A kind of honeycomb silicon carbon composite material, its preparation method and application

A silicon-carbon composite material, honeycomb-like technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of harsh conditions, complex preparation methods of silicon-carbon composite materials, and high cost, and achieve low reaction energy and excellent three-dimensionality. Through the structure, rich effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Wash the collected waste glass with deionized water first, and then dry it with a ball mill at a speed of 400 r / min for 2 hours to obtain micron-level glass powder with a particle size between 200 nm and 5 μm;

[0031] (2) Ball-milled glass powder, Na 2 CO 3 After mixing evenly with magnesium powder in a mass ratio of 10:2:4, put it into a closed reaction kettle, and heat it to 780 °C at a heating rate of 5 °C / min in an argon atmosphere for 5 hours to obtain the reacted mixture. ;

[0032] (3) The reacted mixture obtained in step (1) was cooled to room temperature and then washed in 1.5 mol / L hydrochloric acid for 12 hours. Then, it was cleaned in 0.5mol / L hydrofluoric acid for 60 minutes, and the honeycomb silicon-carbon composite material was obtained after pickling.

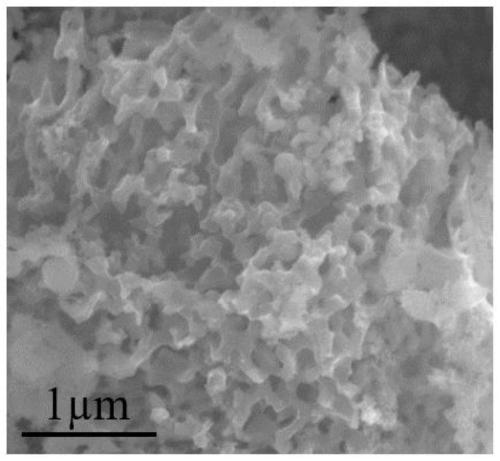

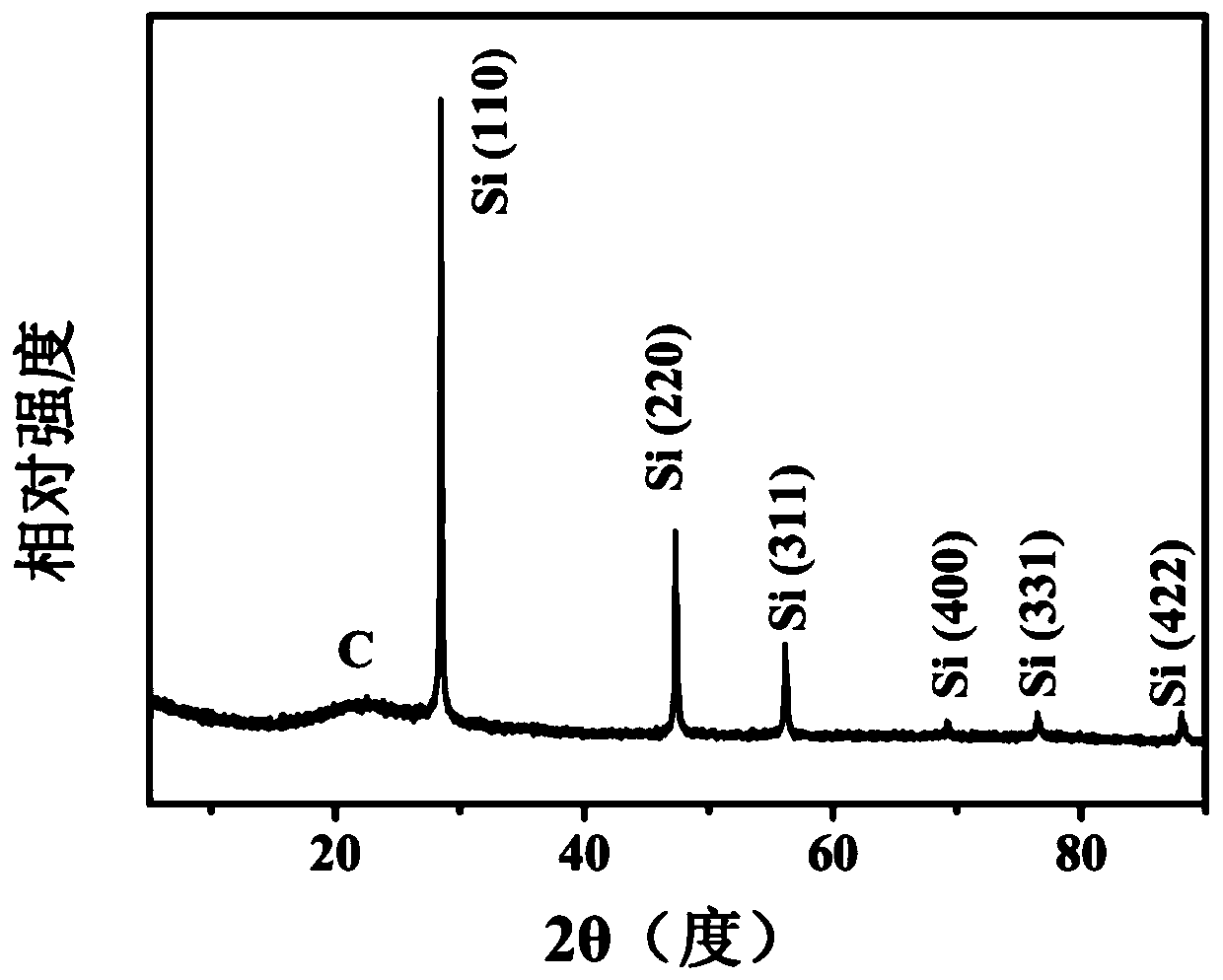

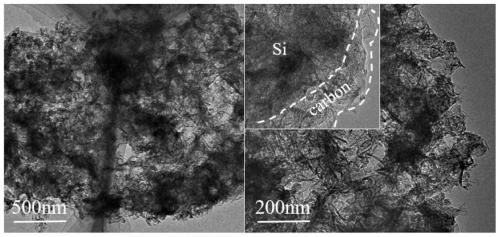

[0033] Depend on figure 1 It can be seen from the SEM image of the silicon prepared in this example that the silicon prepared in this example belongs to a three-dimensional connected structural ...

Embodiment 2

[0039] (1) Wash the collected waste glass with deionized water first, and then dry it with a ball mill at a speed of 300 r / min for 3 hours to obtain micron-level glass powder with a particle size between 500 nm and 5 μm;

[0040] (2) The ball-milled glass powder, K 2 CO 3 After mixing evenly with magnesium powder in a mass ratio of 10:3:6, put it into a closed reaction kettle, and heat it to 850 °C at a heating rate of 3 °C / min in an argon atmosphere for 2 hours to obtain the reacted mixture. ;

[0041] (3) The reacted mixture obtained in step (1) was cooled to room temperature and then washed in 1 mol / L hydrochloric acid for 10 hours. Then, it was cleaned in 1 mol / L hydrofluoric acid for 10 minutes, and the honeycomb silicon-carbon composite material was obtained after pickling.

Embodiment 3

[0043] (1) Wash the collected waste glass with deionized water first, and then dry it with a ball mill at a speed of 400 r / min for 2 hours to obtain micron-level glass powder with a particle size between 200 nm and 5 μm;

[0044] (2) Ball-milled glass powder, NaHCO 3 After mixing evenly with magnesium powder in a mass ratio of 10:2:6, put it into a closed reaction kettle, and heat it to 680 °C at a heating rate of 5 °C / min in an argon atmosphere for 6 hours to obtain the reacted mixture. ;

[0045] (3) After the reaction mixture obtained in step (1) was cooled to room temperature, it was first washed in 2 mol / L hydrochloric acid for 8 hours. Then, it was cleaned in 0.5mol / L hydrofluoric acid for 30 minutes, and the honeycomb silicon-carbon composite material was obtained after pickling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com