Ball screw rod device

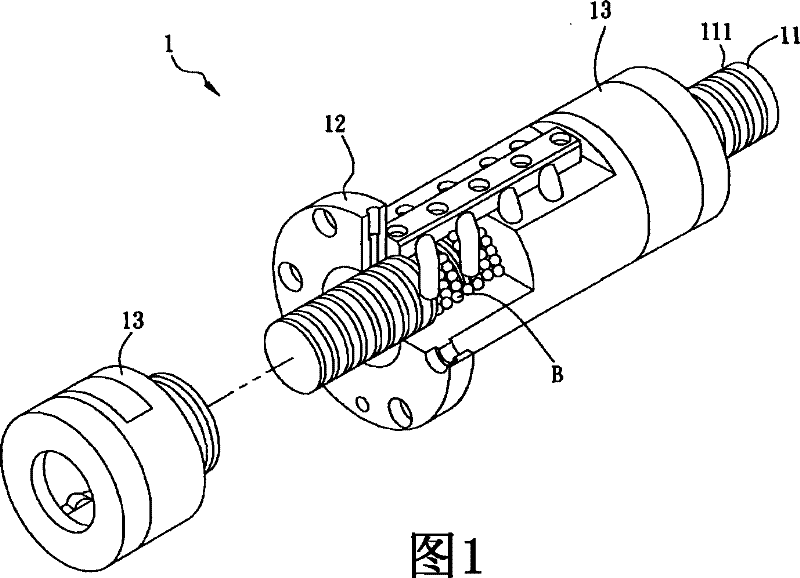

A ball screw and ball nut technology, used in bearings, linear motion bearings, shafts and bearings, etc., can solve the problems of stroke limitation, shortening, and 12 stroke compression of the ball nut, and achieve the effect of avoiding stroke limitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

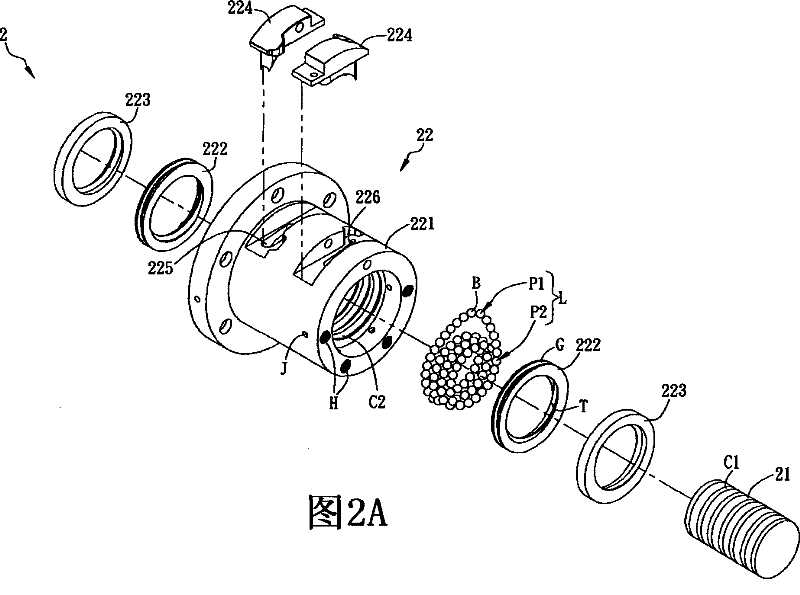

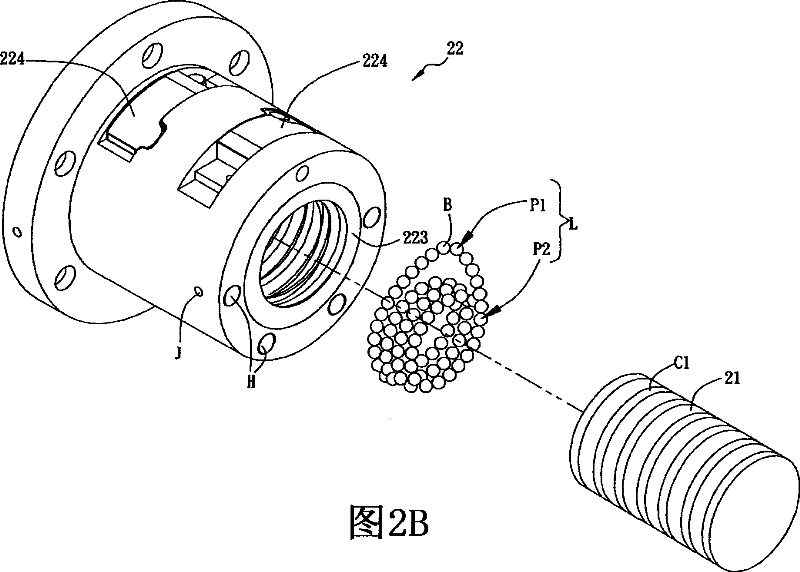

[0039] Please refer to Figure 2A and Figure 2B shown, where Figure 2A It is an exploded schematic view of the ball screw device 2 of this embodiment, Figure 2B It is a combined schematic diagram of the ball screw device 2 . The ball screw device 2 of the first embodiment of the present invention includes a screw 21 and a ball nut 22 .

[0040] The screw 21 has a thread groove C1. The ball nut 22 is sheathed and slidably disposed on the screw rod 21 , and has a nut body 221 and a lubricating element 222 . In this embodiment, the screw 21 has two lubricating elements 222 as an example for illustration, but it is not limiting.

[0041] The nut body 221 has a thread groove C2, and these thread grooves C1, C2 correspond to form a first ball channel P1. The ball nut 22 is provided with a second ball channel P2, the first ball channel P1 and the second ball channel P2 together form a circulation path L, and a plurality of balls B move in the circulation path L. In addition...

no. 2 example

[0049] Please refer to Figure 4A and Figure 4B shown, where Figure 4A It is an exploded schematic diagram of the ball screw device 3 of this embodiment, Figure 4BIt is a combined schematic diagram of the ball screw device 3 . The difference between the ball screw device 3 and the first embodiment is that the ball nut 32 has a nut body 321, a lubricating element 322 and a limiting element 323, and the lubricating element 322 and the limiting element 323 are arranged at one end of the nut body 321, and The lubricating element 322 is sandwiched between the limiting element 323 and the nut body 321 . In this embodiment, two lubricating elements 322 and two limiting elements 323 are used for illustration, and are respectively disposed at two ends of the nut body 321 .

[0050] In addition, in this embodiment, the limiting element 323 further has at least one through hole H, through which fluid such as lubricating oil can be injected into the lubricating element 322 . Herei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com