Ferric fluoride oxide anode material and preparation method thereof, and lithium ion battery

A lithium-ion battery and ferric oxyfluoride technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of further improvement of reversible specific capacity and cycle performance, improve rate performance and cycle stability, and improve electronic Conductivity, process controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

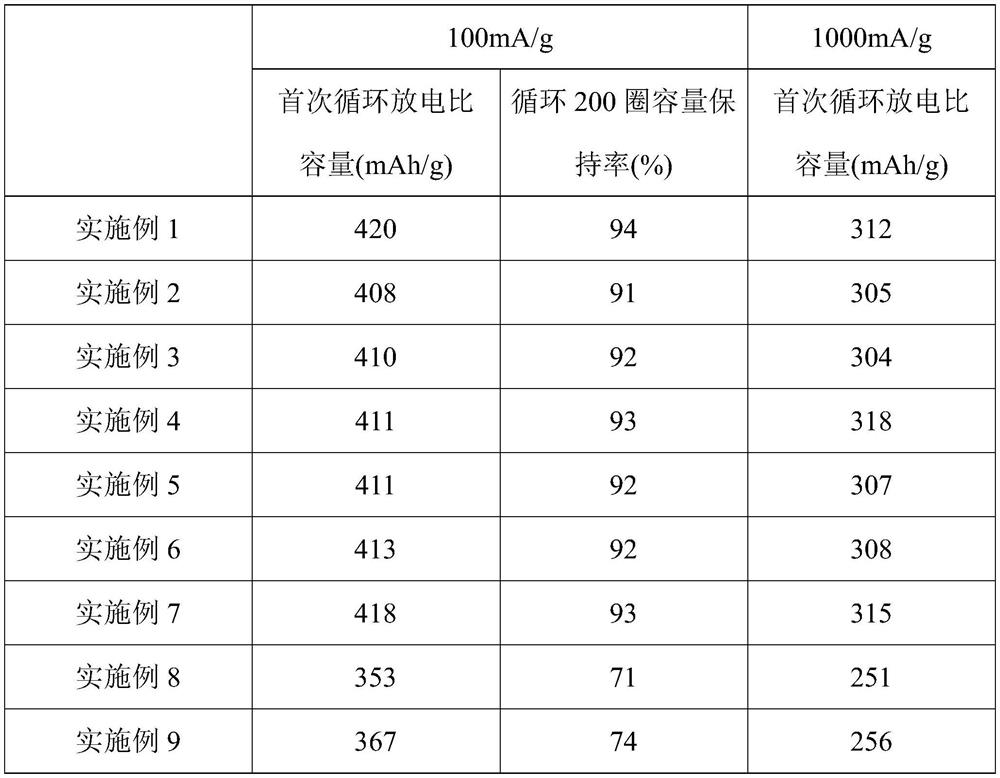

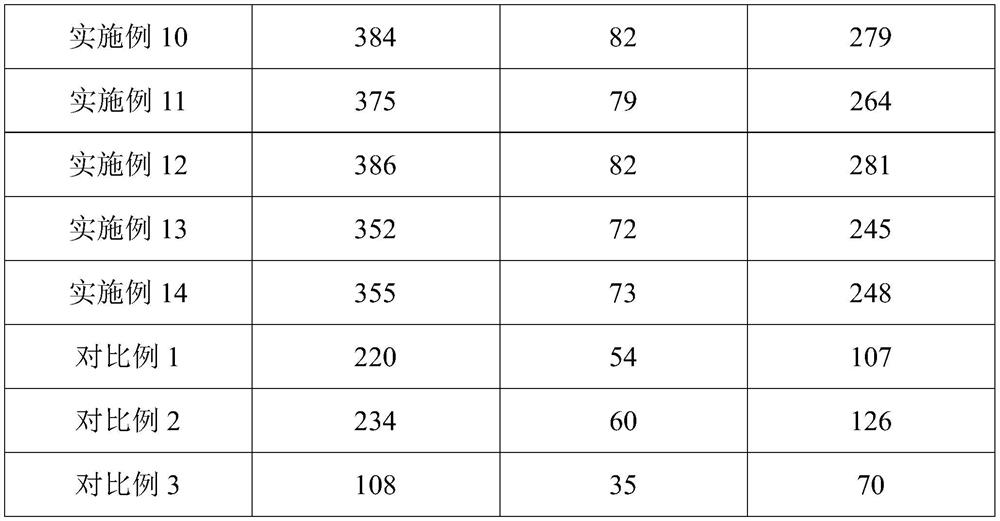

Examples

Embodiment 1

[0047] This embodiment provides an iron oxyfluoride cathode material FeO X f 2-X / C (X=1) preparation method, described preparation method comprises the steps:

[0048] (1) mix iron source, fluorine source, carbon source, reducing agent and solvent, obtain mixed solution; The concentration of metal ion in mixed solution is 2mol / L; The addition of described iron source and reducing agent is to satisfy Fe and reducing agent The molar ratio of the carbon source is 1:0.5; the added amount of the carbon source is to make the molar ratio of Fe in the iron source and C in the carbon source be 1:2; the iron source is ferric nitrate; the fluorine source is fluorine Ammonium borate; The carbon source is sucrose; The reducing agent is ascorbic acid; The solvent is isopropanol;

[0049] (2) The mixed solution obtained in the solvent heat treatment step (1) is subjected to solid-liquid separation after solvent heat treatment to obtain a powder intermediate; the temperature of the solvent...

Embodiment 2

[0052] This embodiment provides an iron oxyfluoride cathode material FeO X f 2-X / C (X=0.5) preparation method, described preparation method comprises the steps:

[0053] (1) mix iron source, fluorine source, carbon source, reducing agent and solvent, obtain mixed solution; The concentration of metal ion in mixed solution is 0.01mol / L; The addition of described iron source and reducing agent is to satisfy Fe and reduction The mol ratio of agent is 1:2; The addition amount of described carbon source is to make the mol ratio of Fe in iron source and C in carbon source be 1:1; Described iron source is ferric chloride; Described fluorine source It is ammonium fluoroborate; the carbon source is glucose; the reducing agent is ascorbic acid; the solvent is n-butanol;

[0054] (2) The mixed solution obtained in the solvent heat treatment step (1) is subjected to solid-liquid separation after solvent heat treatment to obtain a powder intermediate; the temperature of the solvent heat ...

Embodiment 3

[0057] This embodiment provides an iron oxyfluoride cathode material FeO X f 2-X / C (X=0.2) preparation method, described preparation method comprises the steps:

[0058] (1) mix iron source, fluorine source, carbon source, reducing agent and solvent, obtain mixed solution; The concentration of metal ion in mixed solution is 1mol / L; The addition of described iron source and reducing agent is to satisfy Fe and reducing agent The molar ratio of the carbon source is 1:1; the addition of the carbon source is to make the mol ratio of Fe in the iron source and C in the carbon source be 1:4; the iron source is ferrous sulfate; the fluorine source is Ammonium fluoroborate; the carbon source is phenolic resin; the reducing agent is ascorbic acid; the solvent is a mixed solution of n-butanol and isopropanol, wherein the volume ratio of n-butanol and isopropanol is 1 :1;

[0059] (2) The mixed solution obtained in the solvent heat treatment step (1) is subjected to solid-liquid separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com