High-performance hybrid crystal system ferric fluoride positive electrode material and preparation method thereof

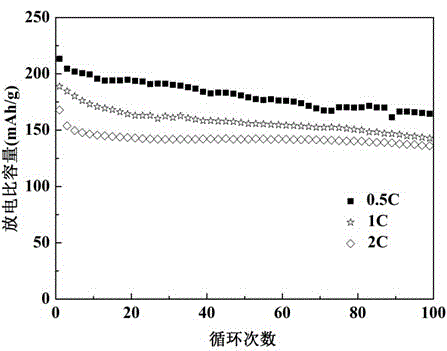

A cathode material and mixed crystal technology, applied in the field of high-performance mixed crystal iron fluoride cathode material and its preparation, can solve the problems of high energy consumption, complex and harsh preparation process conditions, poor electrochemical performance, etc., and achieve low energy consumption , the preparation process is simple, the time-consuming effect is short

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

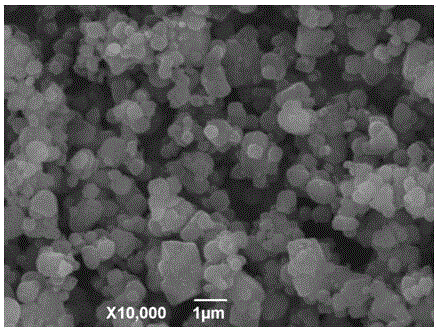

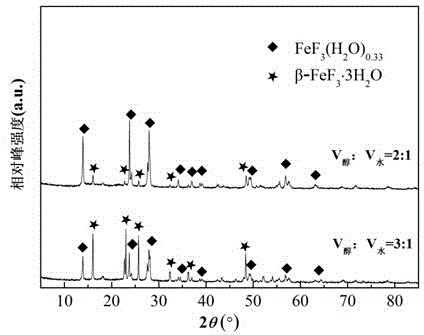

[0027] Prepare 40 mL of 0.5 mol / L ferric nitrate (Fe(NO 3 ) 3 9H 2O) water / ethanol mixed solution (the volume ratio of ethanol and water is 2:1), and 0.02mol oleic acid is added thereto; It is the water / the Ethanol solution (the volume ratio of ethanol to water is 2:1), then add 0.01g polyethylene glycol (molecular weight: 20000) to the two solutions respectively, ultrasonic the two solutions for 30min respectively, and then mix the two solutions at room temperature and pressure Stir at a constant speed for 2 h. The supernatant was discarded by centrifugation, and the precipitate was repeatedly washed with ethanol several times, and dried at 60°C for 8 hours to obtain the target product FeF 3 (H 2 O) 0.33 / β-FeF 3 ·3H 2 O.

Embodiment 2

[0029] Prepare 40 mL of 0.6 mol / L ferric chloride (FeCl 3 ·6H 2 O) water / ethanol solution (the volume ratio of ethanol and water is 3:1), and 0.025mol oleic acid is added thereto; It is the water / ethanol solution of 1mol / L ammonium bifluoride ( The volume ratio of ethanol to water is 3:1), then add 0.02g polyethylene glycol (molecular weight: 20000) to the two solutions respectively, ultrasonicate the two solutions for 30min respectively, then mix the two solutions, stir at a constant speed under normal temperature and pressure 4 h. The supernatant was discarded by centrifugation, and the precipitate was repeatedly washed with ethanol several times, and dried at 60°C for 12 hours to obtain the target product FeF 3 (H 2 O) 0.33 / β-FeF 3 ·3H 2 O.

Embodiment 3

[0031] Prepare 40 mL of 0.5 mol / L ferric nitrate (Fe(NO 3 ) 3 9H 2 O) water / ethylene glycol mixed solution (the volume ratio of ethylene glycol to water is 3:1), and 0.025mol oleic acid is added thereto; prepare 20 mL concentration of 1mol / L fluoride at a molar ratio of 1:3 Water / ethylene glycol mixed solution of ammonium (the volume ratio of ethylene glycol to water is 3:1), then add 0.01g polyethylene glycol (molecular weight 20000) to the two solutions respectively, and ultrasonicate the two solutions for 30min respectively, and then The two solutions were mixed and stirred at a constant speed for 2 h at room temperature and pressure. The supernatant was discarded by centrifugation, and the precipitate was repeatedly washed with ethanol several times, and dried at 60°C for 8 hours to obtain the target product FeF 3 (H 2 O) 0.33 / β-FeF 3 ·3H 2 O.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com