Production process of novel tricyclodecene esters

A technology for the production of tricyclodecenes, which is applied in the field of production techniques for new tricyclodecene esters, can solve problems such as reduced catalytic effects, catalysts that cannot be recycled, and catalyst activity that is easy to damage the ring, so as to improve odor and reduce The effect of wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

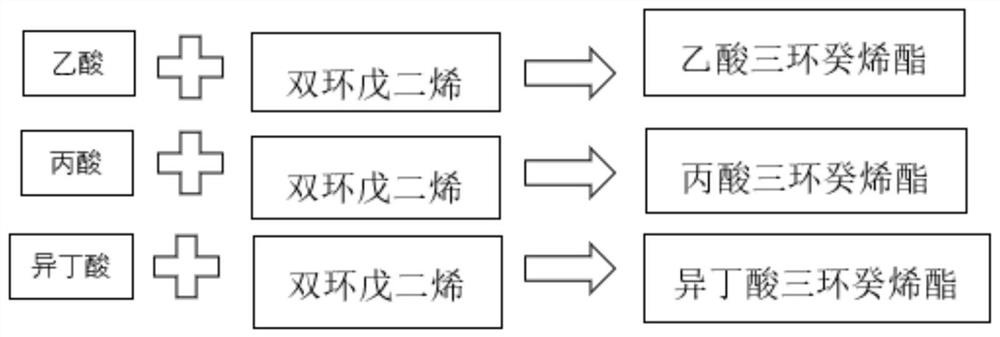

[0021] Such as figure 1 Shown, a kind of production technique of novel tricyclodecene esters, concrete steps are as follows:

[0022] 1) To add acid and remove water, first add excess liquid acid to the reaction kettle, heat up and remove water, and remove the water in the liquid acid until the analysis of water is qualified;

[0023] 2) Catalyzed reaction. After fully stirring the liquid acid that has been dehydrated in 1), add the catalyst to the reactor and slowly raise the temperature to 110°C, then start to add dicyclopentadiene dropwise. The process control is 115°C. The internal dropwise addition is completed, and after the dicyclopentadiene dropwise addition is completed, the constant temperature reaction is carried out for 7.5 hours until the sampling analysis is qualified;

[0024] 3) Filtration and recovery, after the reaction is comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com