Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34 results about "Di-sec-octyl phthalate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

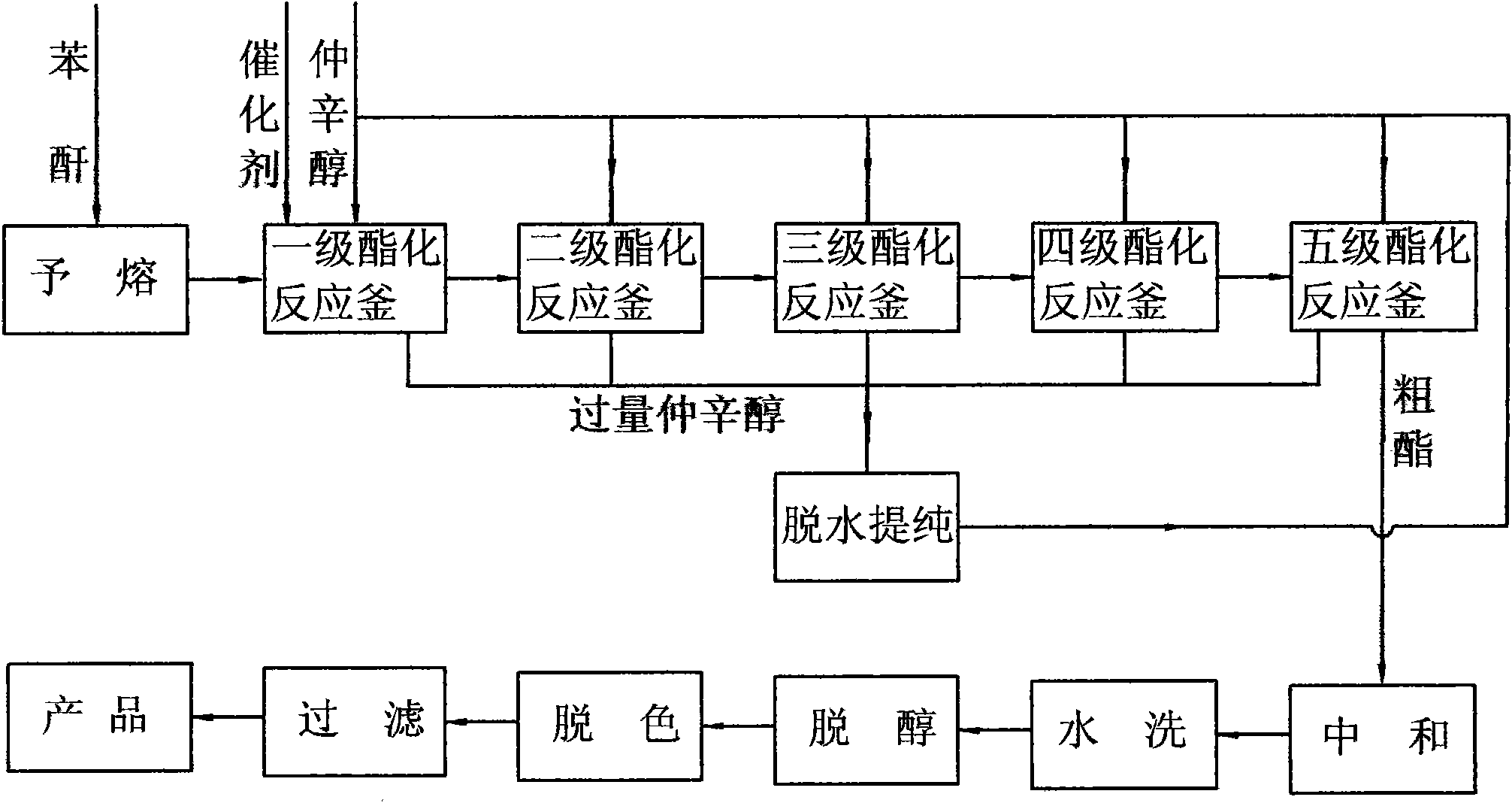

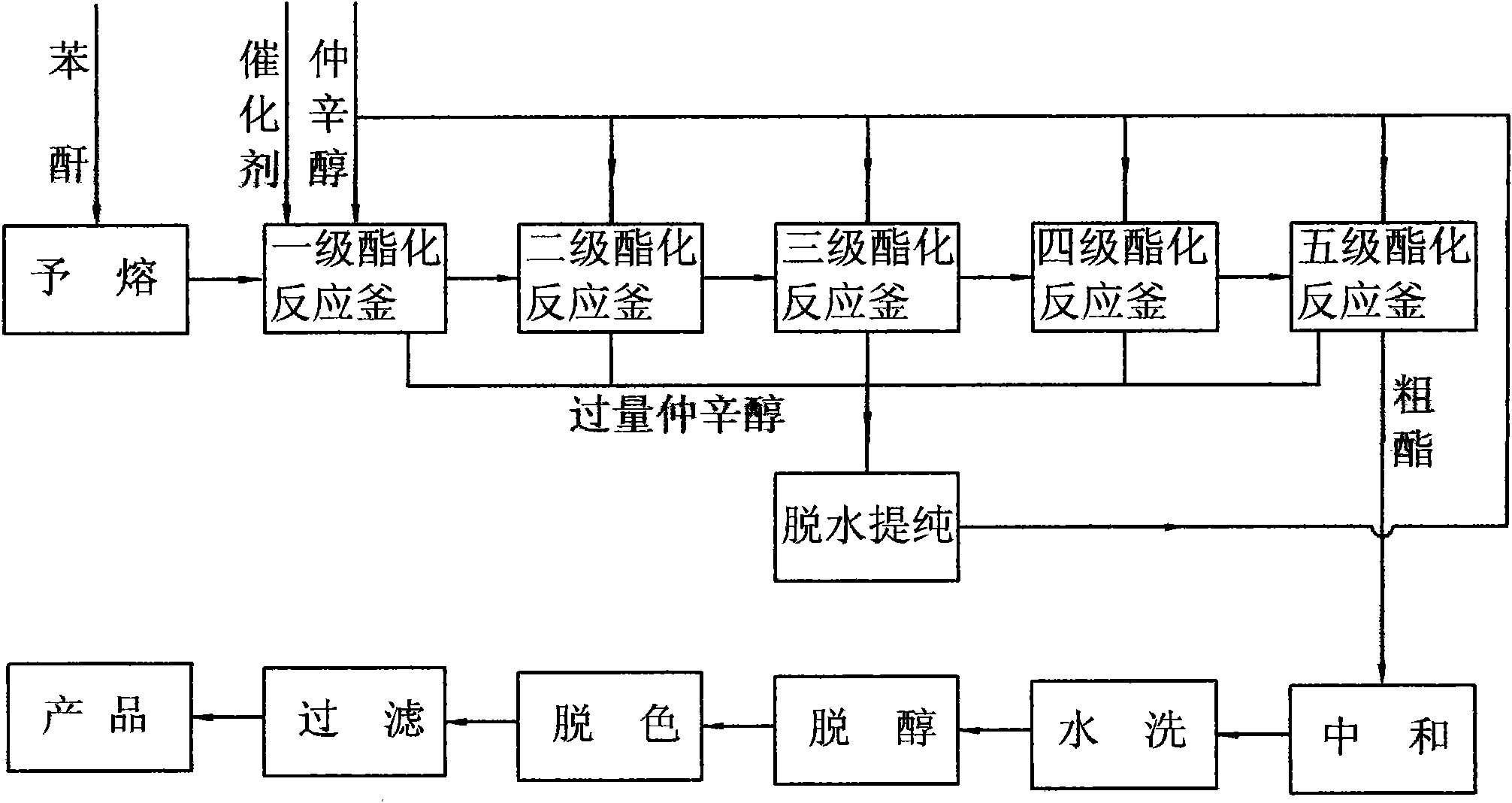

Continuous esterification production method of di-sec-octyl phthalate

ActiveCN101891620AImprove quality and efficiencyIncrease productivityOrganic compound preparationCarboxylic acid esters preparation2-OctanolAcid value

The invention discloses a continuous esterification production method of di-sec-octyl phthalate. The method comprises the following steps: using phthalic anhydride and 2-octanol to perform an esterification reaction under the existence of catalyst and obtain raw ester, and post-processing raw ester to obtain the product di-sec-octyl phthalate, wherein the esterification reaction is a multistage esterification reaction that phthalic anhydride and 2-octanol perform a plurality of esterification continuously. The esterification reaction of the invention adopts the production method of continuous esterification, the esterification reaction is complete, the conversion rate is high, the acid value of the product is low and the purity is high; and the time of esterification is short, the energy consumption is low, the product quality is stable, and the quality and production efficiency of di-sec-octyl phthalate can be effectively increased.

Owner:WEIFANG YUANLI CHEM

Compression-resistant bending-resistant enhanced fiber board material and preparation method thereof

InactiveCN104927374AImprove performanceHigh compressive strengthDomestic articlesFlat articlesFiberCellulose

The invention relates to the field of fiber board, and discloses a compression-resistant bending-resistant enhanced fiber board material and a preparation method thereof. The enhanced fiber board material comprises 12-22 parts of lignocellulose, 5-11 parts of glass fiber, 3-7 parts of bamboo fiber, 3-5 parts of sunflower stem fiber, 4-8 parts of chitin fiber, 0.5-1.5 parts of a coupling agent KH-550, 3-7 parts of urea-formaldehyde resin, 5-10 parts of silicon nitride powder, 3-6 parts of magnesium oxide powder, and 1.5-2 parts of di-sec-octyl phthalate. The preparation method of the compression-resistant bending-resistant enhanced fiber board material comprises the following steps: (1) silicon nitride powder and magnesium oxide powder are crushed; (2) the materials are added into a mixing tank, and are mixed; (3) the mixed material is added into a forming machine, and is subjected to compression forming and cutting, such that the compression-resistant bending-resistant enhanced fiber board material is obtained.

Owner:SUZHOU DEXIANG DECORATION ENG

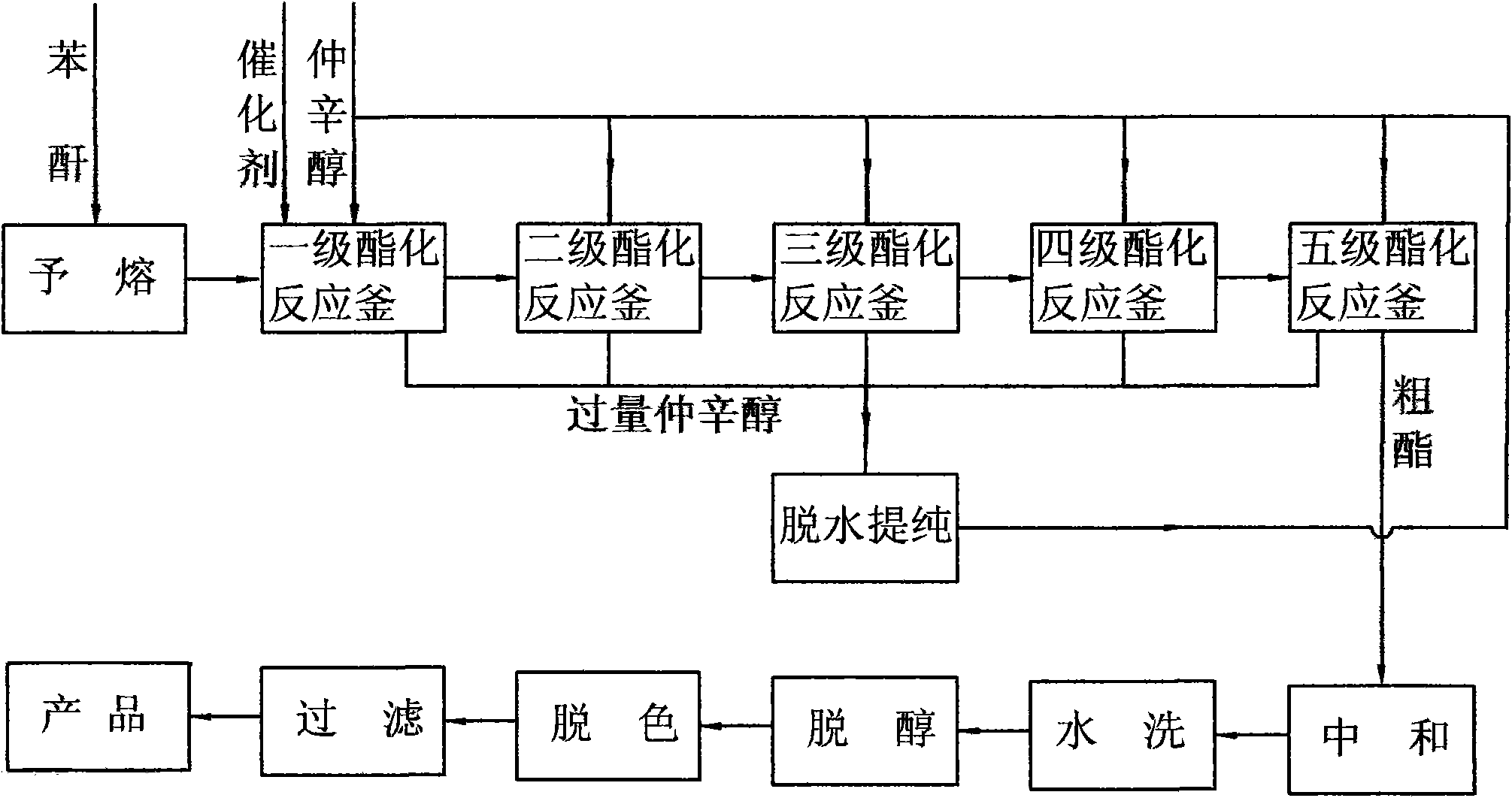

Continuous alcohol-removing device and alcohol-removing method of di-sec-octyl phthalate

InactiveCN102173991AContinuous dealcoholization achievedGood dealcoholization effectOrganic compound preparationCarboxylic acid esters preparationAlcoholRelative pressure

The invention discloses a continuous dealcoholizing device and dealcoholizing method of di-sec-octyl phthalate. The dealcoholizing device comprises an dealcoholizing tower and a stripping tower which are connected in series. The dealcoholizing method comprises the following steps: the material obtained through esterification enters the dealcoholizing tower first to re-dealcoholize under the conditions that the material temperature is 160-180 DEG C, the relative pressure is from -0.08MPa to -0.09 MPa, the top gas-phase temperature is more than 90 DEG C and the relative pressure is no more than -0.084MPa; the re-dealcoholized material enters the stripping tower to dealcoholize under the conditions that the material temperature is 160-180 DEG C, the relative pressure is from -0.083MPa to -0.09MPa, the top gas-phase temperature is 120-170 DEG C and the relative pressure is no more than -0.088MPa; and introducing saturated steam in a saturated steam distributor to perform stripping. In the invention, the continuous dealcoholizing production method is adopted; and the residence time of the material in the device is short, the energy consumption is low, the product purity is high, the quality is stable, and the quality and production efficiency of di-sec-octyl phthalate can be increased.

Owner:WEIFANG YUANLI CHEM

High-strength mica powder modified polypropylene plastic

The invention discloses a high-strength mica powder modified polypropylene plastic which is prepared from, by weight, 50-70 parts of polypropylene resin, 20-50 parts of mica powder, 5-10 parts of titanium dioxide, 5-15 parts of brominated epoxy resin, 4-12 parts of silicone oil, 2-8 parts of polyvinyl alcohol, 5-15 parts of tertiary butylhydroquinone, 10-18 parts of dicapryl phthalate, 4-12 parts of heat stabilizer, 10-15 parts of antifreezing agent, 3-9 parts of light stabilizer and 6-10 parts of ferric oxide. According to the high-strength mica powder modified polypropylene plastic, the original characteristics of being resistant to high temperature, nontoxic and odorless of polypropylene plastic are reserved, the added mica powder has insulation, high temperature resistance, acid-base resistance and corrosion resistance, the low-temperature resistance of the plastic is enhanced through the antifreezing agent, the raw materials are easy to obtain, the cost is low, operation is simple, and wide application can be achieved.

Owner:安徽格锐新材料科技有限公司

Preparation method of ethylene glycol gemini di-sec-octyl phthalate sodium sulfosuccinate

InactiveCN103435519ASimple methodEasy to operateTransportation and packagingSulfonic acids salts preparationAlcoholHydrogen

The invention discloses a preparation method of ethylene glycol gemini di-sec-octyl phthalate sodium sulfosuccinate. The preparation method of ethylene glycol gemini di-n-octyl phthalate sodium sulfosuccinate comprises the following steps: carrying out a mono-esterification reaction for combining maleic anhydride with two hydroxyls on ethylene glycol, so as to generate ethylene glycol di-maleic acid monoester, then carrying out a double-esterification reaction on ethylene glycol di-maleic acid monoester and sec-octyl alcohol to obtain ethylene glycol di-maleic anhydride di-sec-octyl phthalate, and finally carrying out a conjugate addition sulfonation reaction on ethylene glycol di-maleic anhydride di-sec-octyl phthalate and sodium hydrogen sulfite to obtain the ethylene glycol gemini di-sec-octyl phthalate sodium sulfosuccinate product, wherein a catalyst used in the mono-esterification reaction is carbon-based solid acid, and the carbon-based solid acid after the mono-esterification reaction is carried out is directly taken as a catalyst of the double-esterification reaction. The preparation method of ethylene glycol gemini di-sec-octyl phthalate sodium sulfosuccinate is simple, easy to operate and good in environmental protection property.

Owner:NANTONG UNIVERSITY

Flame retardant mine cable sheath material

InactiveCN103788466AGood flexibilityStrong impact resistanceInsulated cablesInsulatorsAluminium hydroxideBoron carbide

The invention discloses a flame retardant mine cable sheath material. The flame retardant mine cable sheath material comprises the following raw materials in parts by weight: 32-47 parts of EVA (ethylene vinyl acetate) resin, 25-35 parts of crosslinked insulated polyethylene, 4-5.5 parts of DCP (di-sec-octyl Phthalate), 1.5-3.5 parts of DBP (dibutyl phthalate), 3-5 parts of zinc oxide, 2-3 parts of triallyl cyanurate, 1.7-2.3 parts of triallyl isocyanurate, 1.5-3 parts of HVA-2, 21-25 parts of channel black, 3-6 parts of aluminium hydroxide, 2-5 parts of magnesium hydroxide, 5-6 parts of boron carbide, 0.5-1.5 parts of triethanolamine, 15-30 parts of calcined pottery clay, 0.5-1.5 parts of anti-aging agent ODA and 1-2.5 parts of anti-aging agent 4010NA, wherein the content of vinyl acetate in the EVA resin is 21-30%. The flame retardant mine cable sheath material is resistant to high temperature, has excellent flame retardance, excellent warping and aging resistance effects and is long in service life.

Owner:安徽华海特种电缆集团有限公司

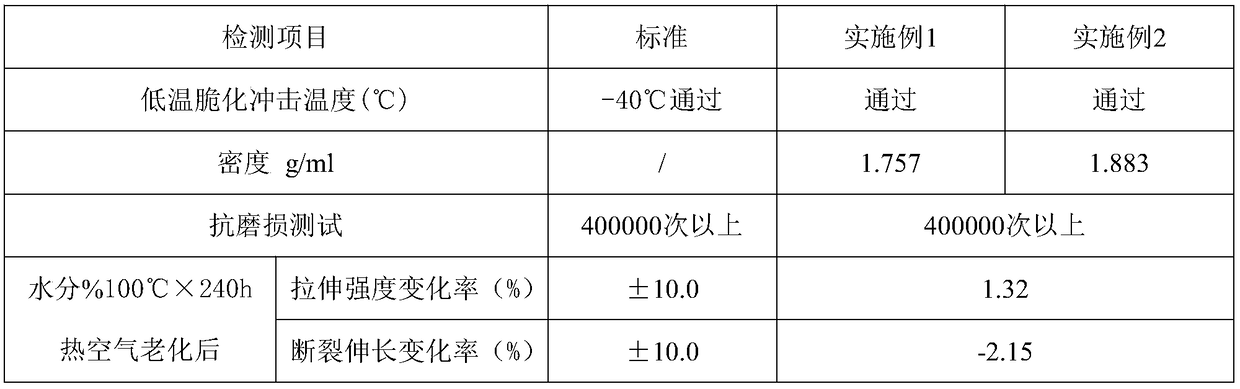

Rubber composition used for valve base, preparation method thereof and the valve base

InactiveCN104974434ACorrosion resistantWith high and low temperature resistanceVulcanizationStearic acid

The invention discloses a rubber composition used for a valve base, wherein the rubber composition includes: ethylene-propylene rubber 4640, carbon black N330, carbon black N220, a carbon black reinforcing agent N774, paraffin oil, light calcium, zinc oxide, stearic acid, a dispersing agent (AFLUX-42), dipentamethylenethiuram tetrasulfide (accelerant TRA), N,N'-m-phenylene dimaleimide (accelerant HVA-2), dicapryl phthalate (plasticizer DCP), and sulfur S. The invention also provides a preparation method of the rubber composition, comprising the steps of internal mixing, open milling and vulcanization. The rubber composition can be used for making a valve base or a wear-resistant valve base of a center line-type butterfly valve. The preparation method is simple in formula and process, is short in vulcanization time, is high in production efficiency, is low in production cost and is easy to achieve industrialization. The valve base made of the rubber composition is good in sealing performance, is uniform in structure, is corrosion-resistant, high-temperature-resistant and low-temperature-resistant, is flame-retarding and environment-friendly, and is wear-resistant.

Owner:天津滨海新区大港汇丰汽车装饰有限公司

PE stretch film material and preparation method thereof

Owner:SUZHOU DINGLI PACKAGING

Polyethylene artificial leather

The invention discloses polyethylene artificial leather. The polyethylene artificial leather comprises, by mass, 100 parts of LDPE, 15-40 parts of EVA modified resin, 0.4-1.0 part of dicapryl phthalate (DCP), 1.5-3 parts of zinc oxide, 2-3.5 parts of foaming agent, 0.3-1 part of lead stearate and 5-10 parts of colorant. According to the polyethylene artificial leather, in the formula, the LDPE serves as a main raw material, the EVA modified resin, the dicapryl phthalate (DCP) and other auxiliary raw materials are auxiliary, and then the polyethylene artificial leather is processed. Cost is reduced, the stability of the product is improved, and in addition, the dimensional stability and anti-crack performance of the product can be improved through the EVA modified resin. The polyethylene artificial leather is mainly used for manufacturing products such as cases and dead heads.

Owner:SUZHOU NEW DISTRICT JIAHE PLASTIC

Biodegradable material for agriculture and preparation method thereof

The invention discloses a biodegradable material for agriculture. The biodegradable material for agriculture is prepared from, by weight, 35-40 parts of polyanhydride, 36-50 parts of lignin, 55-60 parts of polyethylene glycol, 7-11 parts of calcium carbonate, 5-6 parts of polycaprolactone, 8-12 parts of poly(butylene succinate), 30-35 parts of bamboo fibers, 3-9 parts of glycerol, 15-20 parts of kaolin, 16-20 parts of polylactic acid, 3-8 parts of potassium stearate, 2-7 parts of polystyrene foam, 1-6 parts of dicumyl peroxide, 22-26 parts of polyacrylate, 17-25 parts of poly alkyl acrylate, 20-25 parts of benzoyl peroxide, 10-14 parts of epoxy soybean oil, 9-12 parts of diisobutyl phthalate and 6-9 parts of di-sec-octyl phthalate. The biodegradable material for agriculture is high in structural strength, easy to degrade and good in heat-resistant performance.

Owner:WUHU TIANXIONG NEW MATERIAL TECH

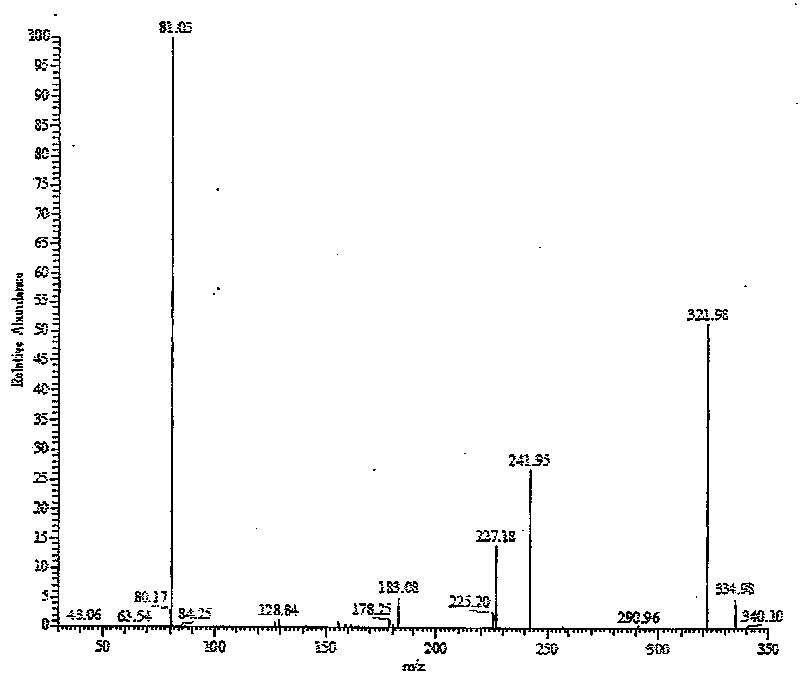

Preparation method of phthalate plasticizer

ActiveCN111517950AReduced neutralization washing stepsShorten production timeOrganic compound preparationCarboxylic acid esters preparationPlatinumPhthalic anhydride

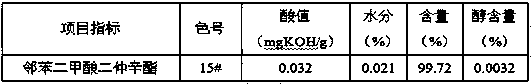

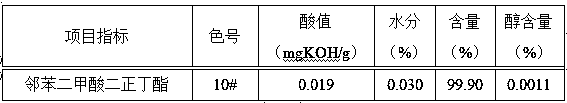

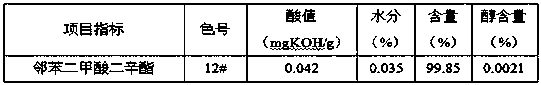

The invention provides a preparation method of a phthalate plasticizer. The method specifically comprises the steps of esterification, crude dealcoholization, cooling, addition of a deacidifying agent, dealcoholization and filtration. The preparation method is adopted; treatment is carried out without a decolorizing agent, the chromaticity of the prepared phthalate plasticizer product can reach 10-15 # through platinum-cobalt standard colorimetry; phthalic anhydride and sec-octyl alcohol are used as raw materials; the acid value of the dioctyl phthalate prepared by the preparation method disclosed by the invention is less than or equal to 0.05 mgKOH / g; wherein the water content is less than or equal to 0.05%, the alcohol content is more than or equal to 99.5% and the alcohol content is less than or equal to 0.005%, and meanwhile, neutralizing and washing steps can be reduced, the wastewater amount is reduced, the alkali washing, washing and settling time is saved, the production cost is greatly reduced and the production benefit is increased.

Owner:山东元利科技有限公司

Polyethylene bearing having high-bearing performance

A polyethylene bearing with high load-carrying performance belongs to the technical field of mechanical parts and is modified from ultra-high molecular weight polyethylene, nitrile rubber, self-lubricating agent, zinc oxide, stearic acid, cross-linking agent, antioxidant, and EVA. It is composed of permanent resin, 2-2-octyl phthalate, zinc oxide, foaming agent, lead stearate, carbon fiber and nano-graphite powder. The composition of the invention is novel. While maintaining the advantages of self-lubrication and wear resistance of ultra-high molecular weight polyethylene, the invention further improves its wear resistance by introducing a self-lubricating agent; by introducing rubber components, it improves its water lubrication While the friction performance has also improved the flexibility of the material, impact resistance, vibration damping; It is much smaller than that and is suitable for use as a water-lubricated bearing material.

Owner:王涛

Polyethylene bearing with high lubricating property

A polyethylene bearing with high lubricating performance belongs to the technical field of mechanical parts and is modified from ultra-high molecular weight polyethylene, nitrile rubber, self-lubricating agent, zinc oxide, stearic acid, crosslinking agent, antioxidant, and EVA. Composed of permanent resin, di-sec-octyl phthalate, zinc oxide, foaming agent, lead stearate and coloring agent. The composition of the invention is novel. While maintaining the advantages of self-lubrication and wear resistance of ultra-high molecular weight polyethylene, the invention further improves its wear resistance by introducing a self-lubricating agent; by introducing rubber components, it improves its water lubrication While the friction performance has also improved the flexibility of the material, impact resistance, vibration damping; It is much smaller than that and is suitable for use as a water-lubricated bearing material.

Owner:王涛

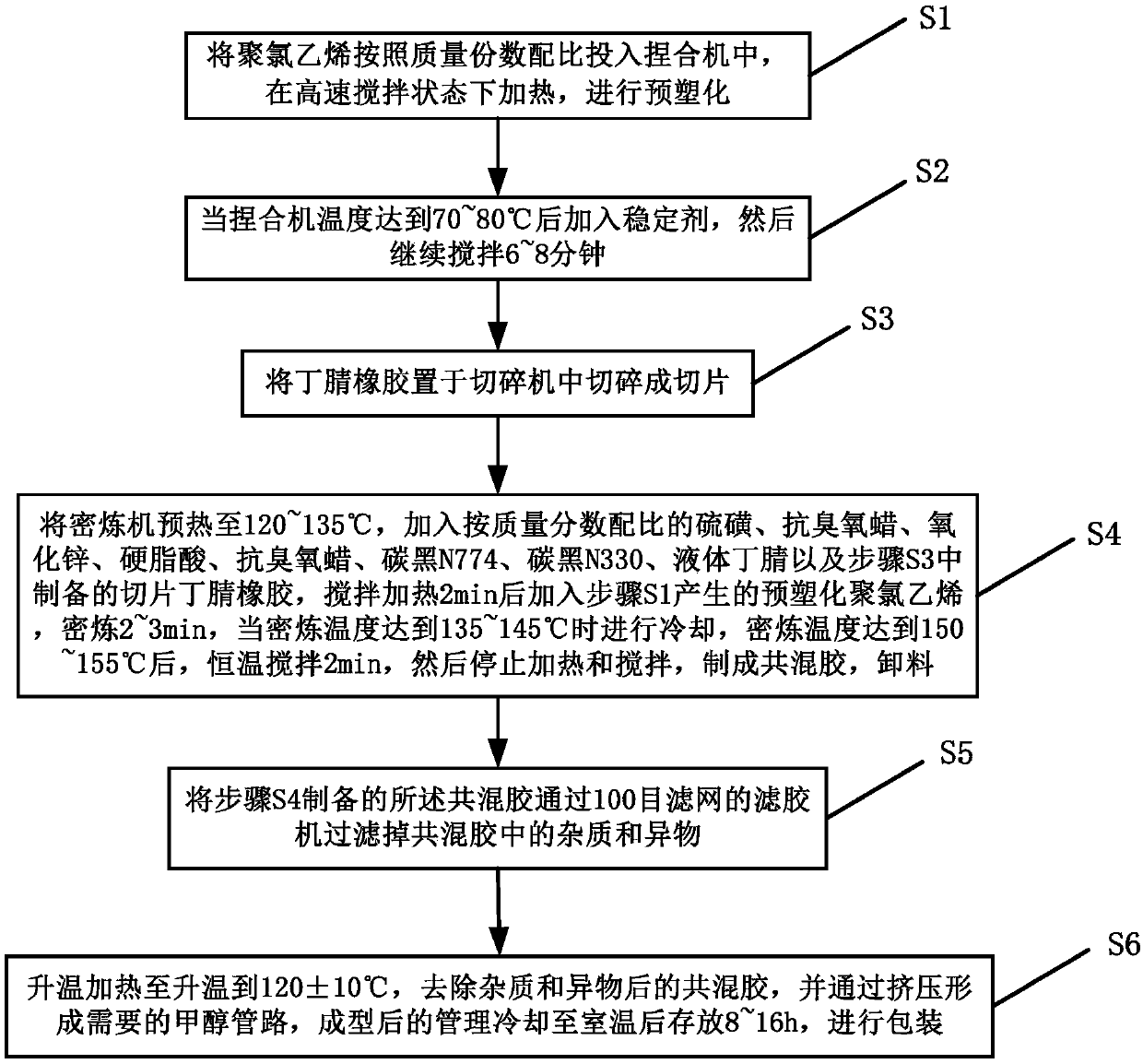

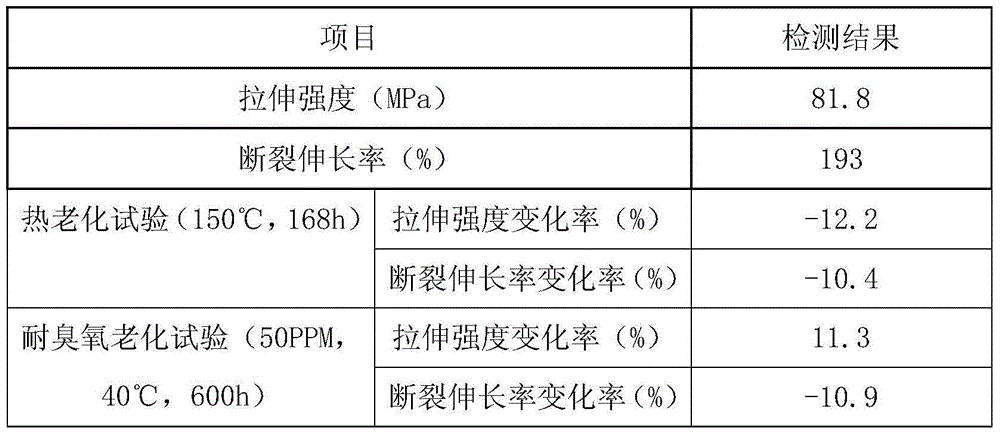

Plastic composition resistant to methanol fuel and gasoline and preparation method of composition

The invention provides a plastic composition resistant to a methanol fuel and gasoline, and relates to the technical fields of vehicle material compositions and production. The composition includes abasic rubber variety, an additive and an anti-aging agent; and the composition concretely comprises the following materials in parts by weight: 50-80 parts of acrylonitrile-butadiene rubber, 20-40 parts of polyvinyl chloride (PVC), 3-6 parts of zinc oxide, 1-3 parts of stearic acid, 0.5-2 parts of sulphur, 1-3 parts of anti-ozone wax, 0.5 part of di-sec-octyl phthalate, 30-50 parts of carbon blackN774 (N774), 20-30 parts of carbon black N330 (N330), 20 parts of barium sulfate, 5-7 parts of liquid butyronitrile, and 3-8 parts of the anti-aging agent. The invention also provides a preparation method of the plastic composition. According to the method provided by the invention, the plastic composition is prepared by co-mixing of the acrylonitrile-butadiene rubber and the polyvinyl chloride,and has the advantages of excellent aging resistance, oil resistance, solvent resistance and chemical corrosion resistance, and additives such as the zinc oxide and the anti-aging agent are added, sothat the material can have corrosion resistance to methanol and gasoline after being shaped.

Owner:HUNAN GEELY AUTOMOBILE COMPONENTS +1

Rat-proof termite-proof water-resistant buried polyvinyl chloride cable material and preparation method thereof

InactiveCN106046615ALow water absorptionImprove water resistancePlastic/resin/waxes insulatorsCellulosePolyvinyl chloride

The invention discloses a rat-proof termite-proof water-resistant buried polyvinyl chloride cable material and a preparation method thereof. The cable material is prepared from, by weight, 46-61 parts of polyvinyl chloride, 19-31 parts of polystyrene, 14-26 parts of highly cyanoethylated cellulose, 6-12 parts of calcium rosinate, 2-4 parts of lead sulfate tribasic, 10-15 parts of diethylene glycol dibenzoate, 4-8 parts of alpha, omega-dyhydroxy polydimethylsiloxane, 3-6 parts of sodium fluoroacetate, 5-10 parts of hydrophobic fumed silica, 10-15 parts of quartz powder, 8-13 parts of di-sec-octyl phthalate phthalate, zirconium acetate, diethylene glycol dibenzoate and the like. Water absorptivity of the cable material can be remarkably reduced, and water resistance of the cable material is improved; due to addition of raw materials such as the sodium fluoroacetate and trichloronitromethane, cables made from the cable material can be effectively protected from being gnawed by rats or damaged by termites.

Owner:ANHUI SAIHUA CABLE

Plastic surface layer material for outdoor sports grounds

The invention belongs to the field of building materials and provides a plastic surface layer material for outdoor sports grounds. The material includes, by weight, 30-40 parts of epoxy resin, 10-15 parts of ABS resin, 10-15 parts of polyvinyl chloride, 10-15 parts of polypropylene, 10-15 parts of organic silicon, 1-5 parts of sodium citrate, 1-5 parts of di-sec-octyl phthalate, 5-10 parts of polyvinyl alcohol, 1-3 parts of pigment fast brilliant red, 1-3 parts of ultramarine blue powder, and 1-3 parts of permanent yellow GR. The plastic surface layer material is free of secondary pollution onindoor environment by means of the high-molecular materials. The product has good weather-resistance and wear-resistance, has water-permeability and breathability, is low in cost and allows large-scale promotion.

Owner:白克雯

Plasticizer

The invention provides a plasticizer, and relates to the technical field of additives. The plasticizer comprises the following components: 33-45 parts of dicapryl phthalate, 15-26 parts of polyvinyl chloride, 8-19 parts of chlorinated rubber, 3-9 parts of gel, 2-7 parts of adhesive, 13-22 parts of sodium carboxymethylcellulose, 1-6 parts of naphthalene, and 2-7 parts of aerographite, wherein the gel comprises the following components: 18-26 parts of glycerinum, 7-15 parts of latex, 2-8 parts of epoxypropane, 4-12 parts of ethylene oxide, 1-6 parts of vaseline, and 3-11 parts of rhenium. The plasticizer has the beneficial effects that the cost is low; the formula is reasonable; the adhering performance is high; the tensile strength is high; in addition, the flavor of mint can be generated; the plasticizer is capable of sterilizing.

Owner:佛山市高明区生产力促进中心

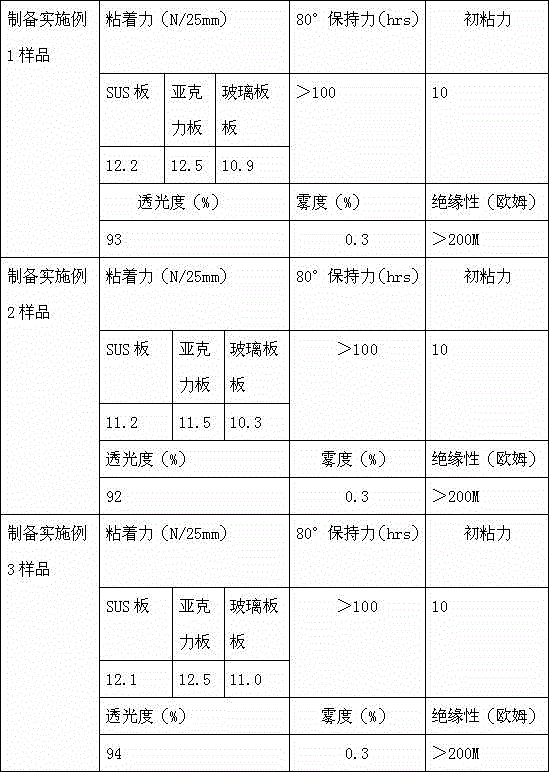

OCA optical adhesive tape

InactiveCN105778791AImprove heat resistanceImprove brittlenessNon-macromolecular adhesive additivesFilm/foil adhesivesCyanoacrylateAdhesive belt

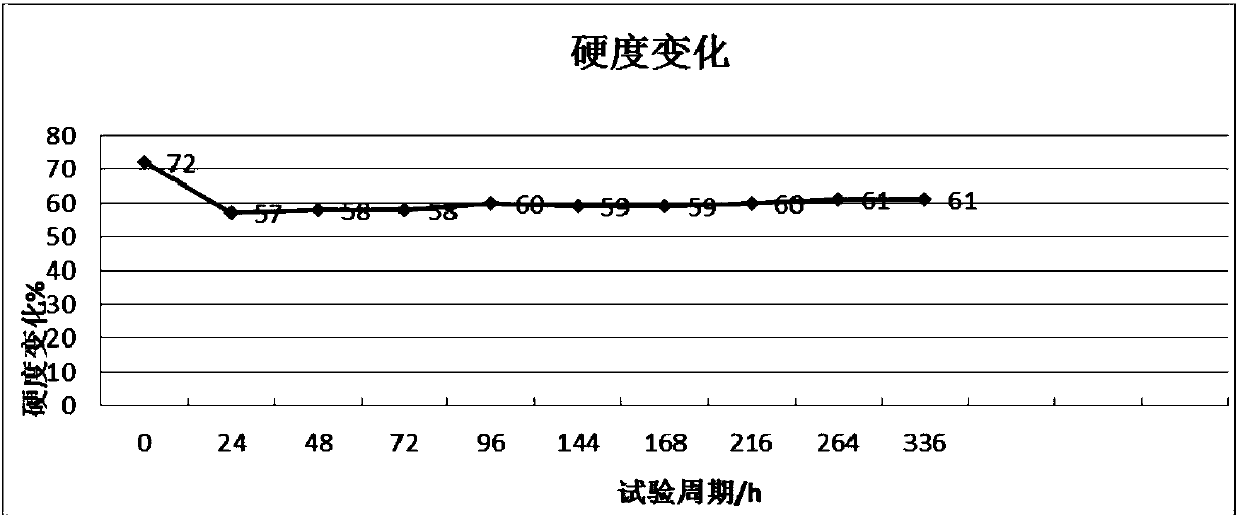

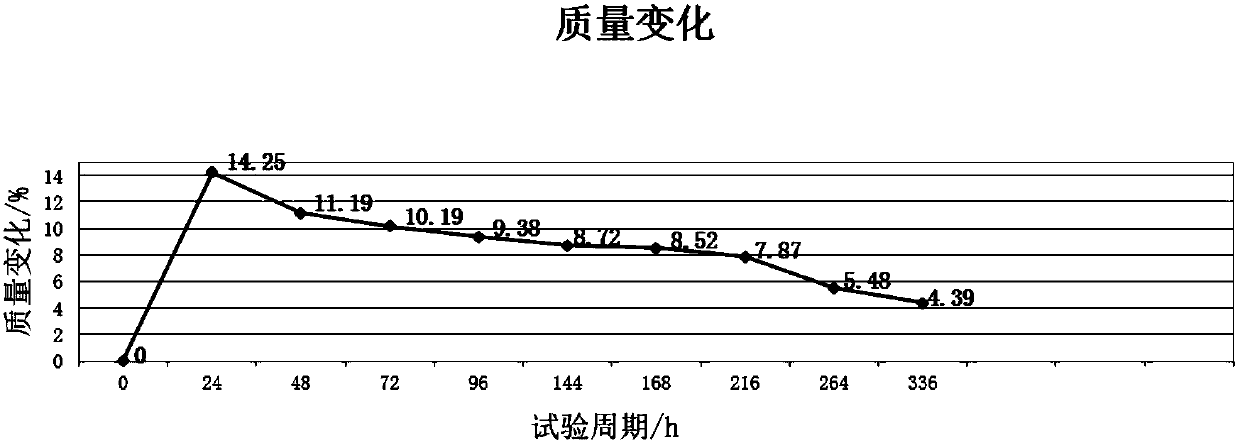

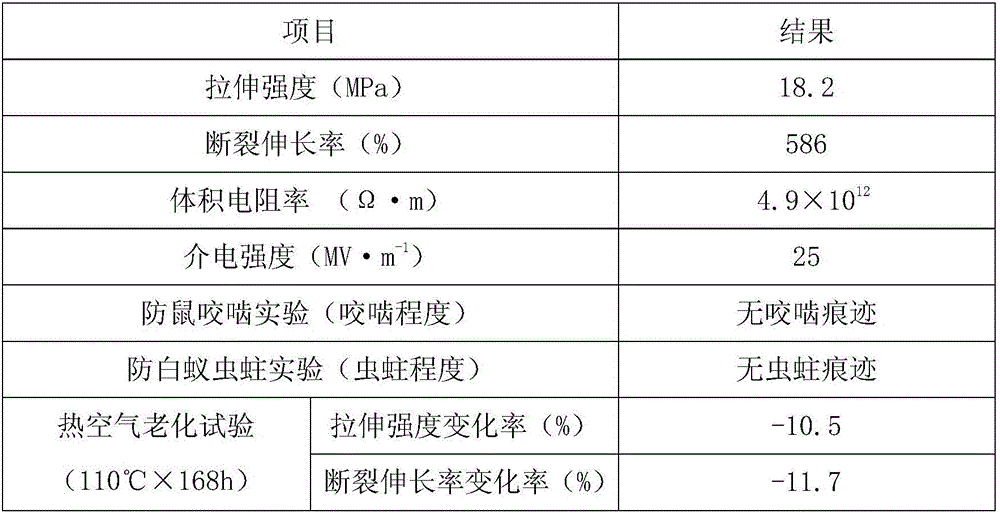

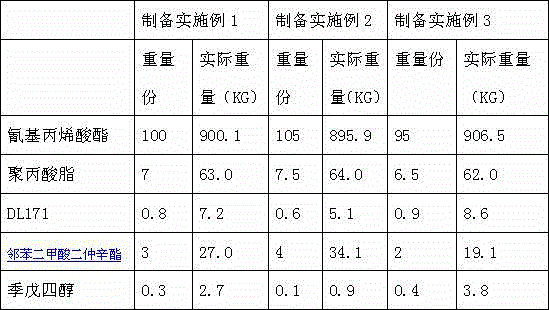

The invention discloses an OCA optical adhesive tape. The OCA optical adhesive tape has a three layer structure, and comprises a lightly peeled PET release membrane layer, an optical rubber layer, and a heavily peeled PET release membrane layer from top to bottom; wherein the optical rubber layer is composed of the following raw materials in parts by weight: 90 to 110 parts of cyanoacrylate, 6 to 8 parts of polypropionate, 0.5 to 1 part of DL171, 1 to 5 parts of di-sec-octyl phthalate, and 0.05 to 0.5 part of pentaerythritol. The provided OCA optical adhesive tape has the advantages of good heatproof and adhesive properties.

Owner:CHANGSHU LIANGYI ADHESIVE TAPE IND CO LTD

Anti-skid shoe material and preparation method thereof

The invention discloses an anti-skid shoe material and a preparation method thereof. The anti-skid shoe material is prepared from raw materials in parts by weight as follows: 50-65 parts of an ethylene-vinyl acetate copolymer, 1-2 parts of t-butyl mercaptan, 10-16 parts of EPDM (ethylene-propylene-diene monomer) rubber, 10-12 parts of a polystyrene-ethylene-butene copolymer, 5-9 parts of talcum powder, 2-5 parts of macromolecular wax, 0.5-1.5 parts of dicapryl phthalate, 1.2-2 parts of a diazinedicarboxamide foaming agent, 0.6-1 part of zinc oxide, 0.3-0.7 parts of stearic acid, 3-5 parts of an antistatic agent, 2-4 parts of color masterbatch, 2-6 parts of superfine white carbon black and 2-3 parts of a rubber modifier. The invention further provides the preparation method of the anti-skid shoe material.

Owner:谢新莉

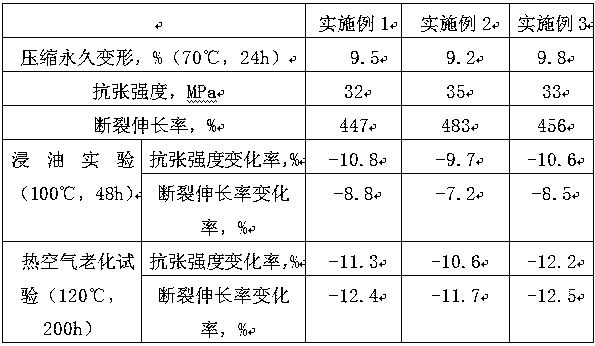

Rubber material for oil-resistant, high-temperature, and high-pressure gaskets and preparation method thereof

ActiveCN106750646BIncrease elasticityGood flexibilityBuilding insulationsRubber materialPolymer science

The invention discloses an oil-resistant and high temperature-resistant high-pressure washer rubber material and a preparation method thereof. The oil-resistant and high temperature-resistant high-pressure washer rubber material is prepared from the following raw materials in parts by weight: 70 to 90 parts of nitrile rubber, 20 to 30 parts of chloroprene rubber, 18 to 22 parts of vinylidene fluoride / chlorotrifluor ethylene copolymer, 5 to 8 parts of epoxidized fatty acid methyl ester, 6 to 8 parts of dicapryl phthalate, 4 to 5 parts of anilmomethyl triethoxy silane, 12 to 16 parts of asphalt oil and the like. The oil-resistant and high temperature-resistant high-pressure washer rubber material has the advantages that by using the nitrile rubber, the chloroprene rubber and the vinylidene fluoride / chlorotrifluor ethylene copolymer as base materials, the good oil-resistant and high temperature-resistant properties are realized; the added dicapryl phthalate and epoxidized soybean oil form a complex plasticizer, and the complex plasticizer is compounded with the epoxidized fatty acid methyl ester, so that the high temperature-resistant property and processing property are improved, and the elasticity and flexibility of the rubber are improved; by adding raw materials of aluminum phosphite, sodium antimonate, basic magnesium chloride whiskers and the like, the flame-retardant property is good; by adding raw materials of silicon boride, precipitated white carbon black, white jade powder and the like, the oil-resistant property of a product is improved, and the abrasion-resistant property of the product is enhanced.

Owner:潘赵翔

Bearing material with low friction coefficient

The invention discloses a bearing material with a low friction coefficient, and belongs to the technical field of mechanical materials, wherein the bearing material comprises the following raw materials by weight: 10-30% of ultra-high molecular weight polyethylene, 10-20% of carbon fibers, 10-20% of nitrile butadiene rubber, 1-2% of a plasticizer, 5-10% of a self-lubricating agent, 0.5-5% of zincoxide, 0.1-1% of stearic acid, 0.1-3% of a cross-linking agent, 0.2-3% of an antioxidant, 5-10% of a modified resin, 0.5-1% of di-sec-octyl phthalate, 1-2.5% of a foaming agent and 0.2-0.8% of a flameretardant. According to the invention, the components are novel, the advantages of self-lubrication and wear resistance of the ultra-high molecular weight polyethylene are maintained while the wear resistance is further improved by introducing the self-lubricating agent, the carbon fibers and other components, the heat resistance of the bearing is further improved by adding the flame retardant and the antioxidant so as to prolong the service life of the bearing, so that the high-requirement occasion of the bearing is further met.

Owner:仪征威业油泵油嘴有限公司

Environment-friendly plastic and formation method thereof

InactiveCN109111633AImprove plasticityPromote degradationEnvironmental resistanceChlorinated paraffins

The invention discloses environment-friendly plastic, which is prepared from the following raw materials in parts by weight: 10 to 20 parts of natural latex, 10 to 40 parts of polyethylene resin, 10 to 20 parts of polypropylene resin, 15 to 25 parts of calcium carbonate, 10 to 18 parts of starch, 5 to 15 parts of talcum powder, 12 to 18 parts of biological degradation agent, 8 to 15 parts of zincsoap laurate, 5 to 15 parts of di-sec-octyl phthalate, 5 to 15 parts of chlorinated paraffin and 4 to 12 parts of lubricant. The environment-friendly plastic provided by the invention is nontoxic andodorless, cannot cause the pollution to air and an environment, is good in plasticity, can be used for making multiple plastic products applicable to the need of production or life, and is high in practicability; the environment-friendly plastic is increased in degradability and improved in environmental friendliness by the added biological degradation agent; the environment-friendly plastic is simple in production process; the raw materials are easily obtained; and the cost is low.

Owner:德阳市米雅乐食品厂

Ultraviolet-resistant and weather-resistant nylon material for mudguards of automobiles and method for manufacturing ultraviolet-resistant and weather-resistant nylon material

InactiveCN105086441AHigh mechanical strengthGood weather resistanceETHYLHEXYL HYDROXYSTEARATEGlycidyl methacrylate

The invention discloses an ultraviolet-resistant and weather-resistant nylon material for mudguards of automobiles and a method for manufacturing the ultraviolet-resistant and weather-resistant nylon material. The ultraviolet-resistant and weather-resistant nylon material comprises, by weight, 38-49 parts of nylon 66, 24-38 parts of polybutylene terephthalate, 16-32 parts of polydiallylphthalate, 5-10 parts of ethylhexyl hydroxystearate, 12-16 parts of flax fibers, 11-16 parts of dicapryl phthalate, 14-22 parts of pigment soot carbon, 18-34 parts of acrylic powder, 5-10 parts of glycidyl methacrylate, 4-6 parts of phenyl salicylate, 15-25 parts of rutile powder, 4-7 parts of ricinoleamide mea, 3-5 parts of lead fumarate and 5-8 parts of auxiliaries. The ultraviolet-resistant and weather-resistant nylon material and the method have the advantages that the ultraviolet-resistant and weather-resistant nylon material manufactured by the aid of the method is high in mechanical strength and excellent in weather resistance, ozone aging resistance and impact resistance, and service requirements of the mudguards of the automobiles can be completely met.

Owner:ANHUI ANLAN MOLD

Anti-oxidation layer of conductive fabric and preparation method

InactiveCN108641236AEfficient anti-oxidation, fire-proof and anti-corrosion performanceImprove antioxidant capacityBuilding insulationsSilanesGlycerol

The invention discloses an anti-oxidation layer of conductive fabric and a preparation method, and relates to the technical field of communication materials. The anti-oxidation layer of the conductivefabric is prepared from the following components: an antioxidant, anhydrous calcium chloride, maleated rosin, di-sec-octyl phthalate, polyvinyl chloride, polystyrene, salt of 3,4-dimethylpyrazole acid, aluminium phosphate, waterborne silicone resin, glycerol monolaurate, triethyl phosphate, nano rubber powder, ammonium polyphosphate, triphenyl phosphate, tung oil modified phenolic epoxy resin, expansible graphite, concentrated hydrochloric acid, silane, propylene pitch resin, isoamyl alcohol and absolute ethyl alcohol. The anti-oxidation layer of the conductive fabric has efficient anti-oxidation, fireproof and anti-corrosion performance, used materials are safe, convenient and easily available and can be directly applied to the conductive fabric, anti-oxidation performance of the conductive fabric is enhanced, and anti-oxidation safety of the materials is improved; the anti-oxidation layer of the conductive fabric is high in anti-oxidation performance, long in service life and good in stability.

Owner:ANHUI COMM IND SERVICE CO LTD

Polyethylene (PE) pipe with high tensile strength

The invention discloses a polyethylene (PE) pipe with high tensile strength. The PE pipe is prepared from the following components: polyvinyl resin, diisononyl phthalate, dicapryl phthalate, azole stearate, epoxy soybean oil, 2-(2'-5-methylphenyl) benzotriazole, and resorcinol monobenzoate. By adopting the way, the PE pipe with high tensile strength has the advantages that tissues of pipes are compact, a shape of a surface is regular, a cross section has a porous reticular structure, the PE pipe has good tensile strength, and the fracture still cannot be occurred under an effect of extremely strong external force.

Owner:TAICANG CHENZHOU PLASTIC

Continuous esterification production method of di-sec-octyl phthalate

ActiveCN101891620BImprove quality and efficiencyIncrease productivityOrganic compound preparationCarboxylic acid esters preparation2-OctanolAcid value

The invention discloses a continuous esterification production method of di-sec-octyl phthalate. The method comprises the following steps: using phthalic anhydride and 2-octanol to perform an esterification reaction under the existence of catalyst and obtain raw ester, and post-processing raw ester to obtain the product di-sec-octyl phthalate, wherein the esterification reaction is a multistage esterification reaction that phthalic anhydride and 2-octanol perform a plurality of esterification continuously. The esterification reaction of the invention adopts the production method of continuous esterification, the esterification reaction is complete, the conversion rate is high, the acid value of the product is low and the purity is high; and the time of esterification is short, the energy consumption is low, the product quality is stable, and the quality and production efficiency of di-sec-octyl phthalate can be effectively increased.

Owner:WEIFANG YUANLI CHEM

Integrated novel double-sided PVC trough plate

The invention discloses an integrated novel double-sided PVC trough plate, which comprises the following raw materials by weight: 15-25 parts of modified polypropylene, 20-30 parts of polyvinyl chloride, 25-45 parts of fluorosilicone rubber, 10-18 parts of mica powder, 45-65 parts of halloysite, 25-45 parts of lignin, 15-25 parts of graphene nanosheet, 0.3-0.9 part of benzoyl peroxide, 1.5-2.5 parts of tert-butyl hydrogen phthalate, 1-1.4 parts of polyethylene oxide, 1.5-2.5 parts of peroxysuccinic acid, 2-3 parts of stearic acid, 2-4 parts of polyvinyl butyral, 0.5-1.5 parts of dicapryl phthalate, 1.6-2.2 parts of polyethylene wax, and 1-2 parts of a foaming agent. The integrated novel double-sided PVC trough plate provided by the invention has the advantages of good toughness, tear resistance, high hardness and good thermal stability.

Owner:安徽优丽普科技有限公司

Antioxidant and flame-retardant optical cable material and preparation method thereof

InactiveCN105936719AHigh thermal decomposition temperatureIncrease char formationPolymer sciencePhosphate

The invention discloses an antioxidant and flame-retardant optical cable material, which is composed of the following raw materials in parts by weight: 1 to 2 parts of antioxidant 168, 1 to 2 parts of anhydrous calcium chloride, 0.6 to 1 part of maleic rosin, 4 to 7 parts of di-sec-octyl phthalate, 100 to 130 parts of polyvinyl chloride, 3 to 4 parts of polystyrene 20-2 sodium hypophosphite monohydrate, 2 to 3 parts of paraformaldehyde, 0.2 to 0.3 part of hydrochloric acid (35-37%), 4 to 6 parts of chlorinated spiro-phosphate, 5 to 7 parts of aluminum chloride hexahydrate, 0.3 to 1 part of polybenzimidazole, 0.2 to 0.4 part of zinc butyl tricaprylate, 1.7 to 2 parts of polyvinyl butyral, 0.1 to 0.2 part of triethylamine, and 0.5 to 1 part of diacetone acrylamide. The provided optical cable material can dilute the flame and reduce the temperature of combustion area; at the same time, phosphor and oxygen free radicals generated during the cracking process can capture free radicals that are generated by cracking polystyrene chain segments, thus the thermal stability of the optical cable material is improved, and the heat release value of the material is reduced.

Owner:安徽电信器材贸易工业有限责任公司

Outdoor sports field plastic surface layer material

The invention belongs to the field of building materials, and provides an outdoor sports field plastic surface layer material, wherein the raw materials comprise, by weight, 30-40 parts of an epoxy resin, 10-15 parts of an ABS resin, 10-15 parts of polyvinyl chloride, 10-15 parts of polypropylene, 10-15 parts of organic silicon, 1-5 parts of sodium citrate, 1-5 parts of di sec-octyl phthalate (DCP), 5-10 parts of polyvinyl alcohol, 1-3 parts of light fast brilliant red toner, 1-3 parts of Ultramarine blue toner, and 1-3 parts of permanent yellow GR. According to the present invention, by usingthe polymer material, the secondary pollution cannot be caused to the indoor environment; and the product has characteristics of good weather resistance, good wear resistance, water permeability, gaspermeability and low cost, and is suitable for large-scale promotion.

Owner:白克雯

Elastic grouting water-stop glue

PendingCN114276773AAvoid environmental problemsImprove adhesionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesFiberPolymer science

The invention relates to elastic grouting water-stop glue. The invention relates to a polyurethane hot melt adhesive which comprises the following components in percentage by weight: 40%-41% of polyether polyol, 7.3%-7.7% of polyphenyl polymethylene polyisocyanate, 26%-28.5% of plasticizer, 23.5%-24.5% of filler, 0.2%-0.4% of pigment and 0.2%-0.6% of antioxidant. The plasticizer is prepared by mixing four of dioctyl phthalate, diisooctyl terephthalate, dinonyl phthalate, butyl benzyl phthalate, di-sec-octyl phthalate, fatty acid methyl ester, acetyl tributyl citrate, tributyl citrate and chlorinated paraffin; the plasticizer is prepared by mixing four of dioctyl phthalate, diisooctyl terephthalate, dinonyl phthalate, butyl benzyl phthalate, di-sec-octyl phthalate, fatty acid methyl ester, acetyl tributyl citrate, tributyl citrate and chlorinated paraffin; the antioxidant is formed by mixing one or two of octadecanol propionate, bis (stearoyl) thiodipropionate, bis (cinnamoyl) thiodipropionate and polysiloxane; the antioxidant is formed by mixing one or two of octadecanol propionate, bis (stearoyl) thiodipropionate, bis (cinnamoyl) thiodipropionate and polysiloxane; the filler is formed by mixing one or two of calcium carbonate, diatomite, talcum powder and carbon fiber; the pigment is formed by mixing one or two of carbon black and graphite.

Owner:SHENYANG GUOJIAN XINTEC TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com