Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

100 results about "Critical control point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

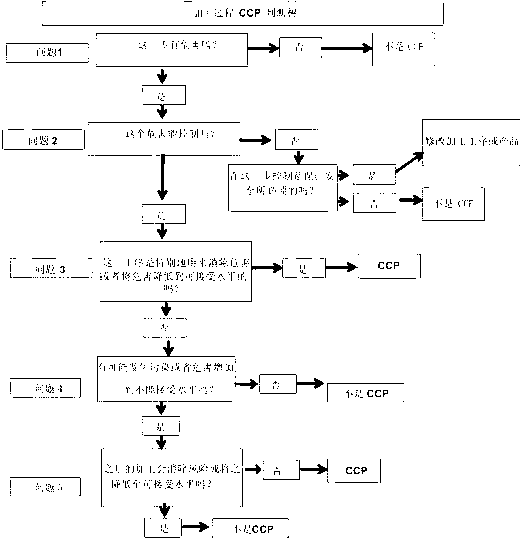

Critical Control Point (CCP) is the point where the failure of Standard Operation Procedure (SOP) could cause harm to customers and to the business, or even loss of the business itself. It is a point, step or procedure at which controls can be applied and a food safety hazard can be prevented, eliminated or reduced to acceptable (critical) levels. The most common CCP is cooking, where food safety managers designate critical limits. CCP identification is also an important step in risk and reliability analysis for water treatment processes.

Smelting method of 9Ni steel

ActiveCN102747181AMeet the requirements of continuous castingReduce lossesManufacturing convertersCritical control pointSmelting process

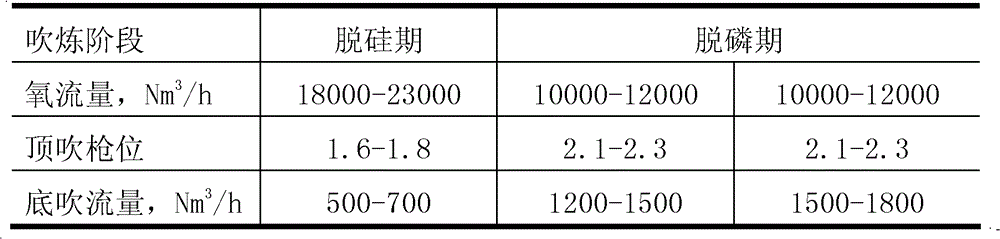

A smelting method of 9Ni steel. The method has the following characteristics: 1.a smelting process comprises steps of pretreatment on molten iron (desulfuration), converter (double dephosphorization, melting nickel plate), LF furnace (desulfuration) and RH (degassing); 2. dephosphorization is conducted in the converter and comprises two steps: step one: blending molten iron desulphurized by KR and steel scrap into a dephosphorization converter for primary smelting, using ''dephosphorization converter smelting critical control point'' to desulphurize the molten iron to a phosphorus content below 0.020%, and carrying out semi-steel tapping; and step two: blending the molten semi-steel and nickel plate into a decarburization converter for converting, desulphurizing the molten steel after converting to a phosphorus content below 0.003%, and carrying out tapping; and 3. the nickel plate is melted in the decarburization furnace. According to the present invention, the two-step dephosphorization is carried out in the converter that molten steel after converting has low phosphorus content and is stably controlled, so as to benefit improvement on the yield of 9Ni steel. Decarburization converter slag has low phosphorus content, and ladle molten steel has a low rephosphorization amount, so as to clear out molten steel in the decarburization furnace and reduce molten steel loss in a steel leaving operation.

Owner:BAOSHAN IRON & STEEL CO LTD

Two-dimensional animation synthesis method based on movement element multiplexing

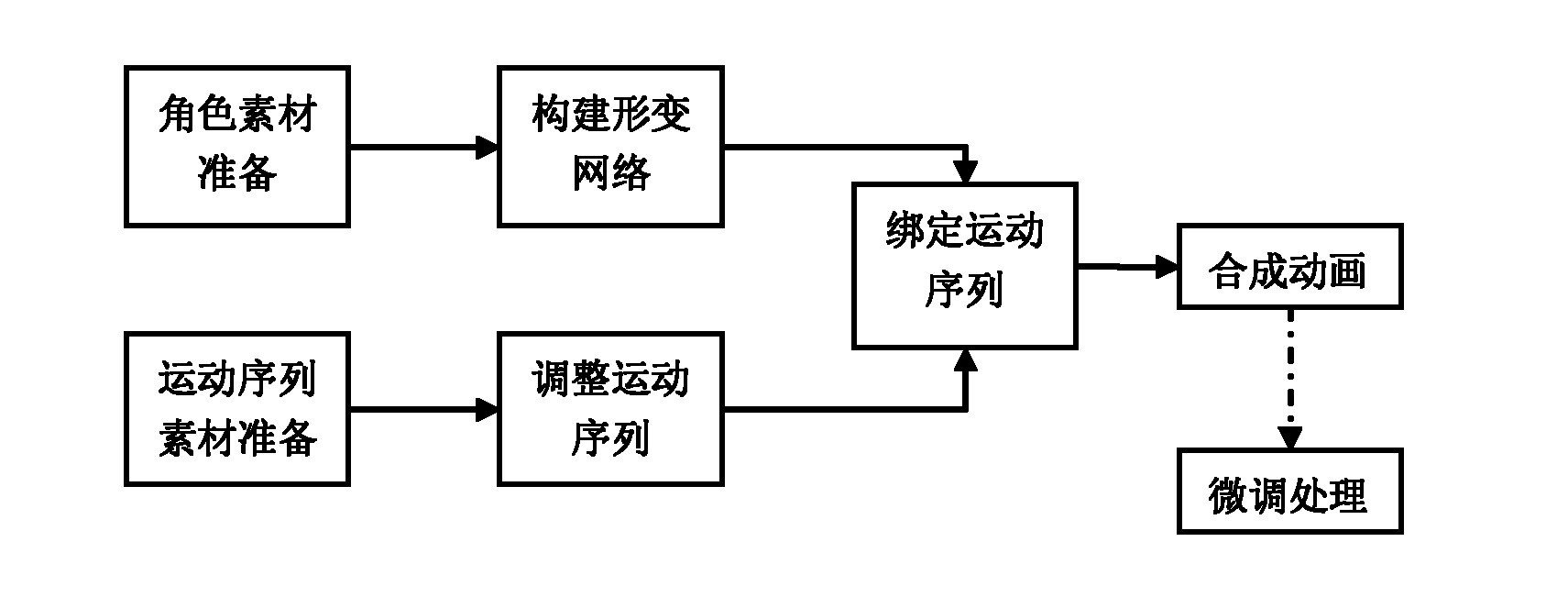

ActiveCN102609970AEasy to operateRigidity varies naturallyAnimationMultiplexingCritical control point

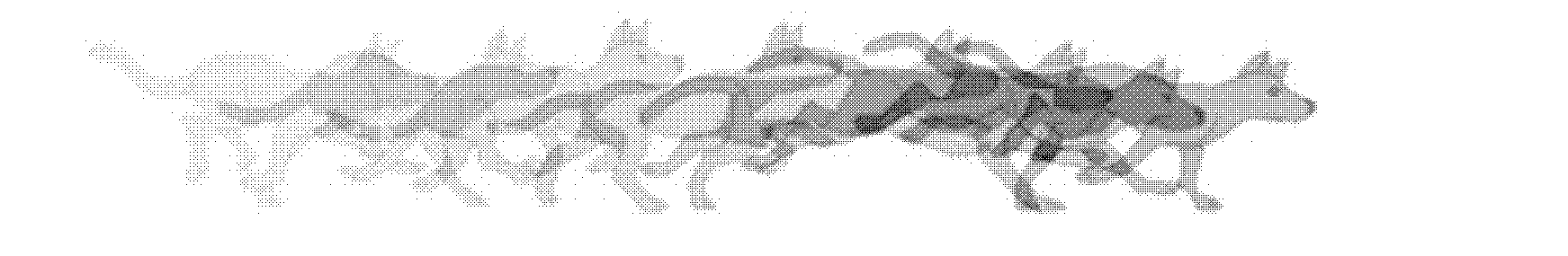

The invention discloses a two-dimensional animation synthesis method based on movement element multiplexing. The two-dimensional animation synthesis method comprises the following steps that: step 1, role materials and movement sequence materials are selected, wherein the role materials have single background colors and single roles, and the movement sequence materials are posture sequences of a two-dimensional framework model; step 2, the selected role materials are subjected to preprocessing operation; step 3, role shaping is bound with movement sequences, and role animations are synthesized. The two-dimensional animation synthesis method has the advantages that the creation efficiency is greatly improved, users only need to set key control points for role shaping, the movement framework is bound, any movements can be easily given to cartoon roles through movement element multiplexing, the animation synthesis operation flow process is greatly simplified, and the expenditure of the repeated creation is reduced; and the complicated framework movement is supported, so the rigidity change of generated animations is more natural than that of the traditional computer auxiliary creation.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD

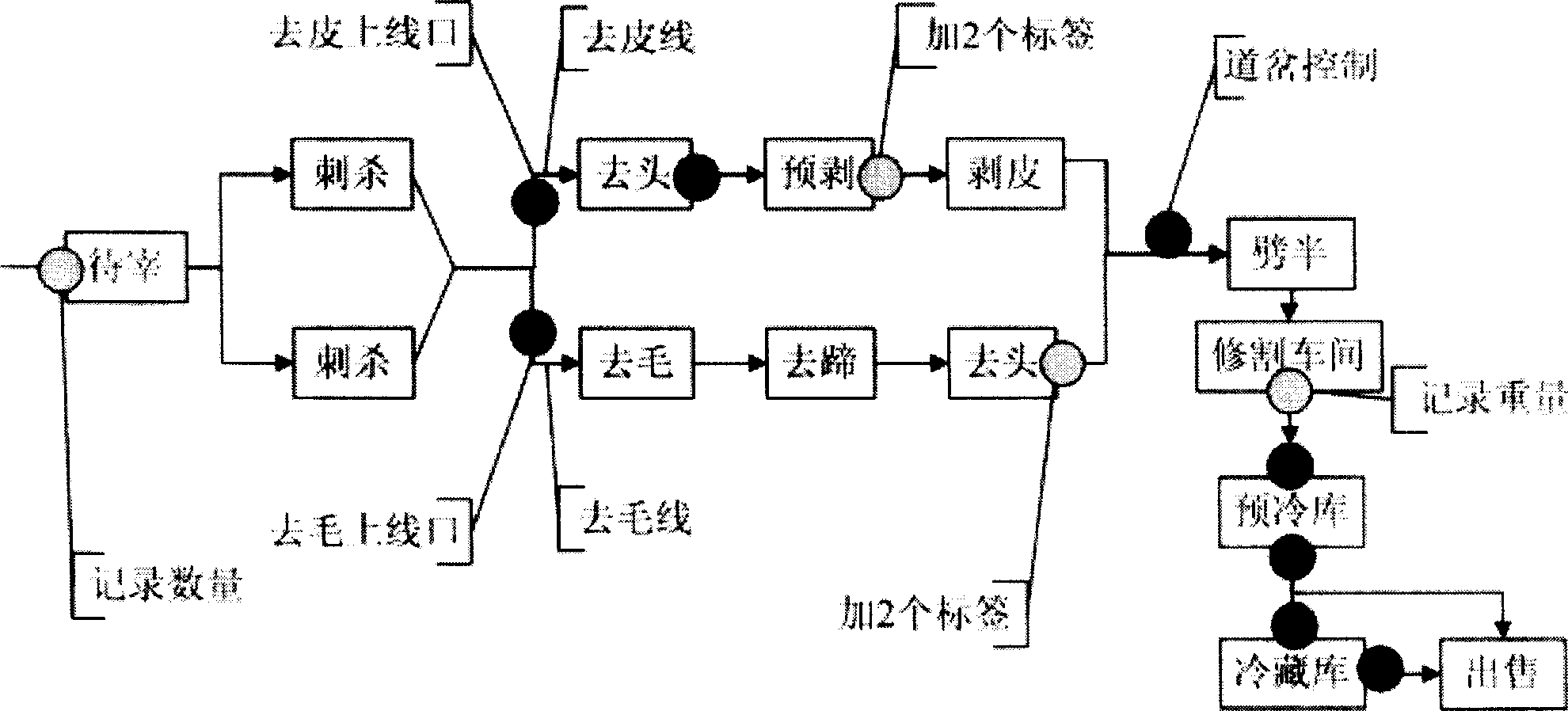

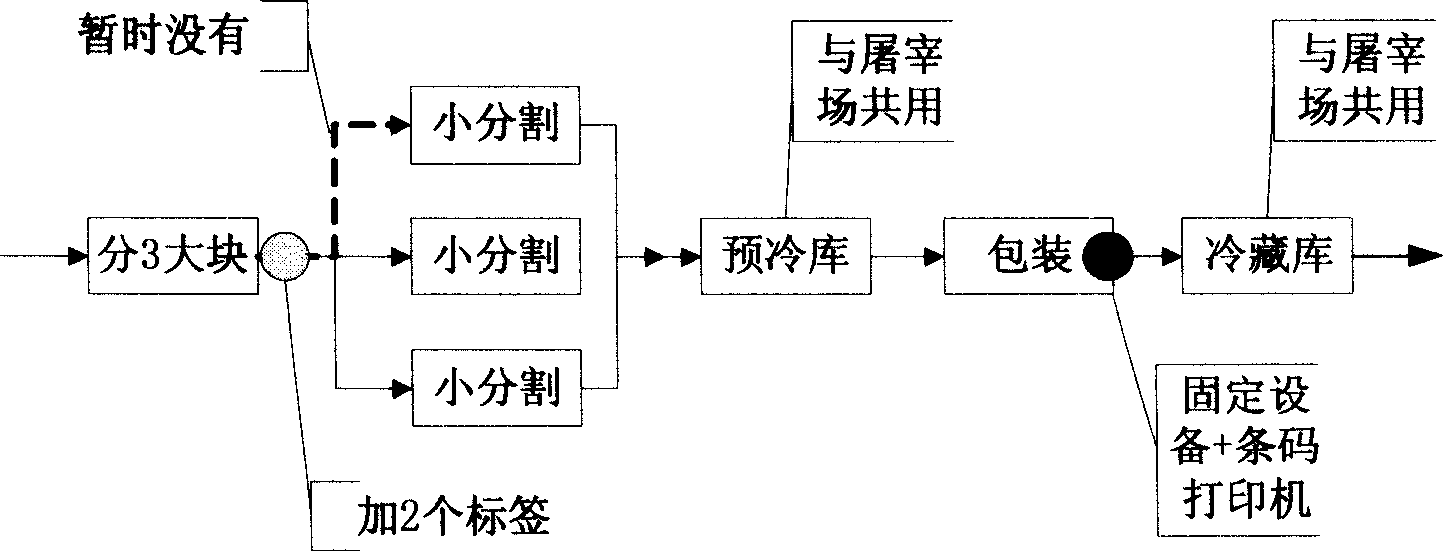

Pork supply system and method

InactiveCN1760886AEnsure hygieneEnsure safetyCo-operative working arrangementsCharacter and pattern recognitionCritical control pointRelevant information

The method applies global uniform tag system to hazard analysis and key control point. Automatic identification resolvent of combining radio frequency identification technique (RFID) and bar code technique supports relevant information in each link of supply chain. In procedures of breeding and killing pig, processing and retail selling pork, the method adds RFID tag on pig and pork. RFID reader reads / writes RFID tag, and transfers and stores information in database of computer for tracking and tracing back pigs and pork. The system includes RFID tag, RFID reader, and computer of having database. RFID tag is put on pig and pork, and the RFID reader is connected to the computer. The invention builds system for tracking and tracing back pigs and pork from breeding base to dining table.

Owner:上海农业信息有限公司 +2

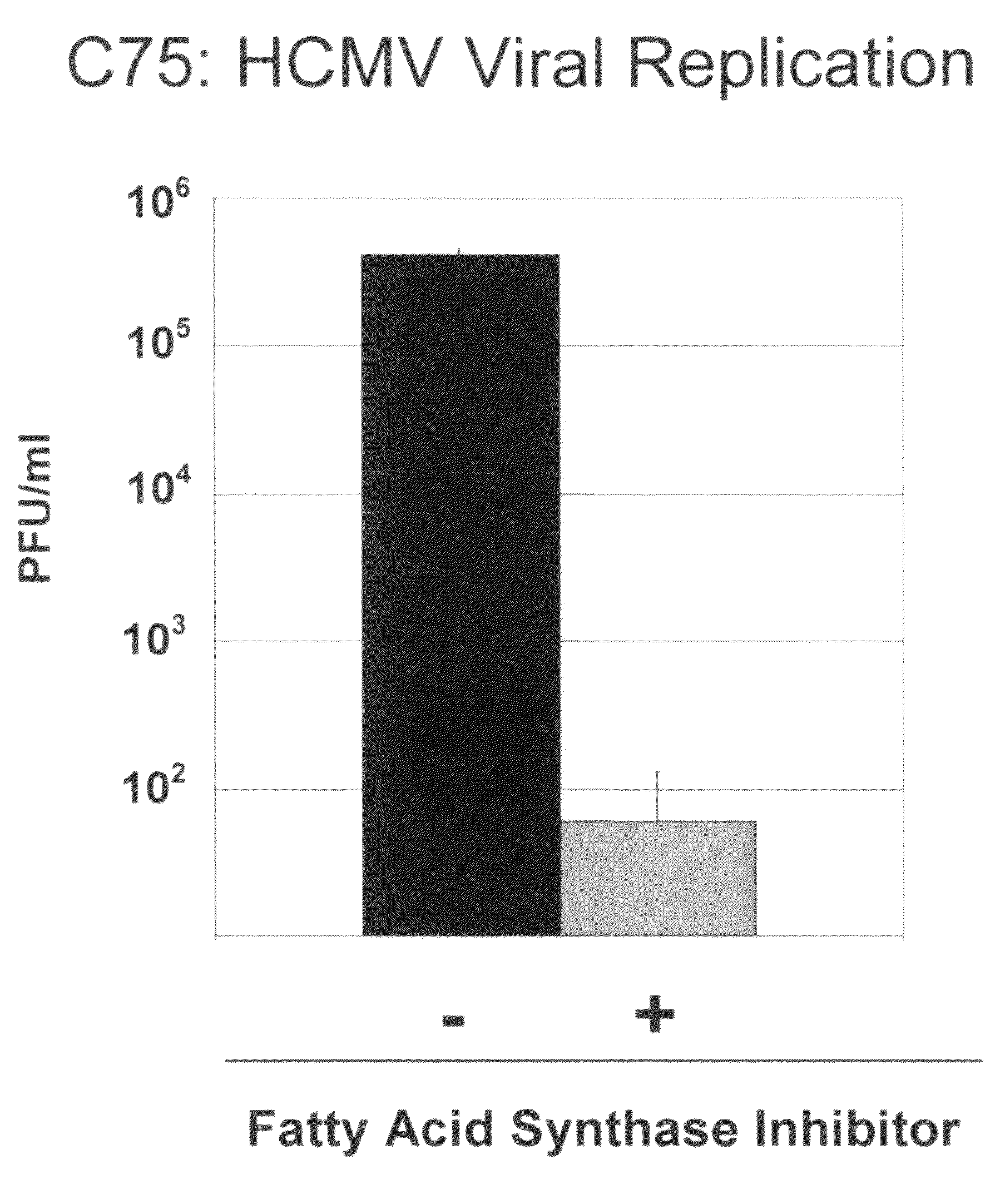

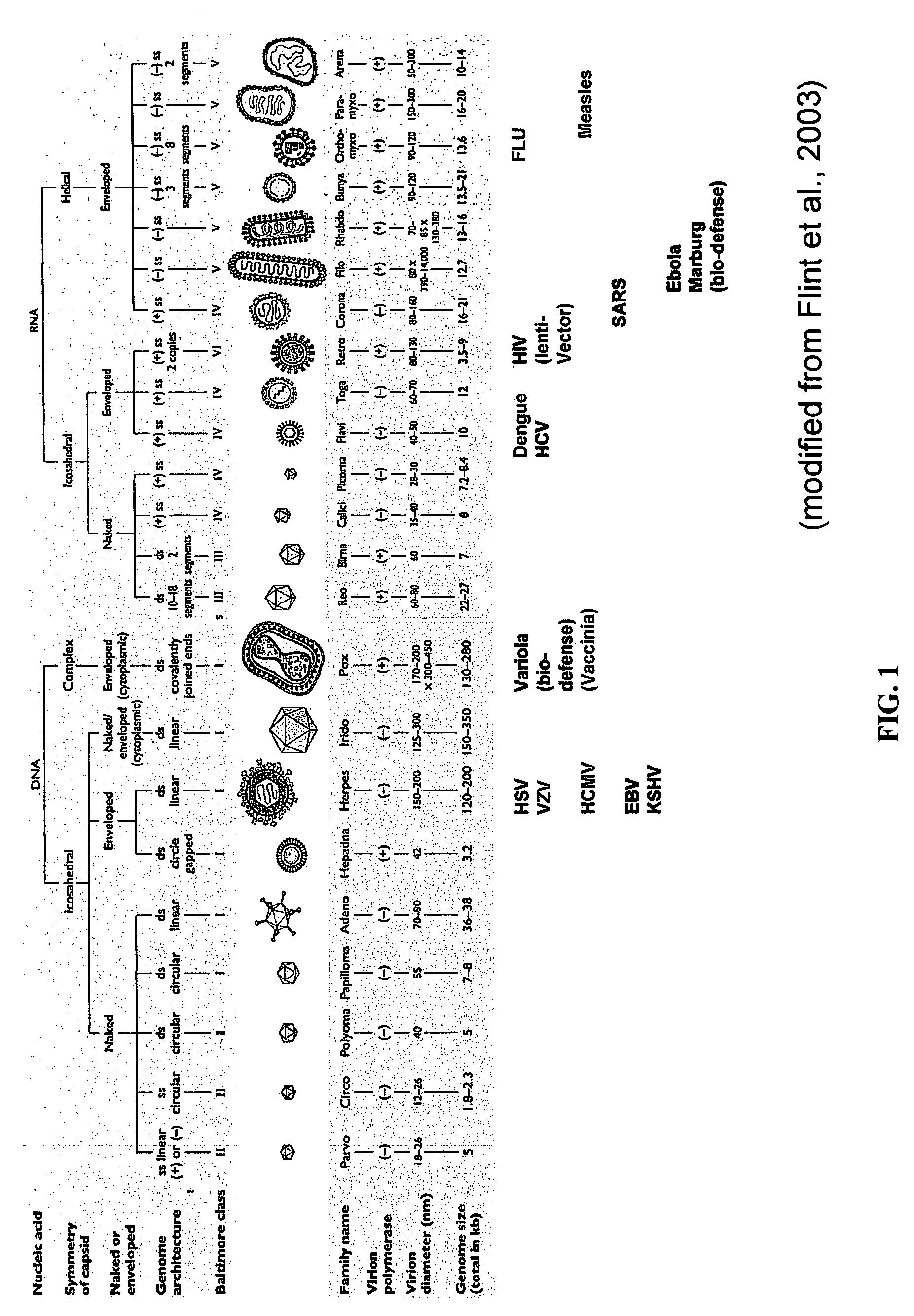

Treatment of viral infections by modulation of host cell metabolic pathways

InactiveUS8158677B2Reduce severityImprove survivalBiocideDigestive systemCritical control pointMetabolite

Owner:THE TRUSTEES FOR PRINCETON UNIV

Treatment of viral infections by modulation of host cell metabolic pathways

InactiveUS20090239830A1Reduction and amelioration of severityShorten the construction periodBiocideDigestive systemCritical control pointAntiviral drug

Alterations of certain metabolite concentrations and fluxes that occur in response to viral infection are described. Host cell enzymes in the involved metabolic pathways are selected as targets for intervention; i.e., to restore metabolic flux to disadvantage viral replication, or to further derange metabolic flux resulting in “suicide” of viral-infected cells (but not uninfected cells) in order to limit viral propagation. While any of the enzymes in the relevant metabolic pathway can be selected, pivotal enzymes at key control points in these metabolic pathways are preferred as candidate antiviral drug targets. Inhibitors of these enzymes are used to reverse, or redirect, the effects of the viral infection. Drug candidates are tested for antiviral activity using screening assays in vitro and host cells, as well as in animal models. Animal models are then used to test efficacy of candidate compounds in preventing and treating viral infections. The antiviral activity of enzyme inhibitors is demonstrated.

Owner:THE TRUSTEES FOR PRINCETON UNIV

Computer-based intelligent control method for food safety and quality

InactiveCN103019121AHighlight substantive featuresSignificant progressProgramme control in sequence/logic controllersAutomatic controlCritical control point

The invention relates to a computer-based intelligent control method for food safety and quality. Hazard analysis and establishment of a critical control point system, real-time monitoring of food production data, a remote monitoring system for food production, a food safety quality manual and establishment of resource management are included. An intelligent and automatic management system for control of food safety and quality is achieved by using the computer intelligent management technology. Widely and internationally accepted food standards are consulted and integrated and serve as guidance, the computer is combined, automatic planning for the food production process is performed firstly, then automatic control for critical control points in production is performed, and management association analysis for the whole production process is performed from an overall perspective; and standard and shared databases are updated in real time through the cloud technology to guide production rules, and food production safety is guaranteed through the latest technologies.

Owner:PSYCHOREALITY SOOCHOW INDAL DESIGN STUDIO

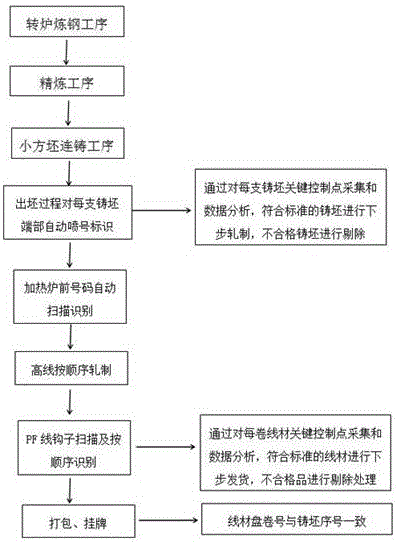

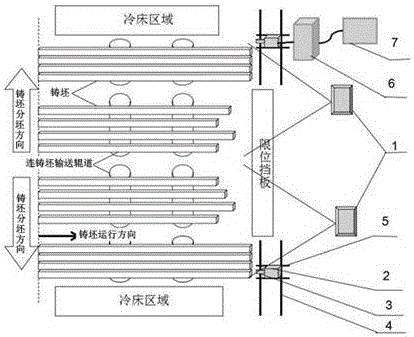

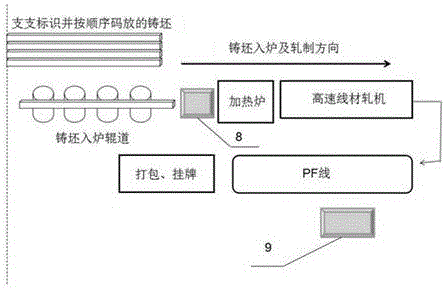

High-speed wire production method for tracking quality states of single casting blank and single coil of steel

ActiveCN105964687AAvoid quality objectionsIncrease production capacityRoll mill control devicesMeasuring devicesSteelmakingCritical control point

The invention relates to a high-speed wire production method for tracking the quality states of a single casting blank and a single coil of steel, and belongs to the technical field of metallurgy. According to the method, a traditional method for carrying out quality tracking and judging with a furnace as the unit is changed in the process of rolling wires with small square blanks as raw materials; each small square blank produced through a multi-stream small square blank continuous casting machine is subjected to independent identification, and critical control points of quality of the converter steelmaking procedure, the refining procedure, the continuous casting procedure, the heating procedure and the rolling procedure corresponding to each casting blank and wire subjected to independent identification are collected and analyzed; unqualified products are removed in the manner of the single casting blank and the single coil of steel, and the method of production tracing and quality tracking control with the serial numbers of the single casting blank and the single coil of steel as identification is achieved; the problems that due to misjudgment caused by the traditional method, cost is wasted, manual intervention efficiency is low, and control force is not high are solved; and product quality is effectively guaranteed, and great significance is achieved in reducing market quality objection and improving product grades.

Owner:HEBEI IRON AND STEEL

Processing path generation method of machine tool

The invention discloses a processing path generation method of a machine tool. The method comprises the following steps: 1, according to geometric shape and technical parameters of a processing part, generating a machine tool processing program; 2, according to the machine tool processing program, adjusting a knife site position and a cutter shaft vector of the machine tool, setting a key control point, adjusting a direction and a cutting depth, and determining a workpiece clamp and a workpiece height; 3, performing acceleration and deceleration planning and smooth switching processing on a processing segment in a processing path of a cutter by use of a five-segment S-curve method; 4, determining cyclic processing frequency; 5, performing compensation processing on a corner according to a radius of the cutter; and 6, fitting the machine tool processing program to perform grinding wheel grinding processing on the processing part. According to the invention, the machine tool processing path is continuous, the cutter can be prevented from turning idly, the processing method is simple, the processing efficiency is high, the processing precision is high, the production cost is low, and therefore, the application prospect is quite large.

Owner:安徽至高机械有限公司

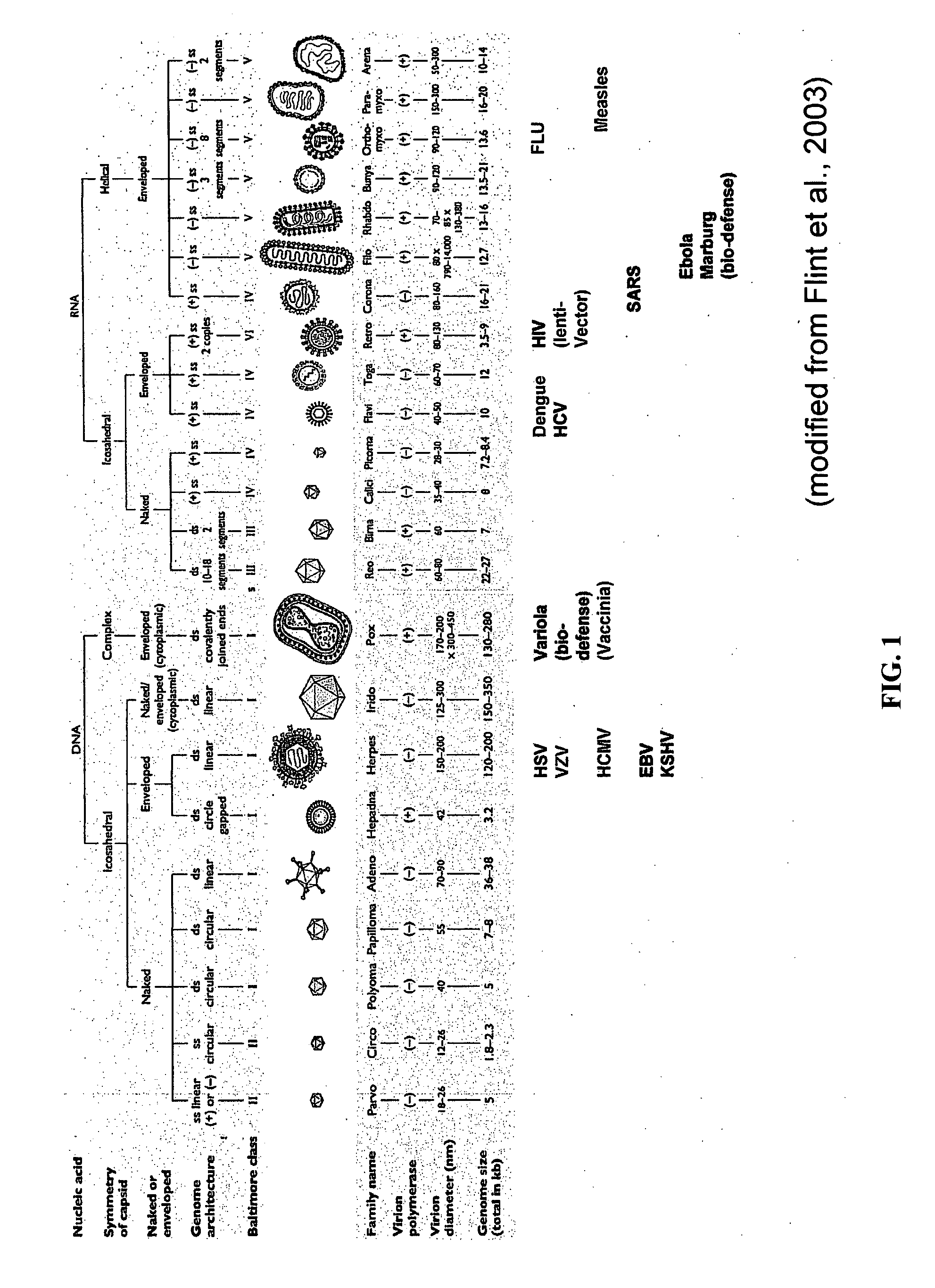

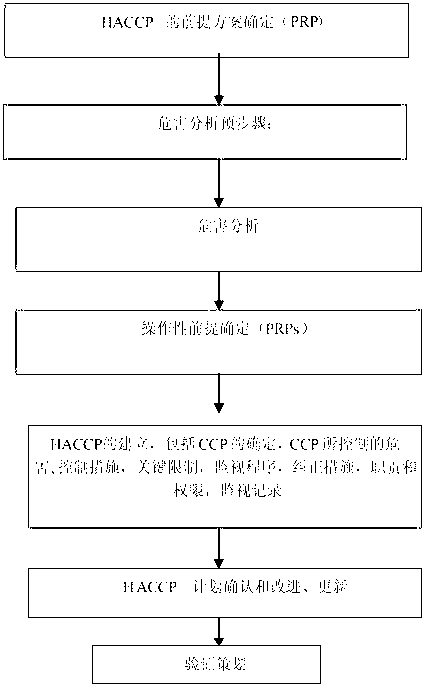

food tracing and query analysis system and method based on an HACCP system

PendingCN109657996AEasy to understandRapid positioningDigital data information retrievalResourcesCritical control pointQuery analysis

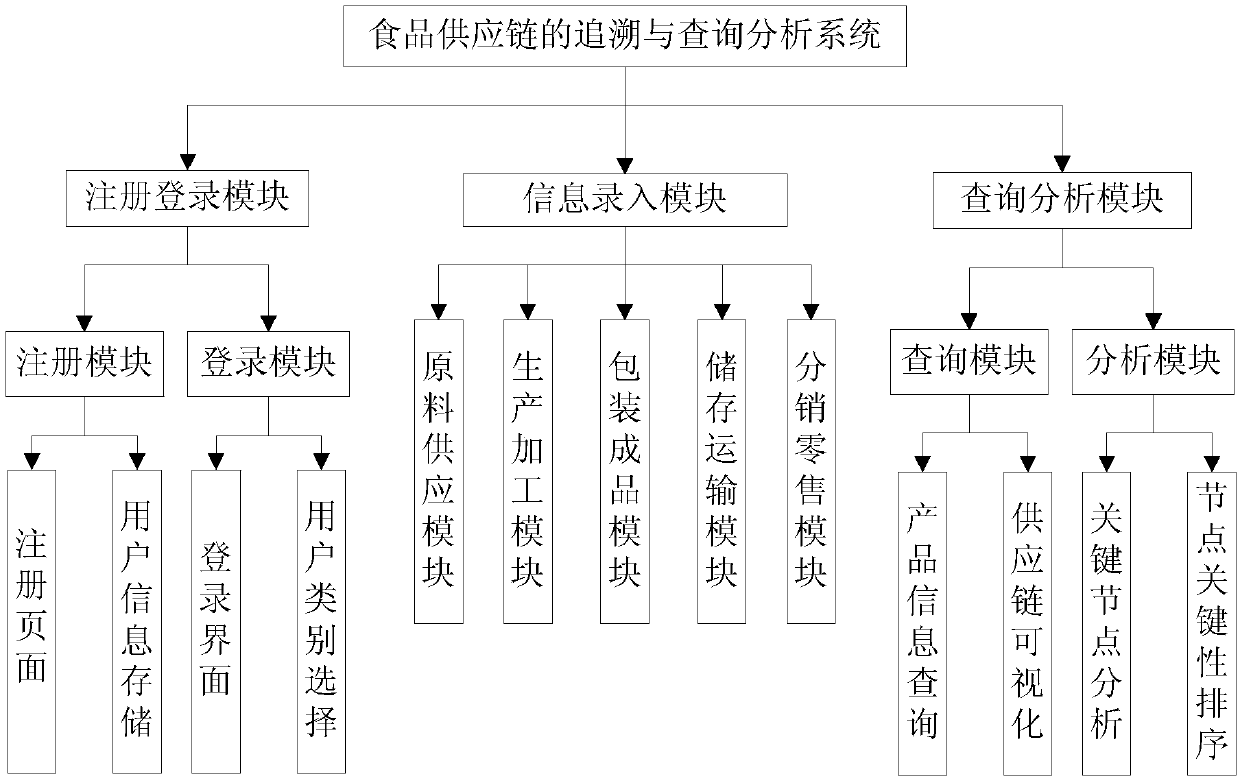

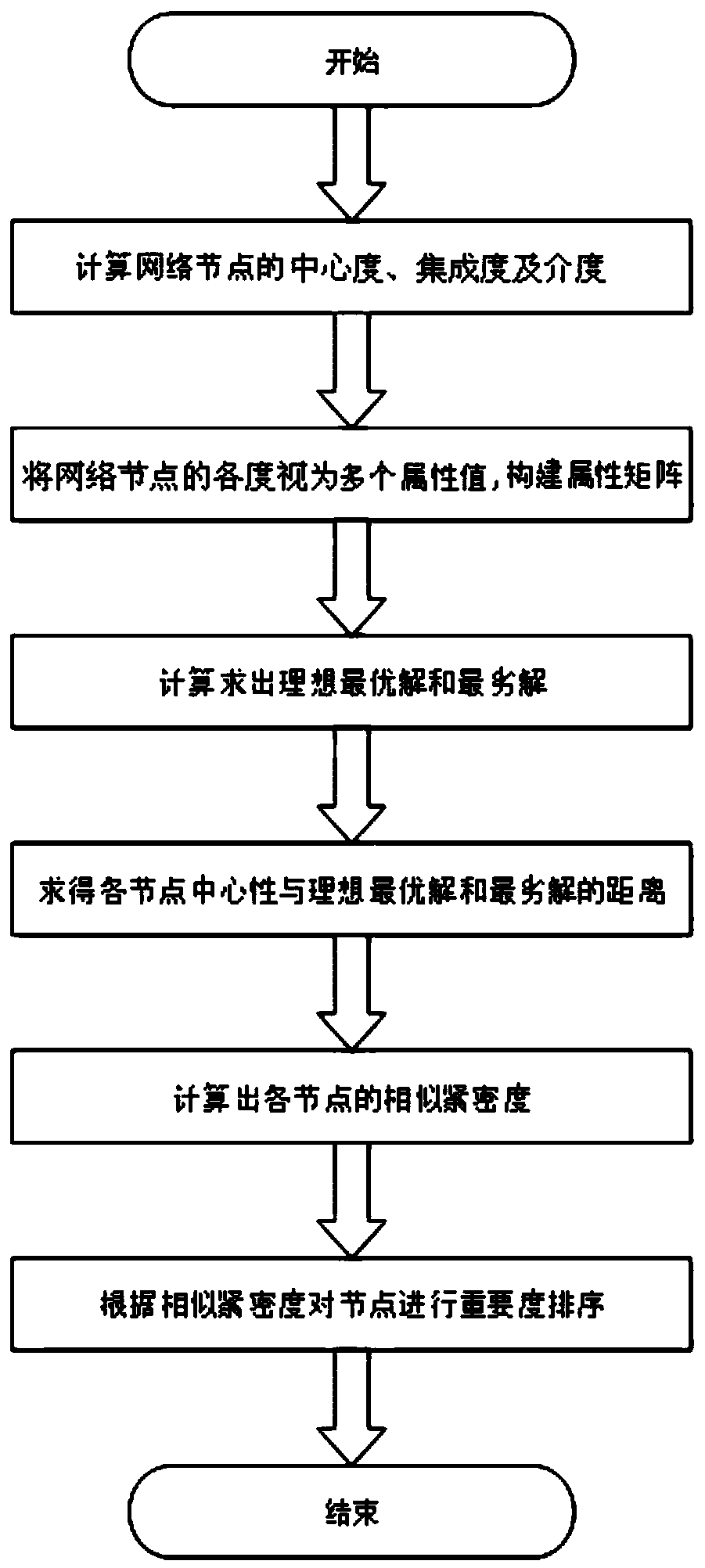

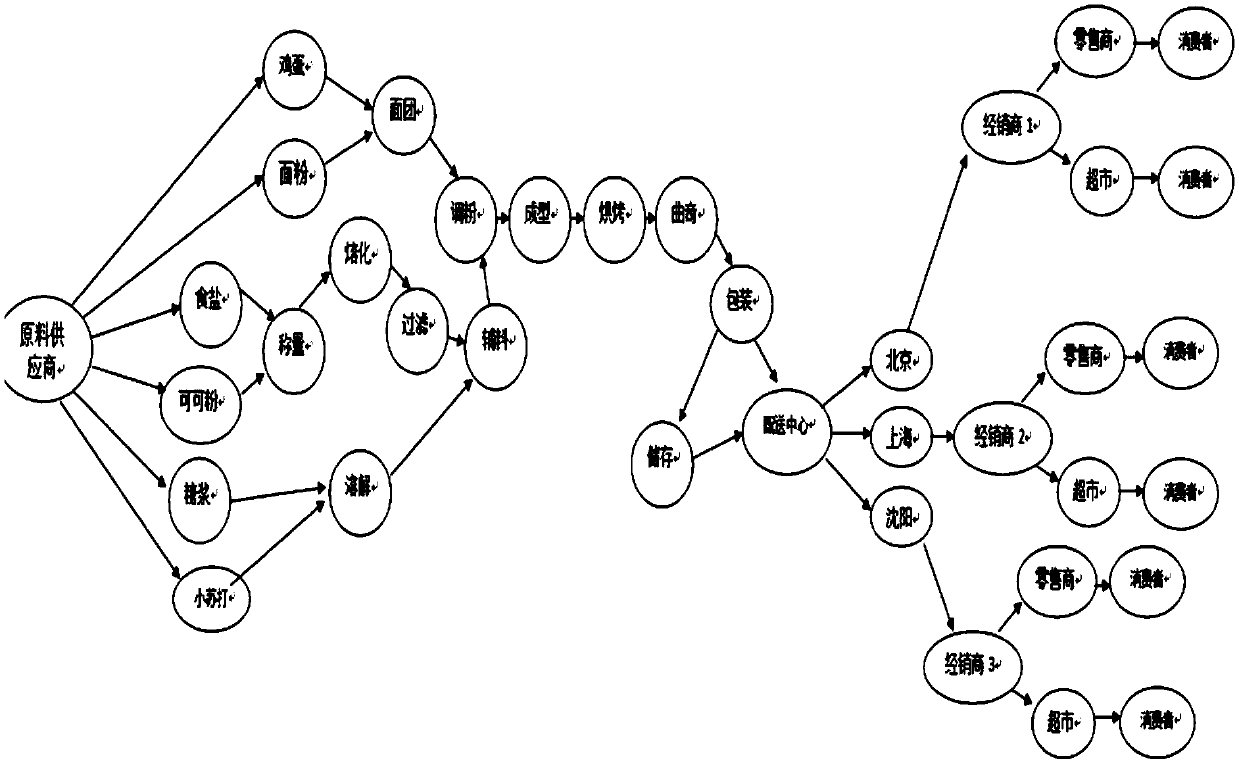

The invention provides a food tracing and query analysis system and method based on an HACCP system, and relates to the technical field of food quality control. The system comprises a registration andlogin module, an information input module and a query and analysis module, The registration login module provides login, registration and user classification functions for users; The information input module provides an information input function for a product production and sales related party; The query analysis module provides a product information query function for a product purchaser, analyzes the key nodes of the food supply chain network based on the HACCP system, finds out the key nodes needing key monitoring, and provides reference for product production and transportation parties.The invention further provides a specific method for analyzing the key nodes of the food supply chain network based on the HACCP system. According to the food tracing and query analysis system and method provided by the invention, the problem product source can be traced more conveniently, the problem node can be found out, the problem product can be recalled, and decision support can be providedfor determining the key control point in the HACCP system.

Owner:NORTHEASTERN UNIV LIAONING

Food safety tracing system

The invention provides a food safety tracing system. An implement object is selected, food raw materials are produced, the final consumption business process is analyzed, food quality safety elements and key control points are analyzed and determined according to all links of a food traceable chain, and limiting values of key elements are determined according to international standards, national standards and industrial standards; then, a food safety tracing index system is built, a tracing unit is determined, a food traceable chain encoding system is built, a quality safety information management system for a food production link, a processing link, a storage and transport link and a selling link is built according to the food traceable chain and the encoding system, a food safety tracing system platform is constructed, and accurate tracing of food is achieved.

Owner:刘丰

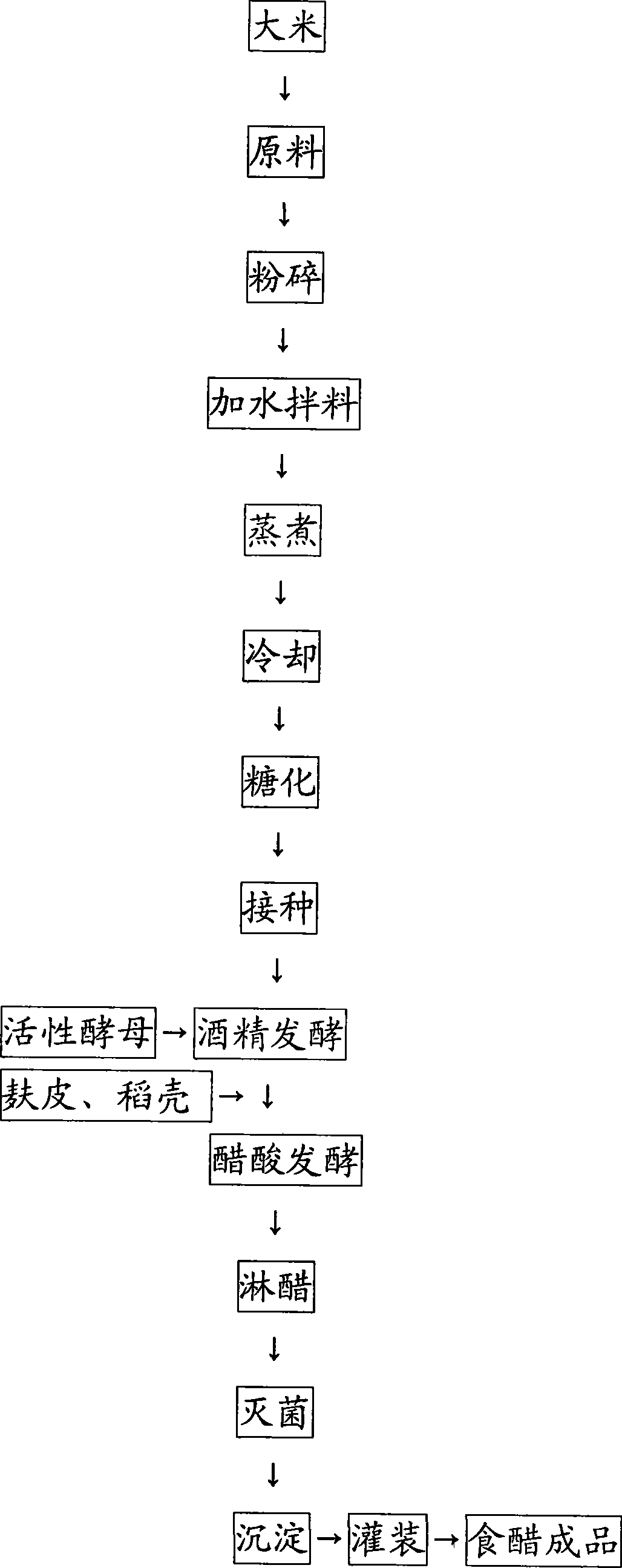

Method for producing edible vinegar

InactiveCN101381670AMeet quality requirementsEnsure safetyVinegar preparationBiotechnologyCritical control point

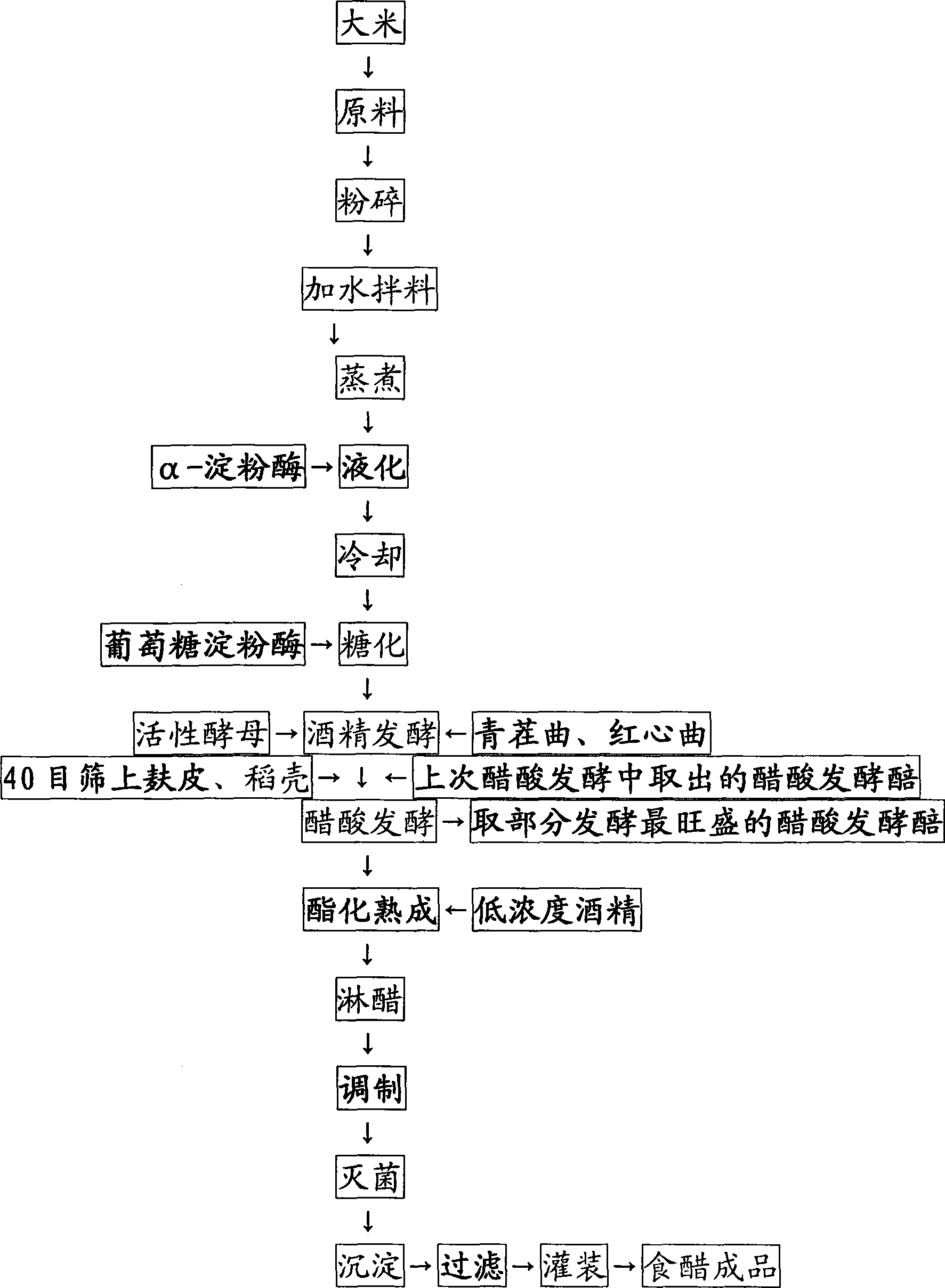

The invention discloses a method for producing an edible vinegar product, which relates to the technical field of edible vinegar production. The top-class optimization of key control points is used to determine a new method and a new edible vinegar product, including the prior technology of the production process of edible vinegar; raw materials are non-transgenic and meet the requirement of green food, the polished rice rate of rice is 80 percent, and the ratio of the materials to water is 1 to 3; eight ten-thousandths liquefying enzyme is added, and the temperature is increased by 120 DEG C for liquefaction; 100U of saccharifying enzyme is added for each gram of starch for saccharification; during the alcohol fermentation, qingchaqu which accounts for 10 to 12 percent of the raw materials and hongxin daqu which accounts for 18 to 20 percent of the raw materials are added, and the alcohol content of mash is 9 degree; during the fermentation of acetic acid, bran which can pass through a 40-mesh sieve and five thousandths of acetic acid fermenting grains are added; 1 to 3 percent of white spirit with the content of between 16 and 18 degrees is added for esterification ripening for 30 days; the blending and filtration are performed; the standard for edible vinegar products for Olympic Games is executed; and no additives are added expect potassium sorbate during the whole production process. The method is used for the production of the edible vinegar. The method is scientific and the product has high quality.

Owner:北京六必居食品有限公司

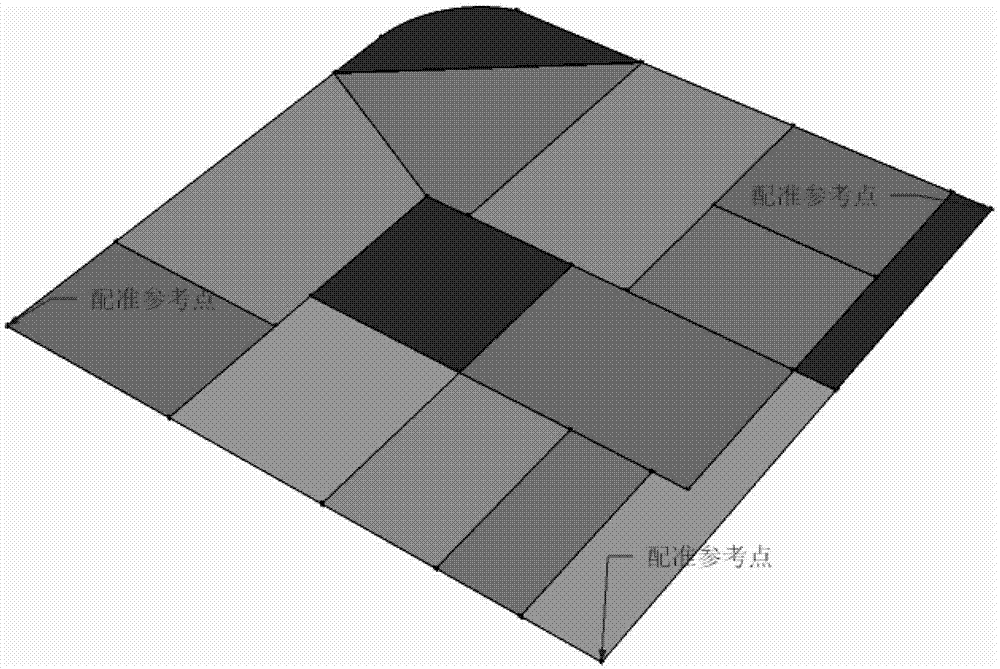

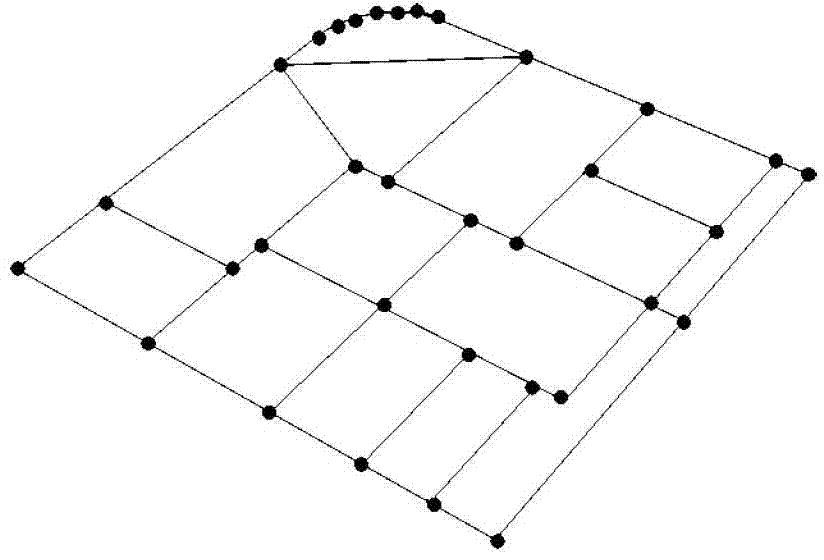

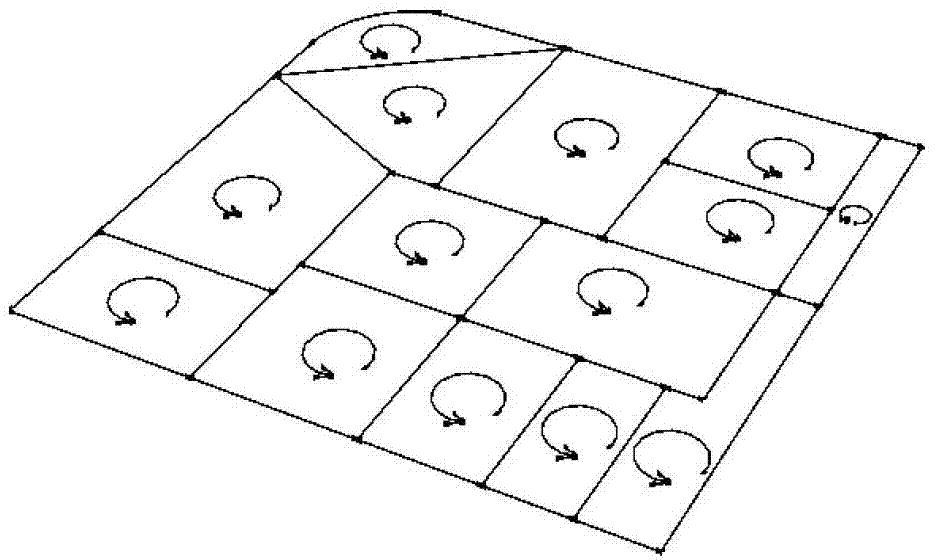

Method for surveying and mapping map by collecting farmland key points

ActiveCN103247062AReduce labor intensityPrevent missed detection2D-image generationDemarcation pointCritical control point

The invention discloses a method for surveying and mapping a map by collecting farmland key points. The method comprises the following steps: 1, obtaining GPS position information; 2, drawing an outline of an area to be surveyed; 3, surveying and mapping a farmland key demarcation point, and marking a land parcel name and note; 4, performing real-time verification, prompting, and dividing the farmland; 5, uploading surveying and mapping data; and 6, obtaining a vector map. Compared with the prior art, in the technical scheme provided by the invention, the real-time mapping can be achieved merely by collecting key control points, simultaneously, initiative verification is further performed according to a logic relation between the key points, the non-collected key points are promoted, and the missed survey and the false survey are prevented; and moreover, the reliability is improved, and the labor intensity of manual operation is reduced simultaneously.

Owner:BEIJING RES CENT FOR INFORMATION TECH & AGRI

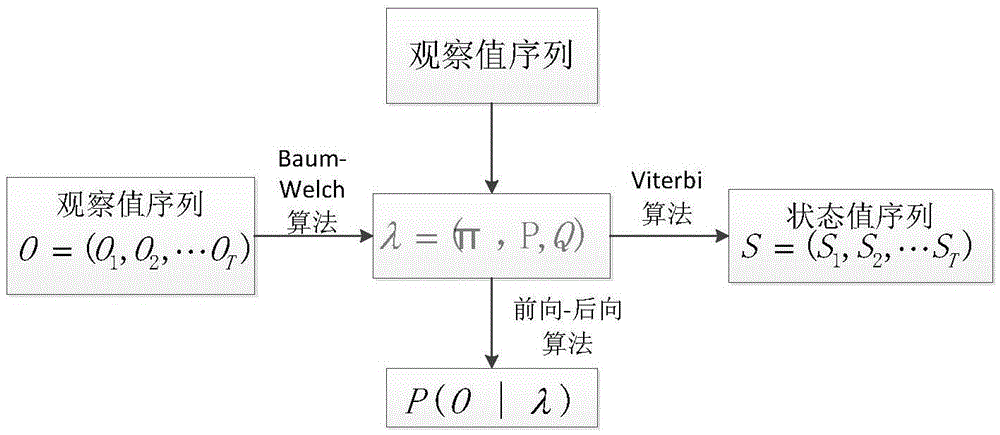

Food safety risk prediction method based on hidden Markov model

InactiveCN105608536AAccurate descriptionImprove scalabilityResourcesCritical control pointFood supply

The invention provides a food safety risk prediction method based on the hidden Markov model. The method comprises the steps: analyzing every step of a food supply chain, and finding out a critical control point of each step; analyzing the critical control point of each step and using the critical control point as a quantitative index of the HMM (hidden Markov model), and establishing a HMM; initializing parameters of the HMM, and training the parameters of the HMM according to a visible state sequence of the HMM and the real state of a system; and performing the risk assessment and value-at-risk calculation on the risk grade of the food supply chain. According to the invention, the HMM is adopted to assess the food quality and safety, the dynamics of every step is considered, the risk state can be responded in real time, a quantitative and qualitative-combined assessment method is adopted, the degree of the supply chain risk can be more precisely described than before, and the method is helpful for decision maker to timely adopt corresponding measures. The risk assessment model can assess the dairy product and has strong expansibility so as to apply to other fields of food safety.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

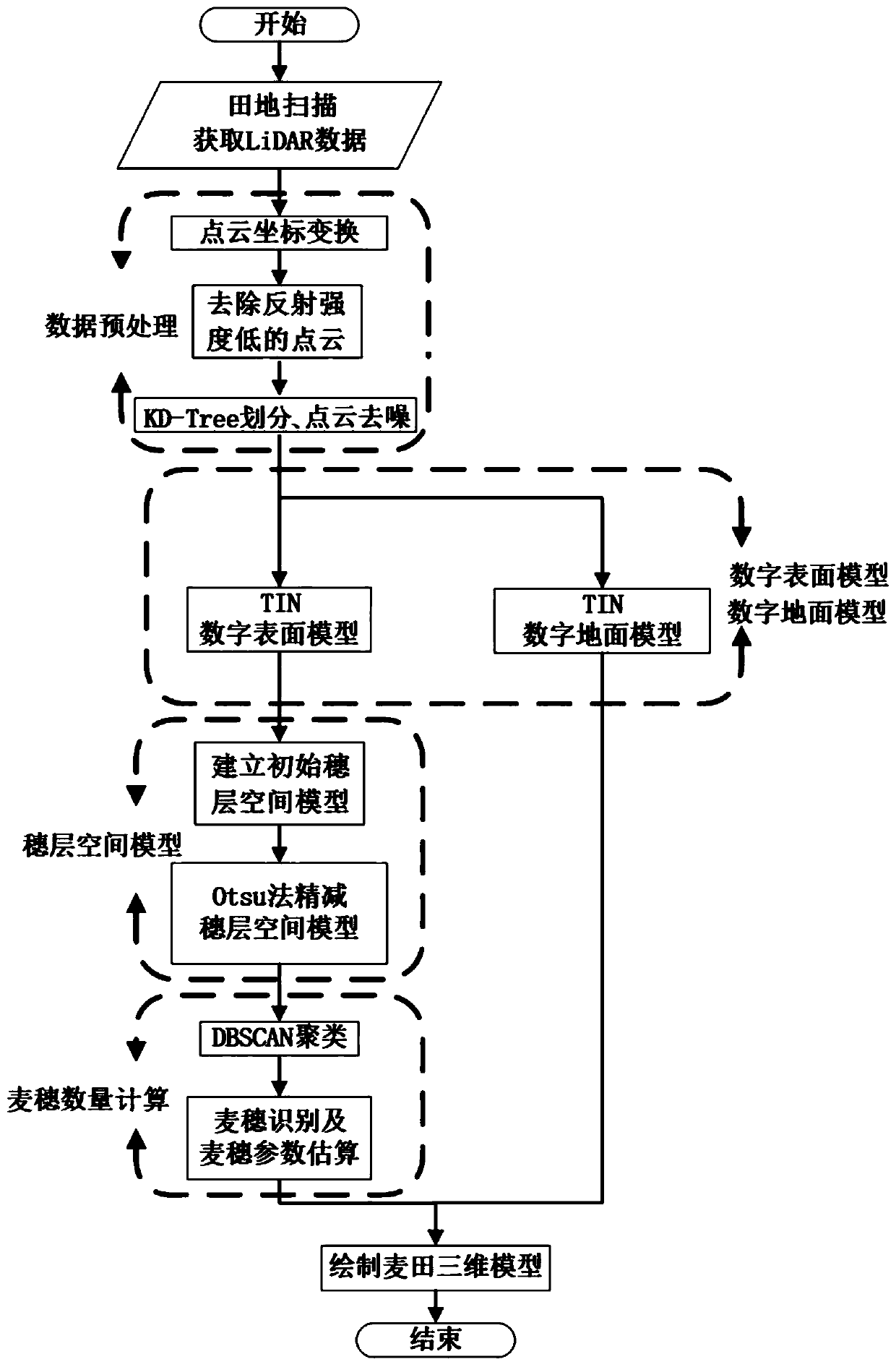

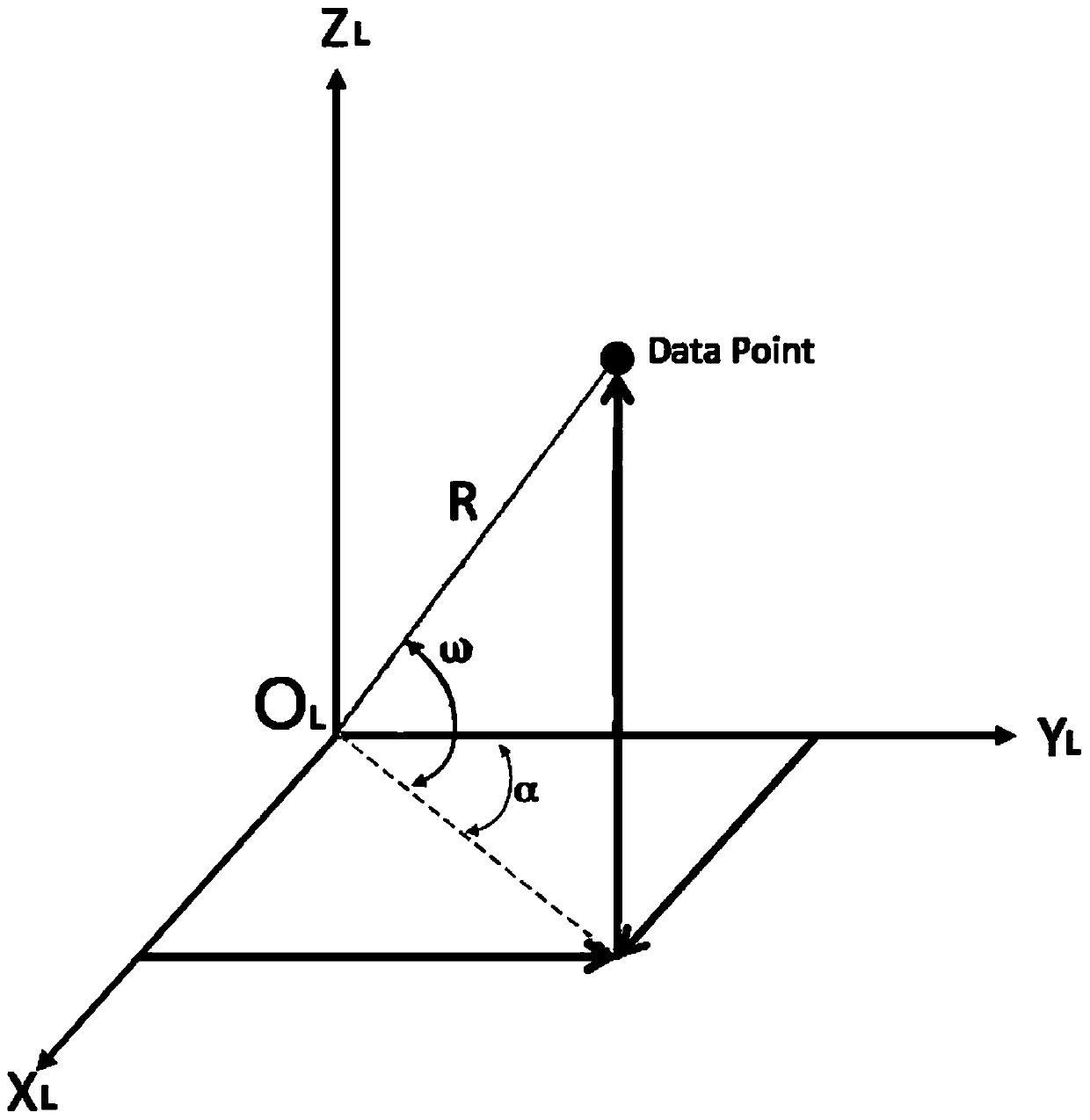

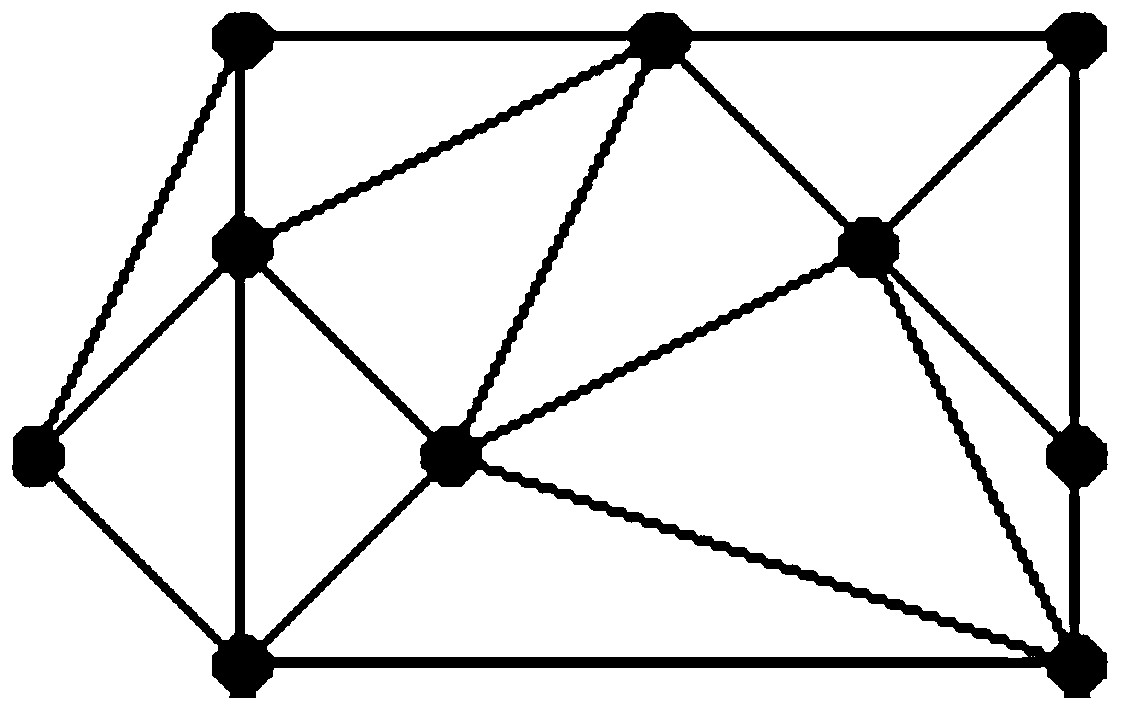

Field crop three-dimensional reconstruction method based on laser radar point cloud

ActiveCN110363861AImprove accuracyReduce labor costsImage enhancementDetails involving processing stepsCritical control pointTriangulation

The invention discloses a field crop three-dimensional reconstruction method based on laser radar point cloud, and the method comprises the steps: obtaining the point cloud data of a field crop through a laser radar, and carrying out the data preprocessing of the point cloud data; extracting a small amount of point clouds as key control points, and establishing a digital surface model and a digital ground model by utilizing the key control points and through an irregular triangulation network; constructing an initial spike layer space model according to the digital surface model, and obtainingpoint cloud data in an actual spike layer space model through an Otsu threshold method; segmenting the point cloud in the actual spike layer space model into a plurality of point cloud clusters by adopting a density-based clustering algorithm; correcting the number of point cloud clusters, the number of the point cloud clusters being the number of crop ears, and calculating the crop height according to a digital ground model; and constructing a three-dimensional model of the crops in the field according to the obtained crop number, crop height and crop spike coordinates. According to the invention, the construction of the three-dimensional model of the field crops is realized, and enough data support is provided for the digital management of the field.

Owner:NANJING FORESTRY UNIV

Chicken fillets coated with snowflake shaped breaders, and preparation method of chicken fillets coated with snowflake shaped breaders

InactiveCN106616457APerfect Taste GuaranteedUniform lengthFood freezingFood ingredient as mouthfeel improving agentFiberIce water

The invention provides chicken fillets coated with snowflake shaped breaders, and a preparation method of the chicken fillets coated with snowflake shaped breaders. The chicken fillets coated with snowflake shaped breaders comprise the following raw materials of chicken breast, ice water, tapioca starch, distinctive flavored dusting materials, white granulated sugar, onion powder, garlic powder, dietary alkali, chili powder, white pepper powder, meat fragrance enhancing powder, a non-phosphorus water retaining agent, sodium tripolyphosphate, trehalose, biological enzymes and breader slices. The preparation method comprises the following steps of treating raw materials, performing rolling, performing pickling, performing bran wrapping, performing quick-freezing, performing packaging and performing warehousing. A slicing machine and a slitter are perfectly combined for performing preliminary treatment on the raw materials, and the length, the width and the thickness are uniform; and besides, key control points (selection of raw materials, preliminary treatment of large breasts, utilization of the large breasts after preliminary treatment, and oblique angle) are utilized, so that the fibers of the large breast raw materials are not destroyed, guarantee is provided for the perfect mouth feel of finished products, the labor cost is further reduced, and the labor efficiency is improved.

Owner:鹤壁市永达调理食品有限公司

High-efficient laying hen breeding method

ActiveCN105613420AExtend peak egg productionImprove farming efficiencyAnimal feeding stuffAccessory food factorsCritical control pointAnimal science

The invention discloses a high-efficient laying hen breeding method, and in particular relates to a technical scheme of breeding targets, nutritional levels and key control points of different breeding stages in a whole laying hen breeding process. The method is characterized by regarding 0 to 15 day-age as a mouth opening stage; (2) regarding 16 to 70-day-age as a brood stage; (3) regarding 71 to 112-day-age as a growing stage; (4) regarding 113 to 220-day-age as a pre-production stage; (5) regarding 221 to 580-day-age as an egg laying peak stage. According to the long-term practice and experience of the applicant, the whole laying hen breeding process is reasonably divided into at least five stages, wherein aiming at the growing features and required nutrition features of laying hens in each stage, the high-efficient laying hen breeding method disclosed by the invention designs reasonable nutritional requirements and stipulates operation key points of each stage; the breeding benefits are improved.

Owner:山东富华伟农农牧科技有限公司

Payment method, payment terminal, server and payment system

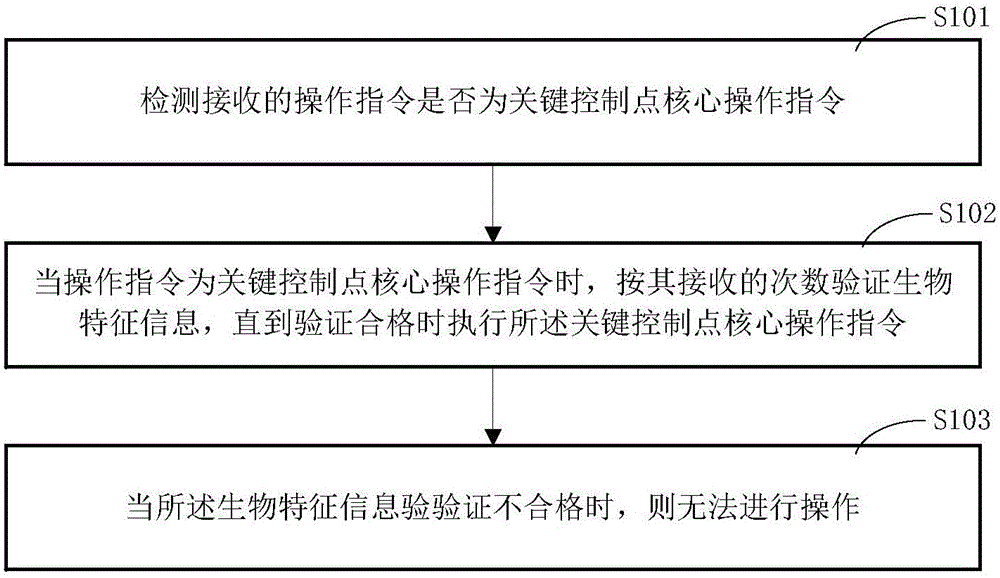

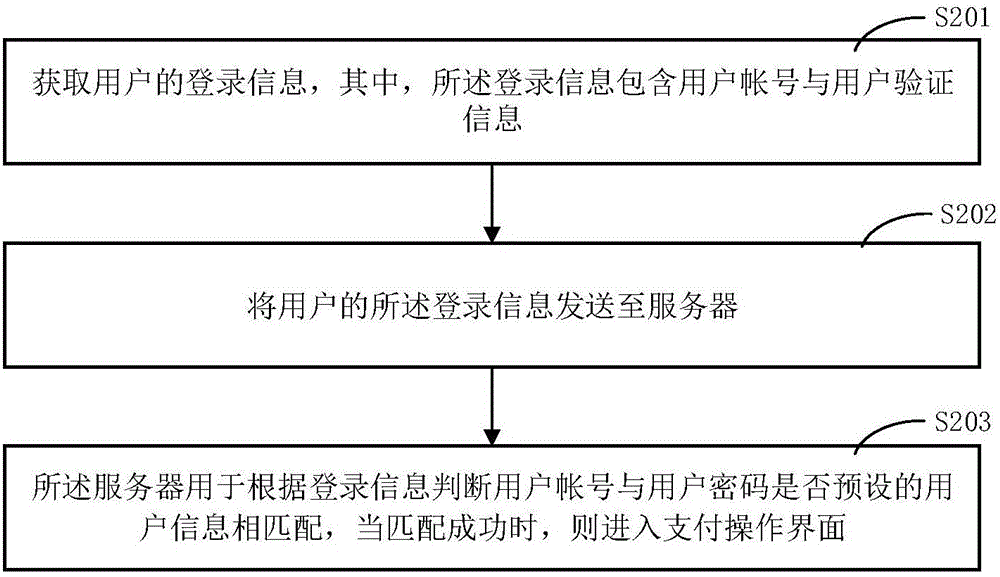

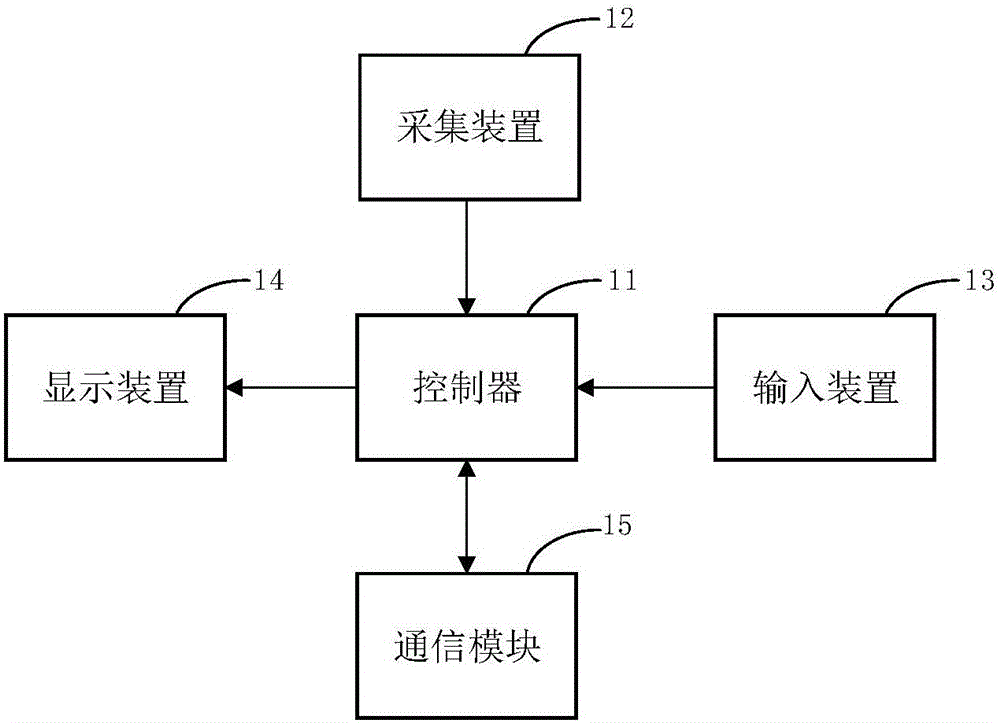

InactiveCN106056386AImprove securityRealize real-name registrationProtocol authorisationCritical control pointPassword

The present invention provides a payment method, a payment terminal, a server and a payment system. The method includes: detecting whether received operation instructions are key operation instructions for key control points or not; when the operation instructions are key operation instructions for key control points, verifying biometric information according to the number of the received key operation instructions for key control points until the biometric information is qualified, and then executing the key operation instructions for key control points wherein the key operation instructions for key control points include withdrawals, transfers, payments, settlements, transactions, or password change; and aborting operations when the biometric information verification is not qualified. The invention also provides a payment terminal, a server and a system based on this method, which not only improves the security of the payment, but also helps realize the tracking and tracing. Using technology for the real name registration management for property funds, the method can effectively prevent telecommunication frauds, money laundering and other illegal and criminal activities.

Owner:重庆馥莉信息科技有限公司

Automatic optimization of the position of stems of text characters

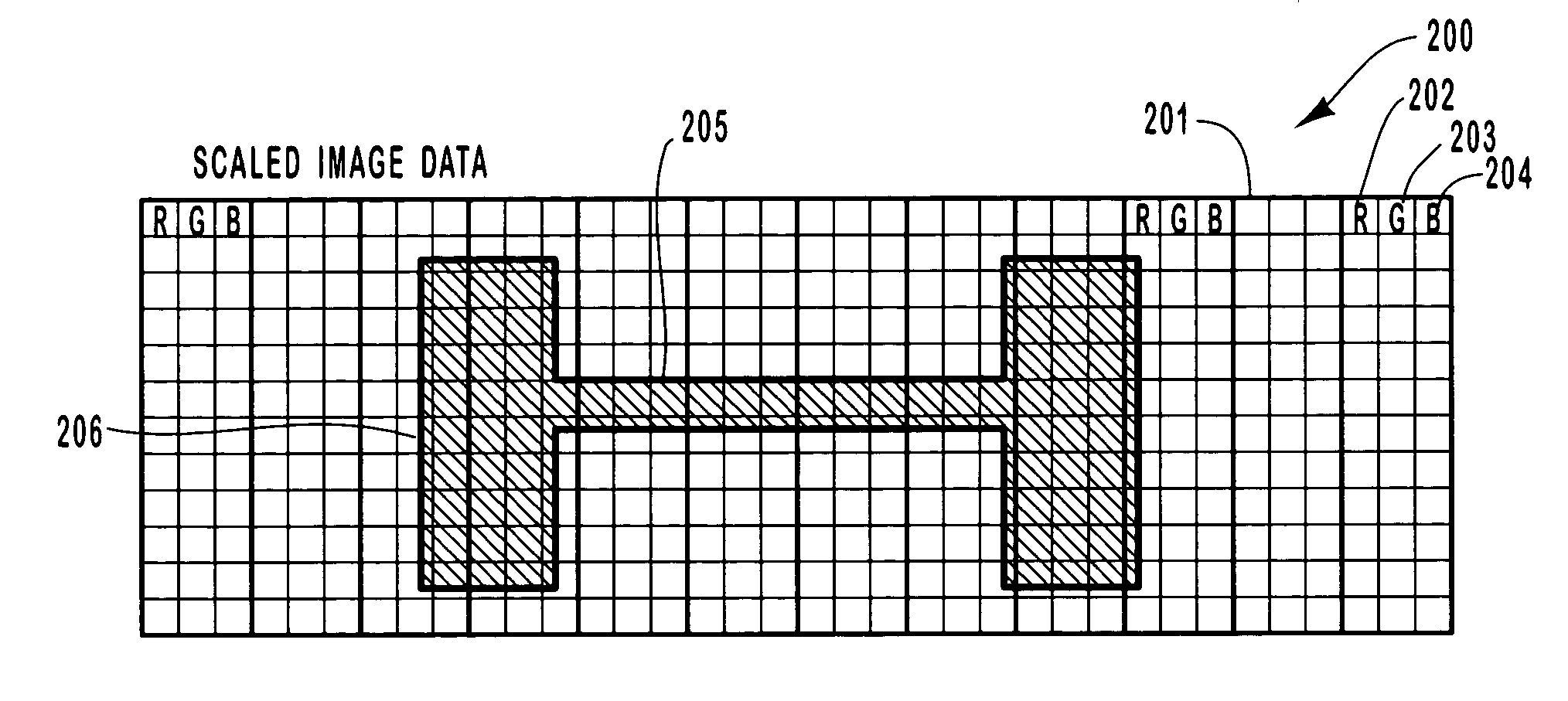

InactiveUS20040004618A1More computationally efficientEfficient analysisDrawing from basic elementsCathode-ray tube indicatorsCritical control pointComputer graphics (images)

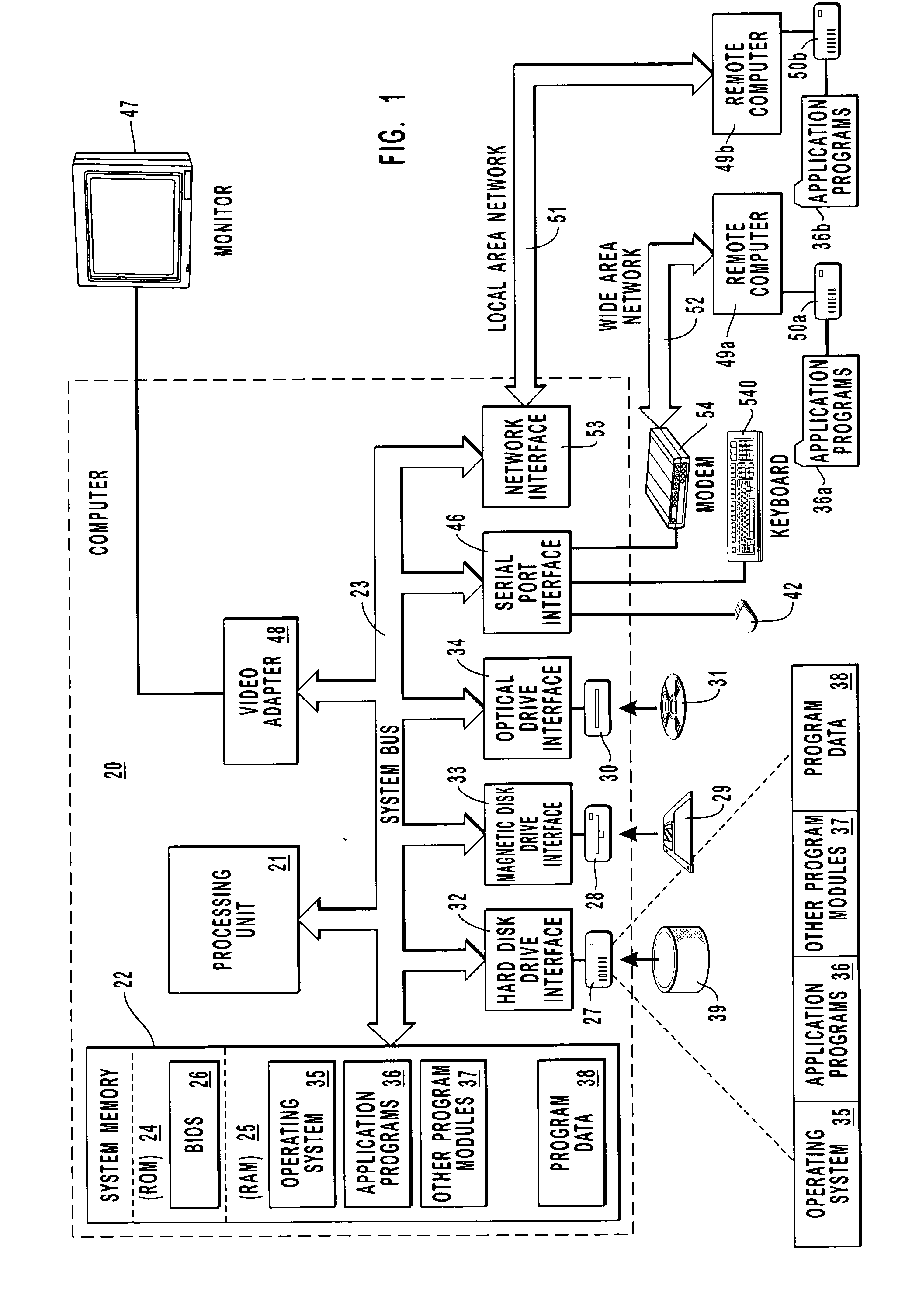

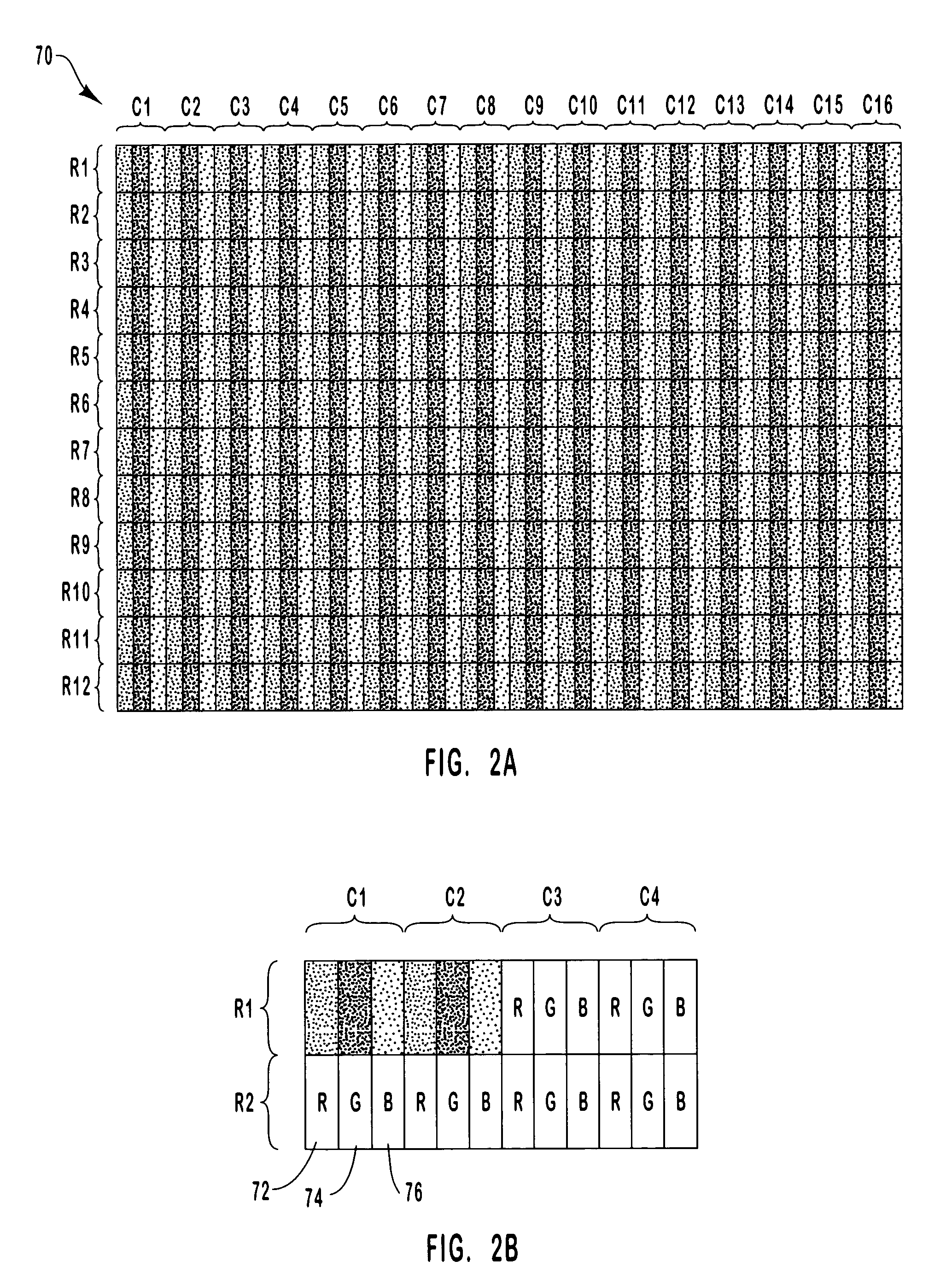

Automatically positioning of typographical features, such as vertical stems or horizontal segments of a character, on high contrast pixel sub-component boundaries as part of a rendering process that uses separately controllable pixel sub-components of pixels to represent different portions of the character. In order to identify the typographical features of the character that are to be aligned with high contrast pixel sub-component boundaries, topology of the character is analyzed at runtime. In display devices having vertical stripes of same-colored pixel sub-components, character legibility is increased when the left edges of stems are aligned with high contrast boundaries between pixel sub-components. Processing time and resources are conserved by performing a partial, rather than a full, topological analysis of the character. For example, some font files include data structures that define the position of key control points associated with the character, thereby indicating where the stems or other typographical features are located, and the relationship between different typographical features.

Owner:MICROSOFT TECH LICENSING LLC

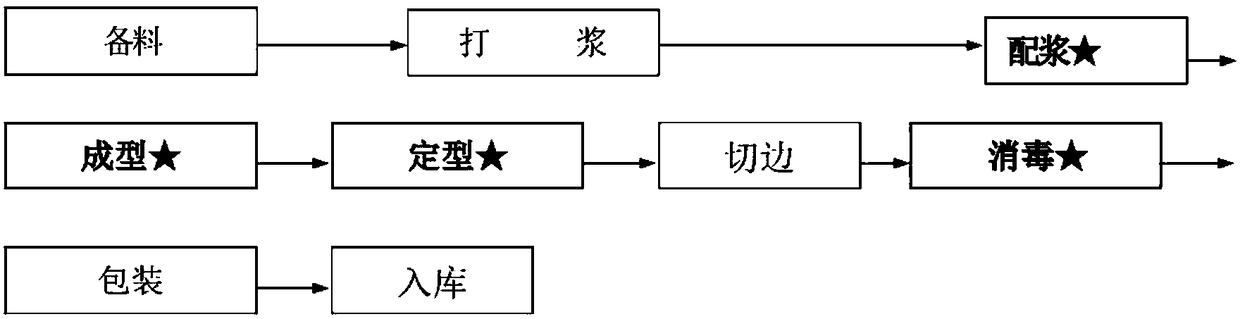

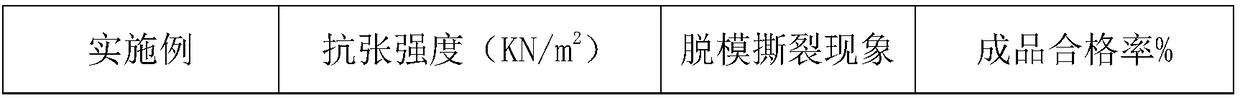

Preparation method of paper pulp molded tableware

InactiveCN108589431AHigh tensile strengthImprove pass rateTextiles and paperCritical control pointPulp and paper industry

The invention aims at overcoming the weaknesses of the existing preparation process of the paper pulp molded tableware, and provides an improved paper pulp molded tableware preparation process. According to the preparation process, a technological condition at a key control point of the paper pulp molded process is optimized, particularly in the pulp preparation process, a pulp-to-water ratio anda ratio of an oil-proof agent to a waterproof agent are optimized, and the technological conditions such as vacuum degree, temperature, pressure in the molding and stereotyping are controlled, so thatthe tensile strength of the product can be improved, in the mold stripping process, the tearing is unlikely to occur, the qualification rate of the product is increased, and the moisture absorption mould phenomenon can be reduced.

Owner:浙江博特生物科技有限公司

Islamic cattle or mutton can and production technique thereof

InactiveCN101455410AChanging long-term direct exportChange productivityFood preparationCritical control pointAdditive ingredient

The invention relates to a Islamic characteristic canned beef or mutton and production technology thereof, belonging to the meat product processing technology field. The product comprise beef or mutton, original cooking liquor ingredients and nourishing ingredients; the production process flow is: slaughtering-> tenderizing-> boning-> cutting-> soaking-> pre-boiling-> arranging-> canning and adding the original cooking liquor or nourishing liquor-> sealing by vacuum-> sterilizing-> heat preserving-> inspecting->finishing. The application of the present invention changes the present single form in beef and mutton product processing, increases animal product added value, and adds resource using approaches; the invention optimizes the production process flow by adopting Islamic slaughtering, mature method tenderizing, socking after cutting, adding pre-boiling and arranging step and shortening sterilization time; by setting key control point of pre-boiling, proportioning and sterilizing according to the HACCP requirement, the product is made to achieve the advantages of neat meat lump, perfect color, clear juice, mild hardness, no mutton smell, and has tonifying function.

Owner:兰州六和德食品有限公司

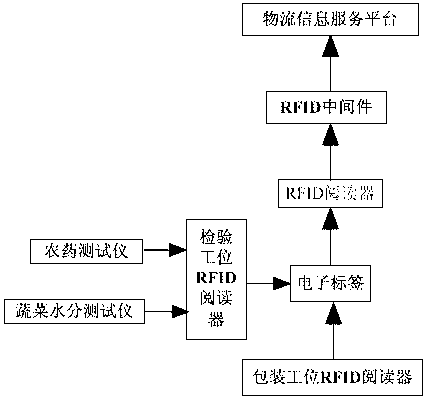

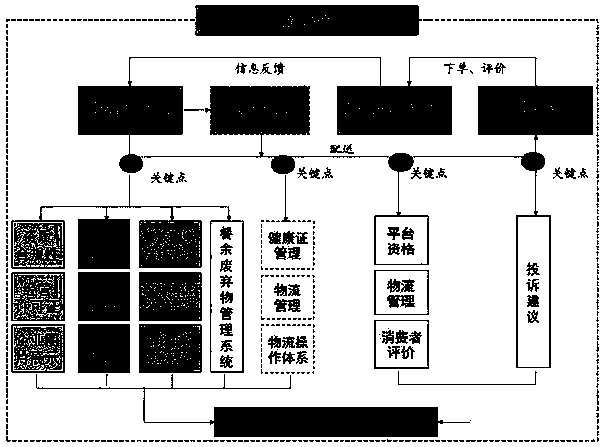

Logistics platform of whole agricultural product supply chain

InactiveCN103345708AEnsure safetyRealize full trackingData processing applicationsCo-operative working arrangementsThird partyCritical control point

A logistics platform of a whole agricultural product supply chain comprises RFID tags, RFID readers, RFID middleware and a logistics information service platform, the RFID tags are arranged on the outer packages of agricultural products, and the RFID readers are arranged on an agricultural product verification station, a packaging station, the entrance of a warehouse, transport vehicles, transshipment points and retail shops. The RFID readers collect the information of the RFID tags, and the information of the RFID tags is processed through the RFID middleware and is sent to the logistics information service platform. By means of an RFID technology, critical control point information of the whole supply chain of the agricultural material and agricultural product logistics is acquired in real time, agricultural material and agricultural product transportation is tracked in the whole processes, and a reliable track service is offered to agricultural materials and agricultural products. Relative information of all processes from vegetable gathering to vegetable transportation is preserved in the RFID tags, and thus a customer can use the high-frequency fixed type RFID readers to scan the bar codes on vegetable packages and know the pesticide content and moisture content of the vegetables and relative information in the gathering process and transportation process. Further, agricultural producers can communicate with third parties about sale and purchase information conveniently.

Owner:ANHUI LONGCOM INTERNET OF THINGS

Frozen minced fillet processing method

The present invention discloses a frozen minced fillet processing method. The processing flow is as follows: raw material acceptance: the raw material fish must be fresh and alive fish cultured in aquaculture farming fields of official quarantine institution recognized non-polluting waters and quarantine. During acquisition, supply certificates need to be acquired before an acceptance. During acceptance, the raw material fish need to conduct sampling inspection, acceptance is conducted according to the acceptance specification, color, sense, freshness and other projects, and dead fish and fish not in line with the specification are refused to be accept. The working procedure is a critical control point, fresh silver carps are used, the fish bodies are intact, the eye balls are clean, the corneas are bright, the gills are red, the fish scales are solidly attached to the fish bodies, the muscles are flexible, the bones and meat are tightly connected, and the freshness should be in line with a first class requirement. The frozen minced fillet is rich in nutrition, not easy to drop dregs, long in preservation time, etc.

Owner:MINGGUANG YONGYAN AQUATIC FOOD

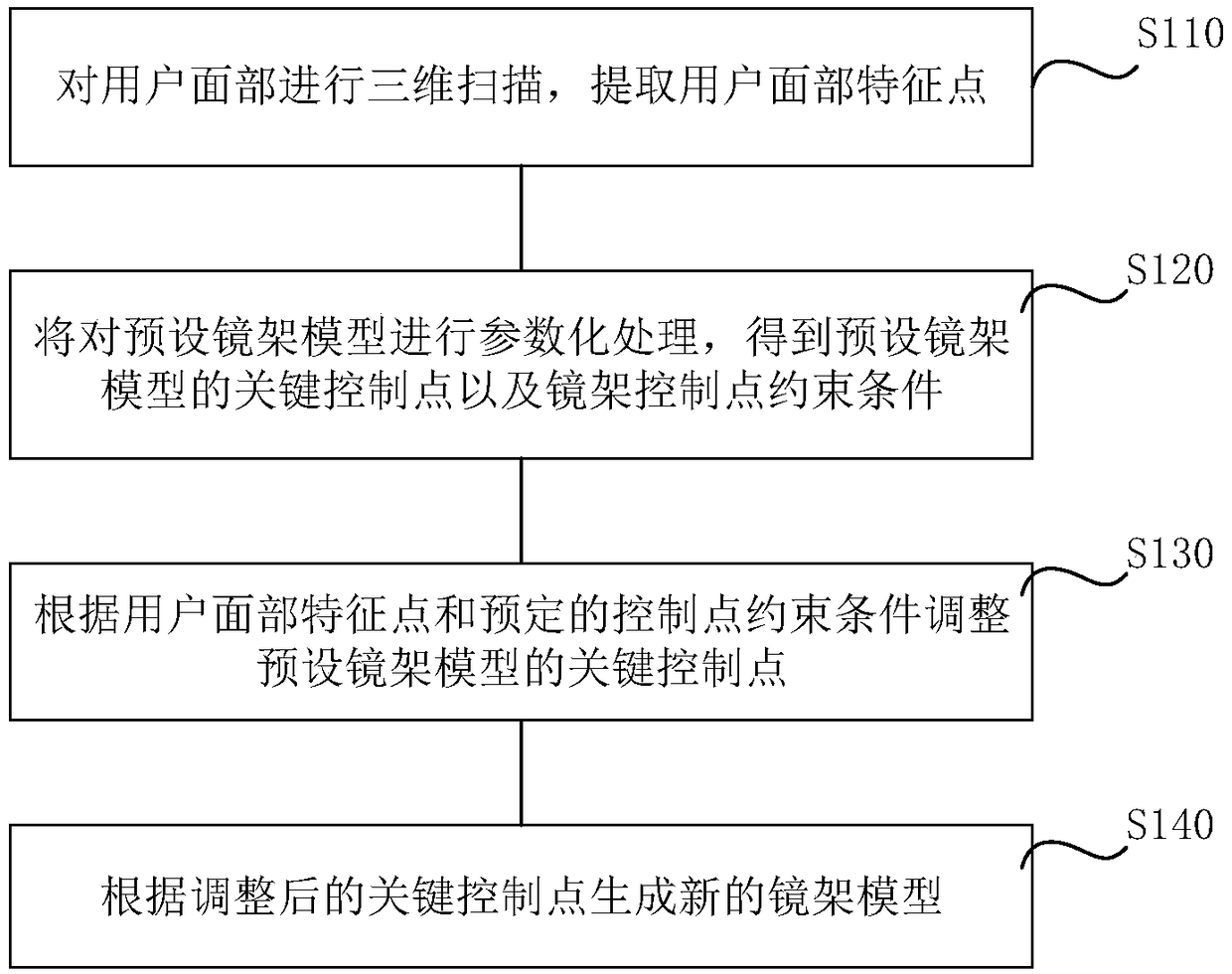

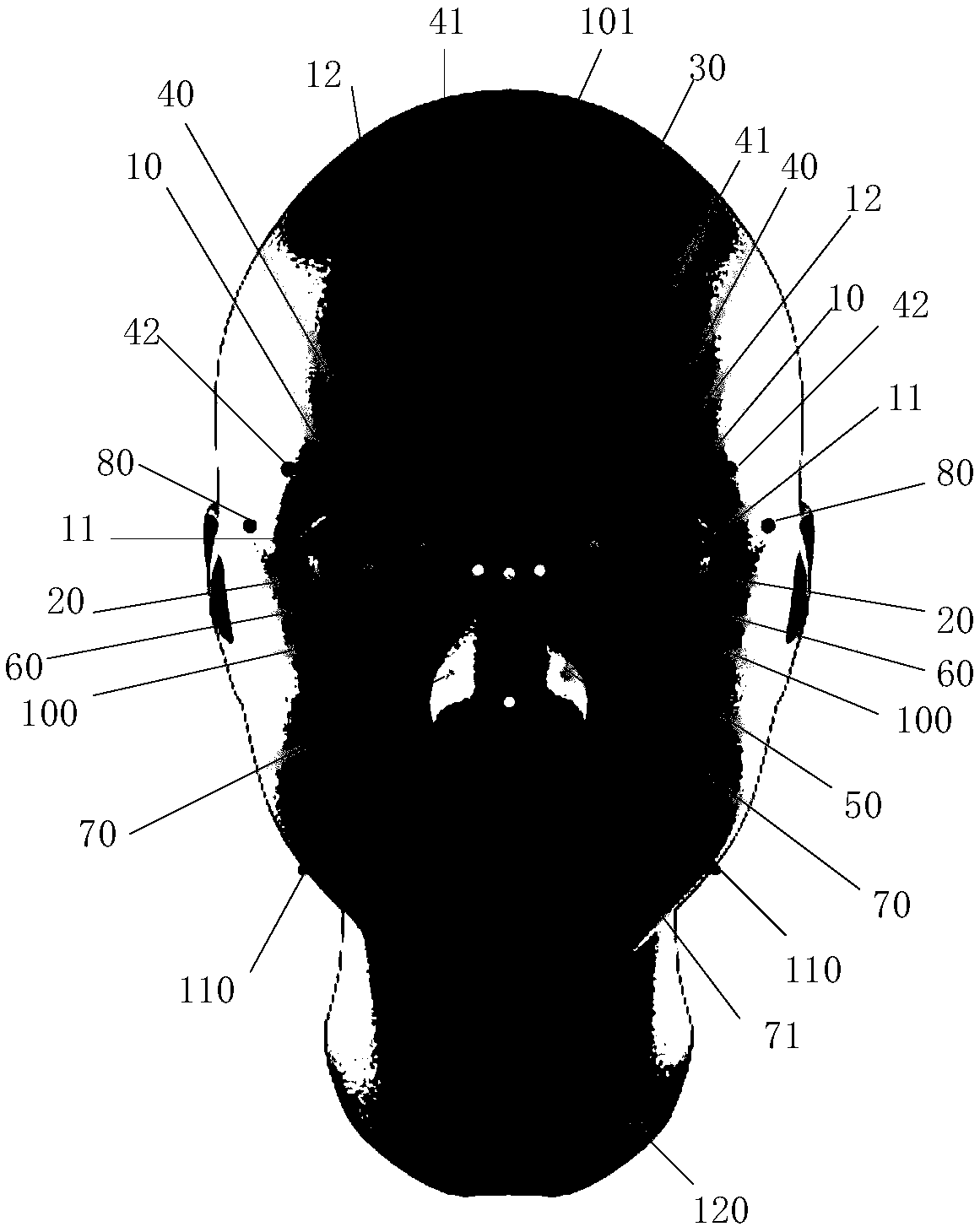

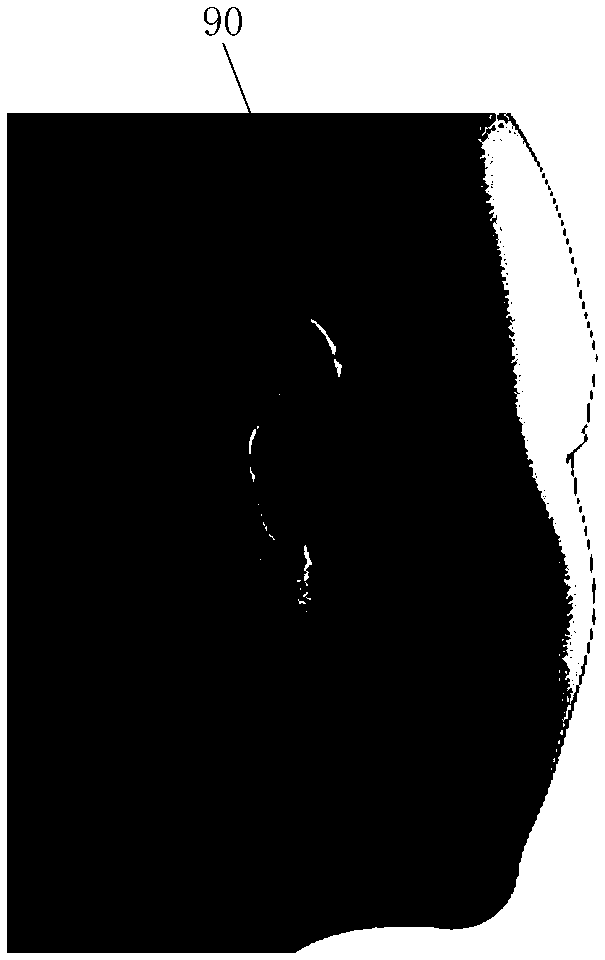

A method and system for generating a mirror frame

ActiveCN109460635AImprove comfortImprove the secondary application rateAdditive manufacturing apparatusCharacter and pattern recognitionPersonalizationCritical control point

The invention provides a method and a system for generating a mirror frame. The method comprises the following steps of: extracting user face feature points by three-dimensional scanning of the user face; Adjusting the critical control points of the preset spectacle frame model according to the constraint conditions of the user's face feature points and the preset control points; A new mirror frame model is generated according to the adjusted critical control points. The invention can individually customize the lens frame according to the user, improves the comfort degree of the lens frame ofthe user, has high modeling efficiency, and avoids repeated labor.

Owner:陈星原 +1

An online ordering food safety supervision mode

InactiveCN108985795AProtection of rights and interestsGuaranteed traceabilityCommerceThird partyCritical control point

The invention provides an online ordering food safety supervision mode, which is mainly used for the supervision of food safety risks and hidden dangers in the network ordering process. The supervision mode is characterized in that the supervision mode comprises a main object, and a critical control point, the main object comprises a catering processing enterprise, a logistics enterprise, a third-party ordering platform and a consumer, and the critical control point includes a first critical control point, a second critical control point, a third critical control point, and a fourth critical control point. The mode can fully cooperate with an enterprise and the third party Internet platform, also can take the road of mutual cooperation and participate in the food safety society co-governance such as popular science propaganda and big data management by utilizing the advantages and channels of the invention, and will play a twice the result with half the effort to solve the food safetyproblem.

Owner:GUANGDONG TESTING INST OF PROD QUALITY SUPERVISION

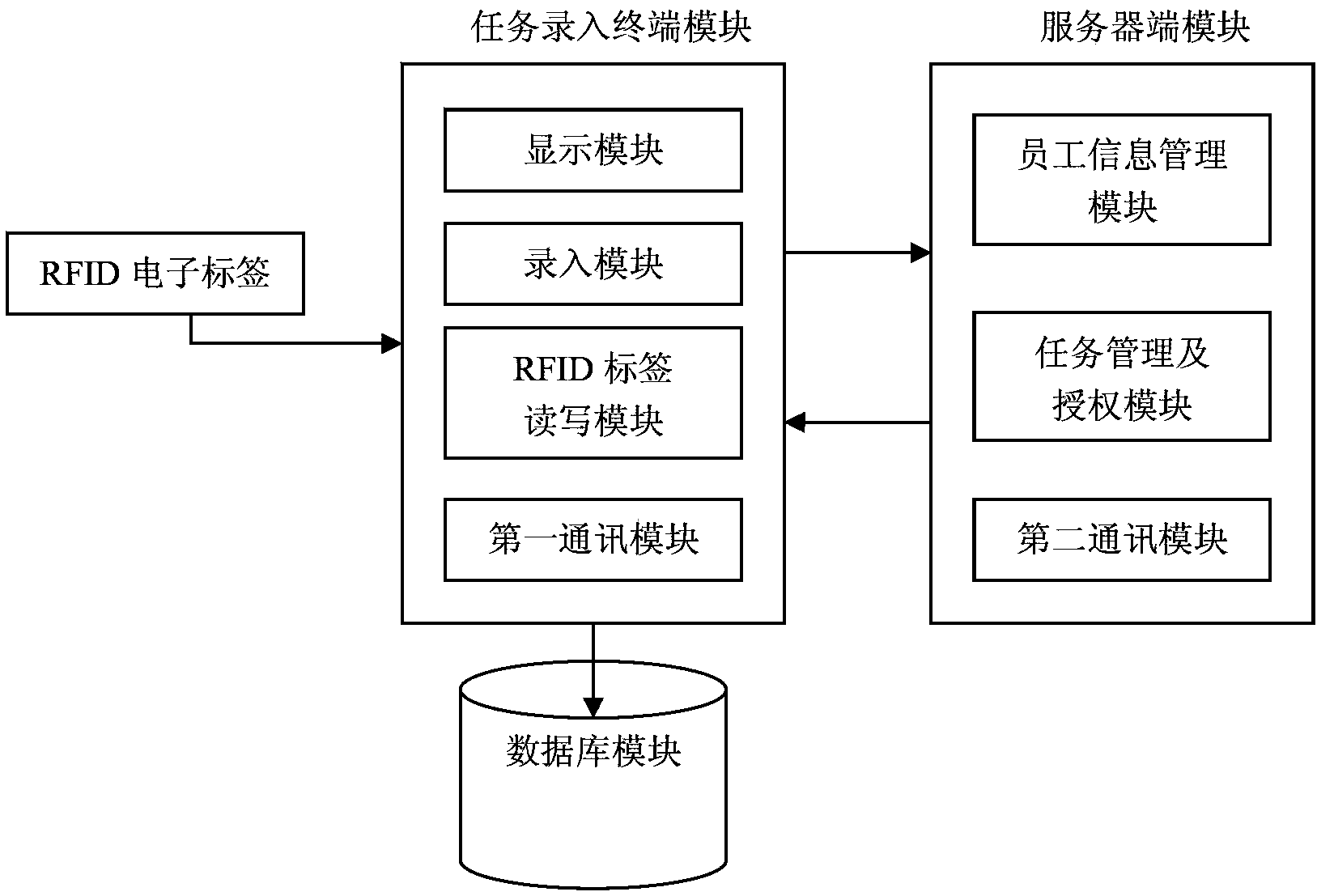

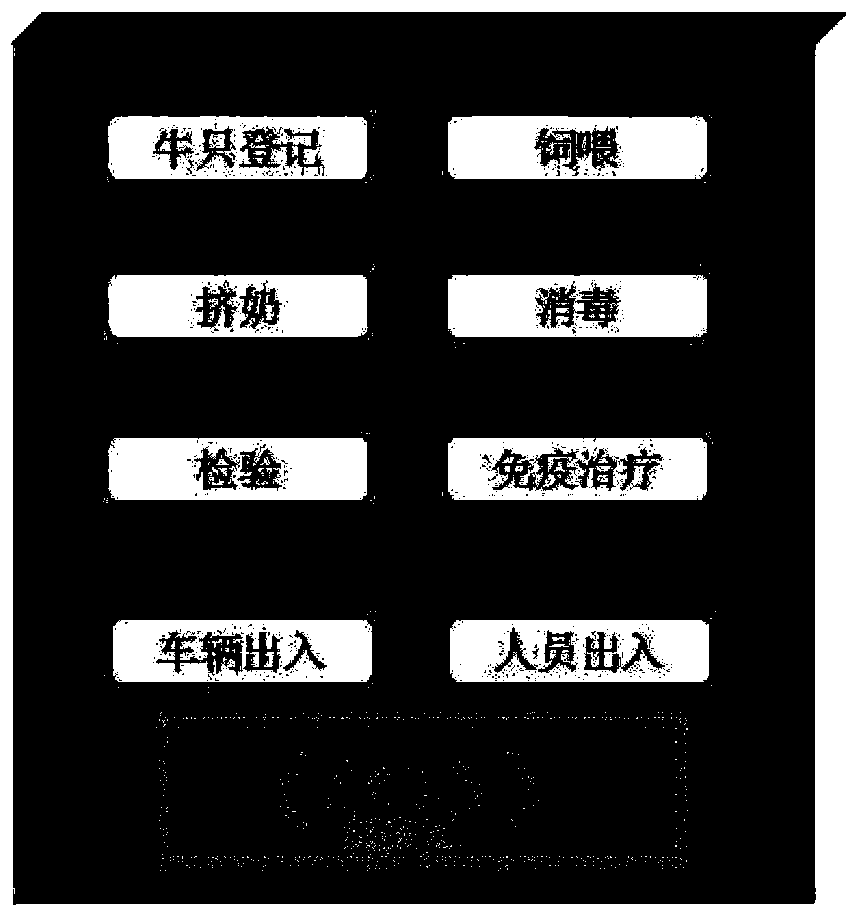

Farm production personnel and task digital supervision system and method

InactiveCN104050523AEffective supervisionFacilitate the determination of responsibilityCo-operative working arrangementsResourcesCritical control pointWork task

The invention discloses a farm production personnel and task digital supervision system and method. The system comprises an RFID electronic label, a task input terminal module, a server end module and a database module, can automatically identify the identities and duties of production personnel and provides corresponding work task interfaces according to the duties of the production personnel, the production personnel inputs key control point information in a task requirement through the work task interfaces, and after input is finished, the system automatically stores the identities of the input personnel and the input time, such that high-efficiency supervision management of each link of a production process is realized, and responsibilities are traced back to certain individuals clearly after quality problems arise.

Owner:BEIJING WISDOM AGRI

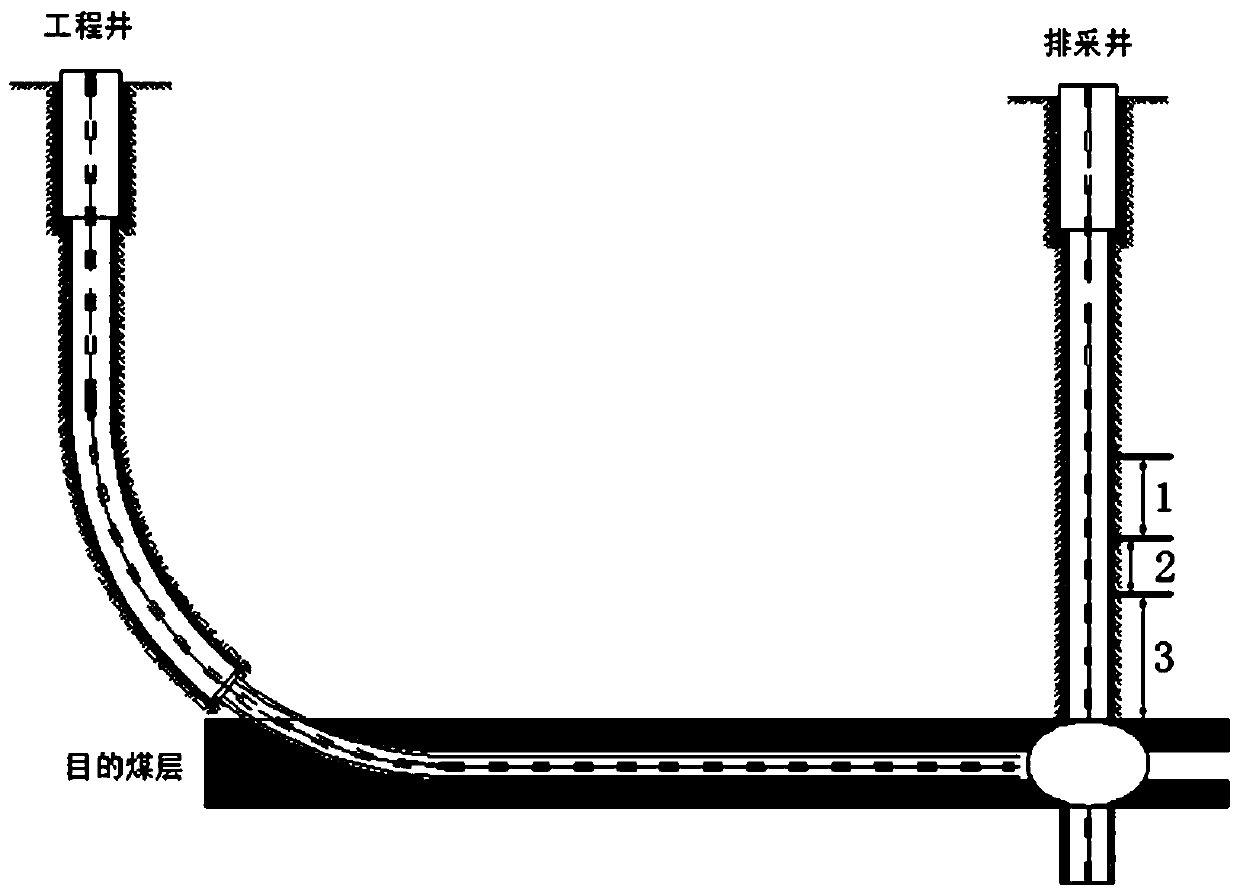

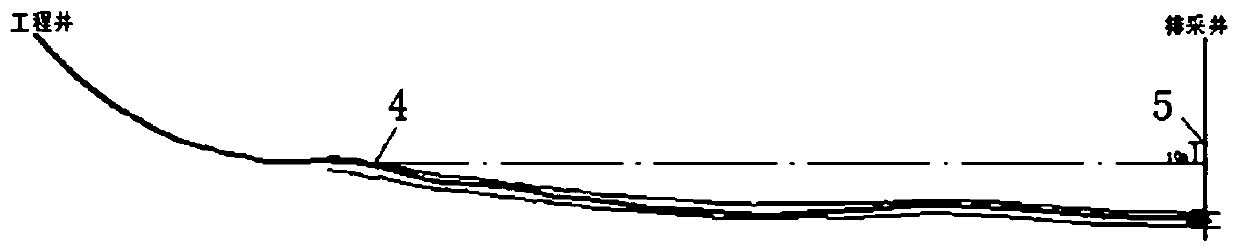

Discharge and mining method for coal-seam gas horizontal well of low-permeability coal reservoir

InactiveCN107558958ASmooth step-down desorptionAvoid extensive exposureFluid removalFlushingCritical control pointUltimate tensile strength

The invention belongs to the technical field of coal-seam gas discharge and mining and provides a discharge and mining method for a coal-seam gas horizontal well of a low-permeability coal reservoir.The discharge and mining method for the coal-seam gas horizontal well of the low-permeability coal reservoir is used for solving the problems of the unstable yield, the poor gas producing effect and the like, caused by inappropriate discharge and mining strength, of a horizontal well discharge and mining system in the prior art. Aiming at a large-dip-angle coal seam, the highest position of a coalseam section of the horizontal well is used as a key control point of discharge and mining, and a quantitative discharge and mining system is made according to different discharge and mining stages of the horizontal well of the low-permeability coal seam, wherein the discharge and mining stages of the horizontal well of the low-permeability coal seam comprise the saturated water unidirectional flow stage, the unsaturated water unidirectional flow stage and the gas-water two-phase flow stabilizing stage. By utilizing the discharge and mining method, it can be guaranteed that the coal-seam gaswell can be depressurized and desorbed stably, large-area exposing of the coal seam due to excessively-fast lowering of the liquid level is prevented, meanwhile, a method is provided for selecting ofthe well repair time, and the adverse influences brought by well repair are avoided as much as possible.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

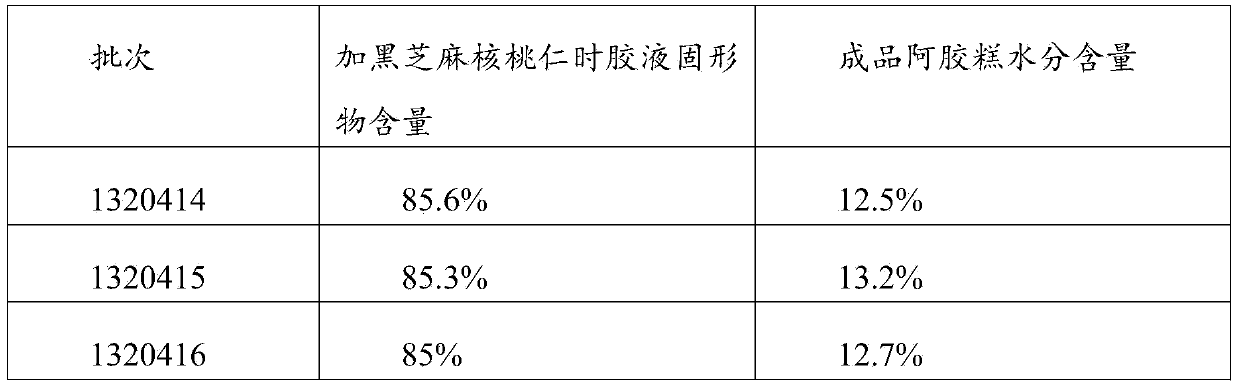

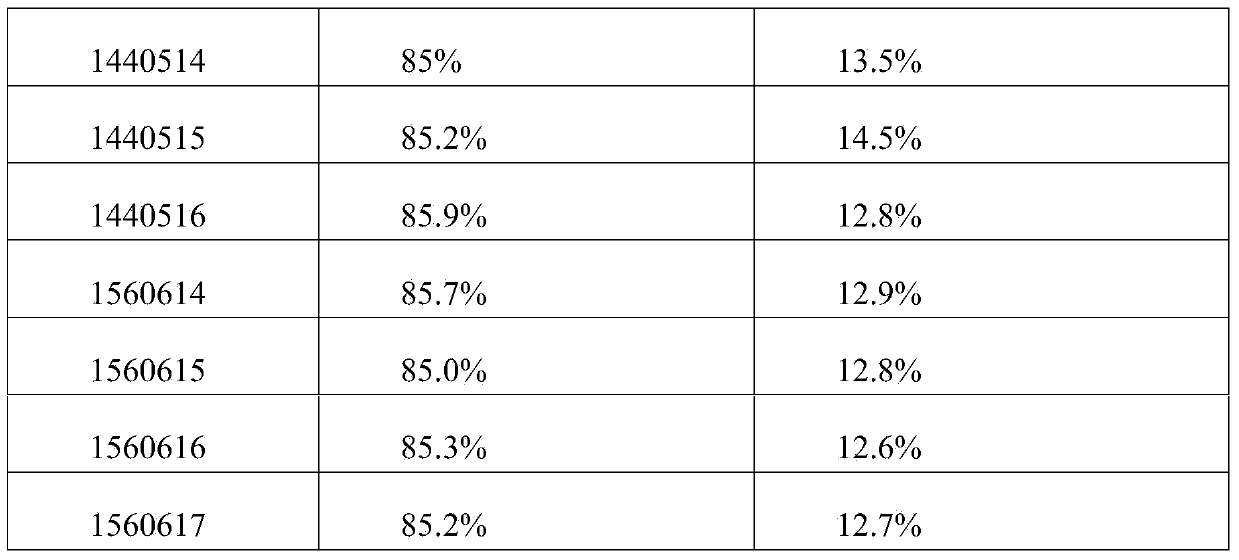

Improved colla corii asini cake stewing technical method

InactiveCN104187630ARetain nutrientsOptimizing Process ParametersFood preparationCritical control pointColla corii asini

The invention provides an improved colla corii asini cake stewing technical method. According to the method, the glue solution solid content in a stewing process is measured by a solid measurer; when the solid content is 85-86 percent, black sesames and walnut kernels are added; by quantification of the key control point, technical parameters in a colla corii asini cake stewing process are optimized, and the stability and the uniformity of the product quality are improved.

Owner:SHAN DONG DONG E E JIAO

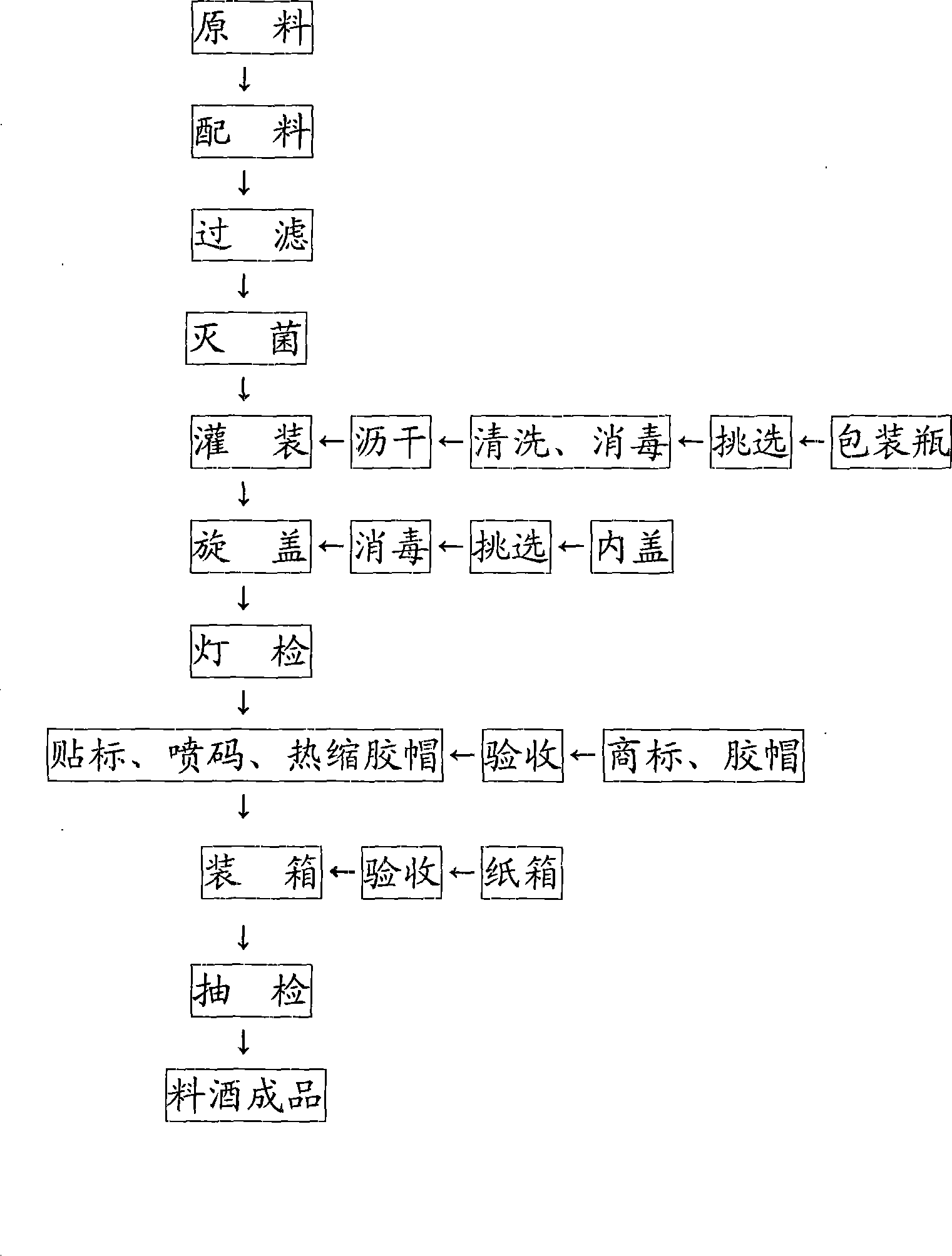

Production method of cooking wine

InactiveCN101396107AEnsure safetyGuaranteed yieldAlcoholic beverage preparationFood preparationCritical control pointGenetically engineered

The invention discloses a method for manufacturing a cooking wine product, belonging to the field of seasonings. The invention is characterized in that: spice is added; different dishes correspond to different alcoholic degree; key control points are optimized. The invention comprised the production course of mixing of raw material, filtering, sterilizing, bulking, cap screwing, lamp testing, labeling and code spraying followed by thermal shrinkage of plastic caps, incasing, and random inspection of the prepared cooking wines. In the invention, non-GM and green food is adopted as raw materials; 2Kg of diatomite is added to the filter recycling barrel with a pressure of 0.3Mpa and the sterilization temperature of 115-120 DEG C; the device is firstly rinsed with 2% alkali lye at 80 DEG C for 20 minutes, secondly rinsed with 2% acid liquor at 80 DEG C for 20 minutes and thirdly rinsed for 30 minutes, and then filled with water for later use; the finished product contains amino-acid nitrogen which is equal to or more than 0.2g / L, total acid which is 3-30g / L, salt which is equal to or more than 10.0g / L, and total sugar which is 0-80g / L, with alcoholic degree being 5-23V / V and color number being 40-50. The invention is characterized in that a spice is added to the raw material for manufacturing the cooking wine, the method is scientific and the obtained product is of top quality.

Owner:北京首农味业集团有限公司

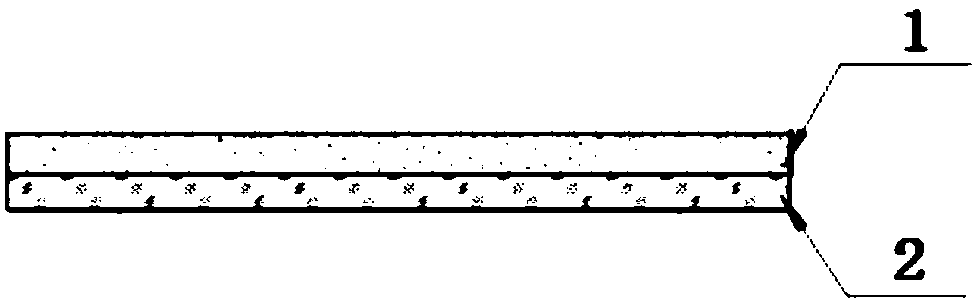

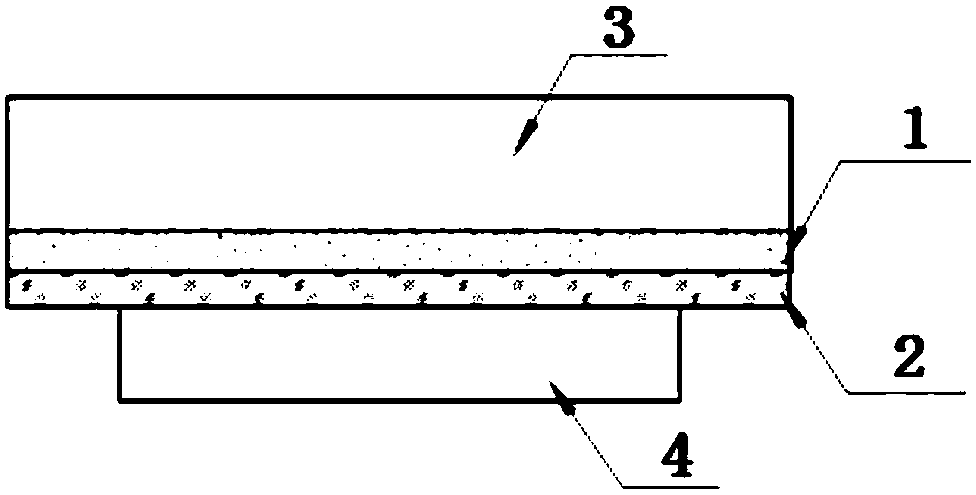

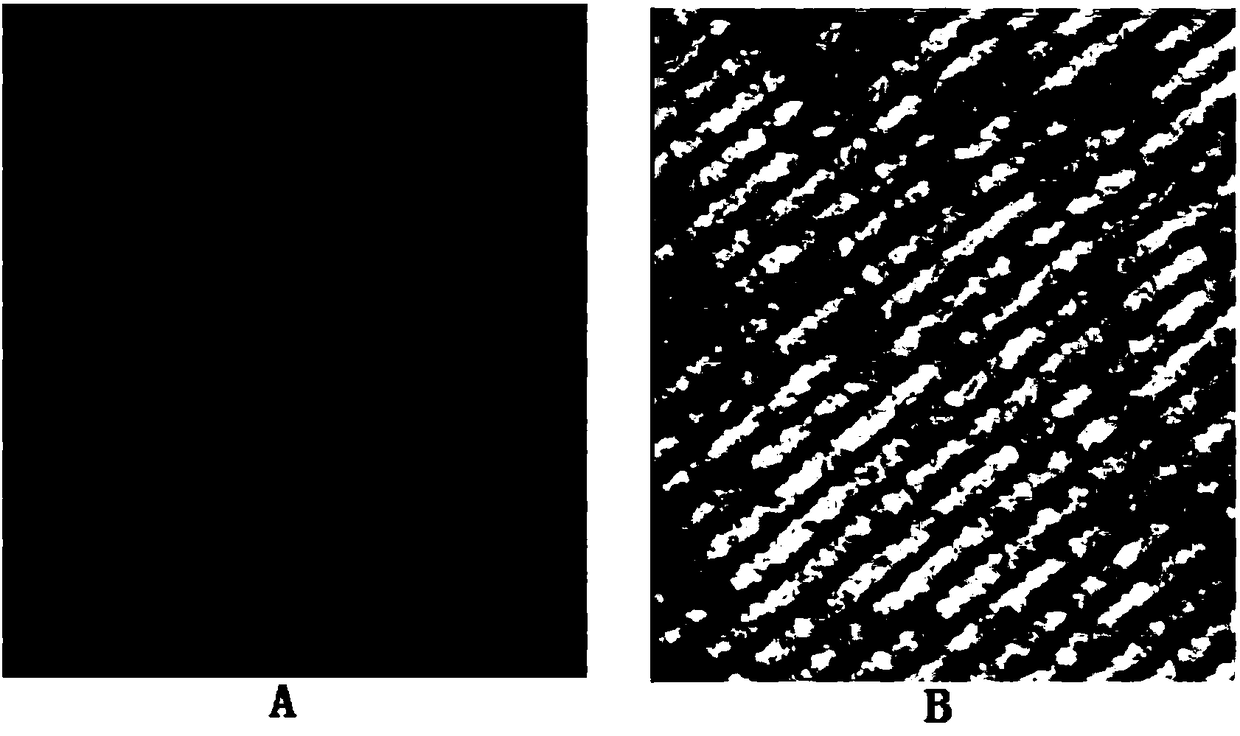

Forging fabric having heat preservation and lubricating effects and application method thereof

ActiveCN108115066AWith lubrication functionWith heat preservation functionForging/hammering/pressing machinesFriction reductionCritical control point

The invention relates to a forging fabric, in particular to a forging fabric having heat preservation and lubricating effects, and belongs to the technical field of forging and pressing. The forging fabric having the lubricating and heat preservation effects is composed of a fiber layer and a graphite layer which is uniformly attached to any plane of the fiber layer. According to the forging fabric, starting from a key control point for reducing deformation resistance during forging, the fabric having lubricating and heat preservation functions at the same time is designed. The fabric takes afiber cloth as a heat insulating material, the influence of hard particles after the compression of heat insulating cotton is eliminated, at the same time the concentration of a graphite lubricant isimproved to 13% to 18%, and graphite can be uniformly attached to the fiber. A method for application of the forging fabric having the heat preservation and lubricating effects comprises causing one side of the forging fabric with the graphite lubricant to be in contact with a die to reduce friction, and causing the other side of the forging fabric to be in contact with a forge piece to prevent temperature loss.

Owner:中国第二重型机械集团德阳万航模锻有限责任公司

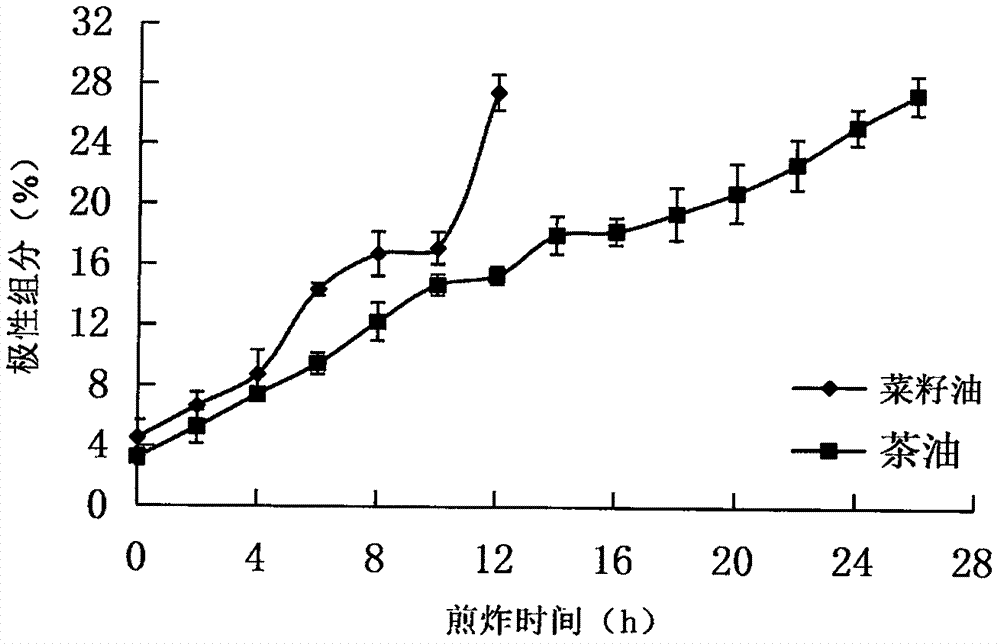

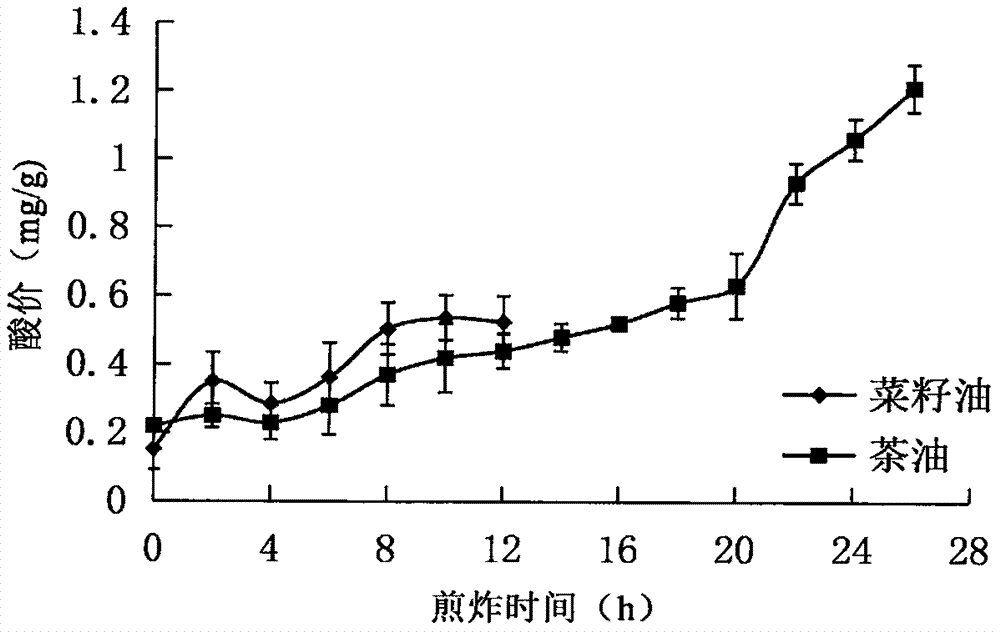

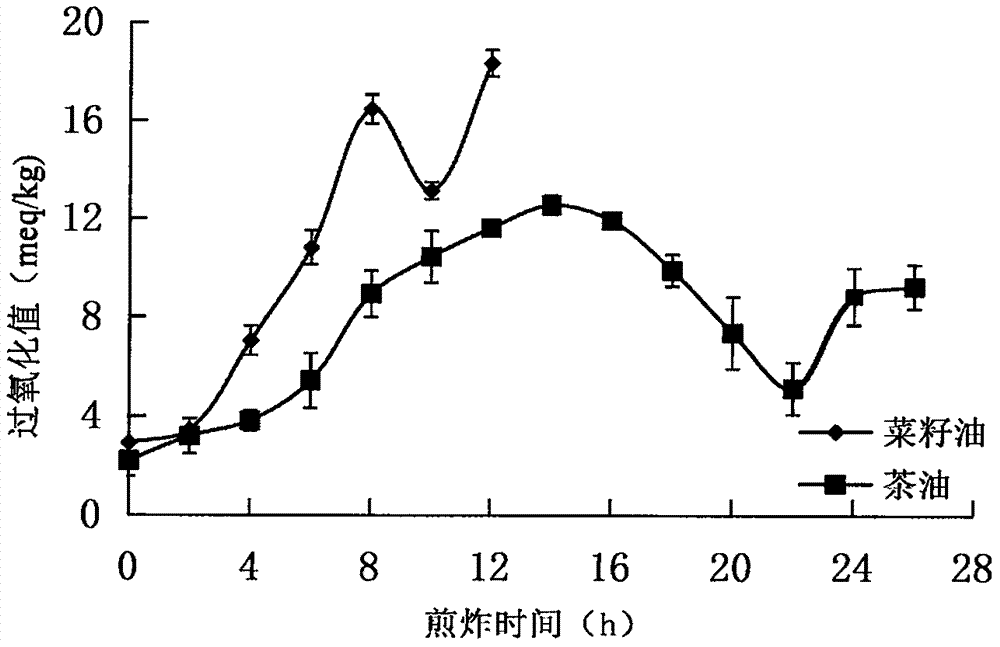

Method for determining frying life of edible oil through acid value determination result

InactiveCN107515284AUp to frying lifeFind direct relationshipTesting foodCritical control pointAcid value

The invention relates to a method for determining frying life of edible oil through an acid value determination result. In practical detection and laboratory exploration practical work, the physical and chemical indexes of grease have strong correlation, the grease detection index can be simplified through the relevant researches. Through researches on change of physical and chemical indexes of edible oil during a frying process, the correlation between the physical and chemical indexes and the frying time / indexes is compared, the invention provides the method for determining whether the edible oil reaches the frying life through the acid value determination result, only the acid value of an edible oil sample is determined, the acid value is compared with an obtained threshold, so that the frying life of the edible oil can be determined, the accuracy and detection efficiency for rapid detection of the grease are increased, and the method is rapid and simple for supervision of fried food and production unit key control points by a food supervisory security department and supervision work of the waste grease.

Owner:上海市崇明区市场监督管理局

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com