Composite positive electrode material and preparation method thereof

A composite material and positive electrode technology, which is applied in the field of positive electrode composite materials and its preparation, can solve the problems of limited FeOF synthesis methods and achieve the effect of increasing conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] An embodiment of the present invention provides a method for preparing a positive electrode composite material, which includes the following steps:

[0019] S1, ferric fluoride (FeF 3 ) and graphene oxide are uniformly mixed in a liquid phase solvent to form a solid-liquid mixture; and

[0020] S2, the solid-liquid mixture is subjected to a hydrothermal / solvothermal reaction at 80° C. to 250° C. in a hydrothermal / solvothermal reaction kettle.

[0021] FeF 3 It may or may not contain water of crystallization, preferably contains water of crystallization, such as ferric fluoride trihydrate (FeF 3 ·3H 2 O), FeF 3 0.33H 2 O, Fe 1.9 f 4.75 0.95H 2 O, FeF 2.5 0.5H 2 O, FeF 3 ·H 2 O and amorphous FeF 3 at least one of the

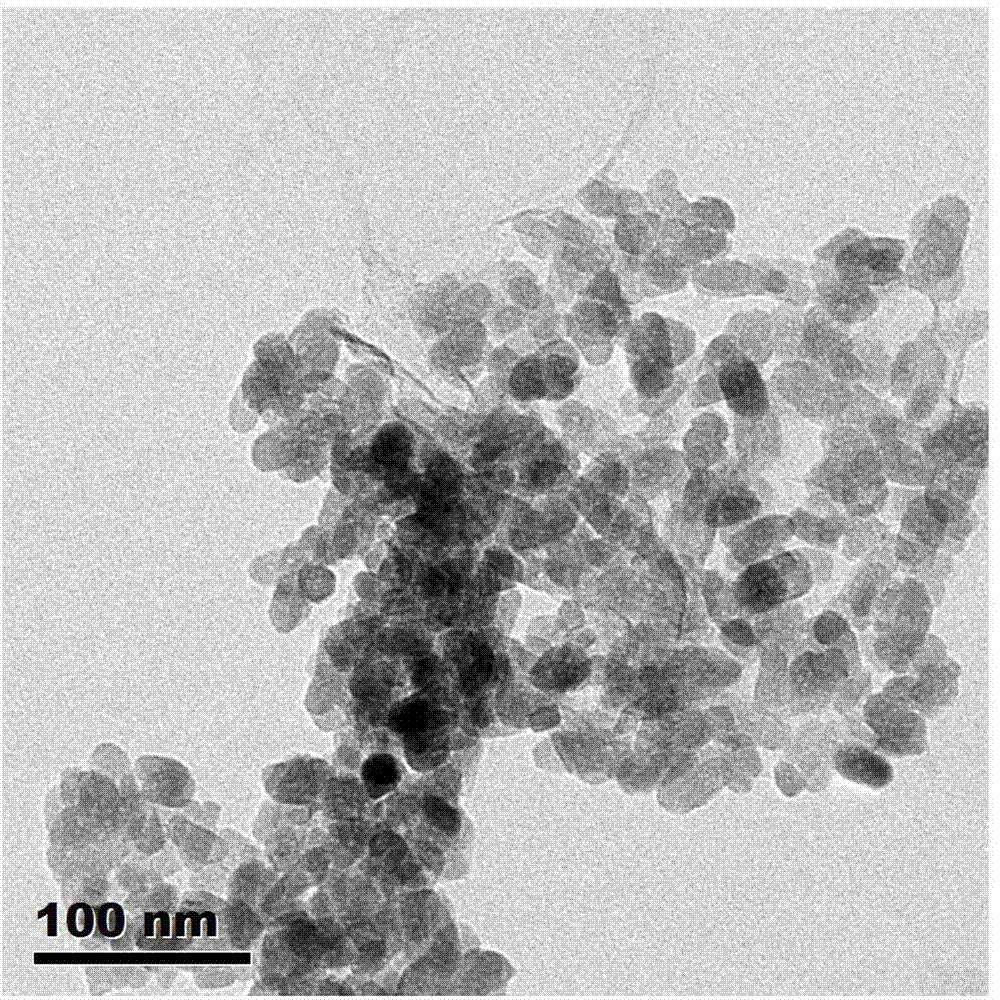

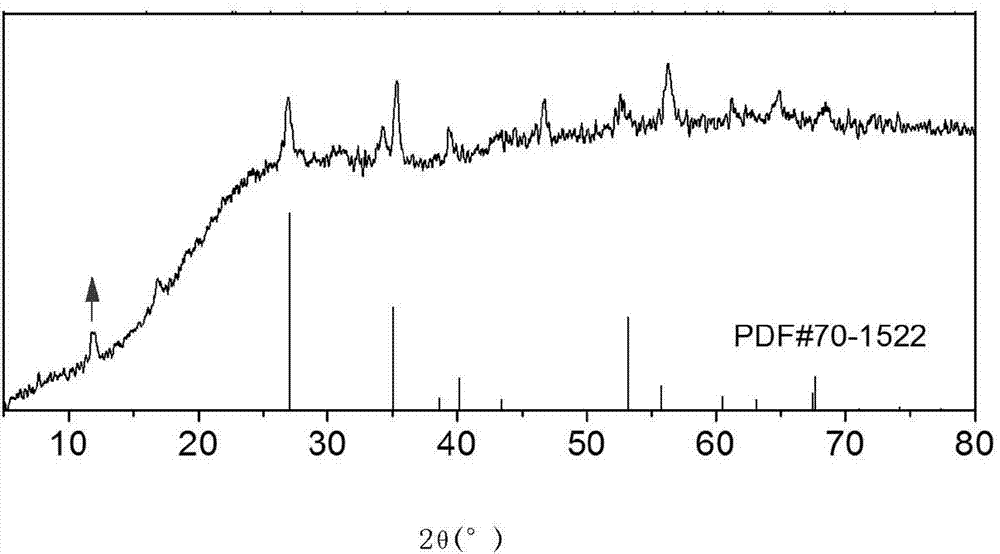

[0022] The graphene oxide reacted with FeF under hydrothermal / solvothermal conditions 3 reaction, in situ generating FeOF on the surface of graphene's carbon atomic layer, and thus chemically bonded with graphene. When all the oxygen in grap...

Embodiment 1

[0038] Iron fluoride trihydrate FeF 3 ·3H 2 Preparation of O: Add 0.1g CTAB to 30mL deionized water, ultrasonically disperse; then add 18 g FeCl 3 ·6H2 O gets Fe 3+ solution; under vigorous stirring, the Fe 3+ The solution was added dropwise into HF (38%, 50 mL), and stirred for 2 h until the reaction was complete. Centrifuge and wash with ethanol until neutral, and dry the precipitate in a common oven at 60°C for 10 h to obtain iron fluoride trihydrate FeF 3 ·3H 2 O.

[0039] Preparation of graphene oxide: Graphene oxide was prepared by the Hummers method. The experimental process was as follows: 5 g of graphite, 2.5 g of sodium nitrate, and 115 mL of concentrated sulfuric acid were mixed in an ice-water bath, and stirred vigorously for 30 min; 30 g of permanganese was added to it. After stirring for 5 hours, graphite was completely oxidized; 200 mL of deionized water was added to the reactant and stirring was continued for 20 minutes, and 400 mL of deionized water and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com