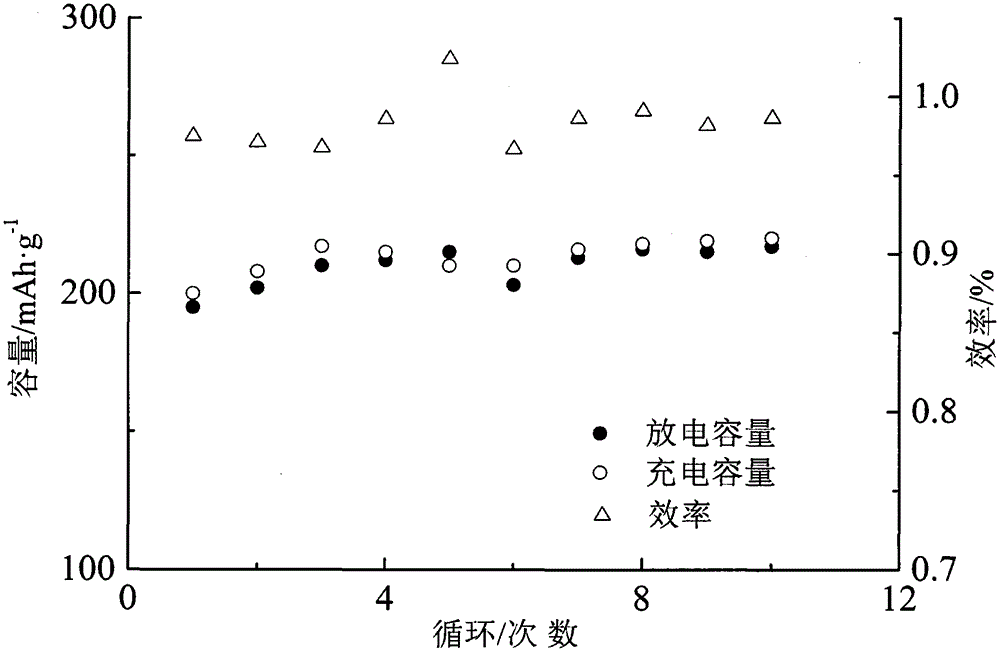

ActiveCN103151522AHigh yieldSmall particle sizeCell electrodesCubic crystal systemReaction temperature

The invention discloses a mixed crystal form ferric fluoride cathode material and a preparation method thereof. The chemical formula of the mixed crystal form ferric fluoride cathode material is (FeF3)x(FeF3.0.33H2O)y / C. The cathode material has the beneficial effects as follows: the product particle size can be optimized through controlling the reaction temperature and time, the obtained product purity is high, and a ferric fluoride preparation method is novel, simple and high in yield. The prepared ferric fluoride is in a mixed crystal form of a cubic system and an orthorhombic system, the ferric fluoride of the orthorhombic system is contributed to maintaining the stability of an FeF3 structure in processes of insertion / deinsertion of lithium ion, so that the cycling performance of the material is improved, and the ferric fluoride of the cubic system is contributed to improving the mass specific capability and thermal stability of the material. The (FeF3)x(FeF3.0.33H2O)y / C material prepared by the method has the advantages of small particle size, uniform distribution, good repeatability and excellent electrochemical performance.

Owner:XIANGTAN UNIV

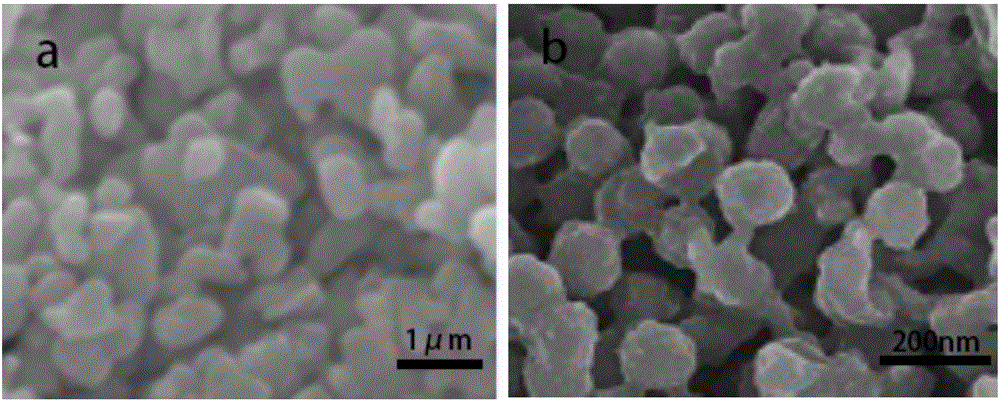

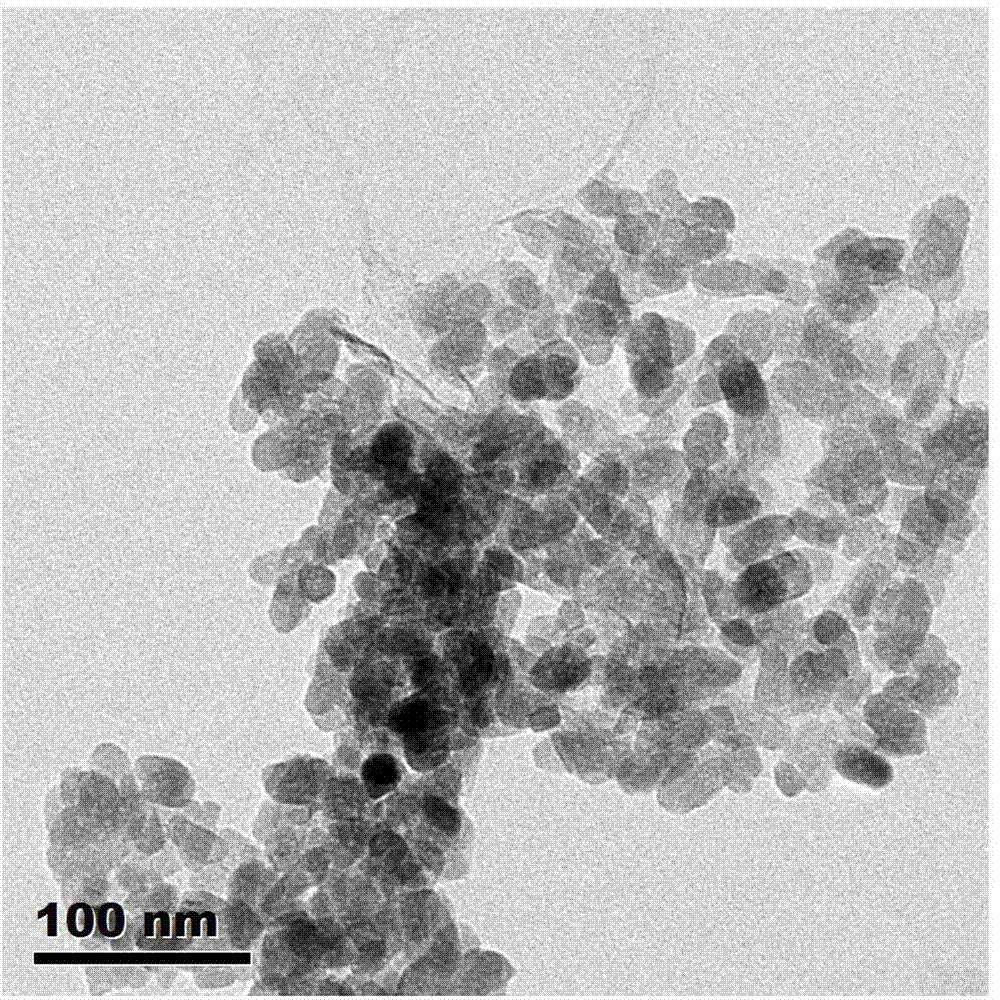

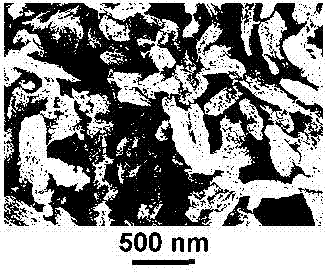

Ferric fluoride nano material and preparation method thereof

The invention discloses a ferric fluoride nano material and a preparation method thereof. The preparation method comprises the following steps of: dissolving inorganic ferric salt in an alcohol solvent to obtain alcohol solution containing iron; dispersing an inorganic fluorine source into the alcohol solution containing iron and adding the solution into a hydrothermal reaction kettle; carrying out the hydrothermal reaction kettle solution for 1 hour to 7 days at a temperature of 40 to 140 DEG C, naturally cooling, carrying out centrifugal separation, washing by ethanol and carrying out vacuum drying to obtain the ferric fluoride nano material. According to the preparation method of ferric fluoride, a volatile hydrofluoric acid fluorine source does not need to be used as a raw material, low-toxicity fluoride is used as the fluorine source, common ferric salt is used as a ferric source, the FeF3.0.33H2O nano material containing trace moisture is obtained by the simple solvent heat treatment, the preparation process is simple, the yield is high and the obtained material has high crystallinity. The method disclosed by the invention is a novel and practical process route for preparing the ferric fluoride nano material and has high actual application value.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

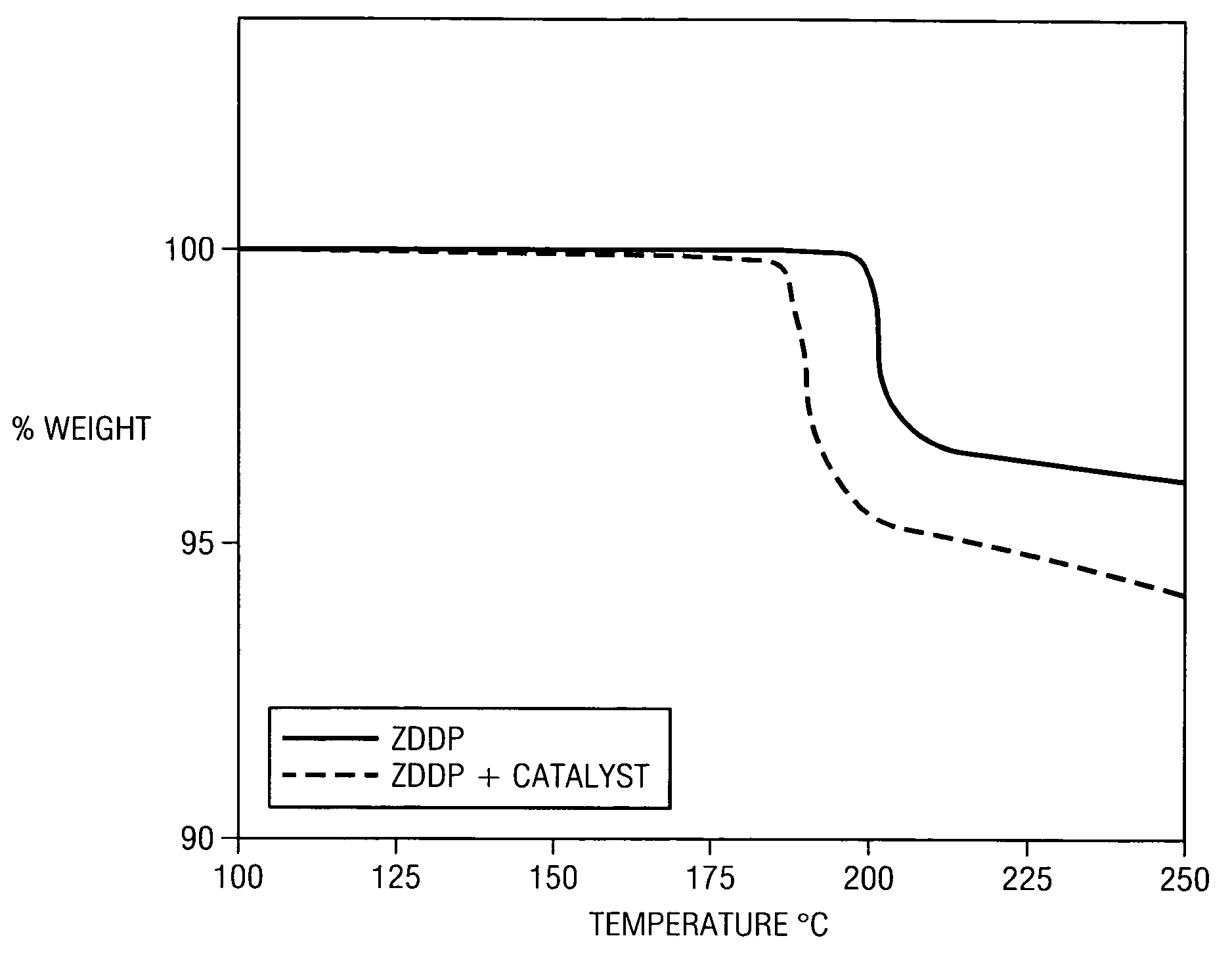

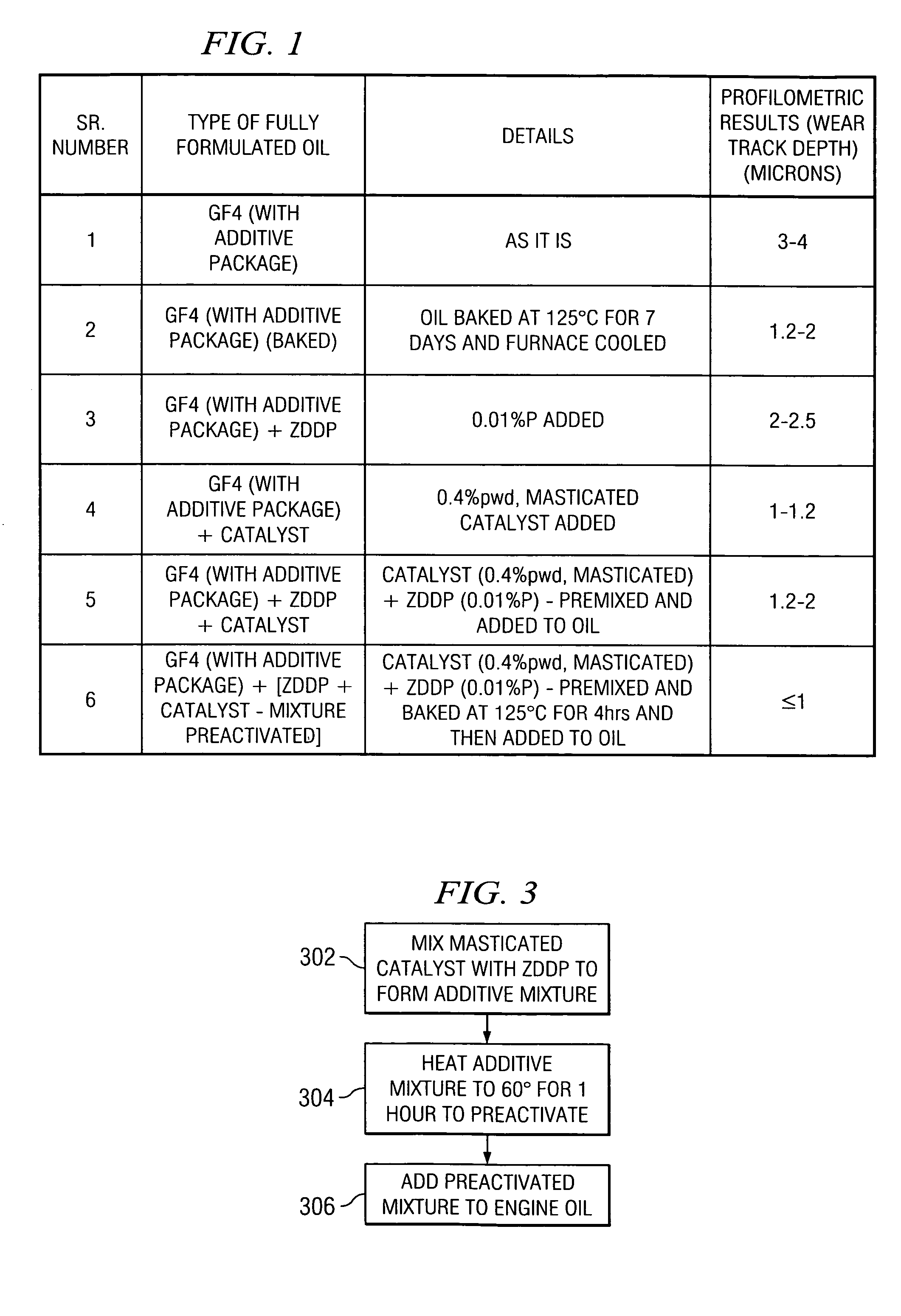

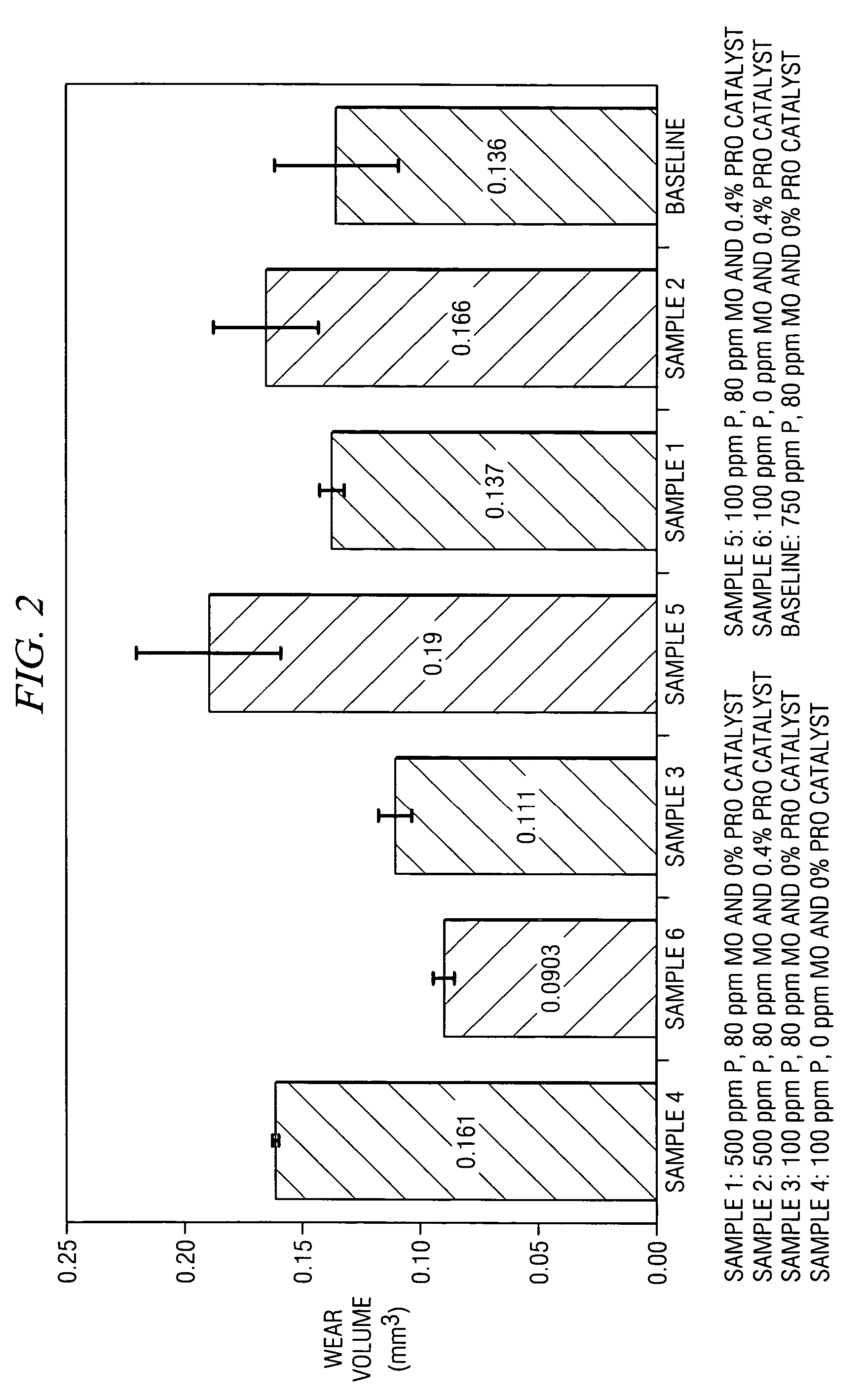

Engine oil additive

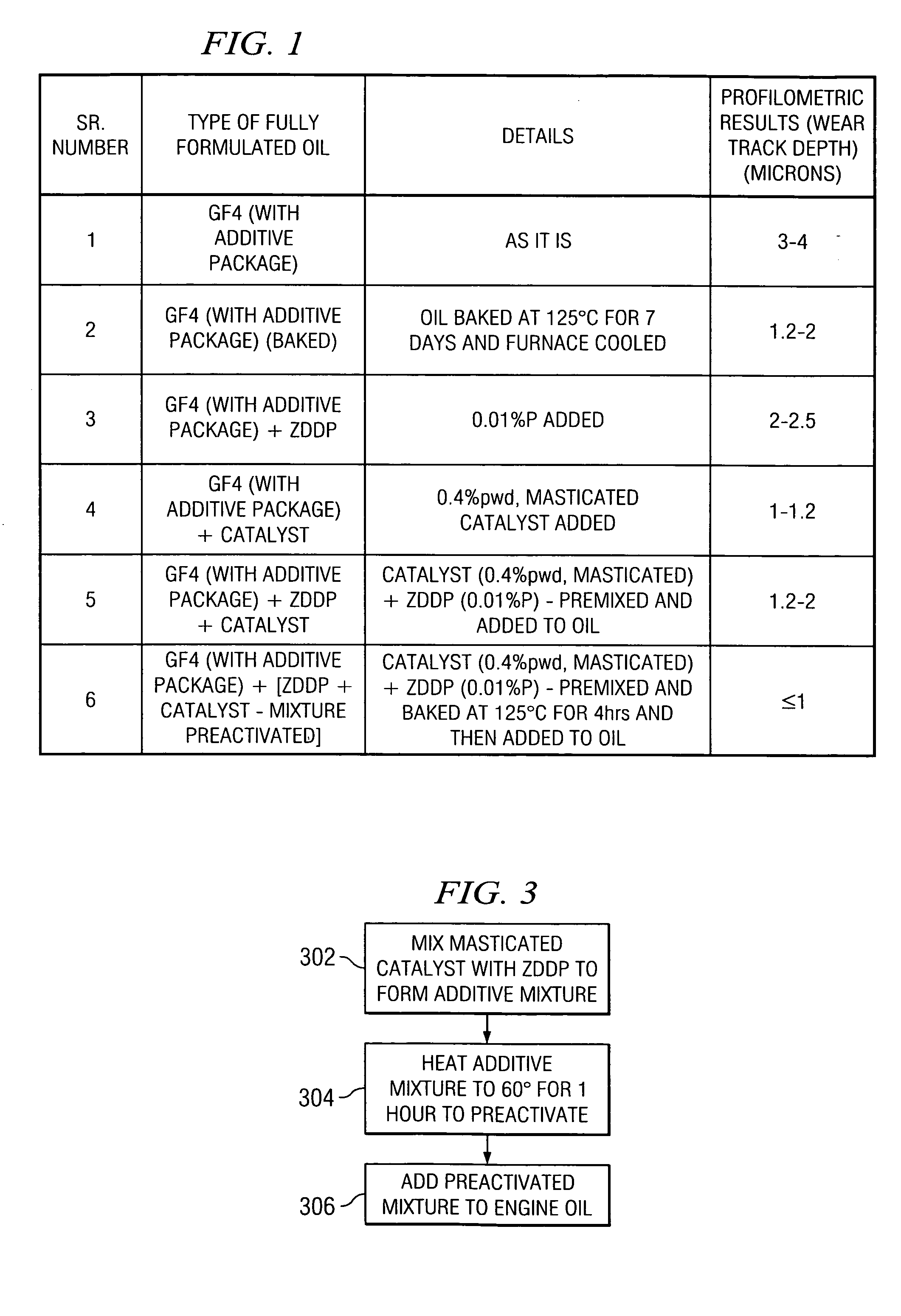

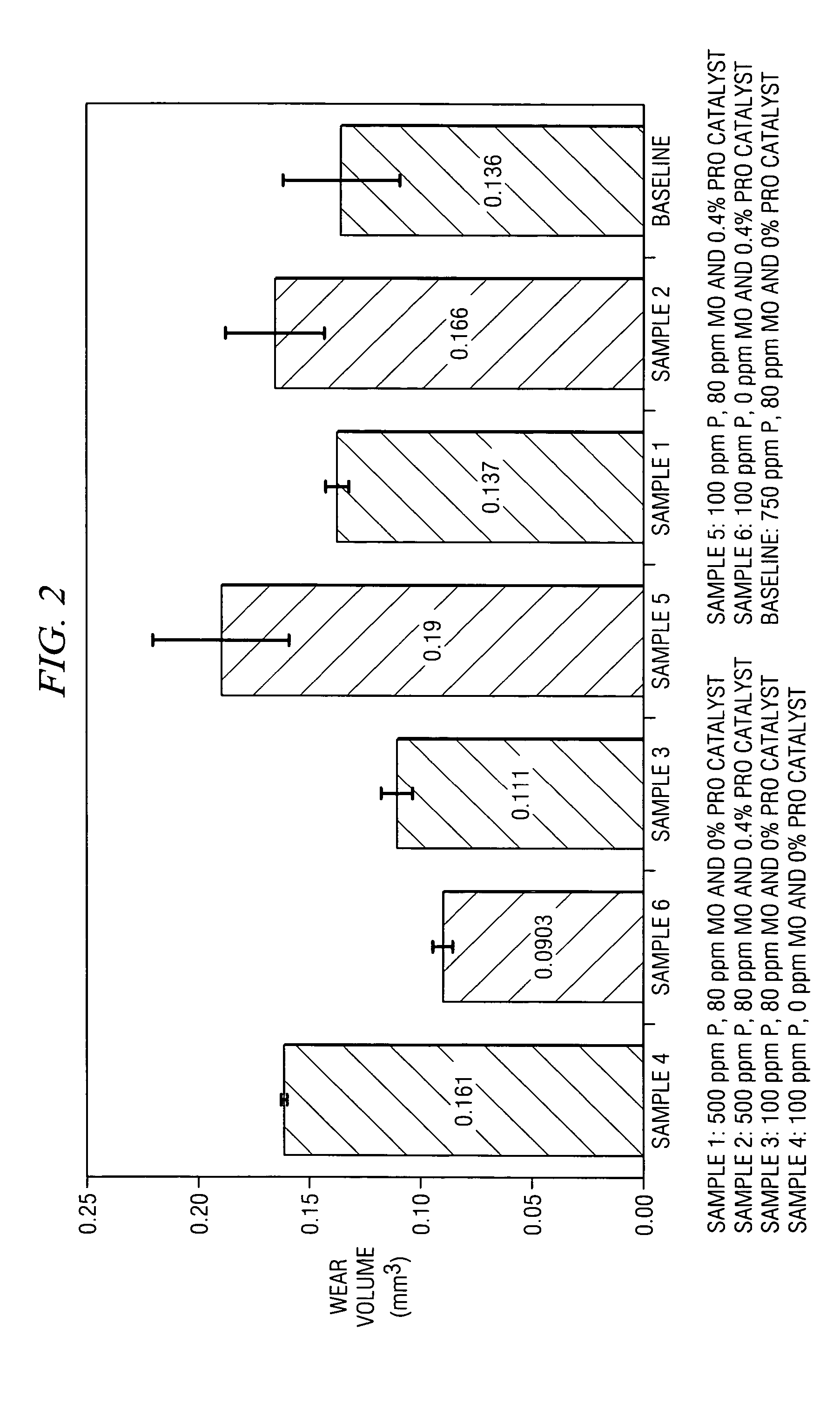

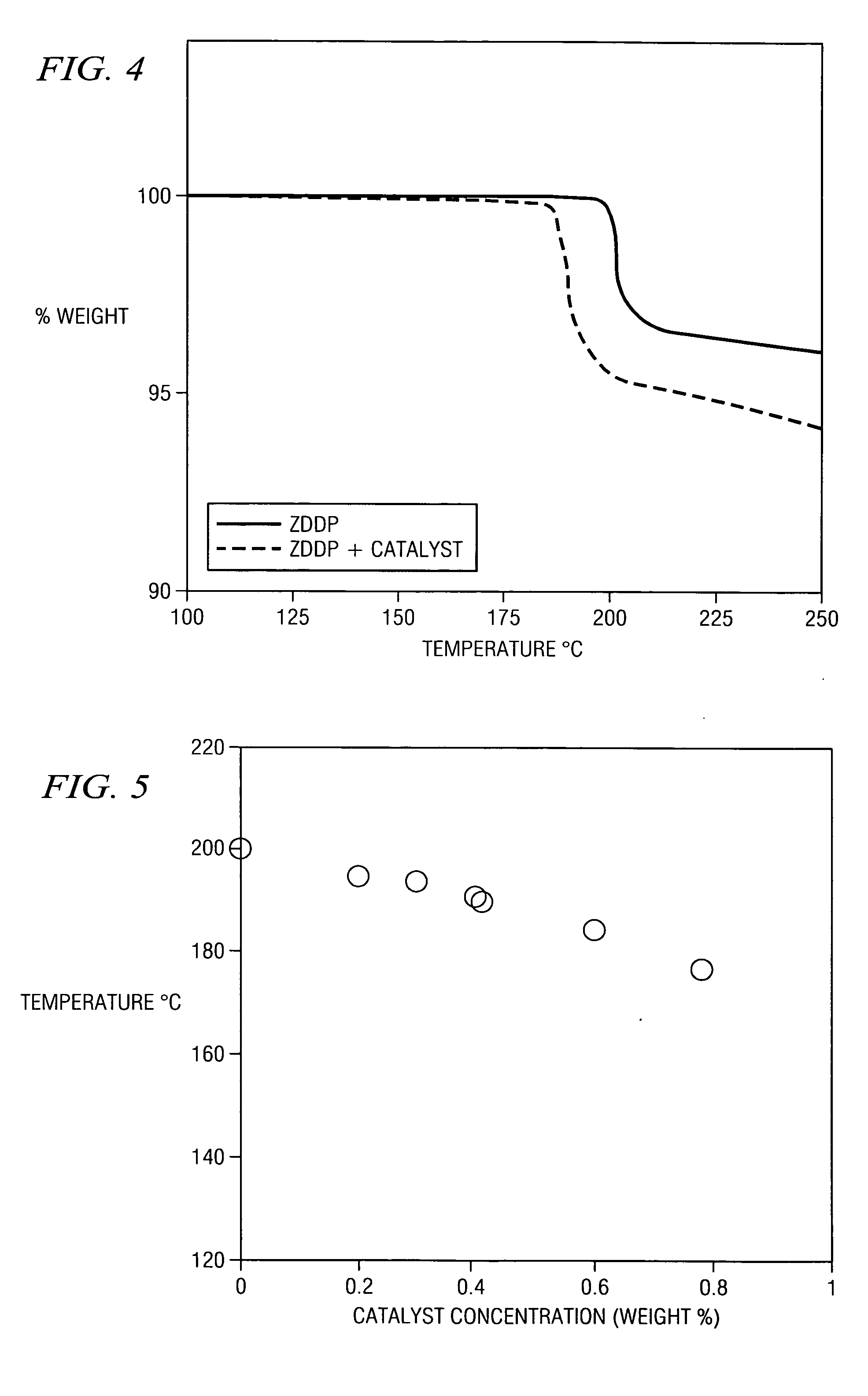

A process and method for manufacturing an improved engine oil comprising mixing ferric fluoride with ZDDP to form an additive mixture, heating the additive mixture to at least 125° C. for at least 4 hours to produce a pre-reacted mixture, and adding the pre-reacted mixture to a fully formulated engine oil not containing ZDDP. Also disclosed is an engine oil prepared by a process comprising mixing catalyst with ZDDP to form an additive mixture, heating the additive mixture to about 60° C. to produce a pre-reacted additive mixture, and adding the pre-reacted additive mixture to a fully formulated engine oil not containing ZDDP.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST +1

Preparation method of graphene-ferric fluoride composite cathode material

InactiveCN103199253AIncrease capacityExtended service lifeCell electrodesDoped grapheneComposite cathode

The invention relates to a preparation method of a graphene-ferric fluoride composite cathode material. The preparation method comprises the following steps of: (1) preparing cobalt-doped ferric fluoride powder; (2) preparing a silicon-doped graphite mixture; (3) mixing the cobalt-doped ferric fluoride powder with the silicon-doped graphite in a ball milling way, and thermally processing after ball milling, thus obtaining the graphene-ferric fluoride composite cathode material. The graphene-ferric fluoride composite cathode material for a lithium ion battery, prepared by the preparation method provided by the invention, has the advantages that a ferric fluoride material which has large discharge capacity is modified by doping cobalt, thus the conductivity is improved; then the ferric fluoride material is combined with a silicon-doped graphene material which has high conductivity and stability, therefore, the characteristics of large capacity and high circulating stability are provided; and as a result, the composite material is relatively large in capacity and relatively long in service life while being applied to the lithium ion battery.

Owner:NANTONG CHENGGUANG GRAPHITE EQUIP

Polymer carbonized in-situ coated ferric fluoride composite positive electrode material and preparation method thereof

ActiveCN106058222AEffective growth controlEasy to controlCell electrodesSecondary cellsLithiumCarbonization

The invention relates to the field of lithium secondary battery positive electrode material, and discloses a polymer carbonized in-situ coated ferric fluoride composite positive electrode material, and a preparation method and an application thereof. The mass ratio of ferric fluoride and carbon in the polymer carbonized in-situ coated ferric fluoride composite positive electrode material is 1:9 to 1:15, and the particle size is 60-120 mm; the composite positive electrode material is prepared by high temperature carbonization of the polymer coating the surface of the ferric fluoride for direct in-situ coating, wherein the polymer is polythiophene, poly(p-xylylenediamine) or polyaniline. The composite positive electrode material disclosed by the invention has the advantages of good rate performance, cycle performance, charge / discharge specific capacity, electronic ionic conductivity and the like; the preparation method disclosed by the invention is simple in steps, low in production cost, and favorable to popularization and application.

Owner:GUANGDONG UNIV OF TECH

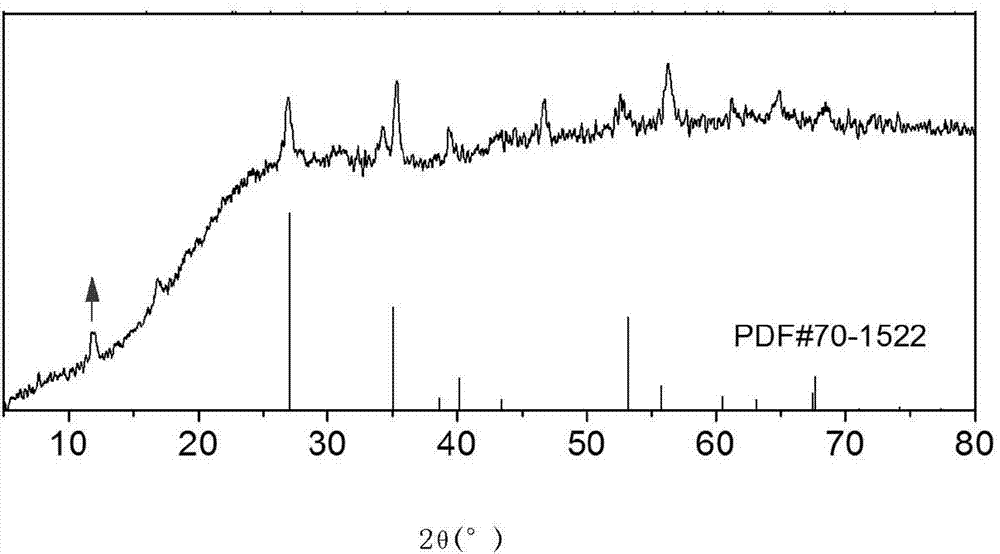

Preparation of nano-ferric fluoride and application of nano-ferric fluoride to positive electrode of high-specific-capacity lithium ion battery

InactiveCN105680043AImprove electrochemical performanceEasy to operateMaterial nanotechnologyCell electrodesWhite powderElectrochemistry

The invention relates to preparation of nano-ferric fluoride and an application of the nano-ferric fluoride to a positive electrode of a high-specific-capacity lithium ion battery. A preparation method of the nano-ferric fluoride comprises the following steps: preparing a Fe(NO<3>)<3>.9H<2>O ethanol solution, and obtaining a colorless transparent solution under an ultrasonic action; preparing a deionized water solution of NH<4>HF<2>; mixing the solutions to obtain (NH<4>)<3>FeF<6> white precipitate; performing centrifugal separation on the white precipitate, cleaning the centrifugally-separated white precipitate and drying the cleaned white precipitate to obtain (NH<4>)<3>FeF<6> white powder; and calcining the (NH<4>)<3>FeF<6> white powder to obtain a FeF<3> nanometer material. A positive electrode of a high-specific-power lithium ion battery is prepared from the FeF<3> nanometer material. The preparation method has the advantages of easiness in operation, low cost, high yield, simple posttreatment, no need of any special reaction instrument and low preparation cost. FeF3 nanometer materials of different grain sizes can be obtained in a way of easily regulating and controlling a volume ratio of ethanol to deionized water. The electrode has superior electrochemical performance in the lithium ion battery.

Owner:TIANJIN UNIV

Composite positive electrode material and preparation method thereof

The invention provides a composite positive electrode material. The composite positive electrode material is a graphene-FeOF composite material, and comprises FeOF particles and graphene which are combined by virtue of chemical bonds. The invention further provides a preparation method of the composite positive electrode material. The preparation method comprises the following steps: uniformly mixing ferric fluoride and graphene oxide in a liquid-phase solvent to form a solid-liquid mixture; performing hydrothermal / solvothermal reaction on the solid-liquid mixture in a hydrothermal / solvothermal reaction kettle at the temperature of 80-250 DEG C.

Owner:JIANGSU HUADONG INST OF LI ION BATTERY +1

Method for preparing graphite fluoride at low temperature

The invention discloses a method for preparing graphite fluoride at low temperature. The method comprises the following steps: using ferric fluoride as a catalyst, and performing reaction of crystalline flake graphite and bromine trifluoride at low temperature to generate a graphite intercalation compound; then, performing reaction of potassium manganese hexafluoride and antimony pentafluoride to generate fluorine; and performing reaction of the fluorine generated and the graphite intercalation compound to form the graphite fluoride with high fluorine content. Through purifying treatment by a solvent, the prepared graphite fluoride is high in purity.

Owner:东莞市致格电池科技有限公司

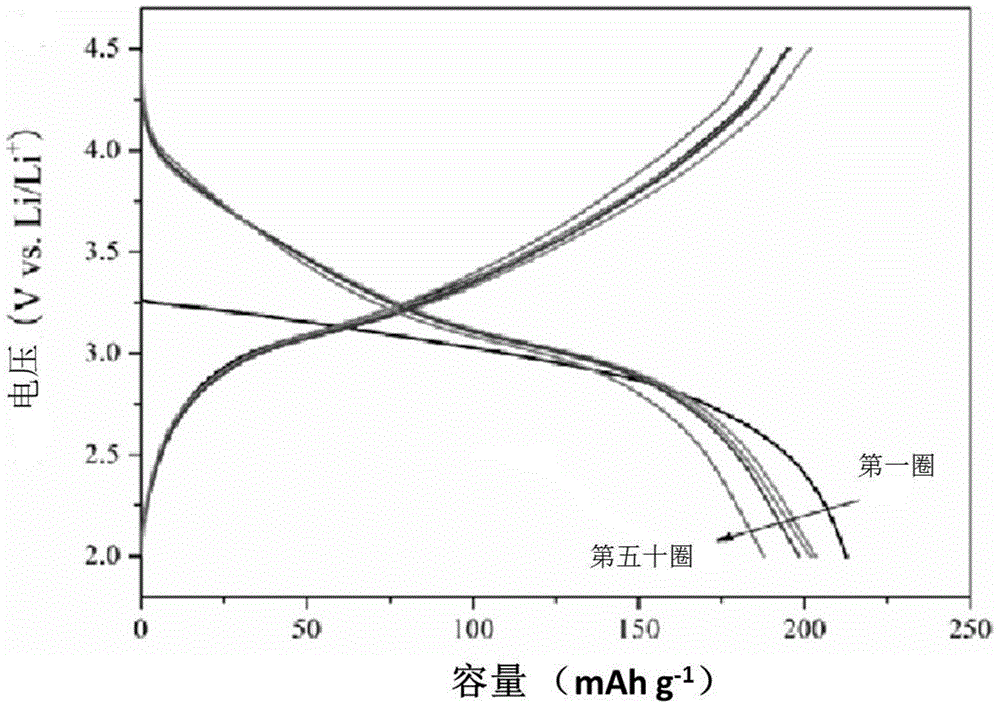

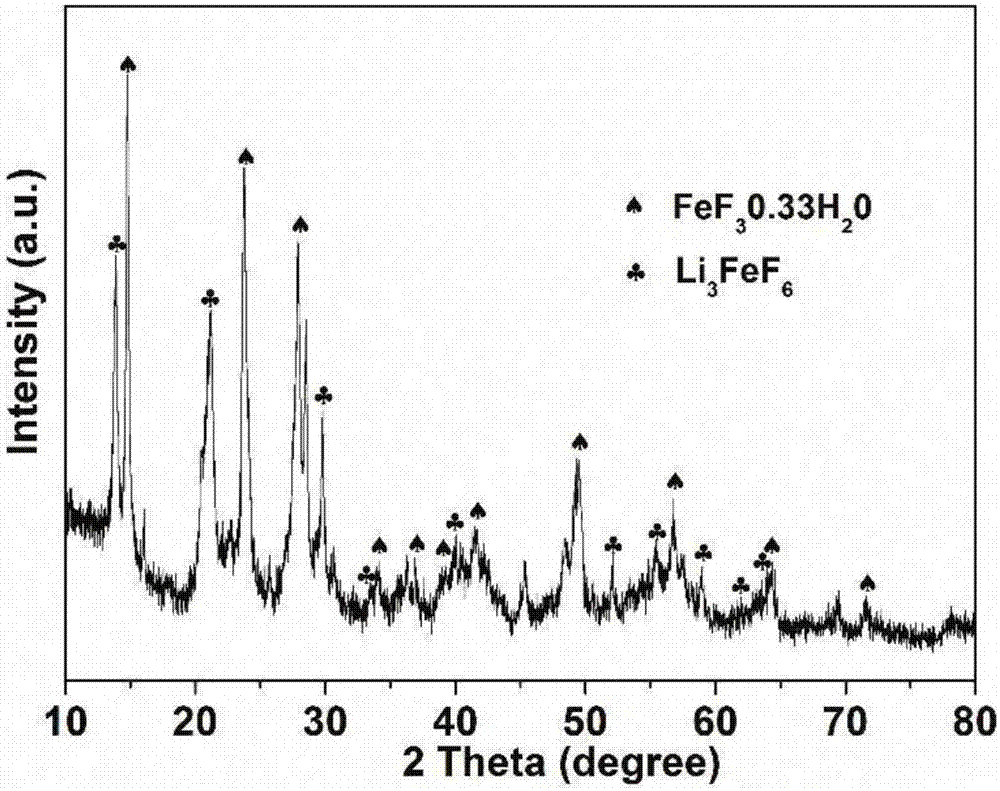

Ferric fluoride/lithium hexafluoroferrate composite positive material and application thereof

ActiveCN107240685AGood electrical propertiesReduce lossesCell electrodesSecondary cellsCyclic processCapacity loss

The invention provides a ferric fluoride / lithium hexafluoroferrate composite positive material, and the composite positive material consists of ferric fluoride and a lithium hexafluoroferrate layer on the surface of the ferric fluoride. The invention also provides a preparation method of the ferric fluoride / lithium hexafluoroferrate composite positive material. The preparation method comprises the following steps: mixing ferric fluoride powder, inorganic lithium salt and an organic solvent together, continuously stirring for a certain period of time, and carrying out low-temperature treatment so that the ferric fluoride / lithium hexafluoroferrate composite positive material can be obtained. For the problems such as the loss of active substances in the ferric fluoride occurring in the charging and discharging process and side reactions occurring when the ferric fluoride is directly in contact with an electrolyte, the surface of ferric fluoride particles is converted into the lithium hexafluoroferrate layer in the organic solvent in situ, so that the protective layer can effectively reduce the capacity loss of the ferric fluoride in the cycling process, and the cycling stability of the positive material is strengthened; and moreover, the method provided by the invention is simple in preparation process and relatively low in cost, and is beneficial for industrial production.

Owner:CENT SOUTH UNIV

Surface modified ferric fluoride cathode material containing three components, such as carbon-based solid acid, aluminium zirconium coupling agent and doped titanium lithium phosphate, and preparation method thereof

ActiveCN103700814ARich in active sitesImprove ionic conductivityCell electrodesSolid acidActive point

The invention provides a preparation method of surface modified ferric fluoride cathode material containing three components, such as carbon-based solid acid, aluminium zirconium coupling agent and doped titanium lithium phosphate. The preparation method is as follows: sulfonated carbon-based solid acid, aluminium zirconium coupling agent, silicon and aluminium doped titanium lithium phosphate Li1.3A10.1Ti1.9Si0.2P2.8O12 and synthetic raw materials are added into a bowl mill for ball milling for a period of time and are subjected to heat treatment. Electronic good conductor sulfonated carbon-based solid acid is coordinated with FeF3 iron ion by sulfonic group, and firm combination is good for forming a complete electronic conductive link; many alkyloxy of the aluminium zirconium bimetallic coupling agent with many active point locations are hydrolyzed into hydroxyl, thereby the aluminium zirconium bimetallic coupling agent is bonded with lithium ion good conductor Li1.3A10.1Ti1.9Si0.2P2.8O12 and is bonded with sulfonic group in sulfonated carbon-based solid acid by polycondensation; simultaneously zirconium is an electron acceptor, and can coordinate with fluorinion in the surface of the FeF3 particles, so the electron conductive agent sulfonated carbon-based solid acid and the lithium ion conductive agent Li1.3A10.1Ti1.9Si0.2P2.8O12 are bonded in the surface of the FeF3 particle, and a complete electron and ion conductive link is formed, thereby improving ion conductivity and electron conductivity of FeF3 material, and improving electrochemistry performance of the material.

Owner:沛县度创科技发展有限公司

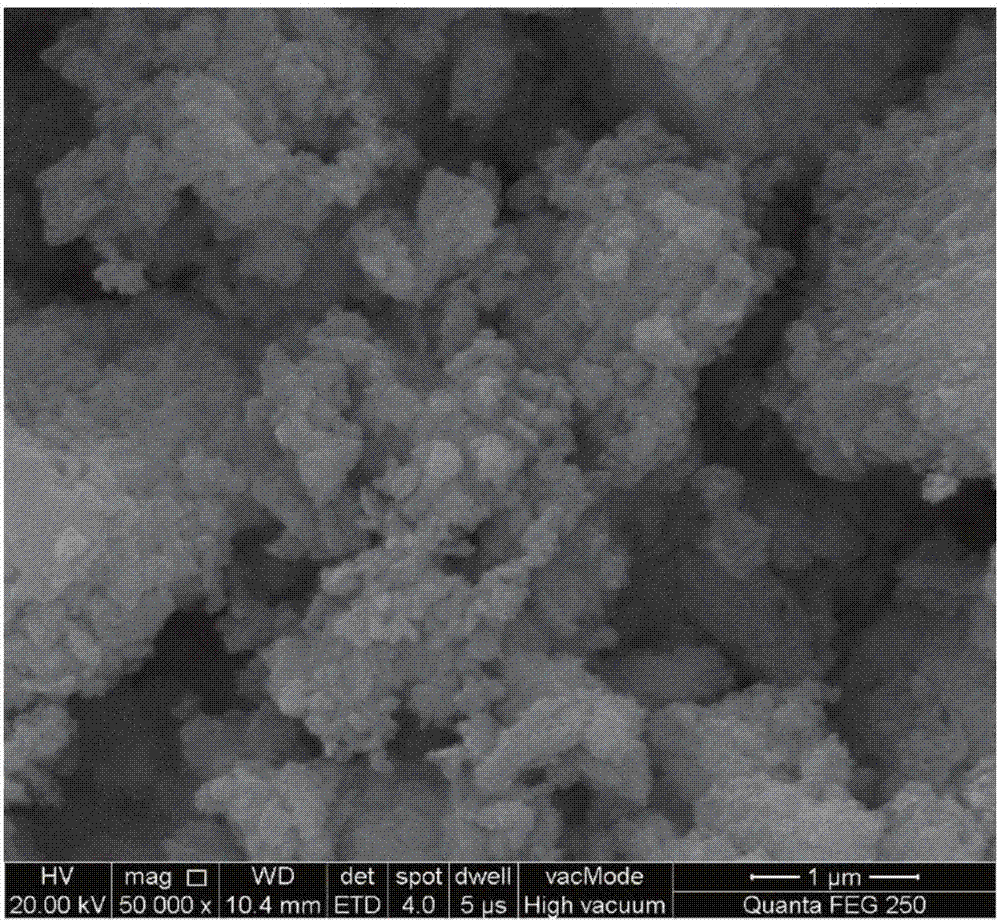

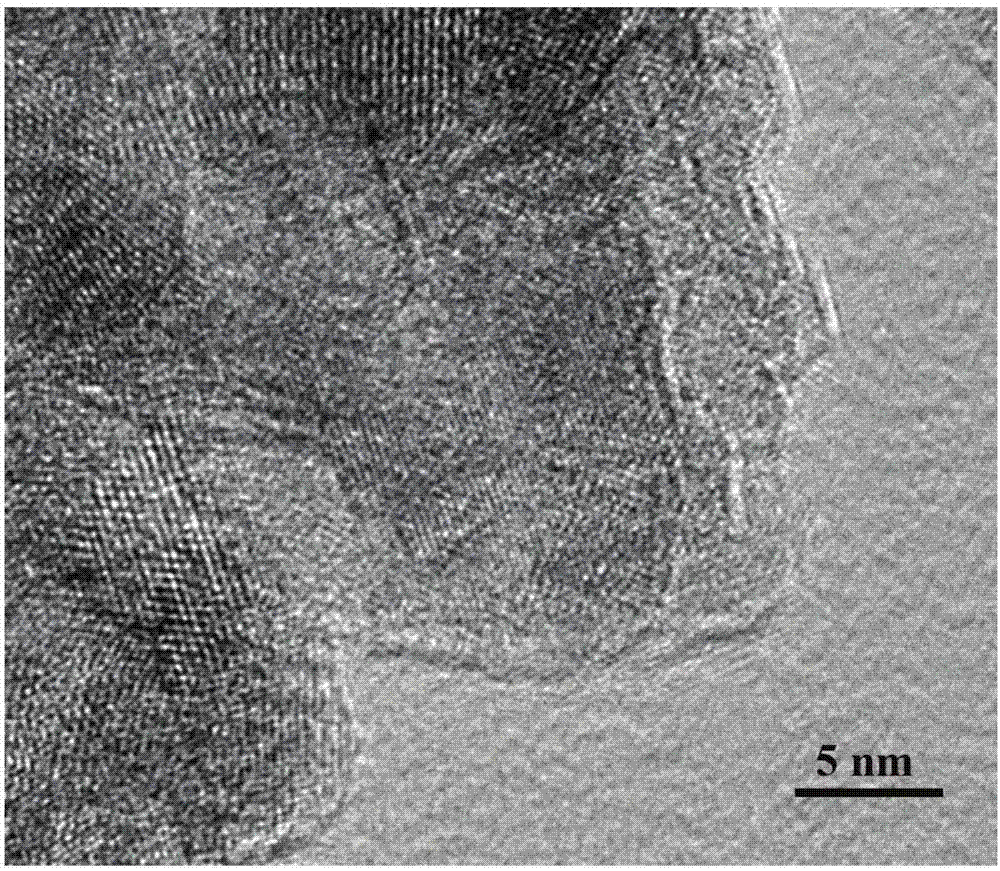

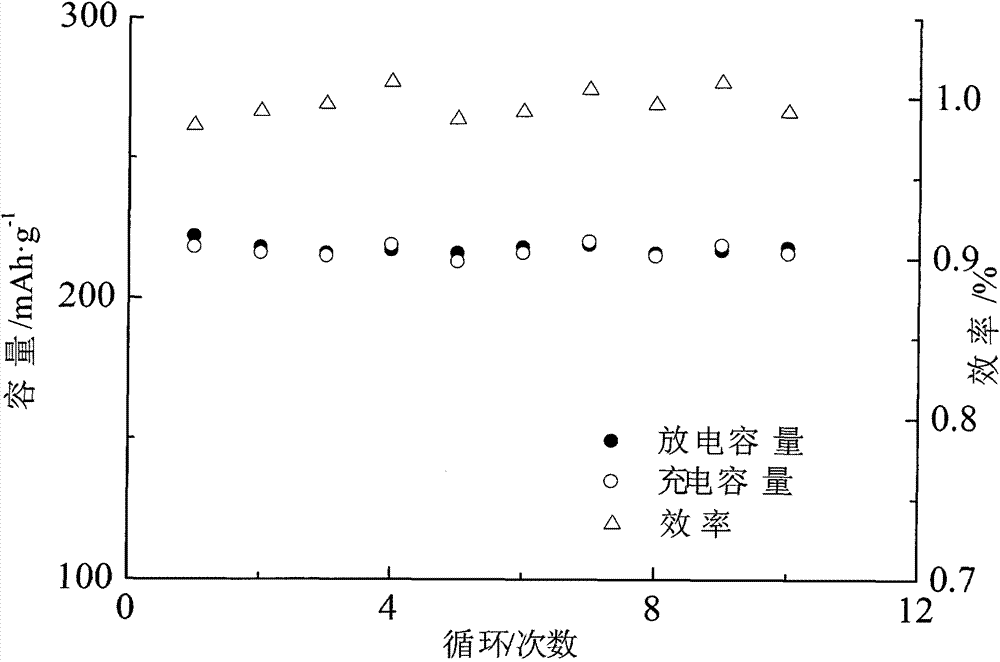

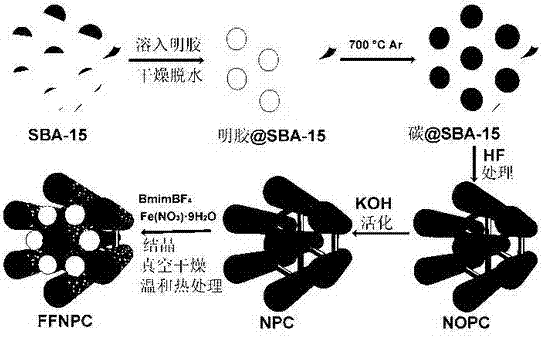

Nitrogen-doped porous carbon-loaded iron-based fluoride three-dimensional nanometer anode material for lithium ion battery and preparation method thereof

InactiveCN107275604AImprove conductivityHigh reversible capacityMaterial nanotechnologyCell electrodesPorous carbonReaction temperature

The invention discloses a nitrogen-doped porous carbon-loaded iron-based fluoride three-dimensional nanometer anode material for a lithium ion battery and a preparation method thereof. The material includes nitrogen-doped porous carbon-coated ferric fluoride. The nitrogen-doped porous carbon coating is in situ performed on the surface of the ferric fluoride. The method comprises the following steps: utilizing an ionic liquid of fluoborate as a fluorine source, ferric salt soluble in alcohol as a ferric source and ethyl alcohol as a dispersing agent; dispersing the prepared nitrogen-doped porous carbon into an ethyl alcohol solution and fully dispersing; adding the ferric source, ultrasonically stirring, adding the fluorine source drop by drop and continuously stirring; after completely dropwise adding, controlling a certain reaction temperature and continuously stirring; centrifugally cleaning and drying; performing thermal treatment under low temperature, thereby acquiring a final material. The prepared nanometer composite material has a special morphological structure and an excellent electrochemical performance.

Owner:SICHUAN UNIV

Ferric fluoride/conducting polymer composite material, preparation method thereof and lithium secondary battery

InactiveCN105977448AImprove stabilityIncrease capacityCell electrodesSecondary cellsPolymer scienceIn situ polymerization

The invention provides a ferric fluoride / conducting polymer composite material. The ferric fluoride / conducting polymer composite material comprises ferric fluoride and a conducting polymer compounded to the surface of ferric fluoride. The invention further provides a preparation method of the ferric fluoride / conducting polymer composite material. The preparation method comprises the step of mixing ferric fluoride powder, a ferric trichloride solution, conducting polymer monomers, an anionic surfactant and an organic solvent to react, so as to obtain the ferric fluoride / conducting polymer composite material. Aiming at the problems that ferric trichloride has over-low electronic conductivity and expands along the polarization in charging and discharging processes, ferric trifluoride nanoparticles are coated with the conducting polymer by virtue of in situ polymerization and compounding, so that the polarization phenomenon of a ferric trifluoride material in the charging and discharging processes can be effectively overcome, the stability and capacity of the cathode material can be enhanced, meanwhile, the problem that the conductivity of a ferric trifluoride cathode material is too low can be well solved, and therefore, the electrochemical performance of the ferric trifluoride cathode material is improved.

Owner:GUANGDONG UNIV OF TECH

Lithium/fluorinated carbon nanotube battery and preparation method thereof

ActiveCN107611403AImprove conductivityGuaranteed electrical conductivityCell electrodesOrganic electrolyte cellsHigh rateInternal resistance

The invention relates to the technical field of batteries, in particular to a novel lithium / fluorinated carbon nanotube battery and a preparation method thereof. The formula of a positive electrode material of the battery comprises the components by percentages: an outer-wall fluorinated multi-walled carbon nanotube containing a ferric fluoride intercalation material, 2-10% of a conductive agent of manganese dioxide composite graphene and 6-8% of a binder, wherein a negative electrode of the battery is lithium. By using the conductive agent of the manganese dioxide composite graphene, the electronic conductivity of the positive electrode material is improved. Meanwhile, by using the outer-wall fluorinated multi-walled carbon nanotube containing the ferric fluoride intercalation material, the internal resistances is reduced while the capacity of the electrode is improved, the polarization phenomenon is reduced and the discharge capability of the battery is improved. Therefore, a primarybattery with relatively high capacity and high rate capability can be provided and has good industrial and commercial value.

Owner:LIAONING LANJING TECH CO LTD

Preparation method of titanium-doping ferric fluoride positive electrode material

InactiveCN106450179AThe synthesis process is simpleWide applicabilityCell electrodesSecondary cellsIron saltsHigh energy

The invention discloses a preparation method of a titanium-doping ferric fluoride positive electrode material. The general formula of the material is Fe<(1-x)>Ti<x>F<3>.0.33H<2>O / C, wherein x is more than or equal to 0.01 but less than or equal to 0.50. The material is obtained by the steps of dissolving a titanium salt and an iron salt, depositing a hydroxide, introducing fluorine ions to a hydrogen fluoride solution, performing deposition, dissolving and evaporation of the hydroxide to obtain a powder material, dehydrating the powder material, performing high-energy ball milling of a carbon material and performing processing. The Fe<(1-x)>Ti<x>F<3>.0.33H<2>O / C positive electrode material prepared according to the method has a complete orthorhombic crystal system, is relatively small in grain size, uniform in element distribution and good in charge / discharge performance, and has relatively high discharge specific capacity, excellent cycle performance and favorable rate performance, and the problem of poor cycle and rate performance of an existing FeF<3>.0.33H<2>O material is solved. The involved raw material is low in cost, the preparation process is simple, the preparation period is relatively short, and the preparation method has a good application prospect.

Owner:XIANGTAN UNIV

Preparation method of ferric fluoride cathode material for lithium ion battery

ActiveCN105336946AHigh purityUniform particle sizeCell electrodesSecondary cellsDispersityIron salts

The invention discloses a preparation method of a ferric fluoride cathode material for a lithium ion battery. The preparation method comprises the steps: firstly, putting a trivalent iron salt into a drying oven, drying, then mixing the dried raw material with a right amount of a high-activity fluorine source, then adding into a polytetrafluoroethylene reaction kettle, carrying out an acid thermal reaction, washing with water, filtering, and drying to obtain the target product ferric fluoride. The prepared ferric fluoride has high purity and uniform particle size; the particle size can be controlled through adjusting process conditions, and the prepared product has good dispersity. The preparation method has the advantages of mild synthetic conditions, simple process, simple and convenient operation, short period, high efficiency, low requirements on equipment and easy industrialized mass production of the high-purity ferric fluoride material containing hydroxyl (or water).

Owner:中国船舶重工集团公司第七一二研究所

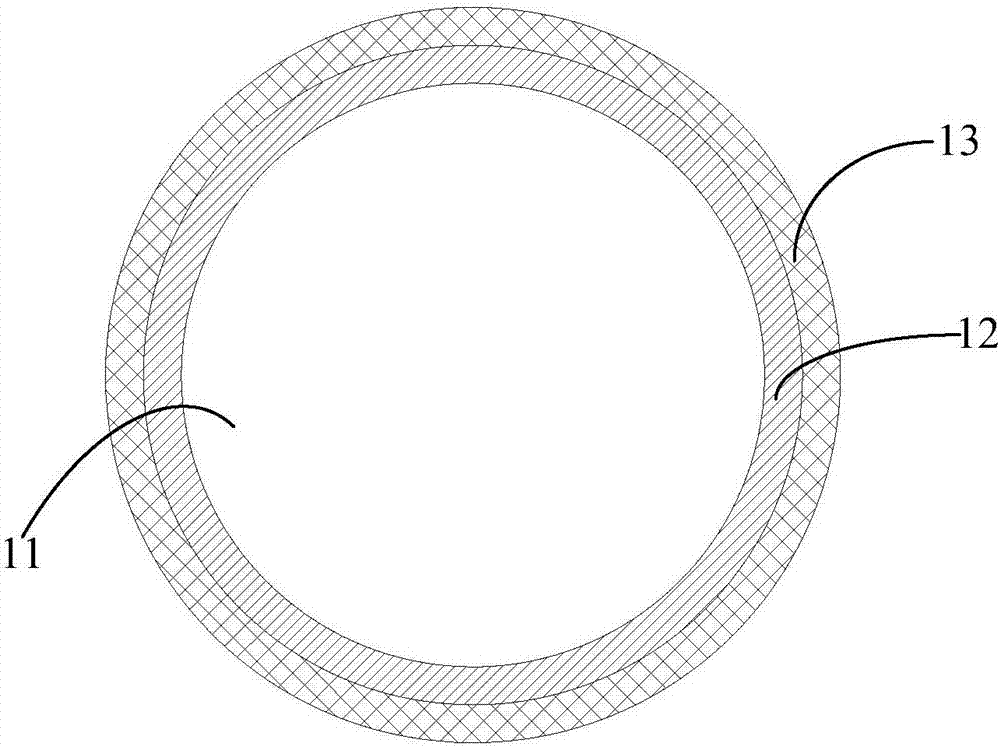

Modified lithium nickel manganese oxide positive pole composite material, preparation method and lithium ion battery

ActiveCN107146881AUnique multiple electron effectHigh charge and discharge capacityCell electrodesSecondary cellsManganese oxideGraphene

The invention provides a modified lithium nickel manganese oxide positive pole composite material. The modified lithium nickel manganese oxide positive pole composite material comprises lithium nickel manganese oxide particles, ferric fluoride layers coated on the surfaces of the lithium nickel manganese oxide particles and graphene layers coated on the ferric fluoride layers. The modified lithium nickel manganese oxide positive pole composite material provided by the invention has relatively high charging and discharging specific capacity, and has better cycle performance. The invention also provides a preparation method of the modified lithium nickel manganese oxide positive pole composite material and a lithium ion battery using the modified lithium nickel manganese oxide positive pole composite material.

Owner:深圳市集创云天新材料有限公司

Cu<2+>, Co<2+>, Zr<4+> and Ag+ doped ferric fluoride composite anode material and preparation method

ActiveCN104157836AHigh lithium ion conductivityHigh specific capacityCell electrodesSecondary cellsHigh energyBall mill

The invention relates to a Cu<2+>, Co<2+>, Zr<4+> and Ag<+> doped modified ferric fluoride anode material and a preparation method. The method is characterized in that copper salt, cobalt salt, zircon salt, silver salt and synthetic raw materials are ball milled for a period of time in a high-energy ball mill and thermally treated to obtain the FeF3 anode material. Cu<2+> partially occupies coordination of iron ions of FeF3, so that the discharge potential can be increased, and the energy density can be improved; by virtue of Co<2+> doping, the electrical conductivity of lithium ions of the material can be increased; by virtue of high-valent Zr<4+> doping, the size of a lithium ion passage can be fine tuned while the specific capacity of the material is improved; by virtue of Ag<+> doping, the conversion reaction activation energy in charging can be reduced; accordingly, the multiplying power characteristics and energy density of the anode material can be improved, so that the comprehensive electrochemical performance of the anode material can be improved.

Owner:求法问律(菏泽)法律咨询服务有限公司

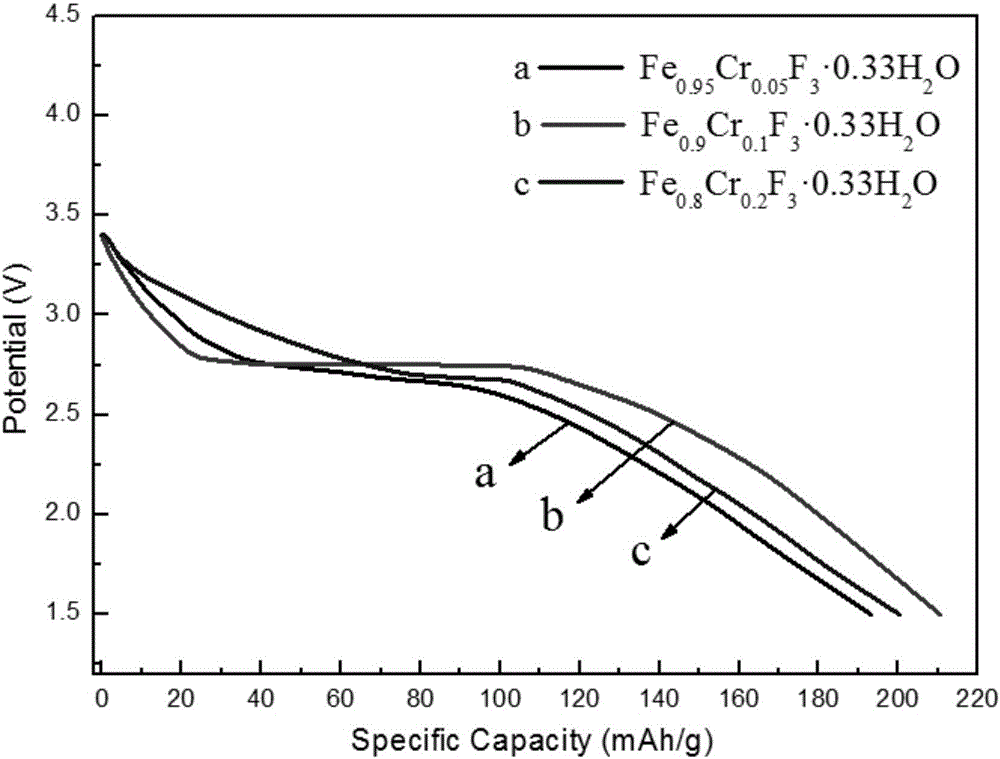

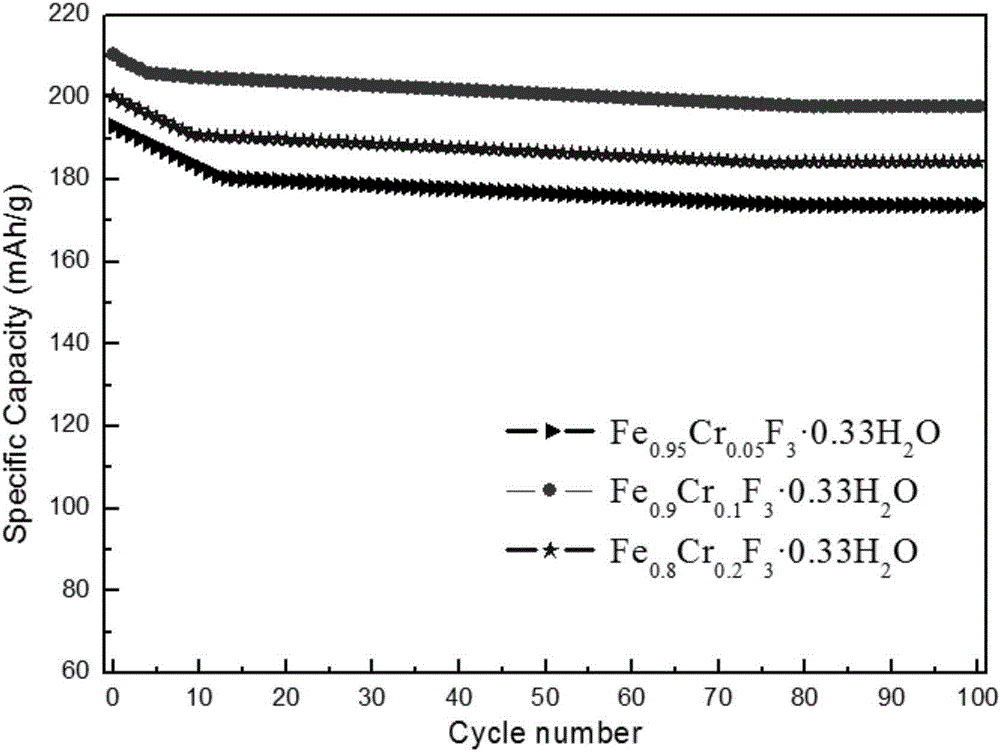

Modified ferric fluoride nano-composite anode material and preparing method and application thereof

ActiveCN106099074AImprove conductivityImprove diffusion abilityMaterial nanotechnologyCell electrodesPhysical chemistrySpecific discharge

The invention relates to the field of battery anode materials and discloses a modified ferric fluoride nano-composite anode material and a preparing method and application thereof. The modified ferric fluoride nano-composite anode material is prepared from a molysite alcohol solution, a villiaumite alcohol solution and chromic salt. The preparing method of the modified ferric fluoride nano-composite anode material comprises the following steps that firstly, the molysite alcohol solution is prepared; secondly, the villiaumite alcohol solution is prepared; third, the molysite alcohol solution and the villiaumite alcohol solution are mixed; fourthly, chromic salt is added, centrifuging is carried out after a mixing and stirring reaction, and precipitate is obtained and washed and centrifuged with absolute ethyl alcohol; fifthly, high-temperature drying is carried out, then a high-temperature reaction is carried out under the protection of inert gas, cooling is carried out, and the product is obtained. The modified ferric fluoride nano-composite anode material is high in specific discharge capacity, multiplying power and circulation stability. The preparing method of the modified ferric fluoride nano-composite anode material is simple in process, low in cost and beneficial to industrial production.

Owner:深圳鑫茂新能源技术股份有限公司

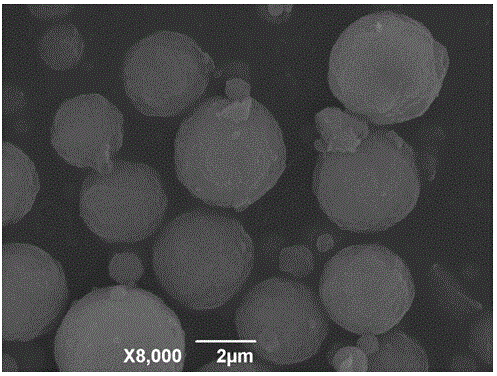

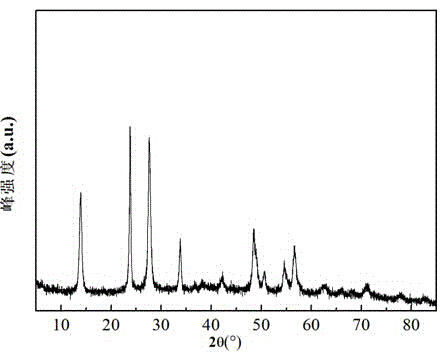

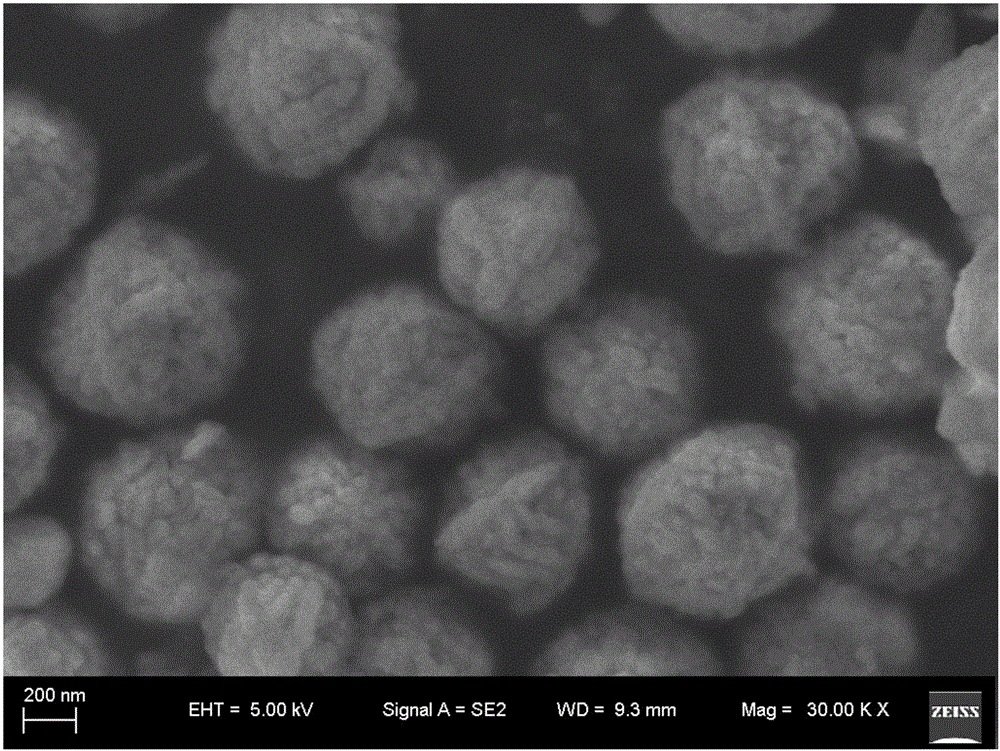

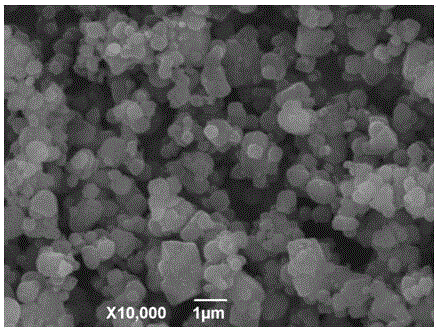

Micron-scale spheroidal ferric fluoride positive electrode material and preparation method thereof

The invention specifically relates to a micron-scale spheroidal ferric fluoride positive electrode material and a preparation method thereof. The micron-scale spheroidal ferric fluoride positive electrode material is prepared from a water / alcohol mixed solution of a ferric salt and a fluorine-containing aqueous solution. The preparation method is performed at a normal temperature and under a normal pressure, the preparation process is simple, the consuming time is short, the energy consumption is low, the cost is low, the environment-friendly effect is achieved, and the industrial production can be realized easily; the prepared FeF3(H2O)0.33 particles are spheroidal at the micron scale; the tap density of the material is improved; the material has excellent mobility, dispersibility and machinability, and is applicable to producing a positive electrode material slurry and coating an electrode plate; meanwhile, the material has a one-dimensional tunnel structure and is beneficial to the migration of lithium ions, so that the electrical conductivity of the material can be improved; in addition, the stability of the FeF3 structure is maintained in the charging / discharging process by use of little crystal water, and therefore, good electrochemical properties can be realized.

Owner:SHANDONG YUHUANG NEW ENERGY TECH +1

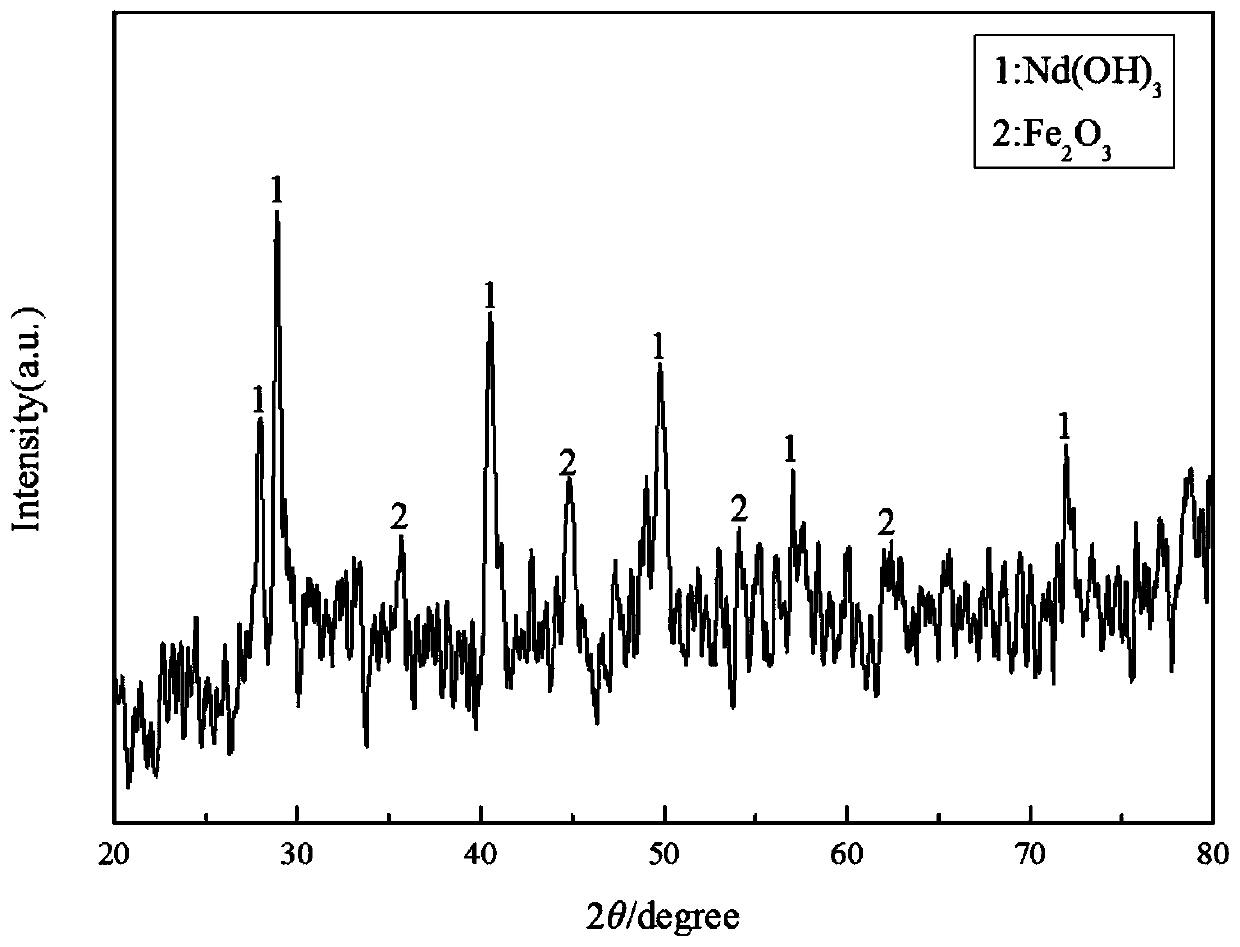

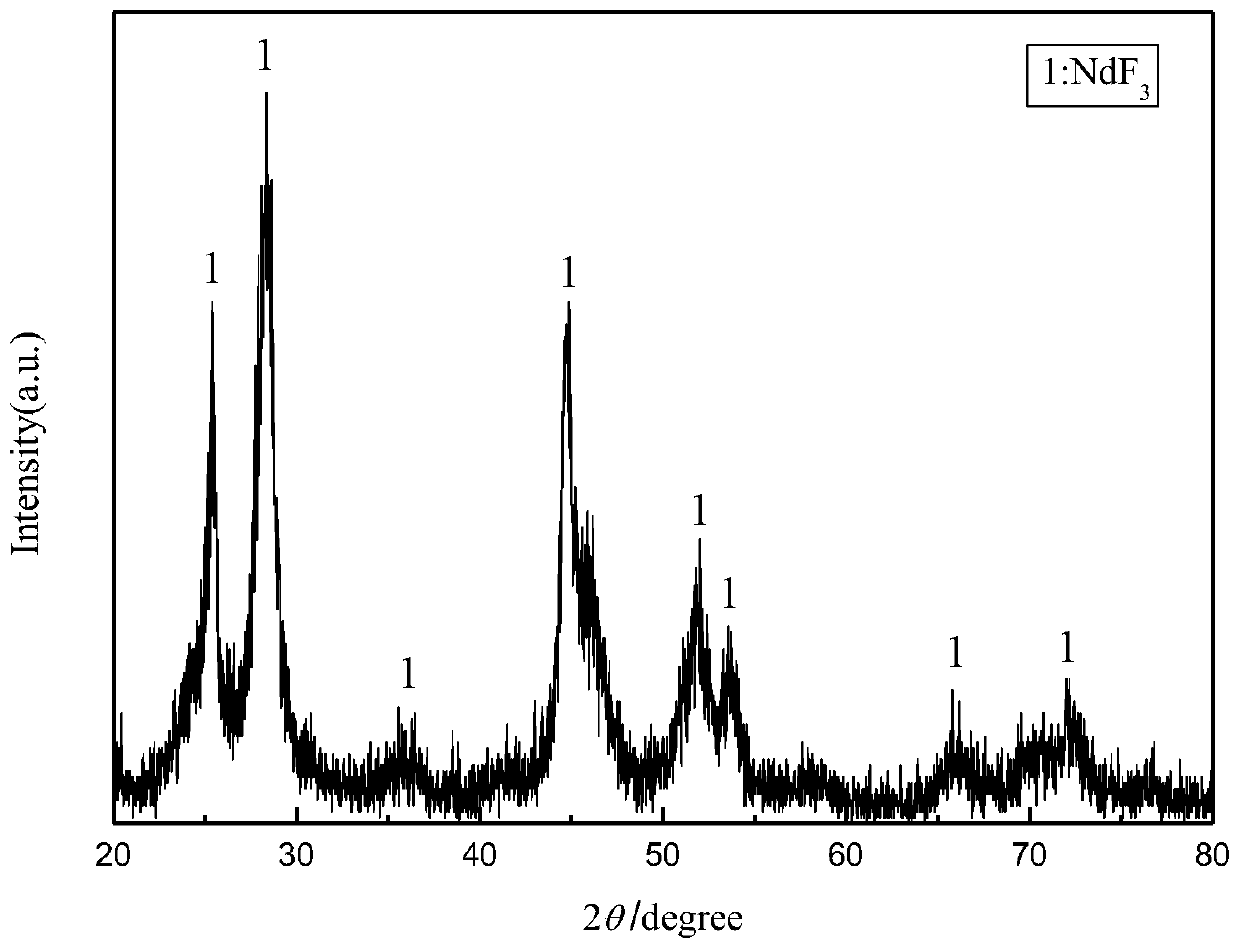

Method for recovering rare earth and iron from ultrafine powder waste generated in neodymium iron boron production process

ActiveCN110592378ARealize zero waste dischargeHigh recovery rateElectrolysis componentsRare-earth elementHydrofluoric acid

The invention relates to a method for recovering rare earth and iron from ultrafine powder waste generated in a neodymium iron boron production process. The method comprises the following steps of firstly dissolving the ultrafine powder waste generated in the neodymium iron boron production process in an acid, stirring to enable the waste to be completely reacted, then filtering and collecting filtrate and filter residue, and washing the filter residue and drying to obtain a rare earth fluoride. According to the method for recovering the rare earth and the iron from the neodymium iron boron production process, waste water, waste gas and waste liquid are not generated in the whole process, unreacted hydrofluoric acid can be reused, rare earth elements in the ultrafine powder are recovered in a form of rare earth fluoride and can be directly used as a raw material of an electrolytic rare earth, and the iron in the filtrate is recovered in forms of ferric fluoride or iron oxide by electrolysis. According to the method, the recovery rate of the rare earth is greatly improved, the rare earth and the iron in the ultrafine powder are recycled, and meanwhile, zero waste discharge in the ultrafine powder recovery process is realized.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

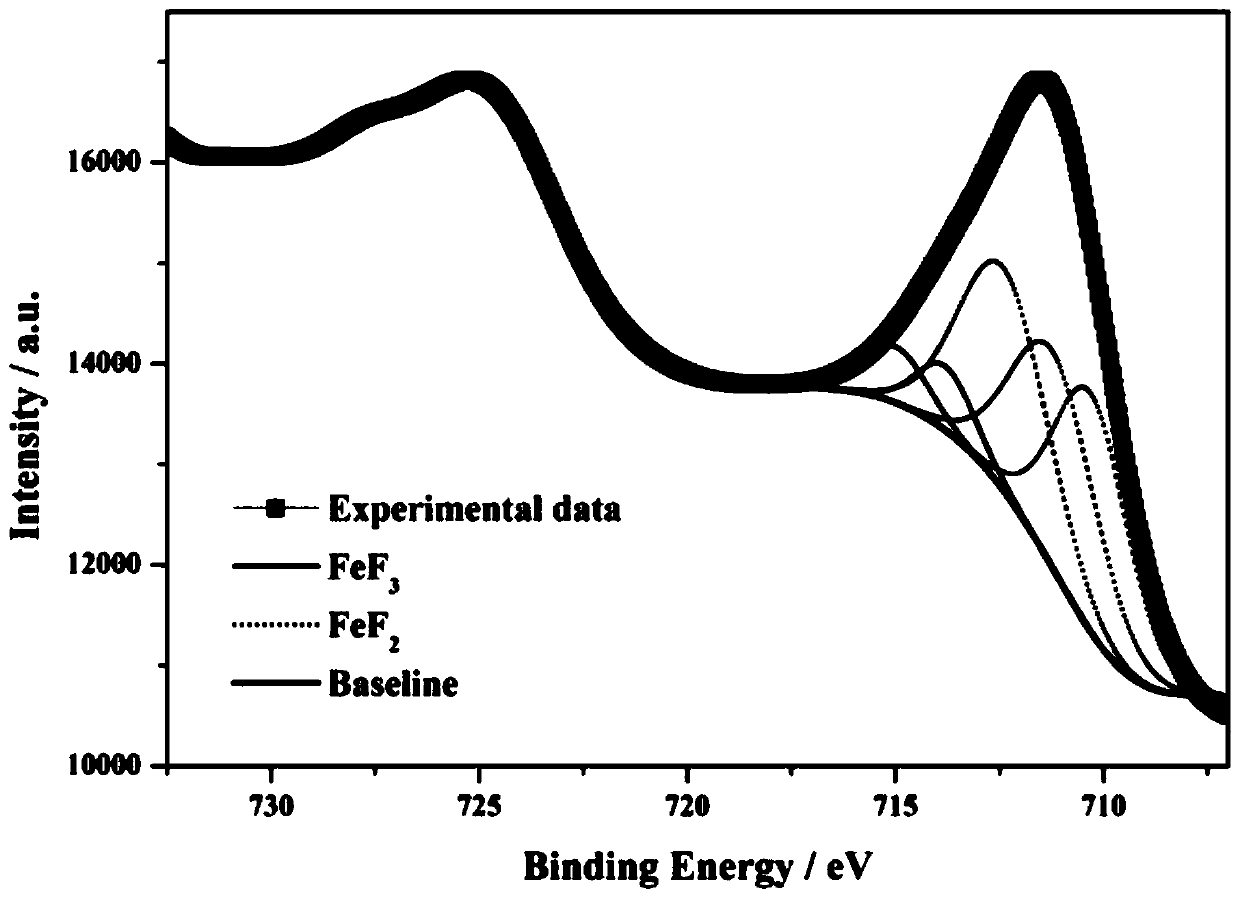

Cupric fluoride-ferric fluoride composite positive electrode material having gradient coatings and used for lithium battery and preparation method thereof

InactiveCN105914349AImprove surface electronic conductivityRetain propertiesCell electrodesSecondary cellsPhysical chemistryLithium-ion battery

The invention provides a Fe2O3 / FeF3-2xOx gradiently-coated cupric fluoride-ferric fluoride two-component composite positive electrode material of a lithium battery and a preparation method thereof. According to the method, the cupric fluoride-ferric fluoride two-component composite positive electrode material is prepared by using a solid-phase preparation method with polyquaternary ammonium salts with different structures as templates; then on the basis of the characteristic that FeF3 is prone to gradual oxidation into Fe2O3 at a high temperature, FeF3-2xOx (wherein 0<x<0.3) and a Fe2O3 layer successively coat the cupric fluoride-ferric fluoride two-component composite positive electrode material so as to improve surface electron conduction capability of the cupric fluoride-ferric fluoride two-component composite positive electrode material and to resist harmful effect of an organic electrolyte on particle surfaces of the material; and thus, the comprehensive electrochemical performance of the cupric fluoride-ferric fluoride two-component composite positive electrode material is greatly improved.

Owner:NINGBO UNIV

Composite Cu<2+>, Co<2+> and Ag<+>-doped ferric fluoride anode material and preparation method thereof

InactiveCN104150542AHigh lithium ion conductivityImprove electrochemical performanceCell electrodesIron halidesHigh energyActivation energy

The invention relates to a composite Cu<2+>, Co<2+> and Ag<+>-doped ferric fluoride anode material and a preparation method thereof. The preparation method comprises the following steps of carrying out ball milling on copper salt, cobalt salt, silver salt and a synthetic raw material in a high-energy ball mill for a period of time and carrying out heat treatment to obtain an FeF3 anode material. By virtue of partially occupying FeF3 iron ligand through Cu<2+>, the improvement of discharge potential is facilitated, and the energy density is improved; by doping Co<2+>, the improvement of the lithium ion conductivity of the material is facilitated; by doping Ag<+>, the activation energy of the conversion reaction during charging is reduced and thus the improvement of the multiplying power characteristic and the energy density is facilitated and the comprehensive electrochemical properties of the material are enhanced.

Owner:NINGBO UNIV

Silicon-doped straw-based charcoal composite electrode material and preparation method thereof

InactiveCN104821239AImprove conductivityHigh specific capacitanceHybrid capacitor electrodesHybrid/EDL manufactureManganese oxideRaw material

The invention discloses a silicon-doped straw-based charcoal composite electrode material. The silicon-doped straw-based charcoal composite electrode material is characterized in that the composite electrode material is prepared by the following raw materials in parts by weight: 3 to 5 parts of micron silicon, 3 to 4 parts of carbonitride, 2 to 3 parts of lithium nickel-manganese oxide, 1 to 2 parts of gold mercaptide, 2 to 3 parts of ferric (III) fluoride, 1 to 3 parts of carboxymethyl cellulose, 1 to 2 parts of a silane coupling agent KH-792, 1000 to 1200 parts of straw, 8 to 12 parts of zinc chloride, 4 to 7 parts of citric acid, 3 to 5 parts of modified acetylene black and 100 to 500 parts of distilled water. According to the invention, the added modified acetylene black has the advantages of enhancing the conductiver performance and improving the high-magnification charge and discharge performance and the like, the added micro silicon has quite high specific capacitance, the capacity attenuation in a circulation process is rapid, the circulating performance is poor, and the carbonitride has the effect of structure stabilization, inhibits the capacity attenuation and improves the charge and discharge circulating performance of an electrode.

Owner:ANHUI JIANGWEI PRECISION IND

Doped-state spherical FeF<3>.0.33H<2>O positive electrode material and preparation method therefor

InactiveCN105845933AUniform particle sizeHigh purityCell electrodesSecondary cellsRough surfaceNitrate

The invention discloses a doped-state spherical FeF<3>.0.33H<2>O positive electrode material and a preparation method therefor. The chemical expression of the positive electrode material is Fe<1-x>M<x>F<3+(n-3)x>.0.33H<2>O, wherein M is doped elements Mg, Co, Ni or Zn; x is equal to 0.03-0.3; and n is the valance of the corresponding doped elements. The preparation method comprises the steps of putting Fe(NO<3>)<3>.9H<2>O into a reactor, adding nitrate of other doped metal; then adding alcohol, magnetically stirring for 10-20min to obtain a settled solution; then adding an HF water solution in a dropwise manner and stirring for 10-20min; moving the mixture to a hydrothermal reaction kettle to react, then carrying out solid-liquid separation; and carrying out vacuum drying at a temperature of 20-80 DEG C to obtain the doped-state spherical FeF<3>.0.33H<2>O particles. The doped state spherical ferric fluoride obtained by the invention has uniform particles, rough surface, high tap density, high repeatability and excellent electrochemical performance; and the reaction yield can reach greater than 80%.

Owner:XIANGTAN UNIV

Aluminum zirconium acid ester-doped titanium phosphate double-component surface-modified ferric fluoride anode material and preparation method

ActiveCN103515598AIncrease contactRich in active sitesCell electrodesSecondary cellsElectrical conductorHigh energy

The invention discloses an aluminum zirconium acid ester-doped titanium phosphate dual-component surface-modified ferric fluoride anode material and a preparation method. The method is characterized by comprising the following steps: loading aluminum zirconium acid ester, silicon / aluminium-doped titanium phosphate Li1.3Al0.1Ti1.9Si0.2P2.8O12, and a synthetic raw materials into a high-energy ball mill, ball-milling for a certain period, and performing heat treatment to obtain the FeF3 anode material. The aluminum zirconium acid ester is a bimetal coupling agent, has multiple active sites, and bonds with Li1.3Al0.1Ti1.9Si0.2P2.8O12 by hydrolysis of multiple alkoxyl groups into hydroxyl groups while having condensation polymerization with hydroxyl groups on the surface of the FeF3 anode material, and zirconium is an electron acceptor, can coordinate with fluorine ions on surfaces of FeF3 particles, therefore, under the action of the aluminum zirconium acid ester, doped titanium phosphate Li1.3Al0.1Ti1.9Si0.2P2.8O12 is bonded to the surfaces of the FeF3 anode particles with good contact between particles, and Li1.3Al0.1Ti1.9Si0.2P2.8O12 is a good lithium ion conductor, and the ionic conductivity of Li1.3Al0.1Ti1.9Si0.2P2.8O12 is 103-104 times of that of lithium cobalt oxide. Therefore, the defect that the FeF3 anode material has an extremely-low ionic conductivity can be overcome, and the electrochemical properties of the FeF3 material are improved.

Owner:沛县度创科技发展有限公司

Carbon solid acid and aluminic acid ester doped ferric fluoride anode material with titanium-phosphate-lithium three-component surface modification, and preparation method of anode material

InactiveCN103682267AThe reactive group is highly activeImprove ionic conductivityCell electrodesSecondary cellsHigh energySolid acid

The invention provides a preparation method of carbon solid acid and aluminic acid ester doped ferric fluoride anode material with titanium-phosphate-lithium three-component surface modification. The preparation method comprises the following steps: ball-milling sulfonated carbon solid acid, aluminic acid ester and titanium-phosphate-lithium doped with silicon and aluminum Li[1.3]A1[0.1]Ti[1.9]Si[0.2]P[2.8]O[12] and synthetic raw materials in a high-energy ball mill for a period of time and carrying out heat treatment. The preparation method is characterized in that sulfonated solid acid is coordinated through iron ions to form an integrated electron conduction link; reactive group alkoxy of an aluminic acid ester coupling reagent is adopted to rapidly hydrolyze into hydroxyl to be combined with the ionic conductive agent Li[1.3]A[10.1]Ti[1.9]Si[0.2]P[2.8]O[12] and combined with a sulfo group on the sulfonated carbon solid acid in a condensation manner at the same time, so as to combine the conductive agent sulfonated carbon solid acid and the ionic conductive agent Li[1.3]A[10.1]Ti[1.9]Si[0.2]P[2.8]O[12] on the surfaces of FeF3 particles, so that an electron and ionic conduction circuit is formed, the ionic conductivity and the electronic conductivity of the FeF3 material are improved greatly, and thus the electrochemical performance of the material is improved.

Owner:NINGBO UNIV

Engine oil additive

A process and method for manufacturing an improved engine oil comprising mixing ferric fluoride with ZDDP to form an additive mixture, heating the additive mixture to at least 125° C. for at least 4 hours to produce a pre-reacted mixture, and adding the pre-reacted mixture to a fully formulated engine oil not containing ZDDP. Also disclosed is an engine oil prepared by a process comprising mixing catalyst with ZDDP to form an additive mixture, heating the additive mixture to about 60° C. to produce a pre-reacted additive mixture, and adding the pre-heated additive mixture to a fully formulated engine oil not containing ZDDP.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST +1

Ferric fluoride oxide anode material and preparation method thereof, and lithium ion battery

ActiveCN112687881AAlleviate stress changesImprove conductivityCell electrodesSecondary cellsPhysical chemistryLithium-ion battery

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

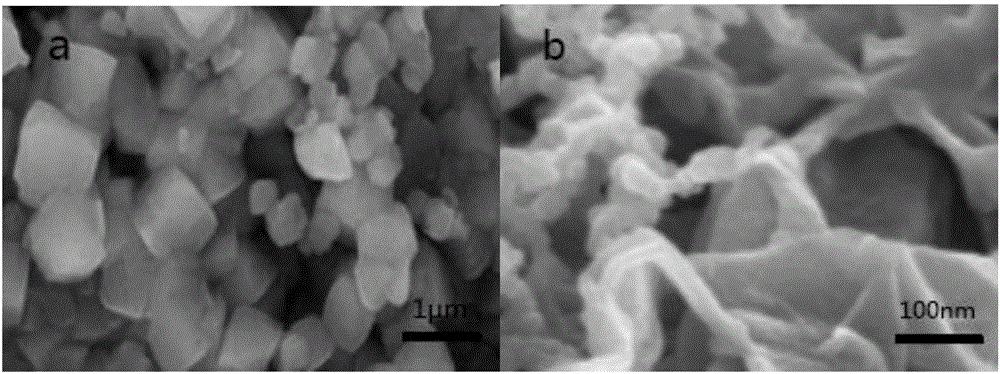

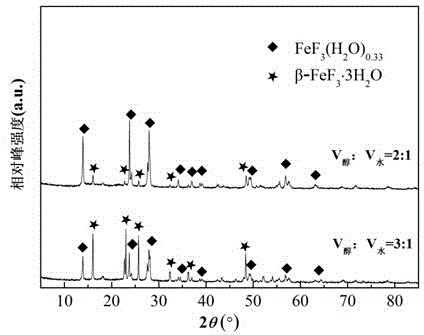

High-performance hybrid crystal system ferric fluoride positive electrode material and preparation method thereof

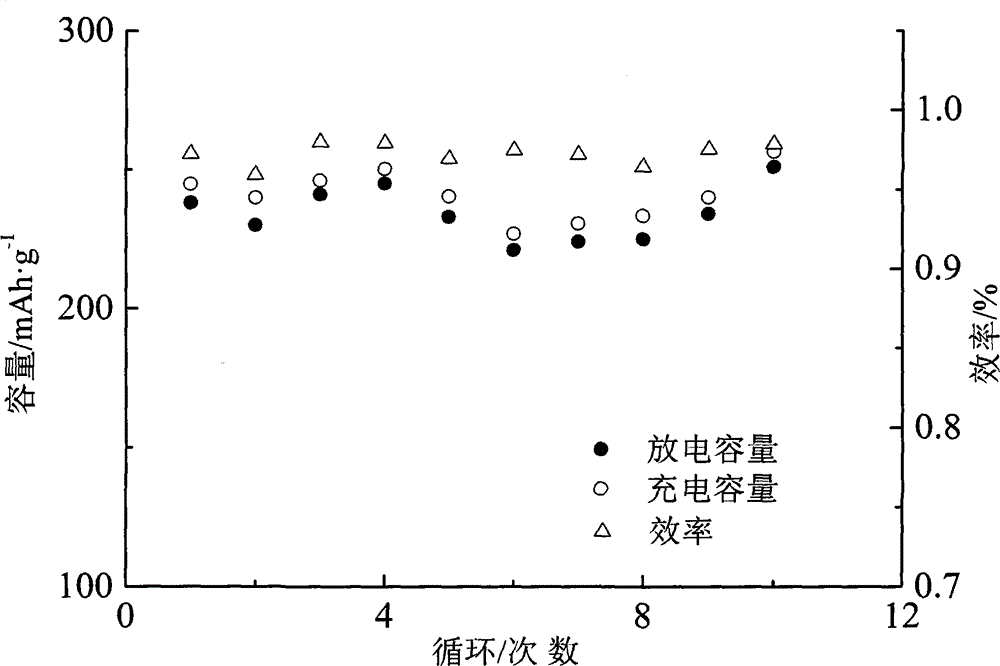

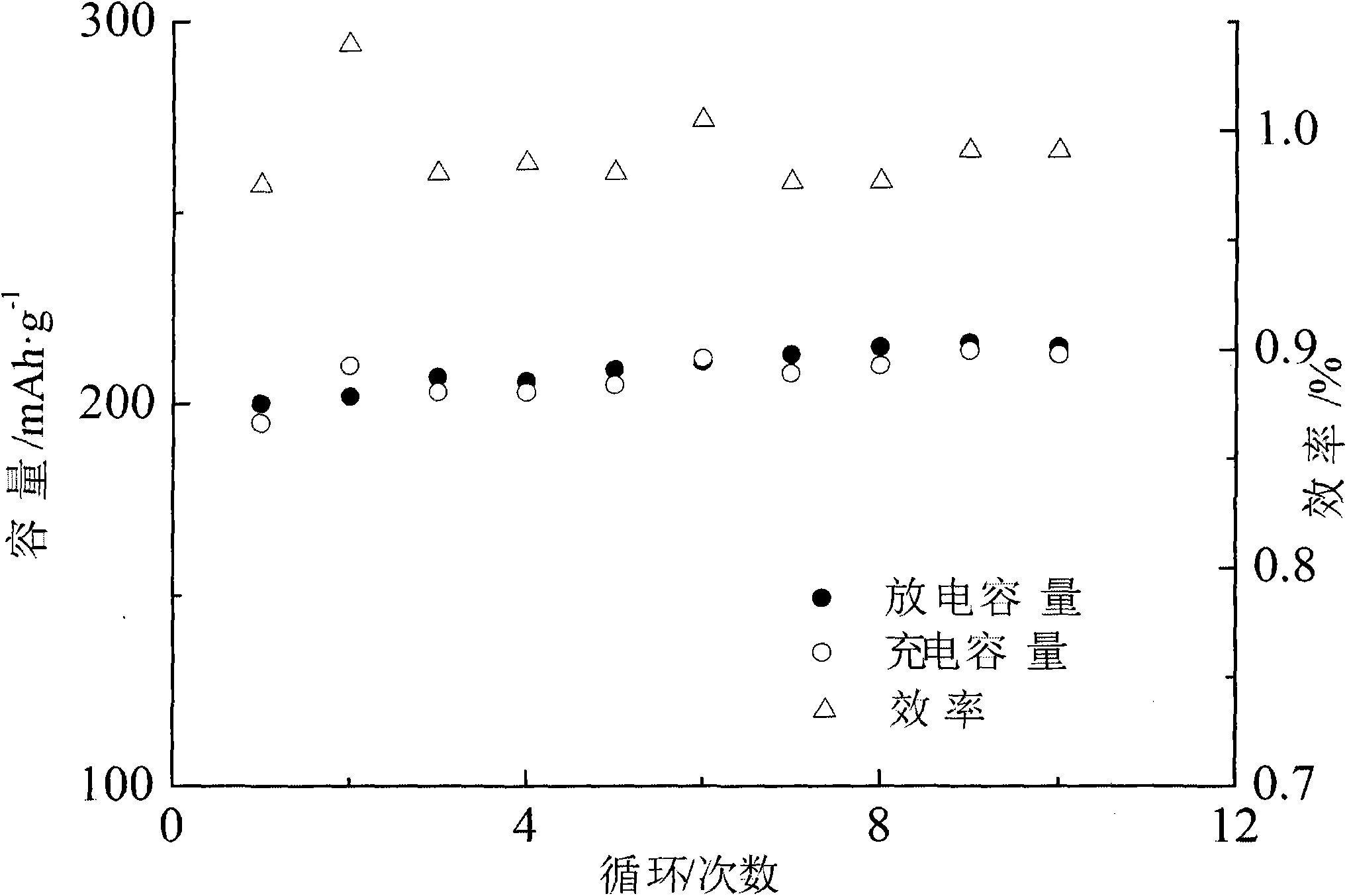

ActiveCN104591296AHigh discharge specific capacityExcellent rate performanceCell electrodesIron halidesCrystal systemHigh rate

The invention in particular relates to a high-performance hybrid crystal system ferric fluoride positive electrode material and a preparation method thereof. The positive electrode material is prepared from a water / alcohol mixed solution containing a ferric salt and a fluorine-containing water / alcohol mixed solution. The preparation method is performed under normal temperature and normal pressure, the preparation process is simple, and the method is low in time consumption, low in energy consumption, low in cost, environment-friendly and easy for industrial production; and the prepared hybrid crystal system FeF3(H2O)0.33 / beta-FeF3.3H2O nanoparticles have high specific discharge capacity, low cost, environment friendliness, high rate capability and excellent cycling stability and have actual application prospects in the fields of power supplies and battery energy storage.

Owner:SHANDONG YUHUANG NEW ENERGY TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com