Linear transmission system

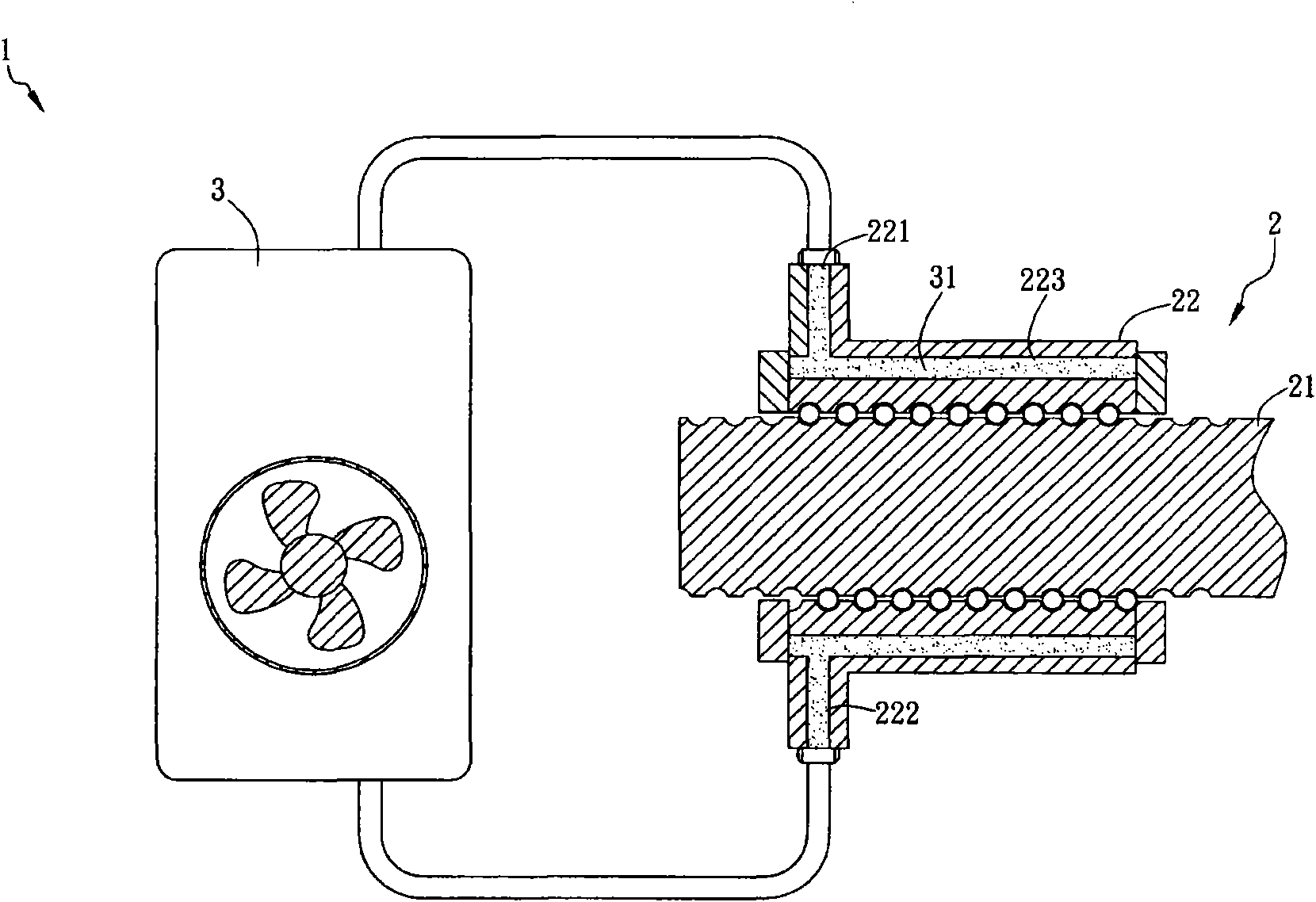

A technology of linear transmission and slide rail, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of poor heat dissipation effect of ball screw device 2, increased manufacturing tolerance of processing system, thermal deformation of screw 21, etc. Achieve the effect of reducing heat engine preparation time, avoiding thermal deformation, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Hereinafter, a linear transmission system according to a preferred embodiment of the present invention will be described with reference to the accompanying drawings, in which the same components are represented by the same symbols.

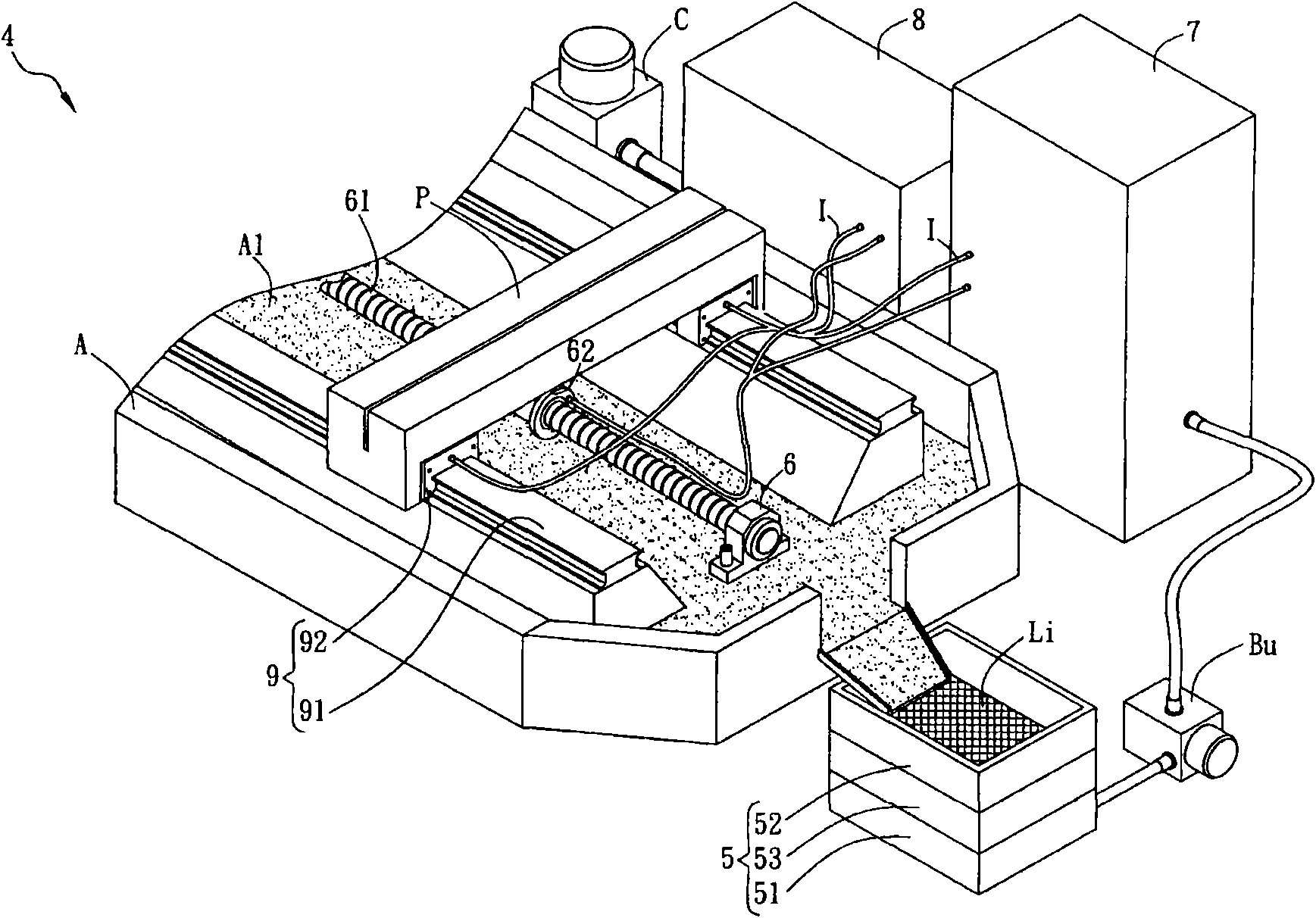

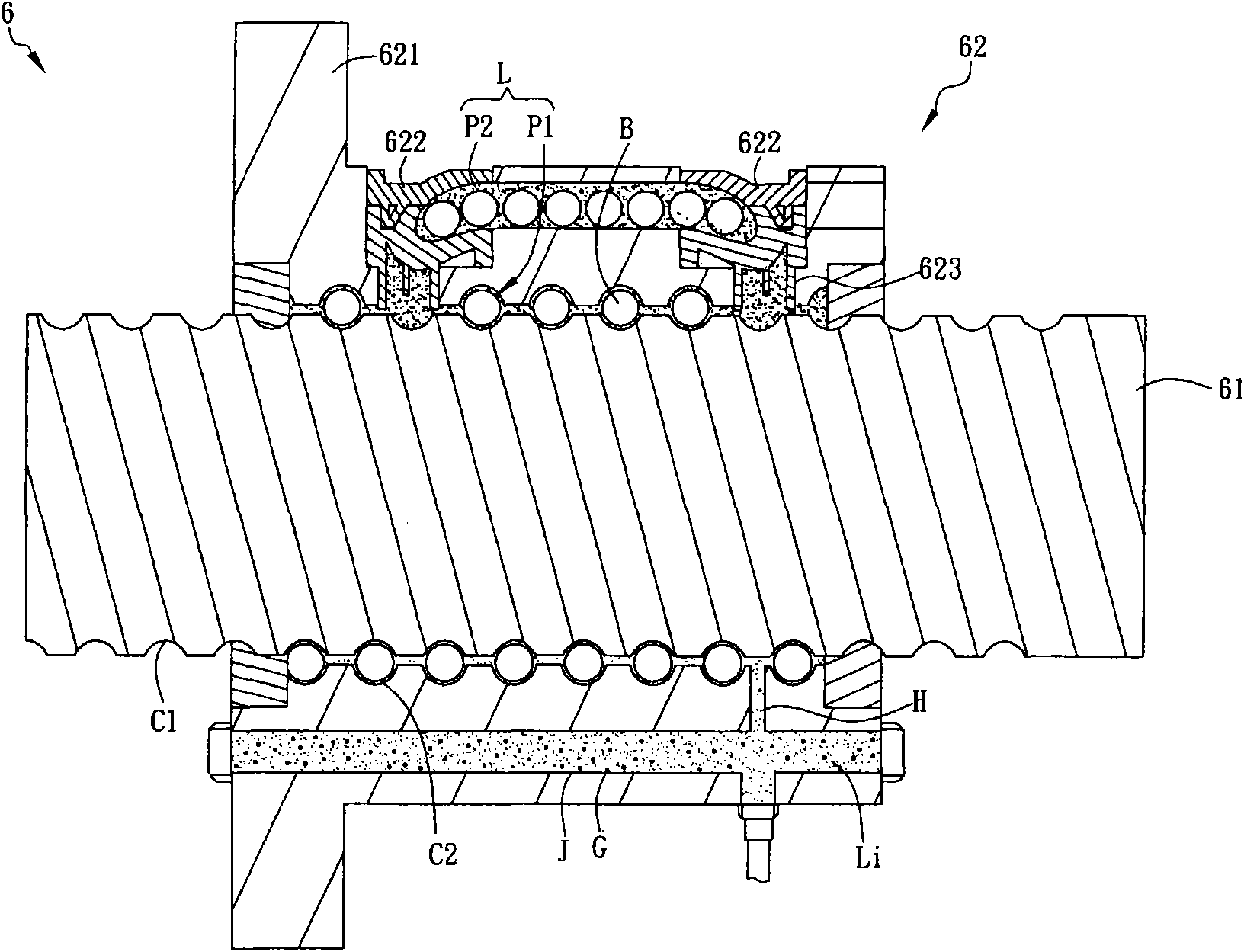

[0052] Please refer to figure 2 As shown, it is a schematic diagram of the linear transmission system 4 of this embodiment. The linear transmission system 4 includes a filter device 5, a linear slide device 9, a ball screw device 6, a liquid temperature control device 7 and a gas temperature control device 8.

[0053] The filter device 5 may have a filter mesh 51, a filter cotton or a filter cloth, for example, and may also have a magnetic filter unit 52 and / or a centrifugal filter unit 53. In this embodiment, the filtering device 5 is provided with a filtering net 51, a magnetic filtering unit 52, and a centrifugal filtering unit 53 as an example for illustration, but this is not limiting.

[0054] The linear sliding rail device 9 has a sliding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com