Lithium/fluorinated carbon nanotube battery and preparation method thereof

A technology of fluorinated carbon nanotubes and multi-walled carbon nanotubes, which is applied in the field of new lithium/fluorinated carbon nanotube batteries and their preparation, can solve the limitations, difficulties in achieving good coordination and balance of capacity and conductivity, and positive electrodes The material carbon fluoride has poor electronic conductivity and other problems, so as to achieve high conductivity, improve the effect of large current discharge, high output voltage and theoretical specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

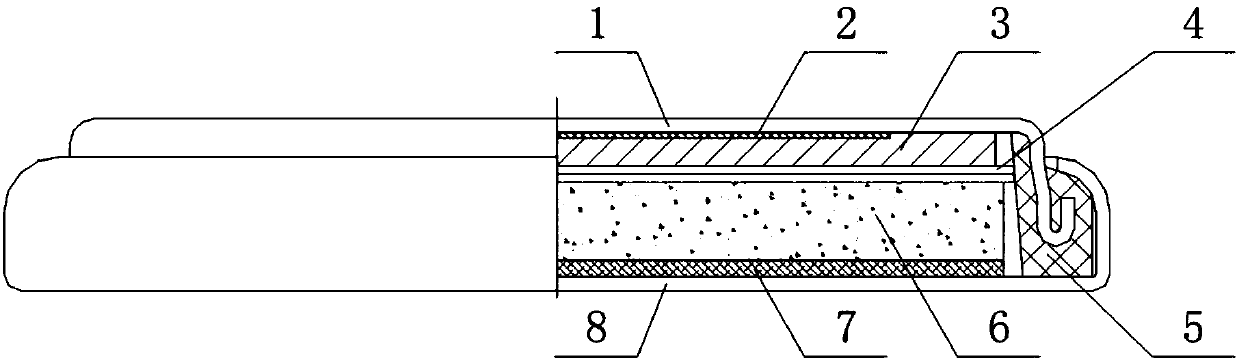

Image

Examples

preparation example Construction

[0023] The preparation method of the outer wall fluorinated multi-walled carbon nanotubes containing the iron fluoride intercalation substance, the specific steps are as follows:

[0024] 1. Mix the multi-walled carbon nanotubes with one or both of KOH and NaOH, and react in a tube furnace at 700-750°C for 3-4 hours under inert atmosphere conditions, so that the end caps of the multi-walled carbon nanotubes Open. Then, after cooling to room temperature, wash with neutral water and dry. After drying with concentrated HCl, concentrated HNO 3 One or both of them are mixed, and the reflux reaction time is 2 to 3 hours at 80 to 90°C, so that the surface of the multi-walled carbon nanotubes is cleaned and the purity is improved (the purity range is 99.0wt% to 99.9wt%). The acid or alkali The mass ratio to multi-walled carbon nanotubes is 30-80:1.

[0025] 2. Place the high-purity multi-walled carbon nanotubes with the end caps opened in a dry, vacuumable heating reactor, and feed...

Embodiment 1

[0034] In this embodiment, the lithium / carbon fluoride nanotube battery and its preparation method are as follows:

[0035] Firstly, an outer wall fluorinated multi-walled carbon nanotube (CFxFey) containing iron fluoride intercalation is prepared, wherein the fluorine-to-carbon atomic ratio is 0.5, and the iron-to-carbon atomic ratio is 0.2. The preparation method includes the following steps:

[0036] 1. Mix the dry multi-walled carbon nanotubes with KOH evenly, and react in a tube furnace at 700°C for 4 hours under a nitrogen atmosphere, then cool to room temperature, wash with water, and then dry. After drying, it is mixed with concentrated nitric acid (concentration: 85% by weight) of 40 times the mass ratio, refluxed at 80° C. for 2 hours, and then washed with water until neutrally dried.

[0037] 2. Place the high-purity multi-walled carbon nanotubes with the end caps opened in a dry, vacuumable heating reactor, and feed ferric chloride vapor with a mass ratio of 2:1 to...

Embodiment 2

[0044] In this embodiment, the lithium / carbon fluoride nanotube battery and its preparation method are as follows:

[0045] Firstly, an outer wall fluorinated multi-walled carbon nanotube (CFxFey) containing iron fluoride intercalation is prepared, wherein the fluorine-to-carbon atomic ratio is 0.6, and the iron-to-carbon atomic ratio is 0.2. The preparation method includes the following steps:

[0046] 1. Mix the dried multi-walled carbon nanotubes with NaOH evenly, react in a tube furnace at 750°C for 4 hours under a nitrogen atmosphere, then cool to room temperature, wash with water and then dry. After drying, mix with concentrated nitric acid (concentration: 85wt%) of 30 times the mass ratio, reflux at 90° C. for 2 hours, and then wash with water until neutral drying.

[0047] 2. Place the high-purity multi-walled carbon nanotubes with the end caps opened in a dry, vacuumable heating reactor, and feed ferric chloride vapor with a mass ratio of 2:1 to the multi-walled carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com