Preparation method of ferric fluoride cathode material for lithium ion battery

A technology for lithium-ion batteries and cathode materials, which is applied in the field of preparation of high-purity anhydrous hydroxy-free ferric fluoride materials, can solve the problems such as the difficulty in preparing high-purity anhydrous ferric fluoride, achieve short cycle, uniform particle size, and easy operation easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] First weigh 0.242g of ferric nitrate and dry it in a 110°C oven, add 2mL of hydrofluoric acid into a 20mL Teflon-lined reactor, then put the reactor into a 110°C oven to remove water, and add the raw materials after 2 hours In the reaction kettle, react at 190°C for 72h, wash with water until neutral, filter with suction and dry at 90°C to obtain ferric fluoride.

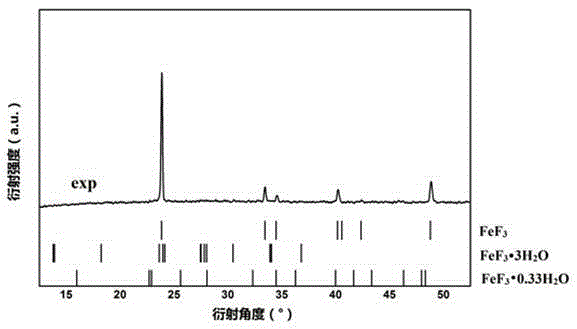

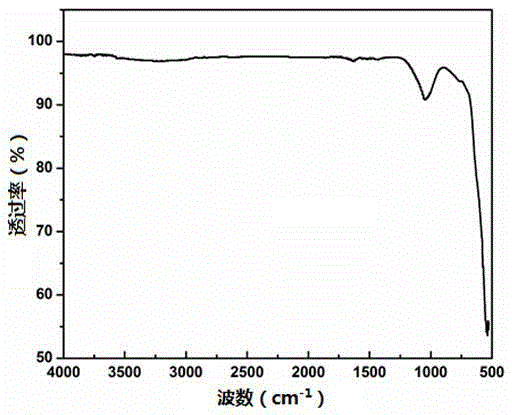

[0016] The X-ray powder diffraction pattern of the ferric fluoride material sample can be found in figure 1 . exist figure 1 Among them, the abscissa is the diffraction angle, the ordinate is the diffraction intensity, the upper curve is the measured X-ray diffraction pattern, and the lower vertical lines are FeF from top to bottom. 3 , FeF 3 ·3H 2 O, FeF 3 0.33H 2 O theoretical diffraction peak position, given by figure 1 It can be seen that the sample is characterized by high purity. Depend on figure 2 It can be seen that the sample does not contain water and hydroxyl groups.

[0017] The inventi...

Embodiment 2

[0019] Weigh 0.242g of ferric nitrate and dry it in an oven at 110°C, add 2mL of hydrofluoric acid into a 20mL polytetrafluoroethylene-lined reactor, add the raw materials to the reactor after 2h, react at 240°C for 48h, and wash with water until Neutral, after suction filtration, dry at 90°C to obtain ferric fluoride.

Embodiment 3

[0021] First weigh 0.242g of ferric nitrate and dry it in an oven at 110°C, add 3mL of hydrofluoric acid into a 20mL polytetrafluoroethylene-lined reactor, add ferric nitrate into the reactor after 2h, react at 240°C for 48h, wash with water To neutrality, after suction filtration, dry at 110°C to obtain ferric fluoride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com