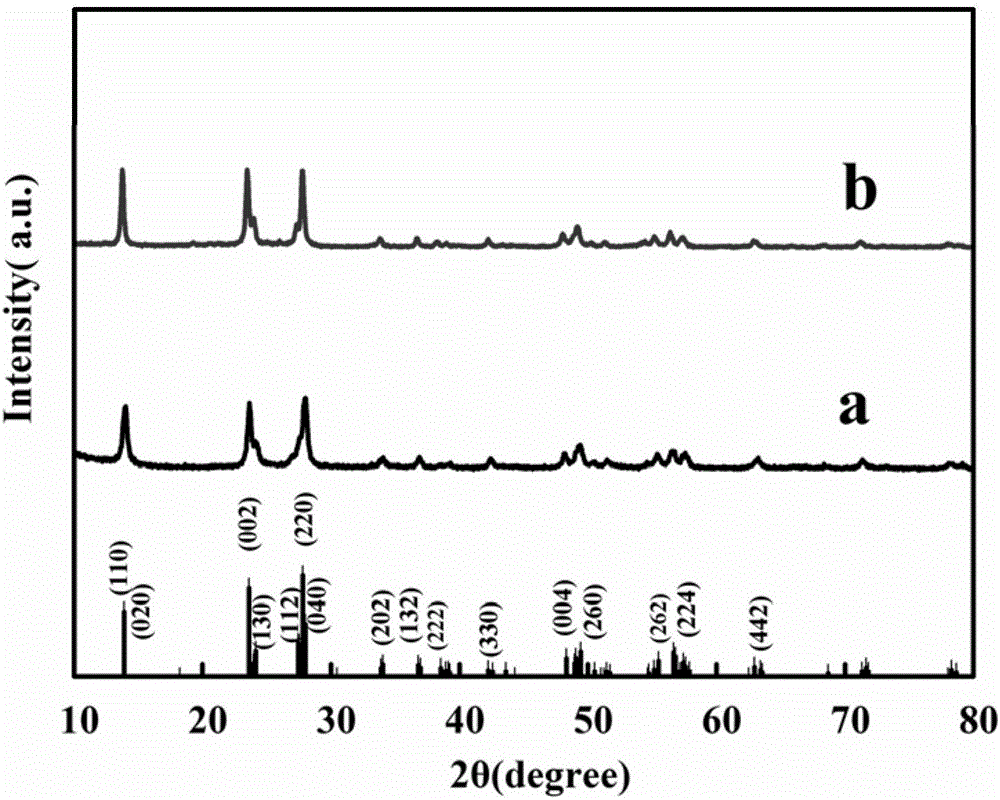

Preparation method of titanium-doping ferric fluoride positive electrode material

A cathode material, iron fluoride technology, which is applied in chemical instruments and methods, inorganic chemistry, battery electrodes, etc., can solve the problems of capacity decline and poor rate performance of iron fluoride cathode materials, and achieves a simple and easy synthesis process. The effect of low recession and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

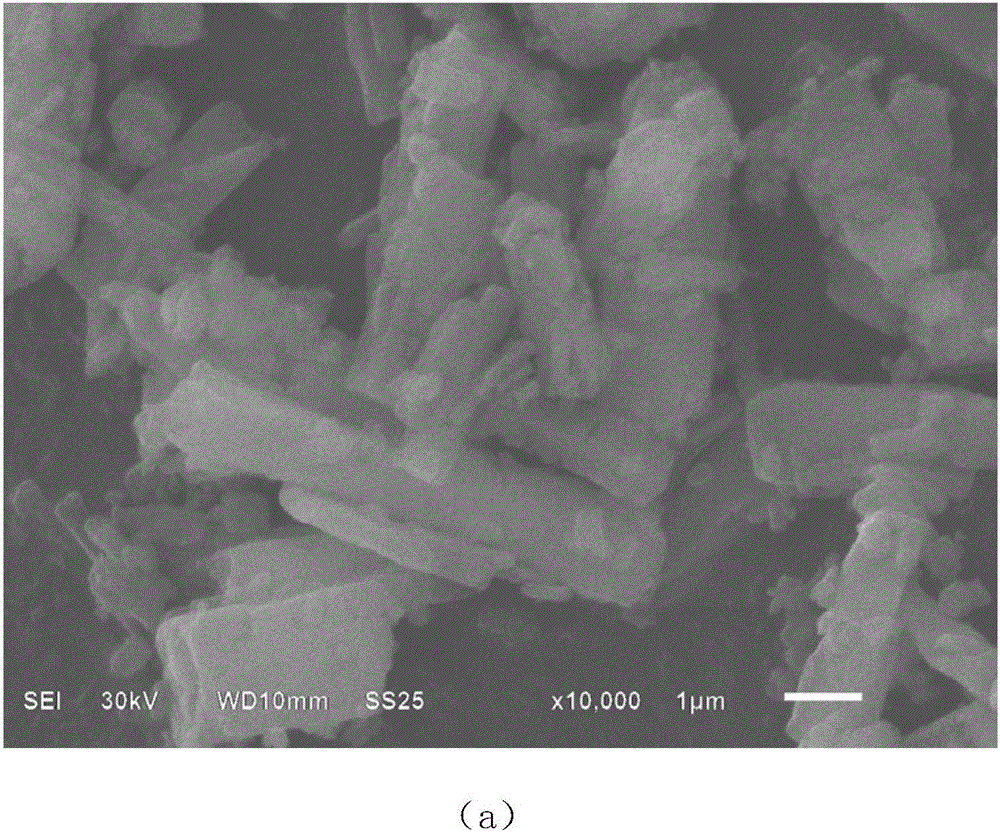

Embodiment 1

[0037] (1) First ferric chloride and titanium chloride are used as starting materials, according to Fe 3+ : Ti 3+ =0.92:0.08 molar ratio dissolved in ethanol, stirred evenly, to obtain a golden yellow transparent solution, wherein the iron ion concentration is 0.3mol / L;

[0038] (2) Slowly add the sodium hydroxide solution with a concentration of 1.5mol / L into the solution obtained in step (1), stir evenly, and age it statically for 36 hours to obtain a brown precipitate, which is repeatedly washed with ethanol and deionized water until the filtrate The pH value is 6-7, and air-dried at 80°C for 6 hours;

[0039] (3) Add 40mL of ionized water to the hydroxide precipitated powder obtained in step (2), and stir to obtain a suspension;

[0040] (4) Slowly add 20 mL of hydrogen fluoride solution to the suspension obtained in step (3), react in an oil bath at 30°C for 12 hours, and dissolve the suspension to obtain a pink solution;

[0041] (5) heat and stir the pink solution ob...

Embodiment 2

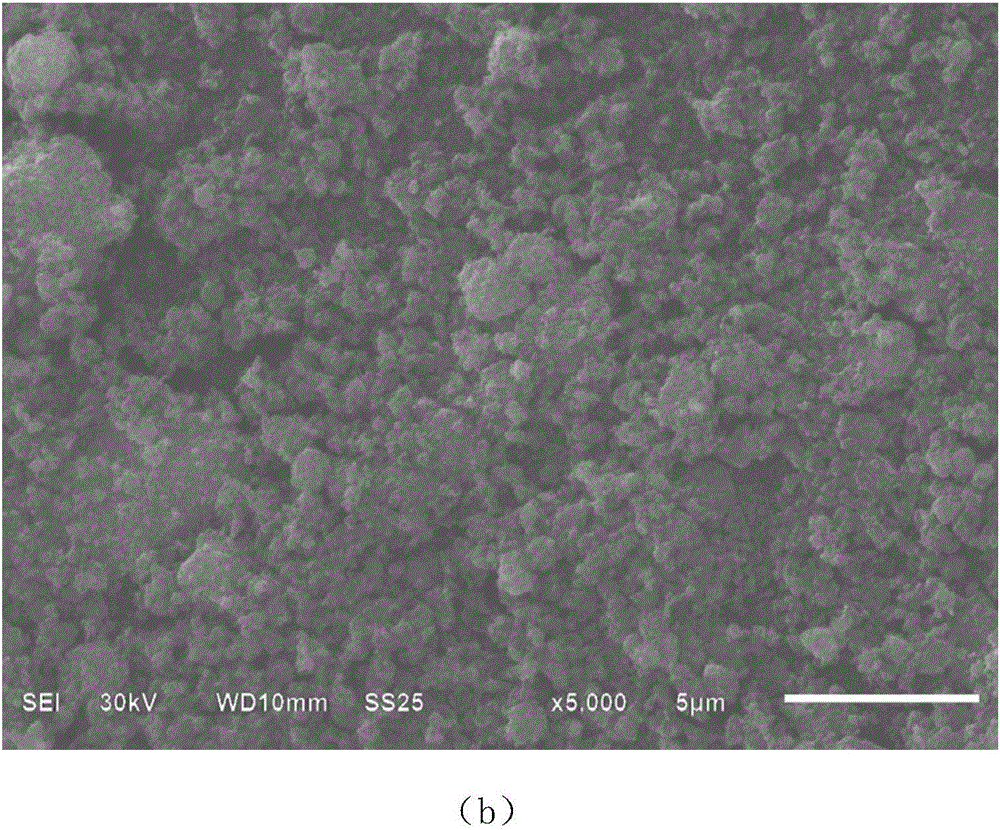

[0048] (1) First, ferric sulfate and titanium chloride are used as starting materials, according to Fe 3+ : Ti 3+ =0.50: Dissolve in ethanol at a molar ratio of 0.50 and stir evenly to obtain a golden yellow transparent solution, in which the concentration of iron ions is 0.25 mol / L.

[0049] (2) Slowly add the potassium hydroxide solution with a concentration of 1.25mol / L into the solution obtained in step (1), stir evenly, and age it statically for 36 hours to obtain a brown precipitate, which is repeatedly washed with ethanol and deionized water until the filtrate The pH value is 6-7, and air-dried at 80°C for 6 hours;

[0050] (3) Add 40mL of ionized water to the hydroxide precipitated powder obtained in step (2), and stir to obtain a suspension;

[0051] (4) Slowly add 20 mL of hydrogen fluoride solution to the suspension obtained in step (3), react in an oil bath at 30°C for 12 hours, and dissolve the suspension to obtain a pink solution;

[0052] (5) heat and stir th...

Embodiment 3

[0057] (1) First, ferric nitrate and titanium chloride are used as starting materials, according to Fe 3+ : Ti 3+ =0.91:0.09 molar ratio dissolved in ethanol, stirred evenly to obtain a golden yellow transparent solution, wherein the iron ion concentration is 0.4mol / L.

[0058] (2) Slowly add the sodium hydroxide solution with a concentration of 2.0mol / L into the solution obtained in step (1), stir evenly, and age it statically for 48 hours to obtain a brown precipitate, which is repeatedly washed with ethanol and deionized water until the filtrate The pH value is 6-7, and air-dried at 80°C for 6 hours;

[0059] (3) Add 40mL of ionized water to the hydroxide precipitated powder obtained in step (2), and stir to obtain a suspension;

[0060] (4) Slowly add 20 mL of hydrogen fluoride solution to the suspension obtained in step (3), react in an oil bath at 30°C for 12 hours, and dissolve the suspension to obtain a pink solution;

[0061] (5) heat and stir the pink solution obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com