Polymer carbonized in-situ coated ferric fluoride composite positive electrode material and preparation method thereof

A composite positive electrode material, ferric trifluoride technology, applied in battery electrodes, electrochemical generators, electrical components, etc., can solve problems such as low electronic conductivity, improve lithium ion conductivity and electronic conductivity, and improve cycle Performance and rate performance, low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

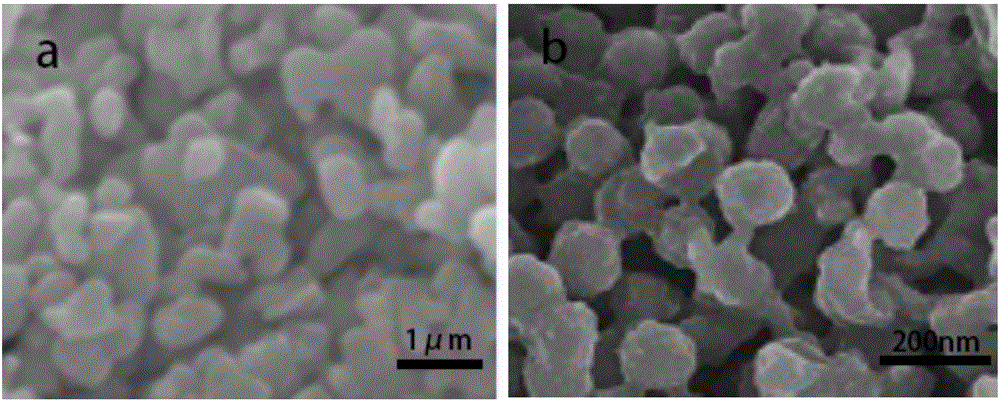

[0033] Example 1 Preparation of polymer carbonization in-situ coated ferric trifluoride composite positive electrode material

[0034] Prepare FeCl with a concentration of 0.3M 3 aqueous solution and a concentration of 1.0M NH 4 F aqueous solution;

[0035] In the polytetrafluoroethylene reactor, the prepared FeCl 3 The solution was mixed with 0.1g lauryltrimethylammonium bromide, the polytetrafluoroethylene reactor was placed on the stirrer and stirred at room temperature for 30min, and then fluoride ion and FeCl were added dropwise. 3 The molar ratio of iron ions in solution is 1:4 with NH 4F solution, stirred and reacted at 80°C for 20h, and FeF containing crystal water was obtained after the reaction was completed. 3 precipitation;

[0036] The above FeF 3 The precipitate was washed 3 times with absolute ethanol, transferred to an 80°C drying oven with argon gas for drying for 12 hours, cooled to room temperature, and then placed in an argon-protected tubular atmosph...

Embodiment 2

[0038] Example 2 Preparation of polymer carbonization in-situ coated ferric trifluoride composite positive electrode material

[0039] Prepare FeCl with a concentration of 0.01M 3 Aqueous solution and NH at a concentration of 0.03M 4 F aqueous solution;

[0040] In the polytetrafluoroethylene reactor, the prepared FeCl 3 The solution was mixed with 0.05g lauryltrimethylammonium bromide, the polytetrafluoroethylene reaction kettle was placed on the stirrer and stirred at room temperature for 20min, and then fluoride ion and FeCl were added dropwise. 3 The molar ratio of iron ions in solution is 1:3 with NH 4 F solution, stirred and reacted at 50°C for 12h, and FeF containing crystal water was obtained after the reaction was completed. 3 precipitation;

[0041] The above FeF 3 The precipitate was washed 2 to 3 times with absolute ethanol, transferred to a 60°C drying oven with argon gas for drying for 15 hours, cooled to room temperature, and then placed in an argon-protec...

Embodiment 3

[0043] Example 3 Preparation of polymer carbonization in-situ coated ferric trifluoride composite positive electrode material

[0044] Prepare FeCl with a concentration of 0.5M 3 Aqueous solution and NH at a concentration of 1.5M 4 F aqueous solution;

[0045] In the polytetrafluoroethylene reactor, the prepared FeCl 3 The solution was mixed with 0.15g lauryltrimethylammonium bromide, the polytetrafluoroethylene reaction kettle was placed on the stirrer and stirred at room temperature for 40min, and then fluoride ion and FeCl were added dropwise. 3 The molar ratio of iron ions in solution is 1:5 with NH 4 F solution, stirred and reacted at 100°C for 28 hours, and FeF containing crystal water was obtained after the reaction was completed. 3 precipitation;

[0046] The above FeF 3 The precipitate was washed 3 times with absolute ethanol, transferred to a 100°C drying oven with argon gas for drying for 10 h, cooled to room temperature, and then placed in a nitrogen-protecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com