Cobaltosic oxide multi-shell hollow sphere cathode material for lithium ion battery and preparation method thereof

A technology of cobalt tetroxide and negative electrode material, which is applied in battery electrodes, battery pack components, circuits, etc., can solve the problems of low specific capacitance, difficulty in preparing multi-shell layers with high yield, and short cycle life, etc. The effect of high current discharge and cycle performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The sucrose aqueous solution with a concentration of 1.5M was hydrothermally reacted in an autoclave at 200°C for about 130min, cooled naturally, filtered with suction, washed with water and ethanol several times, and dried in an oven at 80°C for 24h. The ball diameter is about 3 μm.

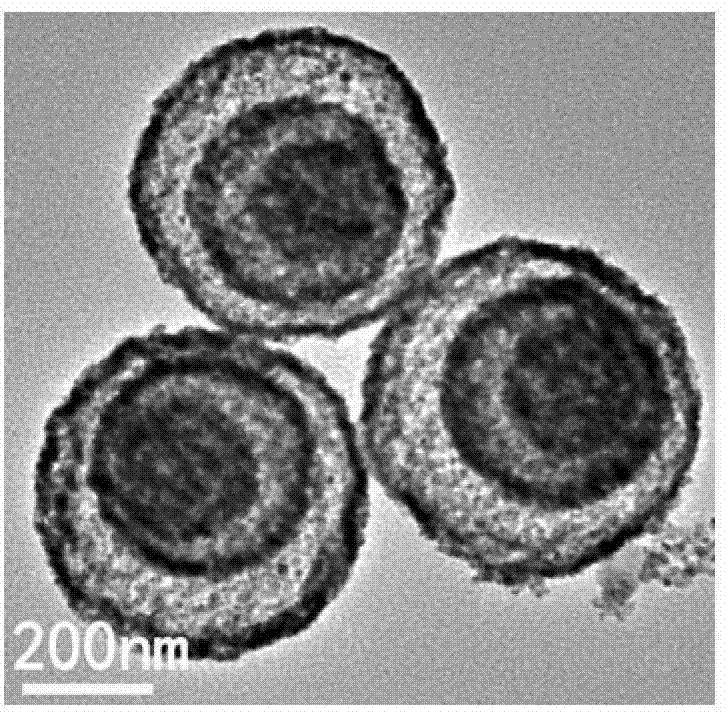

[0028] Disperse carbon sphere template evenly in 1M Co(Ac) 2 4H 2 O solution, wherein the ratio of water to ethanol in the solvent is 1:3. At 30°C, stir for 6h, filter with suction, wash with deionized water for 3 times, put it in an oven at 80°C for 12h, and place the obtained solid powder in In a muffle furnace, heat up to 500°C at 2°C / min, calcine at a constant temperature for 1 hour, and naturally cool to obtain a three-shell Co 3 o 4 Hollow sphere, the shell size is about 864.1nm±21.4nm.

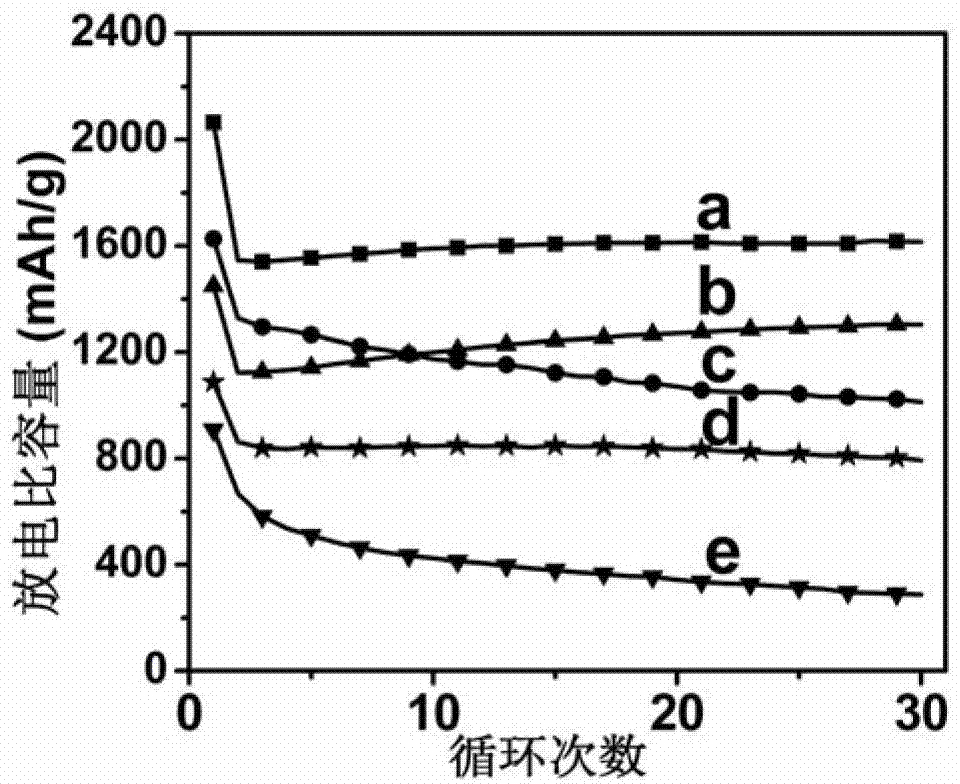

[0029] Three-shell Co with a weight ratio of 5:3:2 3 o 4 Hollow spheres, acetylene black and PVDF are uniformly dispersed in NMP solvent to form a slurry. Apply the slurry evenly on the copp...

Embodiment 2

[0032] The sucrose aqueous solution with a concentration of 1.5M was hydrothermally reacted in an autoclave at 200°C for about 130min, cooled naturally, filtered with suction, washed with water and ethanol several times, and dried in an oven at 80°C for 12h. The ball diameter is about 3 μm.

[0033] The carbon sphere template was uniformly dispersed in 3M Co(NO 3 ) 2 ·6H 2 In O solution, the solvent is deionized water. At 50°C, stir for 4 hours, filter with suction, wash with deionized water for 5 times, dry in an oven at 80°C for 24 hours, place the obtained solid powder in a muffle furnace, heat up to 500°C at 0.5°C / min, and calcine at a constant temperature 3h, the single-shell Co was obtained after natural cooling 3 o 4 Hollow sphere, the shell size is about 859.1nm±22.4nm.

[0034] The single-shell Co with a weight ratio of 8:1:1 3 o 4 Hollow spheres, acetylene black and PVDF are uniformly dispersed in NMP solvent to form a slurry. Apply the slurry evenly on the ...

Embodiment 3

[0037] The sucrose aqueous solution with a concentration of 1.5M was hydrothermally reacted in an autoclave at 200°C for about 130min, cooled naturally, filtered with suction, washed with water and ethanol several times, and dried in an oven at 80°C for 12h. The ball diameter is about 3 μm.

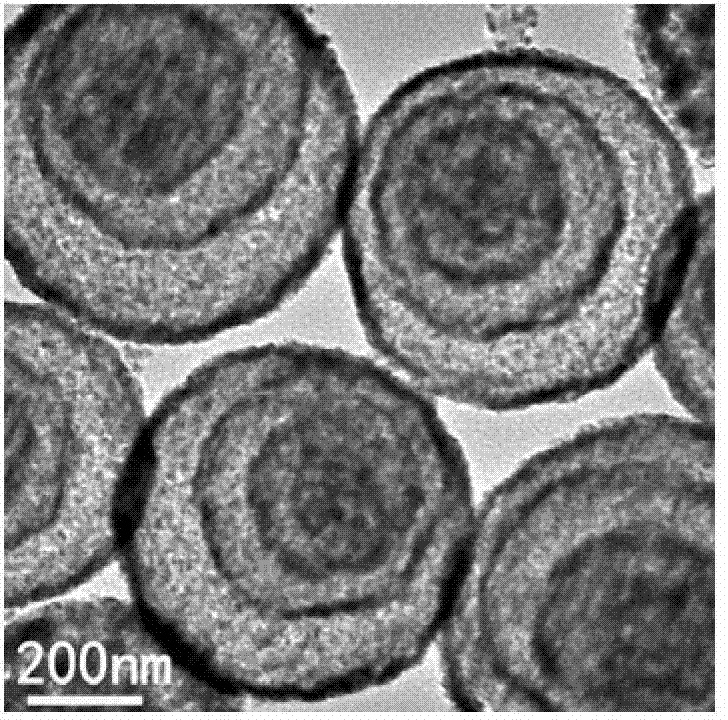

[0038] Disperse carbon sphere template evenly in 3M CoCl 2 4H 2 O solution, the solvent is ethanol, at 20°C, stir for 12h, then filter with suction, wash with deionized water for 3 times, put it in an oven at 80°C for 12h, put the obtained solid powder in a muffle furnace, and heat it at 5°C / Min was raised to 500°C, and then calcined at a constant temperature for 1 h, and after natural cooling, the double-shelled Co 3 o 4 Hollow sphere, the shell size is about 858.6nm±21.3nm.

[0039] Double shell Co with a weight ratio of 7:2:1 3 o 4 Hollow spheres, acetylene black and PVDF are uniformly dispersed in NMP solvent to form a slurry. Apply the slurry evenly on the copper foil. After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com