Preparation method of lithium sulphur battery anode material with high power and high specific capacity

A high specific capacity, high power technology, applied in the direction of battery electrodes, circuits, electrical components, etc., to achieve the effects of high discharge specific capacity, high power density, and simple chemical process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

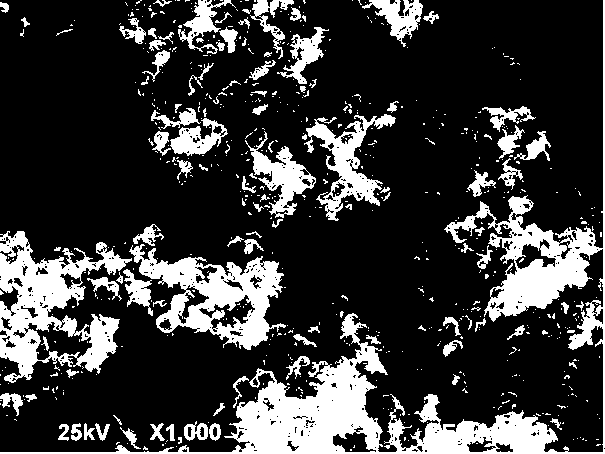

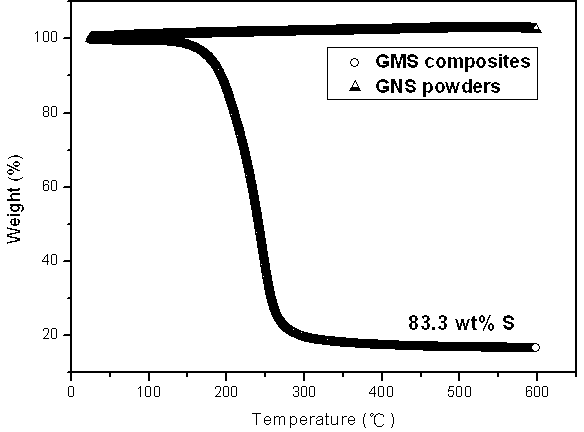

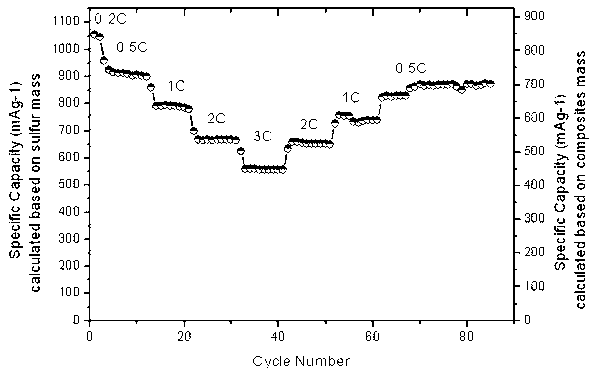

Image

Examples

Embodiment 1

[0023] The first step is to mix 70 milliliters of concentrated sulfuric acid, 4 milliliters of concentrated nitric acid and 3 grams of graphite, stir for 0.5 hours at 0 degrees, and the stirring speed is 300 rpm; then add 9 grams of potassium permanganate , the solution temperature rose to 35 degrees, stirred for 0.5 hours, and the stirring speed was 1000 rpm; then added 200 milliliters of water, the solution temperature rose to 80 degrees, and continued to stir for 0.5 hours; then added 300 milliliters of water and 15 milliliters of concentration 30% hydrogen peroxide, the solution was lowered to normal temperature, and continued to stir for 0.3 hours; then filtered and washed until the pH value of the solution was 5, after ultrasonication and centrifugation, a graphene oxide solution was obtained, and the frequency of oxidation ultrasonic was 20KHz, The ultrasonic time was 1 hour, and the centrifugation speed was 5000 rpm.

[0024] In the second step, 20 ml of hydrochloric a...

Embodiment 2

[0028] The first step The preparation method is basically the same as the first step in Example 1, except that the graphite is 2 grams, and the ultrasonic frequency is 60KHz.

[0029] In the second step, 50 ml of citric acid solution with a concentration of 1M was gradually added dropwise to 200 ml of 0.5M sodium thiosulfate solution, and after stirring at a speed of 600 rpm for 10 minutes, 5 ml of citric acid solution with a concentration of 3% The mixed active agent of urea and Triton TX-100 was slowly added dropwise into the solution, the temperature of the solution was raised to 70 degrees, and then 20 milliliters of graphene oxide solution with a concentration of 1 mg / ml was added. The temperature of the solution was raised to 90 degrees, stirred and heated for 2 hours, and then the product was filtered, washed, and dried to obtain a composite of graphene-coated sulfur particles.

[0030] The third step The preparation method is the same as the third step in Example 1.

Embodiment 3

[0032] The first step preparation method is basically the same as the first step in Example 1, the difference is that the graphene is 1 gram, then add 9 grams of potassium permanganate, the solution temperature rises to 35 degrees, stir for 1 hour, add 15 ml The concentration is 30%, the pH value of the solution is 6, and the centrifugation rate is 12000 rpm.

[0033]In the second step, 10 milliliters of concentrated phosphoric acid was gradually added dropwise to 200 milliliters of 0.5M ammonium thiosulfate solution, and after stirring at a speed of 1000 rpm for 1 minute, 5 milliliters of 3% urea and Qula The mixed active agent through TX-100 was slowly added dropwise into the solution, the temperature of the solution was raised to 70 degrees, and then 20 milliliters of graphene oxide solution with a concentration of 1 mg / ml was added. The temperature of the solution was raised to 90 degrees, stirred and heated for 0.5 hours, and then the product was filtered, washed, and dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com