Preparation method of phthalate plasticizer

A technology of ester plasticizers and phthalic acid, which is applied in the field of preparation of phthalate plasticizers, can solve the problems that colored substances cannot be completely adsorbed, activated carbon has limited adsorption capacity, and is not suitable for industrial production. , to achieve the effect of facilitating precipitation, avoiding saponification reaction, and reducing production steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

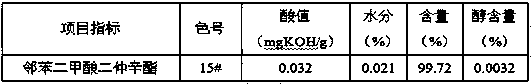

[0036] Embodiment 1 A kind of preparation method of phthalate plasticizer

[0037] A preparation method of phthalate plasticizer di-sec-octyl phthalate, the preparation method comprising 5 steps of esterification, crude dealcoholization, cooling and deacidification agent, dealcoholization and filtration;

[0038] 1. Esterification

[0039] Add phthalic anhydride and sec-octanol into the reaction kettle at a molar ratio of 1:2.5, and at the same time add a resin catalyst in a proportion of 5.0% relative to the total mass of the reaction materials into the reaction kettle, and then turn on heating and stirring to keep the ester The reflux temperature is 200°C, and the heating is stopped when the acid value of the reaction system is 0.92mgKOH / g;

[0040] The resin catalyst is a high temperature resistant macroporous strongly acidic styrene-based cation exchange resin with a total exchange capacity of 5.2mmol / g and a specific surface area of 51m2 / g;

[0041] 2. Crude dealcohol...

Embodiment 2

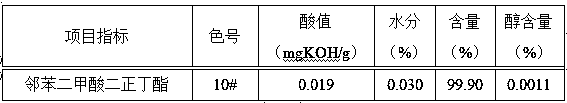

[0055] Embodiment 2: a kind of preparation method of phthalate plasticizer

[0056] 1. Esterification

[0057] Add phthalic anhydride and octanol into the reactor at a molar ratio of 1:2.55 for esterification reaction, and at the same time add a resin catalyst in a proportion of 5.5% relative to the total mass of the reaction materials into the reactor, and then start heating and stirring , keep the esterification reflux temperature at 200°C, and stop the reaction when the acid value of the reaction system is 0.95mgKOH / g;

[0058] The resin catalyst is a high temperature resistant macroporous strongly acidic styrene-based cation exchange resin with a total exchange capacity of 5.5mmol / g and a specific surface area of 53m2 / g;

[0059] 2. Crude dealcoholization

[0060] Use nitrogen to replace the dealcoholization kettle for 5 minutes. After the detection and replacement, the oxygen content in the detection device is less than 0.5%, and the material pump is used to inject th...

Embodiment 3

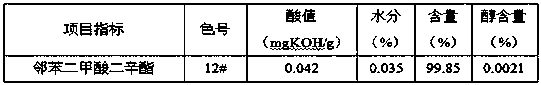

[0073] Embodiment 3: a kind of preparation method of phthalate plasticizer

[0074] 1. Esterification

[0075] Add phthalic anhydride and n-butanol into the reactor at a molar ratio of 1:2.6 for esterification reaction, and at the same time add a resin catalyst with a ratio of 5.8% relative to the total mass of the reaction materials into the reactor, then turn on the heating and Stir, keep the esterification reflux temperature at 200-210°C, and stop the reaction when the acid value of the material reaches 0.90mgKOH / g;

[0076] The resin catalyst is a high temperature resistant macroporous strongly acidic styrene-based cation exchange resin with a total exchange capacity of 5.8mmol / g and a specific surface area of 56m2 / g;

[0077] 2. Crude dealcoholization

[0078] Use nitrogen to replace the dealcoholization kettle for 5 minutes. After the detection and replacement, the oxygen content in the detection device is less than 0.5%, and the material pump is used to inject the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com