Smelting method of 9Ni steel

A smelting method and molten steel technology, which are applied in the smelting field of low temperature high alloy pressure vessel steel and 9Ni steel smelting, can solve the problems of reducing the phosphorus content, nitrogen content, and tapping temperature of molten steel, and achieve the effect of reducing phosphorus return.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] 1. Hot metal pretreatment: adopt KR stirring method, add lime, aluminum slag, fluorite for desulfurization treatment. Outbound molten iron composition: C: 3.84%, Si: 0.68%, Mn: 0.08%, P: 0.097%, S: 0.0013%, temperature 1275°C, weight 162.5t.

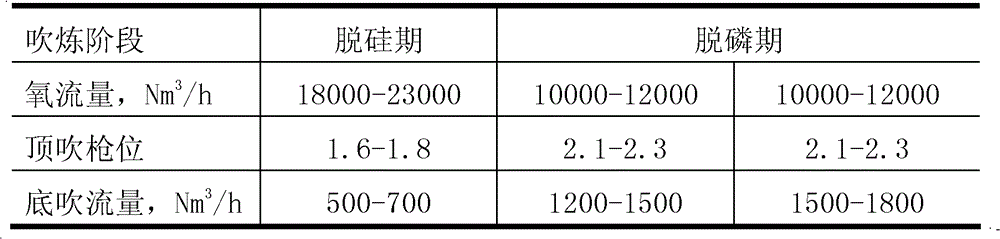

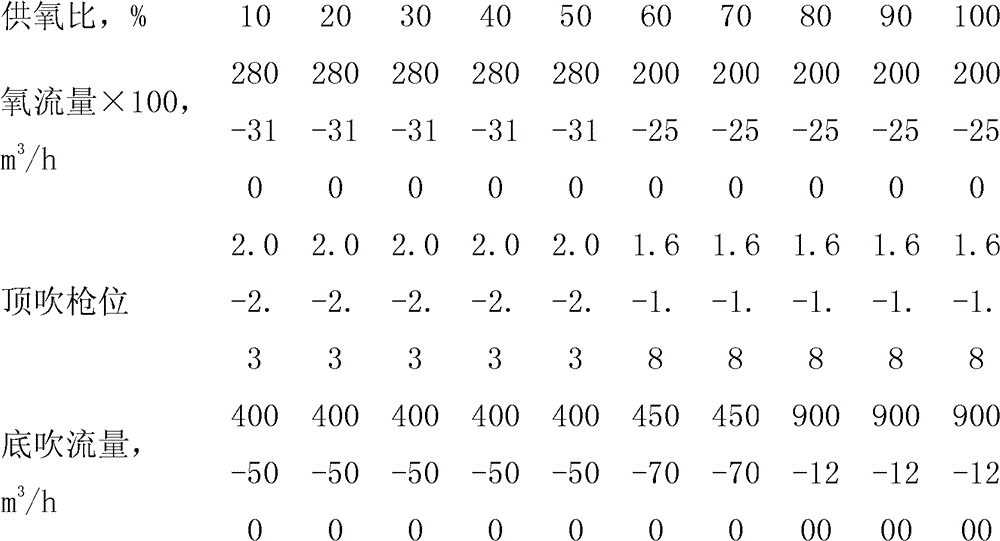

[0063] 2. Converter: Step 1: Mix the pretreated molten iron out of the station into the dephosphorization converter, and then add 11.9t scrap steel as the main raw material for blowing. The blowing control adopts the "key points of dephosphorization converter smelting control" The total input of auxiliary materials: lime 7000kg, light burnt dolomite 3000kg, fluorite 400kg, iron ore 1800kg. 1000kg of ferrosilicon is added when the semi-steel is discharged, and the components of the semi-steel exiting the dephosphorization converter are [C]: 3.44%, [Si]: 0.60%, [Mn]: 0.08%, [Ni]: 0.01%, [P]: 0.012%, [S]: 0.005%, temperature 1350°C, weight 162.5t. The second step: the semi-liquid steel from the dephosphorized and dephosphorized con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com