Forging fabric having heat preservation and lubricating effects and application method thereof

A technique of lubricating effect and application method, which is applied in the field of forging cloth, can solve problems such as inability to form a continuous lubricating layer, affect the surface quality of forgings, and fail to exert lubricating effect, etc., and achieve simple production, lower forging molding pressure, and lower friction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

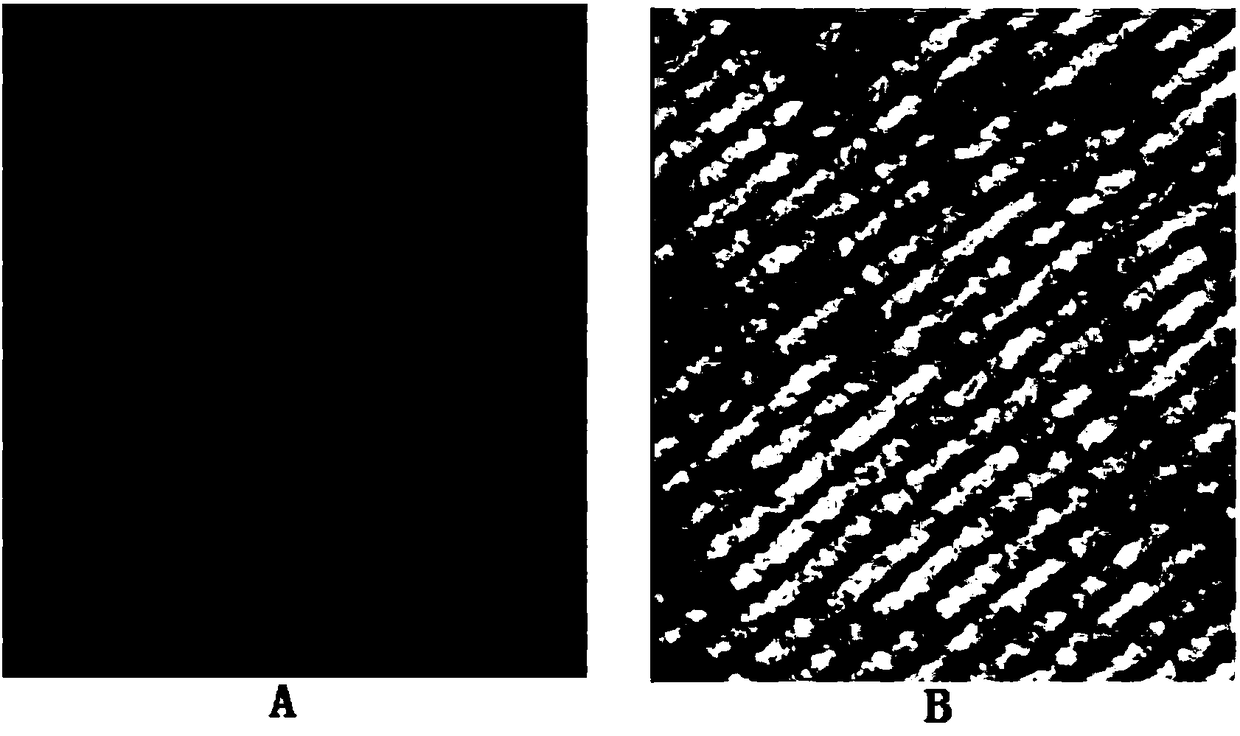

[0038] Get a piece of glass fiber cloth 3500x1000x2mm; adopt clear water to configure graphite mass concentration as 10L of graphite lubricant solution of 16%, the prepared graphite lubricant solution is evenly sprayed on the front of the glass fiber cloth with a spray gun, and naturally air-dried to obtain lubricating and The graphite-coated side of the forging cloth for thermal insulation is as follows: image 3 As shown in A, the other side not coated with graphite is as image 3 Shown in B.

[0039] from image 3 It can be seen that the graphite layer is uniformly attached to one surface of the glass fiber cloth. The thickness of the graphite layer is 0.8 mm.

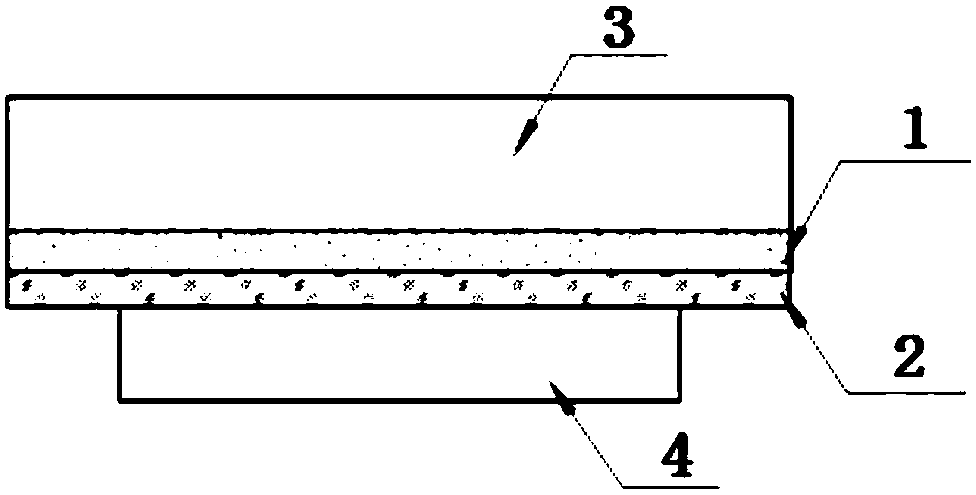

[0040] The prepared forging cloth with lubricating and thermal insulation functions according to figure 2 The structure shown is installed for forging aircraft flanges, a large projected surface forging with high rib and thin web structure, the pressure during forging is 780MN, and the underpressure is 5mm (loa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com