Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36 results about "Carbothermic reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbothermic reactions involve the reduction of substances, often metal oxides (O₂²-), using carbon as the reducing agent. These chemical reactions are usually conducted at temperatures of several hundred degrees Celsius. Such processes are applied for production of the elemental forms of many elements. Carbothermic reactions are not useful for some metal oxides, such as those of sodium and potassium.

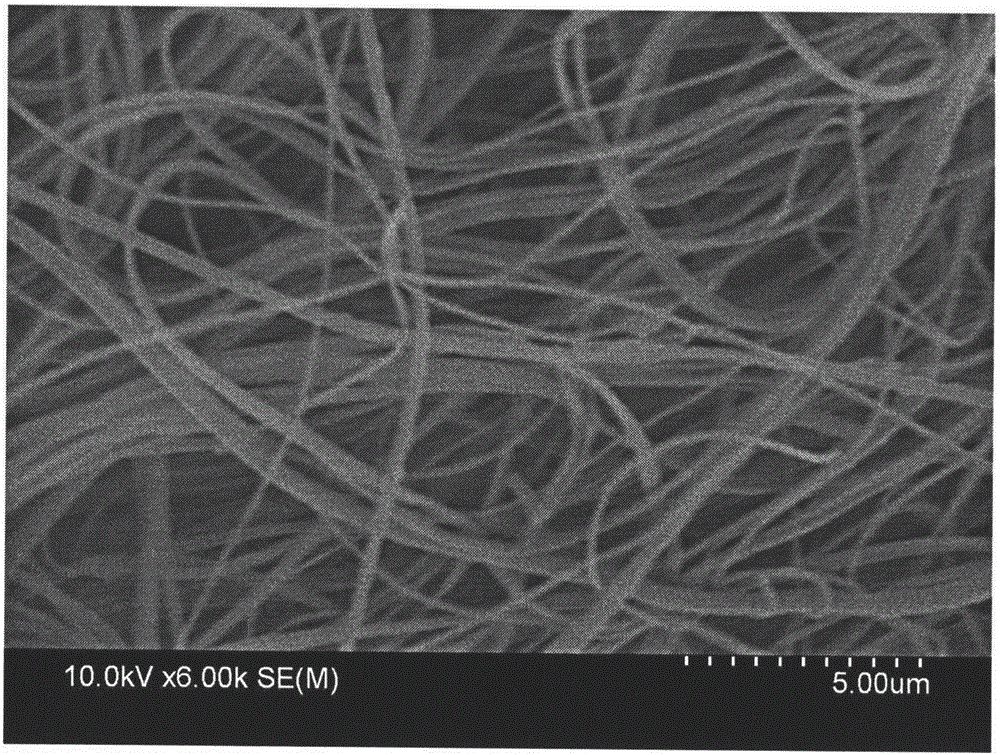

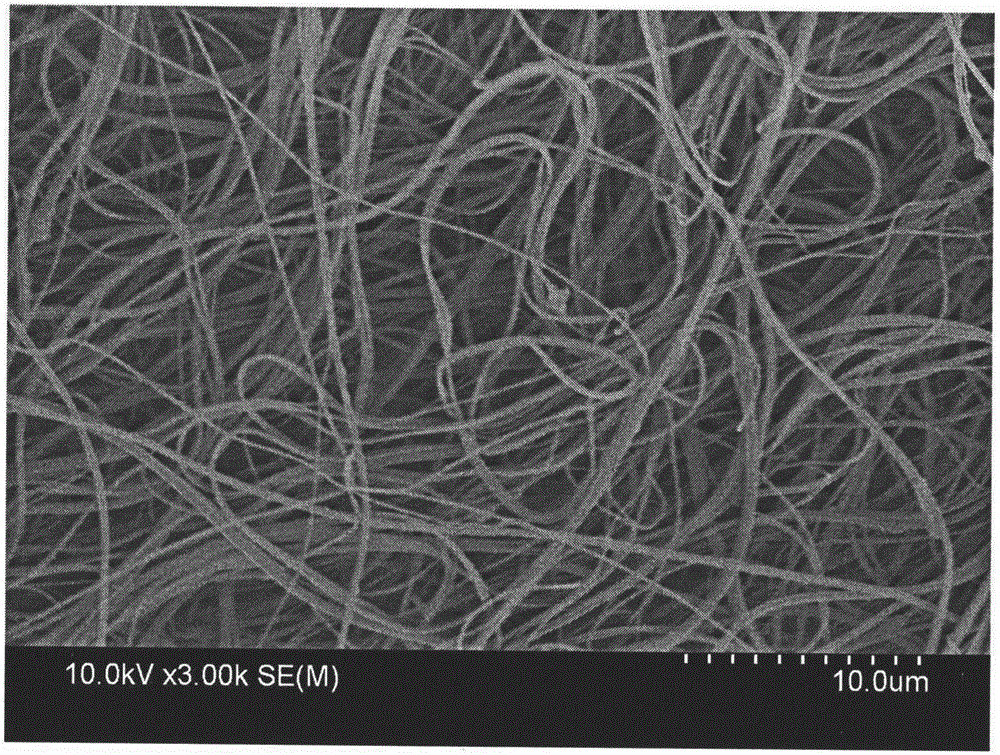

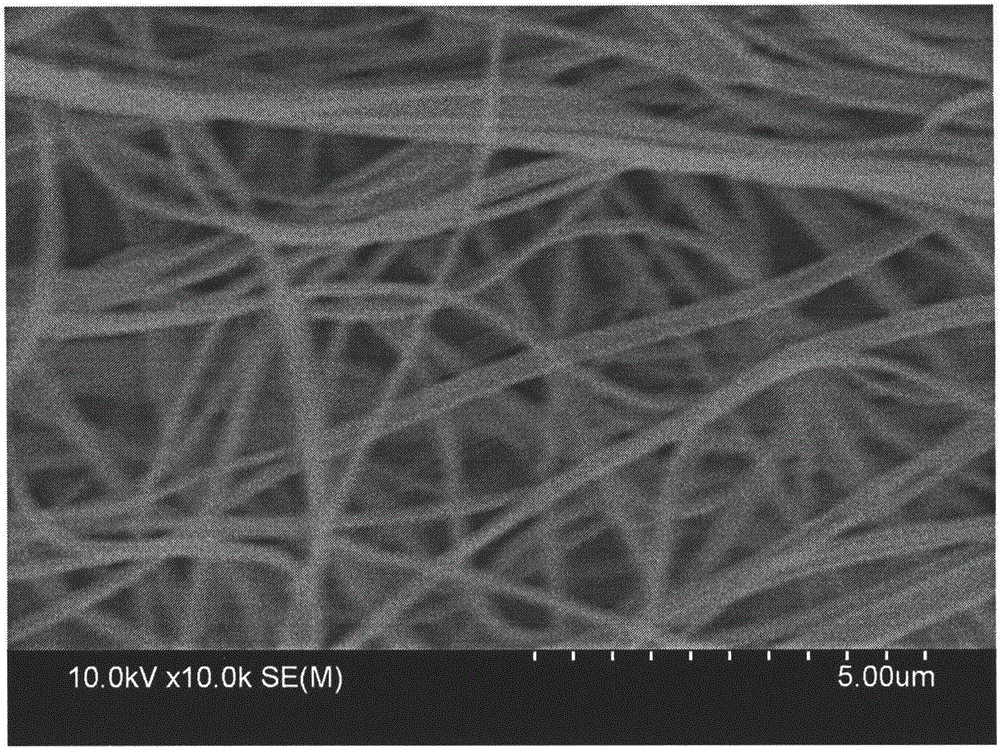

Method for efficiently preparing titanium-based-carbon three-dimensional crimped nano fibers

ActiveCN106048783AReduce consumptionSimple processArtifical filament manufactureCarbonizationElectrochemistry

The invention provides an efficiently-prepared titanium-based-carbon three-dimensional crimped nano fiber material and a preparation method thereof. According to the material, polyacrylonitrile and titanium dioxide are adopted as raw materials, Ti-based nano fibers are prepared through three spinning technologies (static spinning, rotor spinning and combination of static spinning / rotor spinning); pre-oxidation, low-temperature carbonization and carbothermal reactions are carried out, and the Ti(TiO2, TiC, Ti(Cl-xNx), TiN)-based-C nano fiber three-dimensional crimped nano fiber material is prepared in gas shield. The application range and application of a nano titanium-based compound and a carbon-based hybridization three-dimensional crimped nano fiber material in the fields of high temperature resistance, corrosion resistance, aging resistance, electro-catalysis, strength resistance and friction resistance and electrochemistry are greatly widened, and the material is applied more and more widely in later industrialization.

Owner:苏州纤创智造新材料科技有限公司

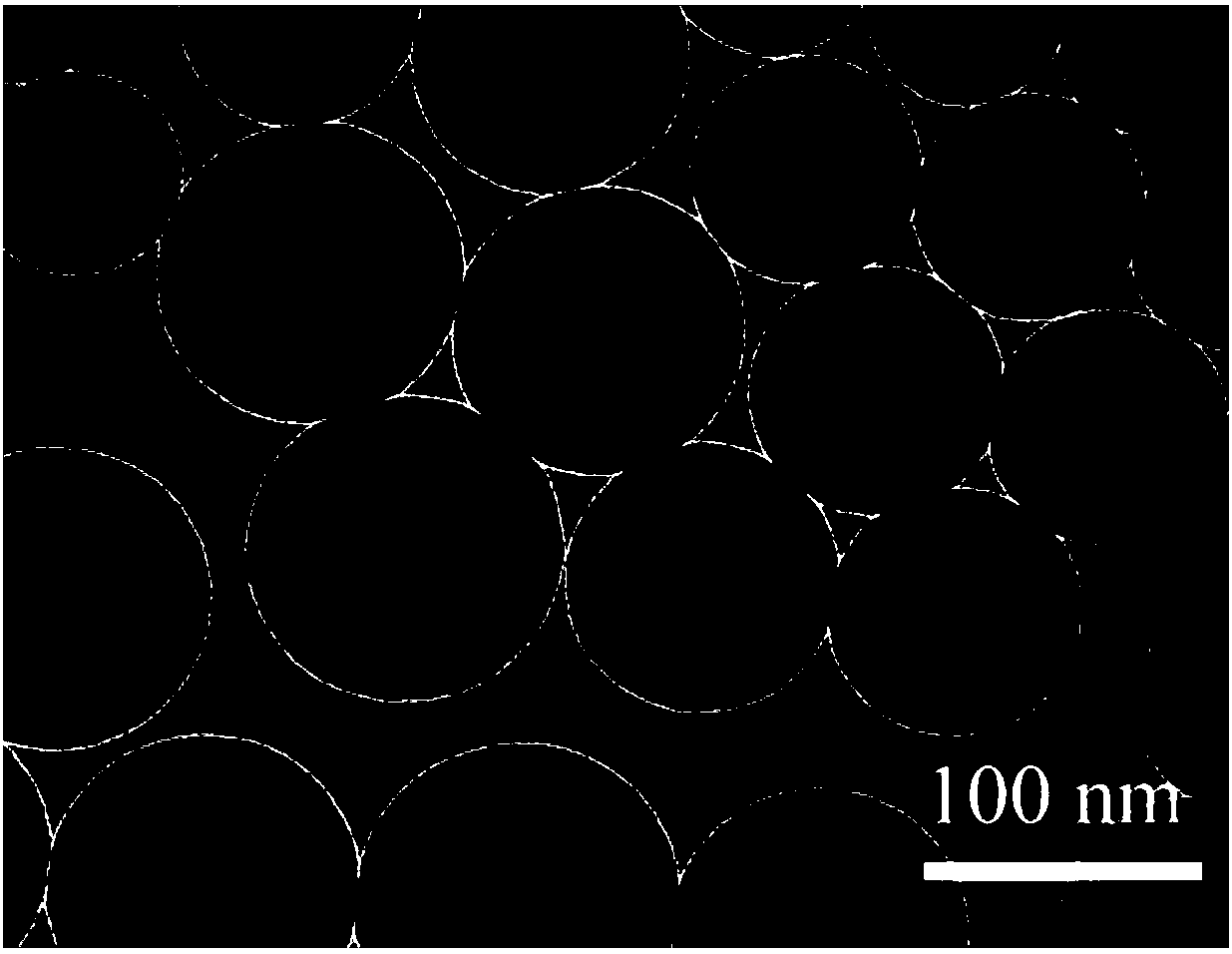

Synthesis method of molybdenum disulfide/carbon nano composite material

InactiveCN106423218AReach protectionMaterial nanotechnologyPhysical/chemical process catalystsCarbon filmCarbon composites

The invention discloses a synthesis method of a molybdenum disulfide / carbon composite material for preparing potassium humate, belonging to the field of inorganic non-metal materials. The method comprises the following steps: dissolving a soluble molybdenum salt ammonium molybdate tetrahydrate in water, adding potassium humate into the solution, reversely dropping the mixed solution into nitric acid, and regulating the pH value to 1-3 to prepare a precipitate; and roasting in argon or any other inert atmosphere by a fused salt roasting process to generate carbon thermal reaction, thereby obtaining the composite structure on which nanorods with the length of 100nm or so are carried on the carbon film. The method has the advantages of simple technique and low cost. The biomass material potassium humate is used as the carbon source to directly synthesize the loaded nano composite structure.

Owner:XINJIANG UNIVERSITY

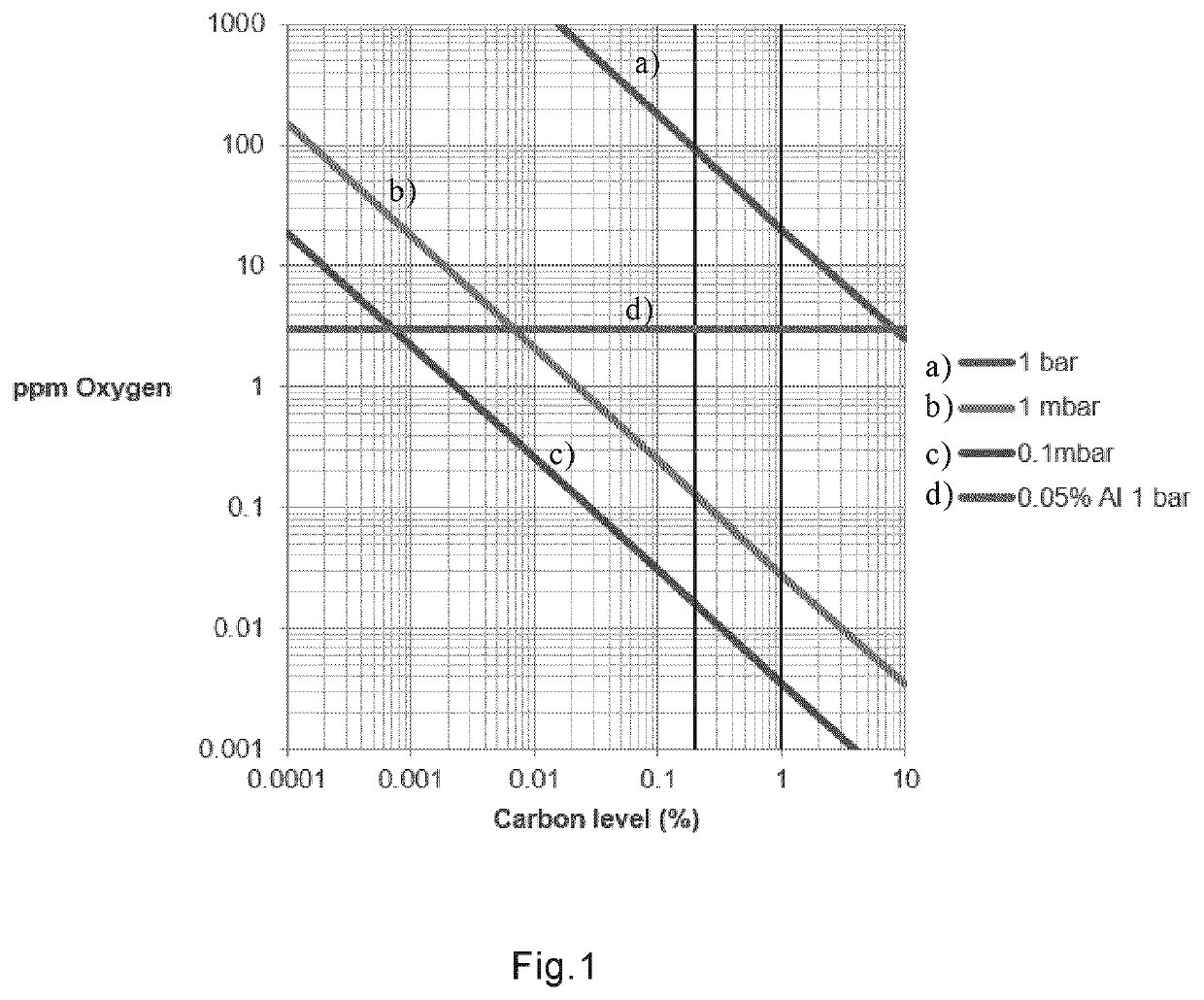

Method for extracting metallic aluminium from aluminum oxide by vacuum carbothermal reduction

The invention provides a method for extracting metallic aluminium from aluminum oxide by vacuum carbothermal reduction, which comprises the following steps: adopting aluminium oxide or minerals containing aluminium oxide as raw material, auxiliarily taking graphite as reducing agent and aluminium trichloride as chlorinating agent, carrying out carbothermal reaction in a vacuum furnace under the condition that the system pressure is 20Pa, the reducing temperature is 1400-1600 DEG C and the reaction time is 60-90min, then carrying out chlorination to carbothermal residue for 30-60min and finallyobtaining aluminum subchloride (AlCl), when temperature lowers, disproportioning and decomposing AlCl into metallic aluminium and aluminium trichloride at the temperature less than 660 DEG C, and obtaining metallic aluminium with purity more than 95% and recovery efficiency reaching more than 80%. The recovery efficiency of aluminium trichloride is more than 80%; and the process flows are short,the cost is low and the pollution to environment is small.

Owner:KUNMING UNIV OF SCI & TECH

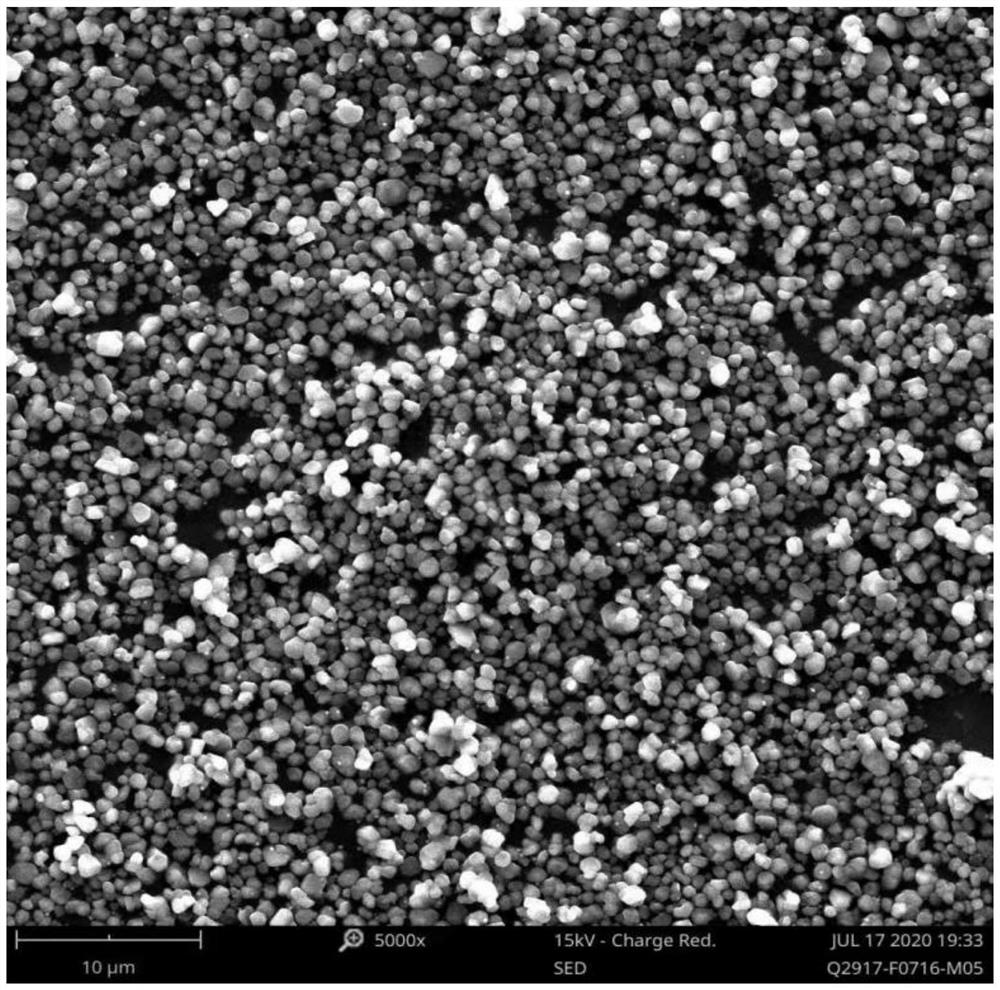

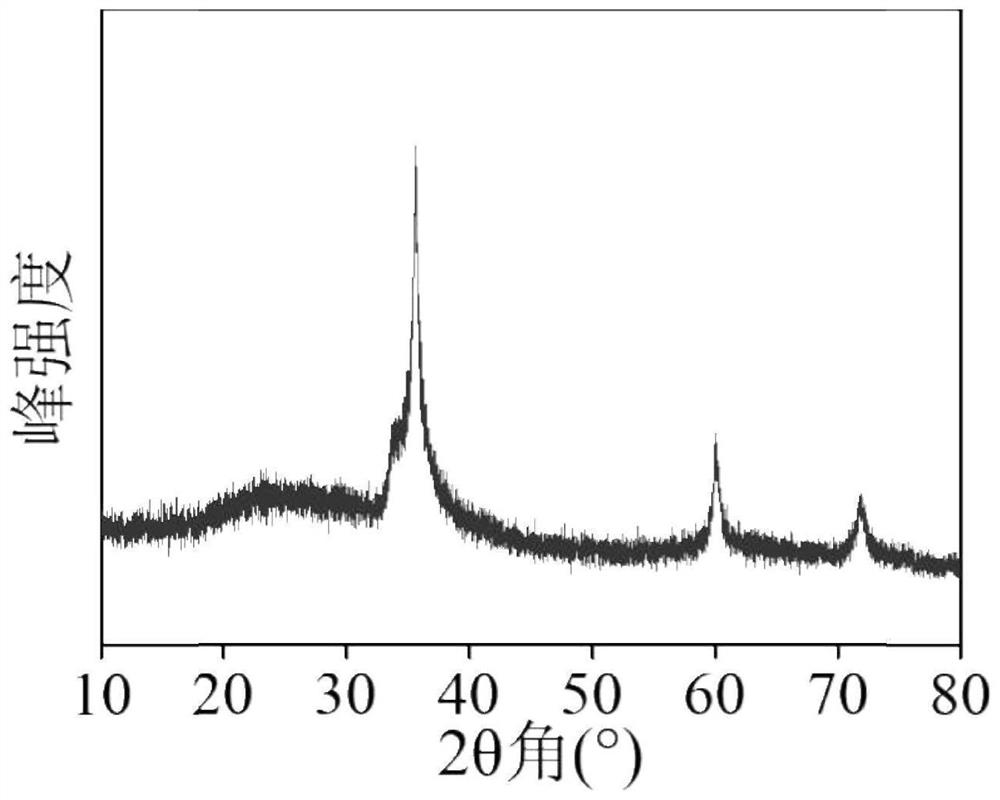

Method for preparing iron phosphide and carbon composite structure by utilizing carbothermic reaction

InactiveCN104084224AWell mixedMix well and evenlyPhysical/chemical process catalystsCarbon compositesPhosphate

The invention relates to a method for preparing an iron phosphide and carbon composite structure by utilizing carbothermic reaction, and particularly relates to a simple and easy method for preparing the iron phosphide and carbon composite structure. The method is suitable for preparing a composite structure of iron phosphide, other metal phosphides and carbon in large scale. The method comprises the following steps: soaking melamine by a mixed solution of ferric chloride hexahydrate and ammonium dihydrogen phosphate by adopting a soaking method in which the ferric chloride hexahydrate, the ammonium dihydrogen phosphate and the melamine are used as raw materials, then carrying out high-temperature pyrolysis on melamine under inert gas by adopting a high-temperature pyrolysis method, reducing metal phosphates into metal phosphides, thereby obtaining the iron phosphide and carbon composite structure. According to the method, the uniform refining of the iron phosphide and carbon composite structure can be achieved by changing the ratio of the ferric chloride hexahydrate to the melamine and conditions of the pyrolysis reduction, such as warming velocity, holding temperature, temperature holding time, so that the iron phosphide and carbon composite structure which is uniform in granule and excellent in catalytic performance can be obtained.

Owner:JIANGSU UNIV

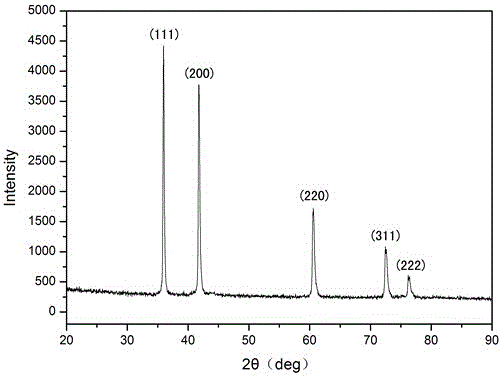

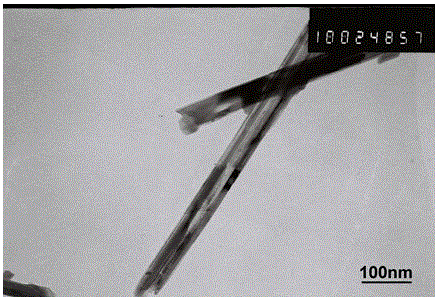

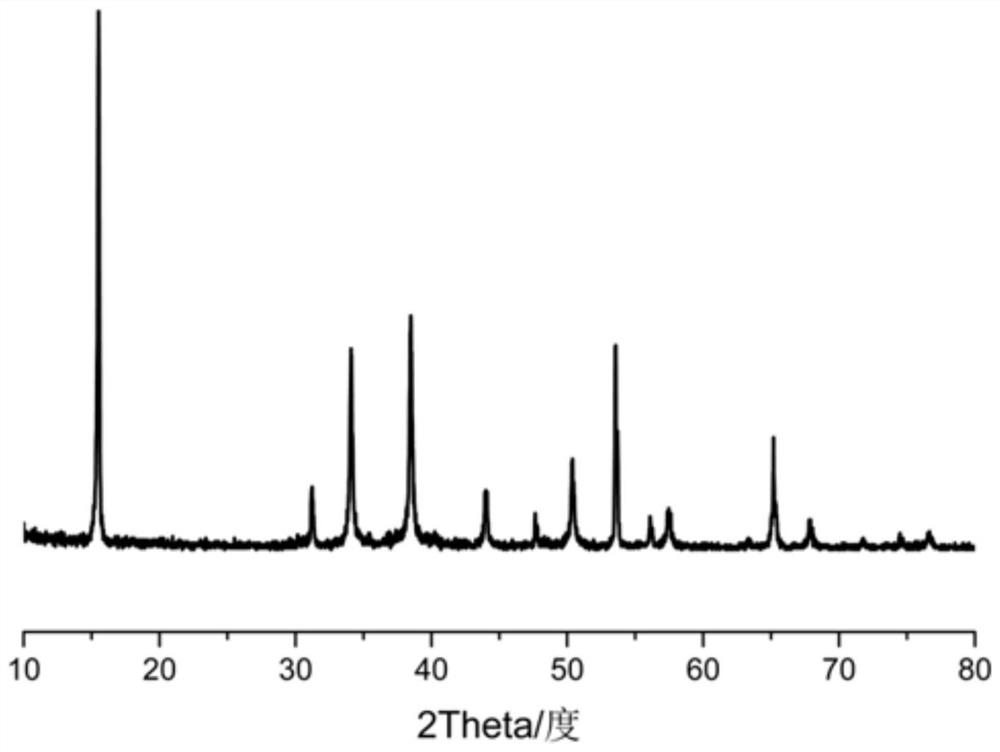

Preparation method of nano Cr3C2 crystal whisker

InactiveCN103849934AWell mixedLow reaction temperaturePolycrystalline material growthFrom solid stateAmmonium dichromateDistilled water

The invention discloses a preparation method of a nano Cr3C2 crystal whisker. The preparation method comprises the following steps: (1), by taking ammonium dichromate, a carbonaceous reducing agent and a halogenating agent as materials, placing the materials into distilled water, and uniformly stirring to prepare precursor liquor; (2), drying the precursor liquor to obtain a fluffy precursor mixture; (3), placing the precursor mixture into a reaction furnace, preserving heat for 0.5 hour-2 hours to carry out carbothermic reaction at a temperature of 700 DEG C-900 DEG C under an Ar gas or vacuum condition to obtain unpurified nano Cr3C2 crystal whisker; and (4), firing the unpurified nano Cr3C2 crystal whisker for 2 hours-8 hours at the temperature of 500 DEG C-600 DEG C in air for decarburization, removing Cr2O3 in HF liquor, and cleaning and drying to obtain the nano Cr3C2 crystal whisker with diameter smaller than 100 nm. The preparation method disclosed by the invention is simple in process, easily controllable in parameter and low in cost; the surface of the prepared Cr3C2 crystal whisker is smooth, and the crystal whisker diameter is smaller than 100 nm.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Iron manganese vanadium phosphate precursor, iron manganese vanadium lithium phosphate/carbon anode material and preparation method

ActiveCN106486668AHigh purityImprove electrochemical performanceCell electrodesSecondary cellsElectrochemistryPrecipitation

The invention discloses an iron manganese vanadium phosphate precursor, an iron manganese vanadium lithium phosphate / carbon anode material and a preparation method. The preparation method includes following steps: 1), preparing a mixed solution of ferric iron source, manganous source, pentavalent vanadium source and phosphor source, and preparing an ammonia water solution; 2), mixing the mixed solution with the ammonia water solution according to a set proportion for co-precipitation reaction to obtain a precipitation product; 3), subjecting the precipitation product to washing, drying and pre-sintering to obtain an iron manganese vanadium phosphate precursor material, well mixing the iron manganese vanadium phosphate precursor material with a lithium source and a carbon source, drying, and calcining in an inert atmosphere to obtain the iron manganese vanadium lithium phosphate / carbon anode material. The iron manganese vanadium phosphate precursor is prepared firstly, a ferric iron compound is used as an iron source in the process of preparation, control on valence state changing of iron is unique, ferric iron can be ensured to be reduced into ferrous in the subsequent carbothermic reaction step, and then the LiFe1-xMn2x / 3Vx / 3PO4 material high in both purity and electrochemical performance is obtained.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI +1

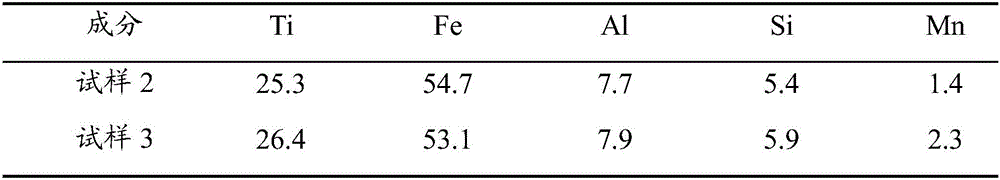

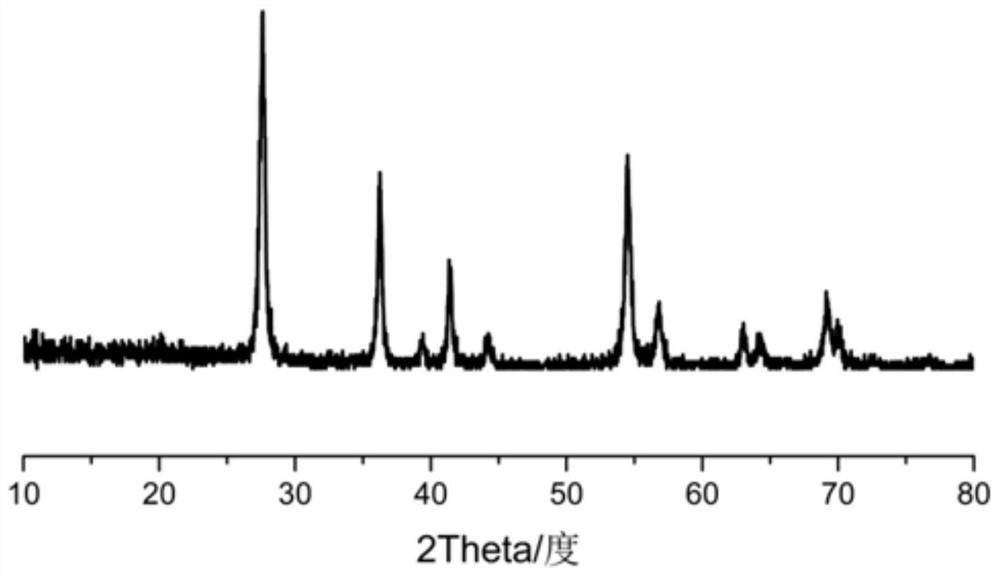

Titanium-iron alloy preparation method

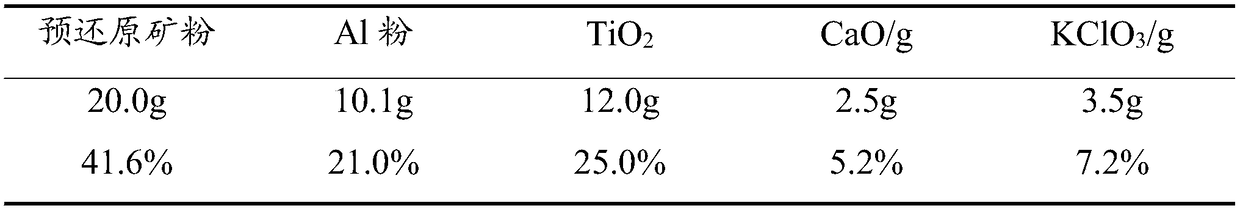

The invention discloses a titanium-iron alloy preparation method, and relates to the technical field of metal smelting. The method comprises the following steps: carbothermic reaction: mixing vanadium-titanium magnetite used as a raw material and coal powder used as a reducer, adding bentonite water accounting for 1% of the mixture in mass into the mixture, mixing, pelletizing, drying the formed wet pellets, performing constant-temperature heating, cooling the heated dry pellets in a closed manner, pulverizing, and screening to obtain prereducing ore powder; and aluminothermic reduction reaction: according to mass percentage, uniformly mixing 9-10% of prereducing ore powder, 23-26% of Al powder, 55-58% of titanium concentrate powder, 5-6% of CaO and 3-5% of KClO3, igniting with a magnesium ribbon, performing self-propagating aluminothermic reduction reaction, cooling the mixture after the reaction, and deslagging to obtain a titanium-iron alloy cast ingot. The preparation method in the invention reduces the aluminum consumption, lowers the production cost and provides diversified titanium-iron alloy varieties.

Owner:NORTHEASTERN UNIV

Titanium-iron alloy preparation method

The invention discloses a titanium-iron alloy preparation method, and relates to the technical field of metal smelting. The method comprises the following steps: carbothermic reaction: mixing vanadium-titanium magnetite used as a raw material and coal powder used as a reducer, adding bentonite water accounting for 1% of the mixture in mass into the mixture, mixing, pelletizing, drying the formed wet pellets, performing constant-temperature heating, cooling the heated dry pellets in a closed manner, pulverizing, and screening to obtain prereducing ore powder; and aluminothermic reduction reaction: according to mass percentage, uniformly mixing 40-42% of prereducing ore powder, 21-23% of Al powder, 24-26% of titanium white, 5-6% of CaO and 7-9% of KClO3, igniting with a magnesium ribbon, performing self-propagating aluminothermic reduction reaction, cooling the mixture after the reaction, and deslagging to obtain a titanium-iron alloy cast ingot. The preparation method in the invention reduces the aluminum consumption, lowers the production cost and provides diversified titanium-iron alloy varieties.

Owner:NORTHEASTERN UNIV

Nano (Ti, M) C solid solution crystal whisker and preparation method thereof

ActiveCN106087060AWell mixedLower reaction synthesis temperaturePolycrystalline material growthFrom solid stateDistilled waterWhiskers

The invention discloses a nano (Ti, M) C solid solution crystal whisker and a preparation method thereof. The nano (Ti, M) C solid solution crystal whisker is prepared from the following components: 40-79.9% of Ti, 0.1-40% of M and the balance of C, wherein M is at least one of W, Mo, V, Cr, Ta and Nb. Preparation raw materials comprise a component precursor of (Ti, M) C, a halogenating agent and a catalyst. The preparation method comprises the following steps: preparing a precursor mixed solution from all raw materials with distilled water, and drying so as to obtain precursor mixed powder; putting the precursor mixed powder into a reaction furnace, performing carbon-thermal reaction at 1100-1300 DEG C, firing the obtained nano (Ti, M) C solid solution crystal whisker for 4-6 hours at 350-400 DEG C in the presence of air for decarbonization, washing, performing eccentric separation, and finally drying, thereby obtaining the nano (Ti, M) C solid solution crystal whisker. The nano (Ti, M) C solid solution crystal whisker can be used as a nano ceramic phase crystal whisker toughening reinforcing metal based and ceramic based composite material, and is in good interface combination with a substrate.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

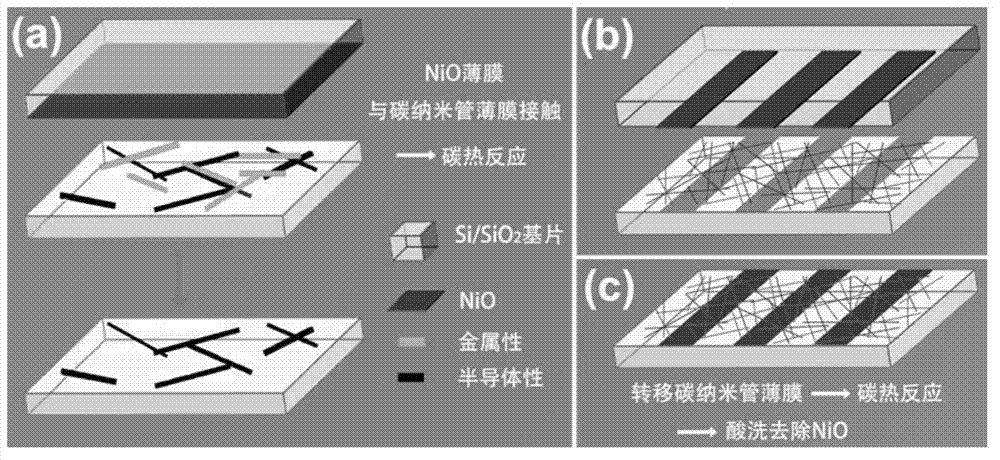

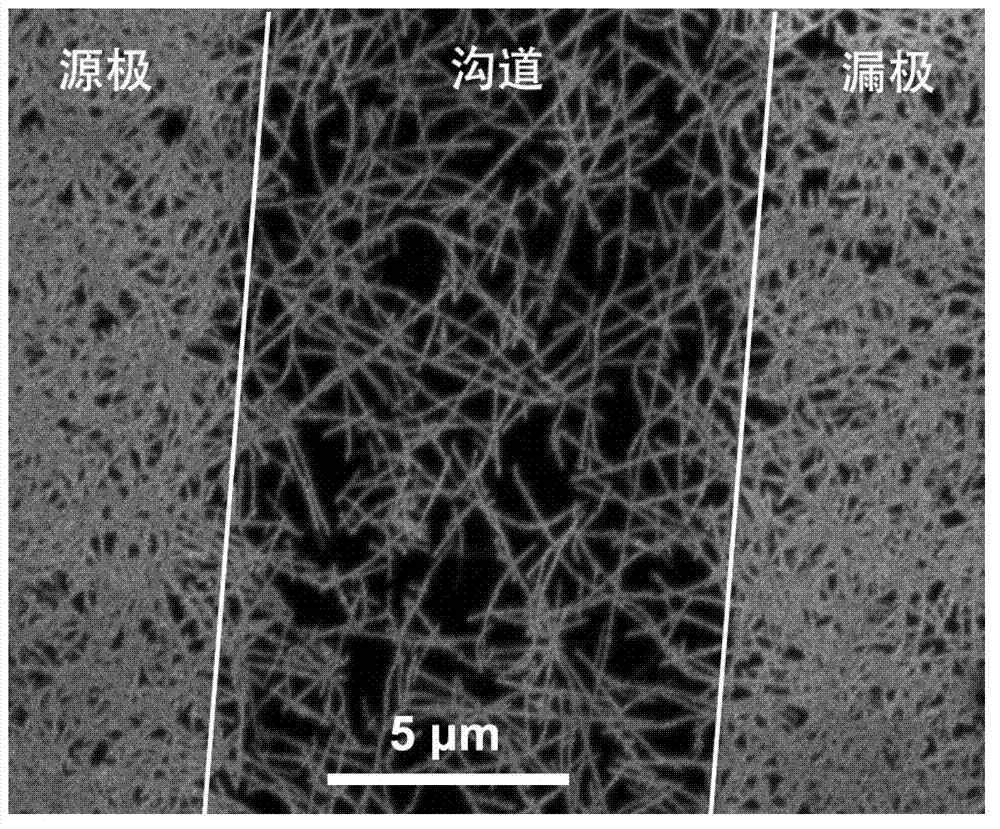

All-single-walled carbon nanotube field effect transistor and preparation method thereof

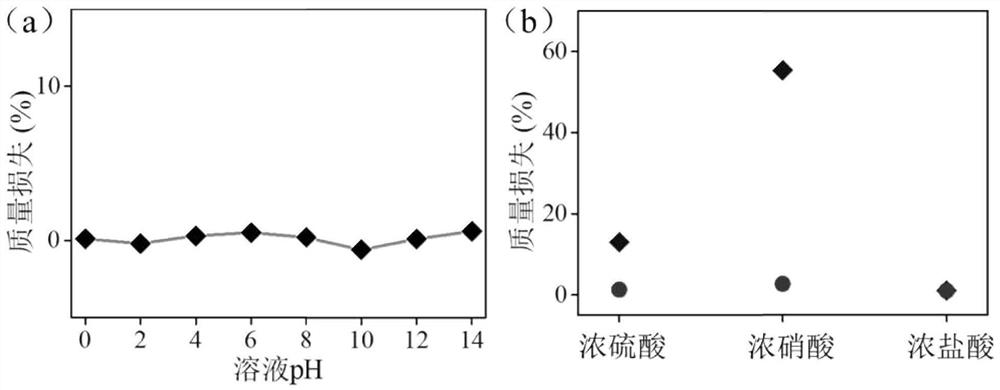

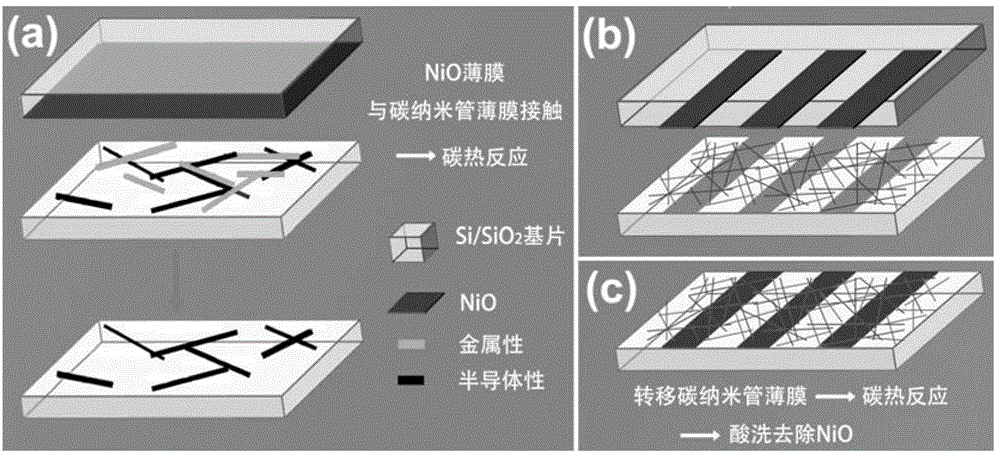

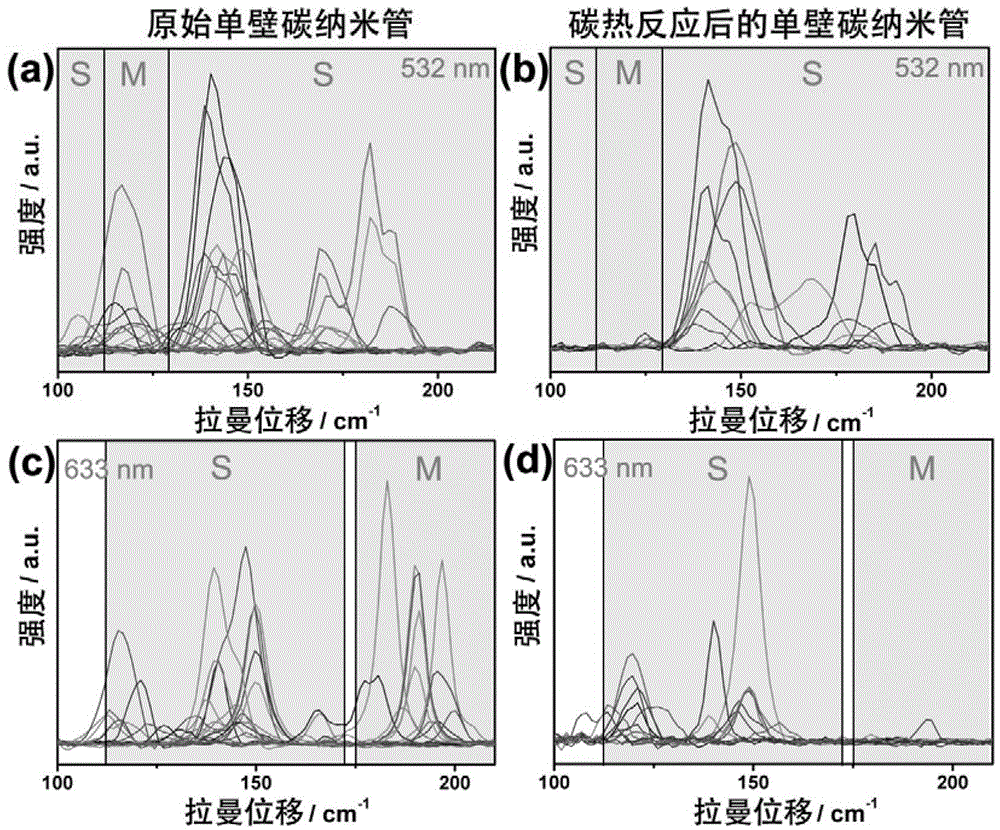

ActiveCN102903747AHigh reactivityPrecise Width ControlNanoinformaticsSemiconductor/solid-state device manufacturingCarbon nanotubeCarbon nanotube field-effect transistor

The invention relates to the field of single-walled carbon nanotubes, in particular to an all-single-walled carbon nanotube field effect transistor and a preparation method thereof. Semiconductor single-walled carbon nanotubes are utilized as channels of field effect transistors, and metallic / semiconductor single-walled carbon nanotube mixtures are used as source and drain electrodes. Metallic oxide and the single-walled carbon nanotubes can be in carbon heat reaction at proper temperature, and high-chemical-activity metallic single-walled carbon nanotubes are selectively etched to obtain semiconductor single-walled carbon nanotubes. A metal film is deposited on a Si / SiO2 substrate by using photolithography, and is pre-oxidized to obtain a metallic oxide film. Only the semiconductor single-walled carbon nanotubes are reserved in the single-walled carbon nanotube film and a reaction region which is in contact with metal oxide and are used as the channels of the field effect transistors, and the single-walled carbon nanotubes which are unaffected and are positioned out of the channels are utilized as the source and drain electrodes. Metal electrodes are not required to be deposited; and the all-single-walled carbon nanotube field effect transistor can be used for flexible devices, has the characteristics of cleanness and high efficiency, and can be used for manufacturing large-scale all-carbon integrated circuits possibly.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for preparing lithium iron phosphate electrode material by using twice carbon adding technology based on liquid phase mixing material

InactiveCN103956489AShorten the time of the thermal reduction reactionReduce generationCell electrodesSecondary cellsSolubilitySolid particle

The invention relates to a method for preparing a lithium iron phosphate electrode material by using a twice carbon adding technology based on a liquid phase mixing material. The method comprises the following steps of firstly mixing a lithium source, an iron source, a phosphorus source and a carbon source material to prepare a liquid-state single phase mixture, mixing the obtained solid product with a volatile solvent containing a dissolved solubility organic compound, carrying out mechanical grinding on the obtained mixture so that organic compound and solid particles are mixed fully, so as to reduce the grain diameter of the solid. The carbon source materials in different space positions can respectively and simultaneously reduce ferric iron and coat the surface of lithium iron phosphate with carbon through the twice carbon adding technology, a purpose for preparing carbon coating structure lithium iron phosphate material in a primary high-temperature heating process is reached, and the completeness of a carbothermic reaction and the electric conductivity of the material are good. The method provided by the invention has the advantages that the cost is low, the energy dissipation is low, the cycle is short, and the batch stability is high.

Owner:SHANGHAI UNIV

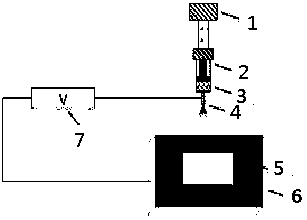

Method for preparing nanoparticles in situ by transmission electron microscope

ActiveCN110323457AImprove performancePrevent oxidationMaterial nanotechnologyCell electrodesFiberCarbon fibers

The invention discloses a method for preparing multi-component alloy nanoparticles loaded on nano carbon fibers in situ by a transmission electron microscope. The method comprises the steps of: obtaining nano carbon fibers subjected to carbonization treatment through the electrospinning technique and heat treatment; loading a precursor salt of an alloy on the nano carbon fibers; mounting a metal needle tip in a fixed end of a sample rod of the transmission electron microscope, loading the nano carbon fibers on a gold needle platform, and mounting a gold needle on a movable end of the sample rod; inserting the sample rod with the metal needle tip and the gold needle loaded into the transmission electron microscope, adjusting the height and position of the gold needle at the movable end of the sample rod, so that the nano carbon fibers on the gold needle platform are in contact with the metal needle tip, and applying a certain voltage within a certain instantaneous time, so that the precursor salt loaded on the nano carbon fibers on the gold needle platform generates an instantaneous carbothermic reaction to form the alloy nanoparticles.

Owner:ZHEJIANG UNIV

Transmission electron microscope technology for in-situ study of three-dimensional distribution structure of nanoparticles

ActiveCN110208168AImprove performancePrevent oxidationPreparing sample for investigationIndividual particle analysisConventional transmission electron microscopeCarbon fibers

The invention discloses a transmission electron microscope technology for in-situ study of a three-dimensional distribution structure of nanoparticles. The transmission electron microscope technologyis characterized by comprising the steps of: acquiring carbon nanofibers after carbonization treatment by adopting an electrospinning technique and thermal treatment; loading precursor salt of alloy on the carbon nanofibers; assembling a metal needle tip into a sample rod fixing end of a transmission electron microscope, the carbon nanofibers are loaded with a gold needle platform, and a gold needle is arranged on the movable end of a sample rod; the sample rod loaded with the metal needle tip and the gold needle is inserted into the transmission electron microscope, the height and position ofthe gold needle at the movable end of the sample rod are adjusted, such that the carbon nanofibers on the gold needle platform are in contact with the metal needle tip, a certain voltage is applied within certain instantaneous time, so that the precursor salt loaded on the carbon nanofibers on gold needle platform undergoes an instantaneous carbothermic reaction to form alloy nanoparticles, and the distribution variations and sintering situations of the alloy nanoparticles under the action of a current field are observed; and two-dimensional projection transmission electron microscope pictures are photographed, the electron microscope pictures are subjected to alignment, three-dimensional reconstruction and visualization by means of software.

Owner:ZHEJIANG UNIV

Method for preparing aluminum nitride by directly nitriding aluminum alkoxide

ActiveCN113603067AHigh purityImprove particle size uniformityNitrogen compoundsCarbonizationAluminum can

The invention discloses a method for preparing aluminum nitride by directly nitriding aluminum alkoxide, and belongs to the technical field of aluminum nitride preparation, the method comprises the following steps: S1, putting aluminum alkoxide into a kiln, raising the temperature in the kiln to 200-500 DEG C under the nitrogen atmosphere, and keeping the temperature for 1-4 hours; and S2, raising the temperature in the kiln to 1100-1600 DEG C in the nitrogen atmosphere, performing heat preservation for 2-4 h, and preparing a reaction product containing aluminum nitride. According to the method for preparing the aluminum nitride by directly nitriding aluminum alkoxide, the characteristic that the aluminum alkoxide can be thermally decomposed and carbonized under the anaerobic high-temperature condition is utilized, the carbon amount of a carbon thermal reaction can be met under the condition that other carbon sources are not introduced, the introduction amount of pollution factors is reduced, and the purity of the aluminum nitride is improved; in the self-thermal decomposition and carbonization process of the aluminum alkoxide, carbon and aluminum can be in direct and full contact, so that the reaction area is increased; a large number of holes and pores are formed in the thermal decomposition and carbonization process of the aluminum alkoxide, so that nitrogen can enter conveniently, and the reaction is more thorough.

Owner:山东瞻驰新材料有限公司

An Efficient Method for Preparation of Titanium-Carbon Three-dimensional Curly Nanofibers

ActiveCN106048783BReduce consumptionSimple processArtifical filament manufactureCarbonizationElectrochemistry

The invention provides an efficiently-prepared titanium-based-carbon three-dimensional crimped nano fiber material and a preparation method thereof. According to the material, polyacrylonitrile and titanium dioxide are adopted as raw materials, Ti-based nano fibers are prepared through three spinning technologies (static spinning, rotor spinning and combination of static spinning / rotor spinning); pre-oxidation, low-temperature carbonization and carbothermal reactions are carried out, and the Ti(TiO2, TiC, Ti(Cl-xNx), TiN)-based-C nano fiber three-dimensional crimped nano fiber material is prepared in gas shield. The application range and application of a nano titanium-based compound and a carbon-based hybridization three-dimensional crimped nano fiber material in the fields of high temperature resistance, corrosion resistance, aging resistance, electro-catalysis, strength resistance and friction resistance and electrochemistry are greatly widened, and the material is applied more and more widely in later industrialization.

Owner:苏州纤创智造新材料科技有限公司

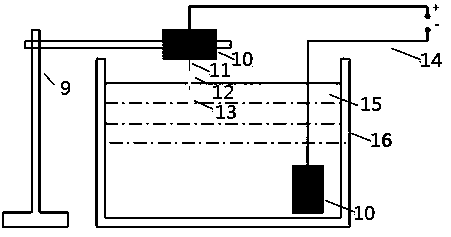

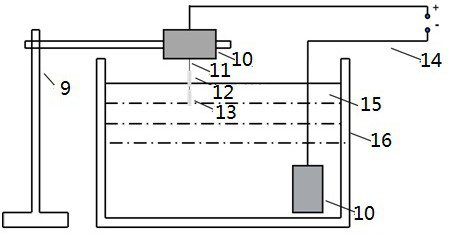

Method for ex-situ absorption of waste gas produced during carbothermic lithium extraction of waste lithium batteries

PendingCN113842742AImprove reduction efficiencyReduce processing costsGas treatmentDispersed particle separationFlue gasPhysical chemistry

The invention relates to the technical field of lithium battery recovery, in particular to a method for ex-situ absorption of waste gas produced during carbothermic lithium extraction of waste lithium batteries. The method comprises the following steps: S1, filling a flue gas absorption device with a positive electrode material; S2, introducing flue gas produced in a carbothermic reduction process into a flue gas absorption device, wherein the flue gas absorption device is kept at a certain temperature; S3, when the concentration of carbon monoxide and VOC at the outlet of the flue gas absorption device exceeds the standard, replacing the positive electrode material in the flue gas absorption device with a positive electrode material which does not absorb the flue gas; S4, mixing the replaced positive electrode material which absorbs the flue gas with carbon powder, carrying out a carbothermic reaction, and allowing generated flue gas to enter the step S2; and S5, preheating the positive electrode material to be packed into the flue gas absorption device with the flue gas exhausted from the flue gas absorption device, and allowing the preheated positive electrode material to enter the step S1. The method has the beneficial effects that 1) a carbon source utilization rate is high; 2) the reduction efficiency of a positive electrode material is high; and 3) flue gas treatment cost is low.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드 +2

A kind of supercapacitor carbon/titanium carbide core-shell composite ball electrode material and preparation method thereof

ActiveCN106024402BEasy to controlHigh magnificationHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceHigh energy

The invention discloses a carbon / titanium carbide core-shell composite spherical electrode material for a supercapacitor and a preparation method thereof. Glucose is hydrothermally carbonized, followed by the first step of heat treatment to generate cross-linked carbon nanospheres loaded with nickel foam, and then passed through atomic Layer deposition method, with titanium tetrachloride and deionized water as the reaction source, react to obtain the TiO2 coating layer; then the second step of heat treatment will be carried out, and the carbon nanospheres and the TiO2 coating layer will undergo carbon thermal reaction to form supercapacitor carbon spheres and Titanium carbide core-shell composite sphere electrode material, including a substrate, carbon nanospheres arranged on the substrate, and a titanium carbide nanolayer coated on the surface of the carbon nanosphere. 50nm. The electrode material of the invention has high specific capacitance, high cycle life, high energy and high power density and high cycle life, and has broad application prospects in the fields of mobile communications, electric vehicles, aerospace and the like.

Owner:ZHEJIANG UNIV

Nano zinc sulfide loaded carbon-based oxygen reduction electrocatalyst

PendingCN112635777ASimple methodEasy to controlFuel and primary cellsCell electrodesPtru catalystReaction temperature

The invention discloses a preparation method of an electrocatalytic oxygen reduction (ORR) electrocatalyst. With the reaction temperature controlled, the reaction degree of the carbon thermal reaction of zinc sulfide can be induced, so that the size and content of the zinc sulfide and the density of carbon defects generated by the carbon thermal reaction can be regulated and controlled, and therefore, the nano zinc sulfide loaded defect-based carbon nano electro-catalytic material can be obtained. Compared with other synthesis methods, the method is simple and easy to control. The nano zinc sulfide loaded defect-based carbon nano electro-catalytic material has efficient ORR catalytic performance; and the limiting current density of the material in an alkaline electrolyte solution is -5.3 mA / cm <2>, the half-wave potential of the material is 0.894 V, and the material has excellent oxygen reduction electro-catalytic performance. Researches show that the change of the temperature is beneficial to controlling the degree of the carbon thermal reaction of the zinc sulfide and controlling the growth process of the zinc sulfide, and obtained nano zinc sulfide particles and defect sites can be used as ORR electrocatalytic active centers.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

A method for in-situ preparation of nanoparticles by transmission electron microscopy

ActiveCN110323457BImprove performancePrevent oxidationMaterial nanotechnologyCell electrodesFiberCarbon fibers

The invention discloses a method for preparing multi-component alloy nanoparticles loaded on nano carbon fibers in situ by a transmission electron microscope. The method comprises the steps of: obtaining nano carbon fibers subjected to carbonization treatment through the electrospinning technique and heat treatment; loading a precursor salt of an alloy on the nano carbon fibers; mounting a metal needle tip in a fixed end of a sample rod of the transmission electron microscope, loading the nano carbon fibers on a gold needle platform, and mounting a gold needle on a movable end of the sample rod; inserting the sample rod with the metal needle tip and the gold needle loaded into the transmission electron microscope, adjusting the height and position of the gold needle at the movable end of the sample rod, so that the nano carbon fibers on the gold needle platform are in contact with the metal needle tip, and applying a certain voltage within a certain instantaneous time, so that the precursor salt loaded on the nano carbon fibers on the gold needle platform generates an instantaneous carbothermic reaction to form the alloy nanoparticles.

Owner:ZHEJIANG UNIV

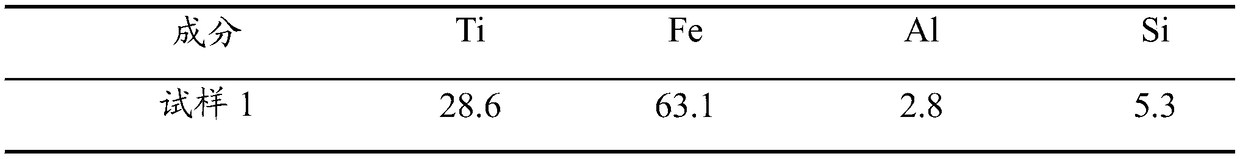

A kind of preparation method of ferro-titanium alloy

The invention discloses a preparation method of titanium-iron alloy and relates to the technical field of metal smelting. The method includes: carbothermal reaction, mixing with vanadium-titanium magnetite as raw material and coal powder as reducing agent, adding 1% bentonite water by mass of the mixture to the mixture, mixing and forming balls, and drying the formed wet balls. After heating at a constant temperature, the heated dry balls are airtightly cooled, crushed and sieved to obtain pre-reduced mineral powder; for the aluminothermic reduction reaction, according to the mass fraction, 40-42% pre-reduced mineral powder, 21-23% Al powder, 24 -26% titanium dioxide, 5-6% CaO and 7-9% KClO3 are mixed evenly and then ignited with a magnesium strip to perform a self-propagating aluminothermic reduction reaction. The reacted mixture is cooled and slag removed to obtain a titanium-iron alloy ingot. The preparation method in the present invention reduces the consumption of aluminum, lowers production costs, and provides diversified varieties of titanium-ferroalloy alloys.

Owner:NORTHEASTERN UNIV LIAONING

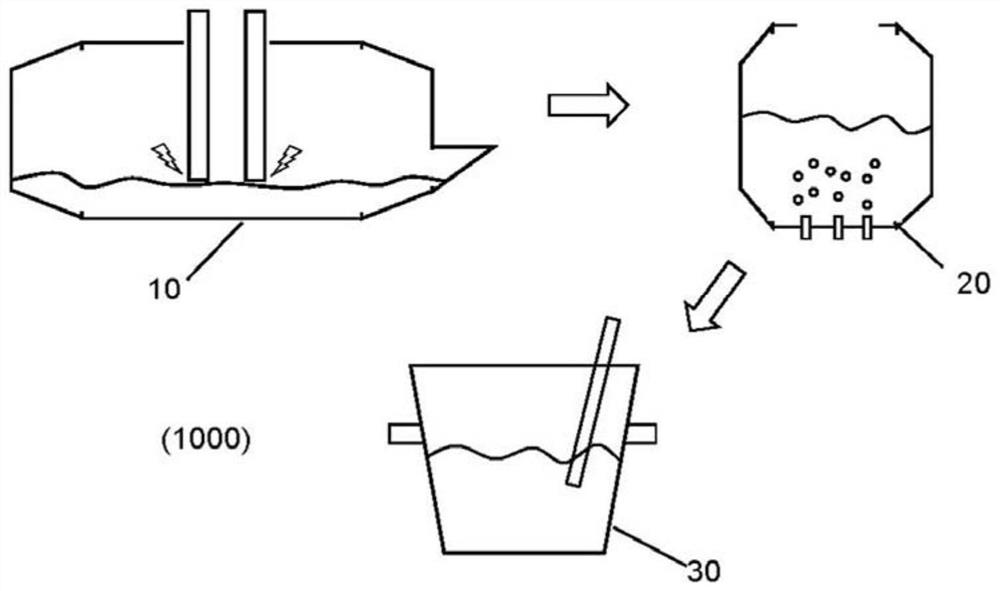

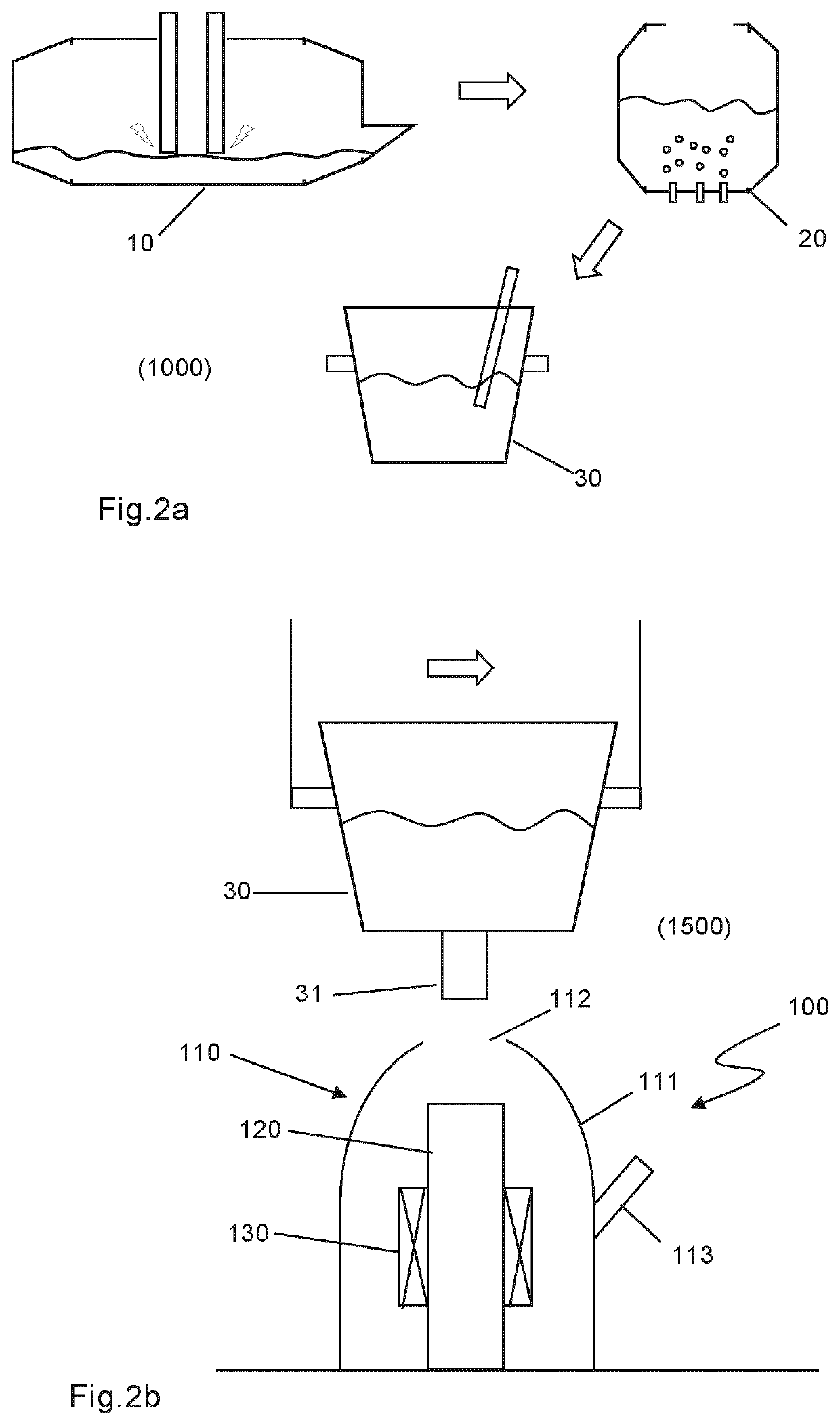

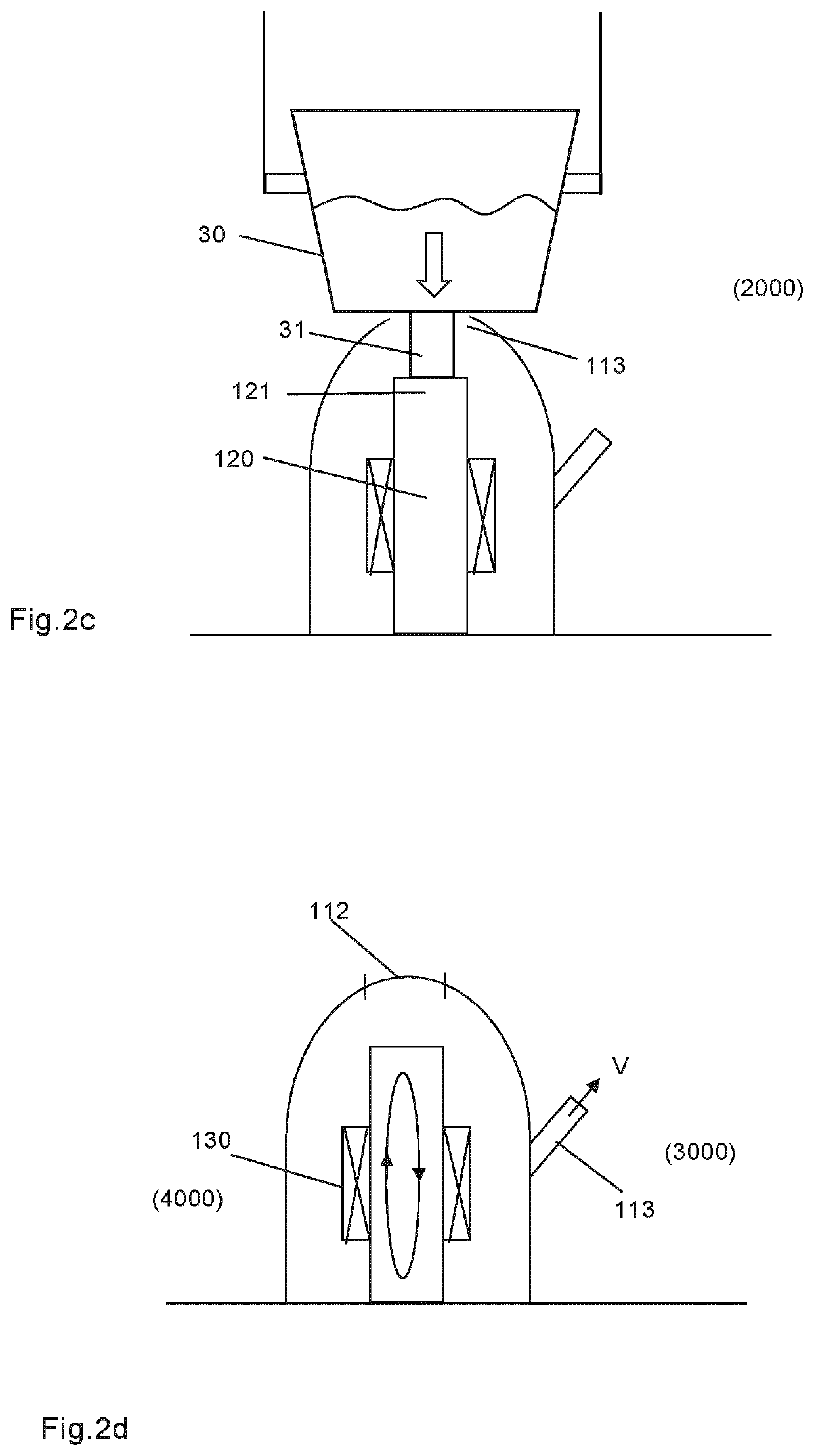

A method for manufacturing a steel ingot

A method for manufacturing a steel ingot in a casting arrangement (100) comprising a vacuum vessel (110); an ingot mold (120) arranged within the vacuum vessel and a stirrer (130) arranged to stir liquid steel in the ingot mold, comprising: -providing (1000) a liquid steel melt; filling (2000) the ingot mold (100) with the liquid steel melt; applying (3000) a reduced pressure within the vacuum vessel (110); allowing the liquid steel melt to solidify into an ingot; allowing the liquid steel melt to solidify under stirring within the ingot mold at a reduced pressure during solidification of the steel melt; wherein, the liquid steel melt comprises a predetermined amount of carbon and; incidental impurity elements in the form of oxides, wherein during stirring the oxides are reduced by carbothermic reaction in which oxygen in the oxides and carbon in the steel melt form carbon-monoxide.

Owner:OVAKO SWEDEN AB

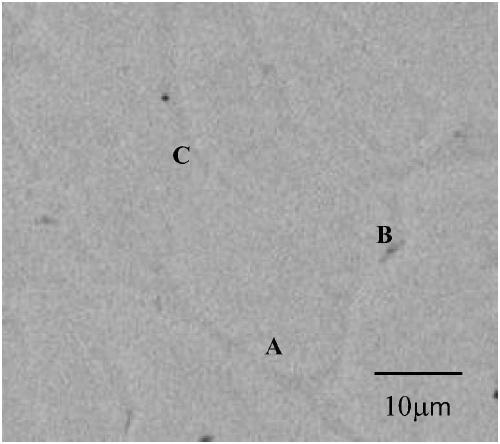

A kind of preparation method of particle reinforced aluminum matrix composite material

The invention discloses a method for preparing a particle-reinforced aluminum-based composite material. First, SiC powder (or Al 2 o 3 whiskers), foaming agent, graphite powder, K 2 TiF 6 Pretreatment with rare earth oxides, proportioning and mixing uniformly according to the mass percentage, putting the aluminum alloy ingot into the crucible and heating until it is completely melted, removing the scum, blowing the mixed powder into the aluminum melt, and waiting for complete The reaction is subjected to degassing treatment, extrusion casting is used for molding, and finally T6 heat treatment is carried out to obtain a particle-reinforced aluminum matrix composite material. The present invention adopts foaming agent, releases a large amount of gas at high temperature, fully stirs melt; Graphite powder, K 2 TiF 6 Carbothermal reaction with rare earth oxides to increase the reaction temperature of the melt to generate TiAl 3 , TiC and Al 2 Ti 20 Ce refines the grains, making SiC (Al 2 o 3 Whiskers) particle-reinforced aluminum matrix composites are evenly distributed in the reinforcement phase, which greatly improves the comprehensive performance of the material.

Owner:FUZHOU UNIV

A kind of method for synthesizing metal sulfide by carbothermal reaction

ActiveCN110002407BShort processSimple processTitanium sulfidesSulfide/polysulfide preparationSulfurPhysical chemistry

The invention discloses a method for synthesizing the sulfide of metal M by carbothermal reaction, wherein M is Ti, Zr, Hf, Cr, Mo, W, V, Nb, Ta, Fe, Co, Ni, Mn, Cu, Zn, Si, Ge, Pb, Sn, Ag, Au, Pt, Pd, Rh, Ir, Ru, Os, Re, Al, B, Ga, In, Tl, Sc, Y, U, One or more of lanthanide series and actinide series. The metal oxide is uniformly mixed with carbon and sulfur in a certain proportion, and the mixture is reacted in a high temperature vacuum environment to prepare the solid sulfide of metal M. The method starts from metal oxides, the raw materials used are cheap and easy to obtain, the production process is simple, safe and feasible, and the reaction speed is fast, which provides a new method for mass production of metal sulfides.

Owner:WUHAN UNIV

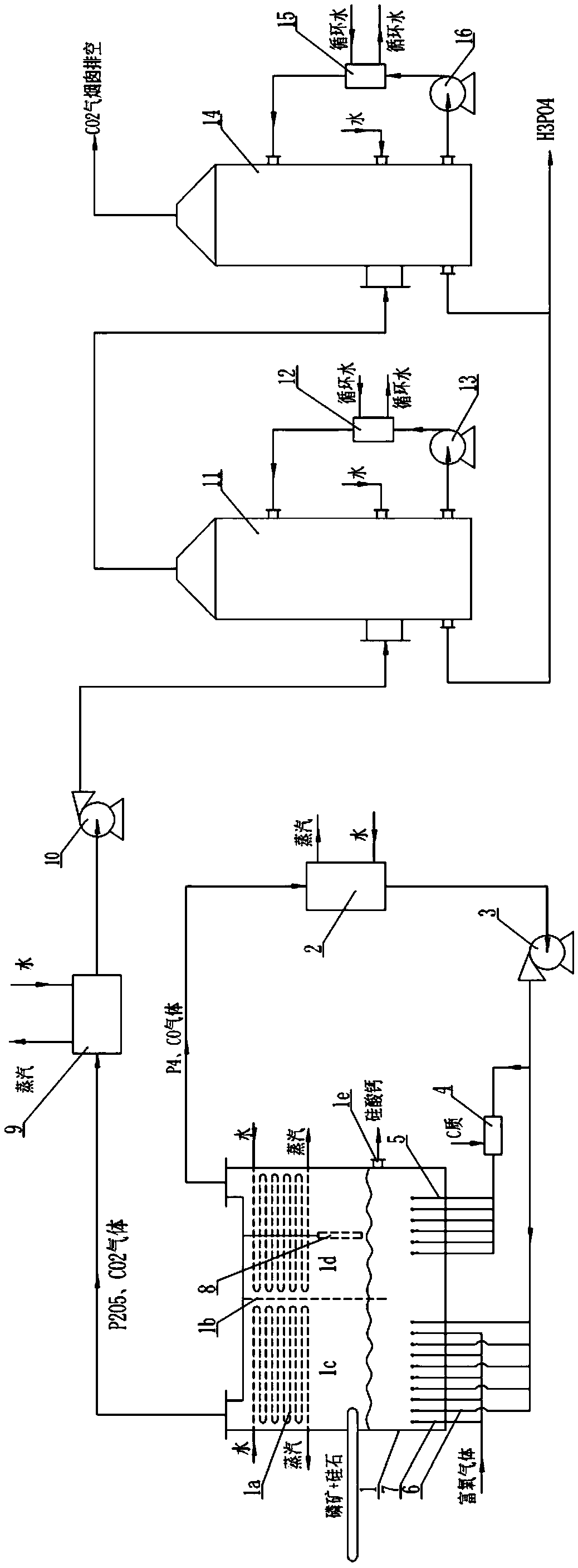

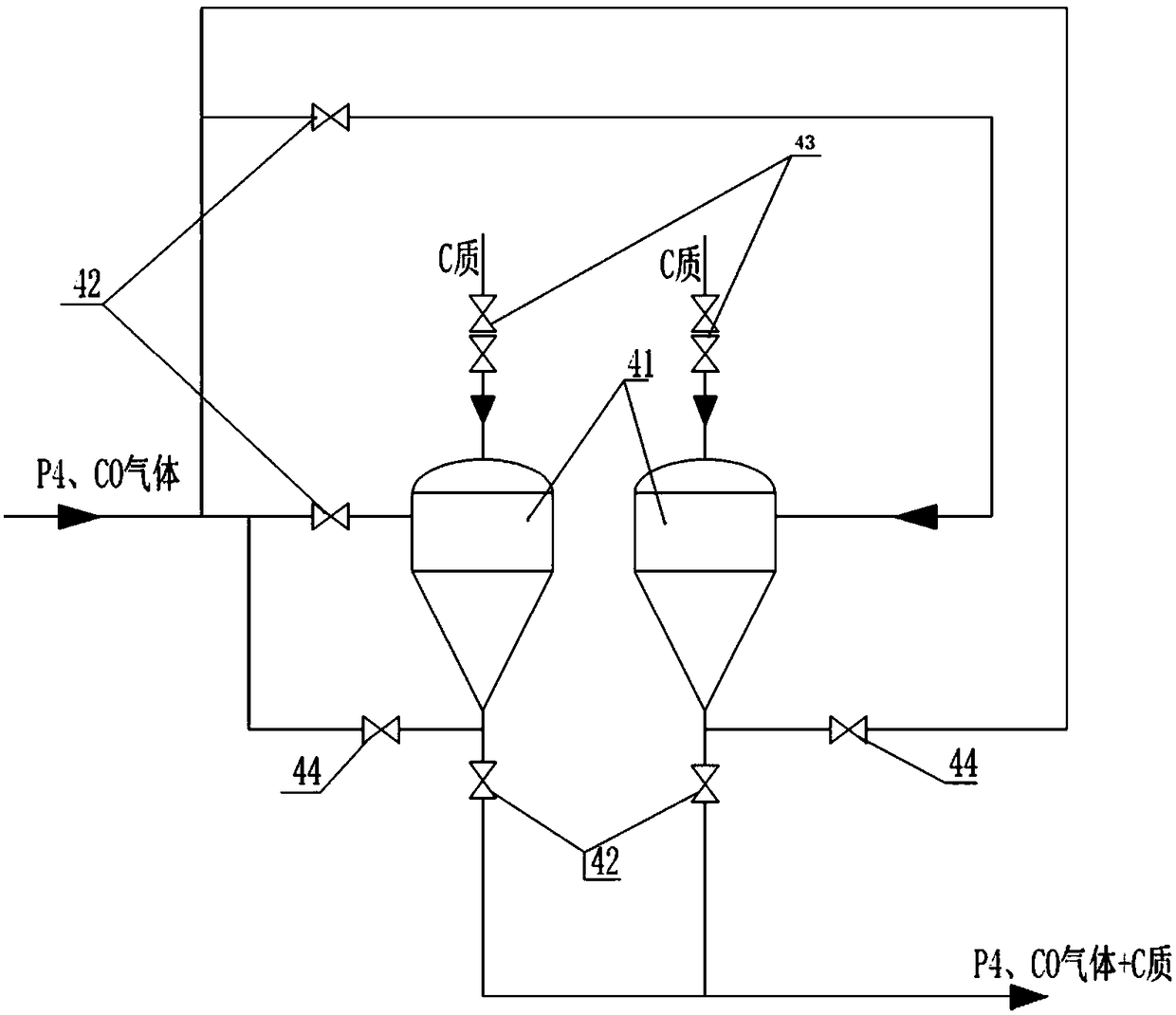

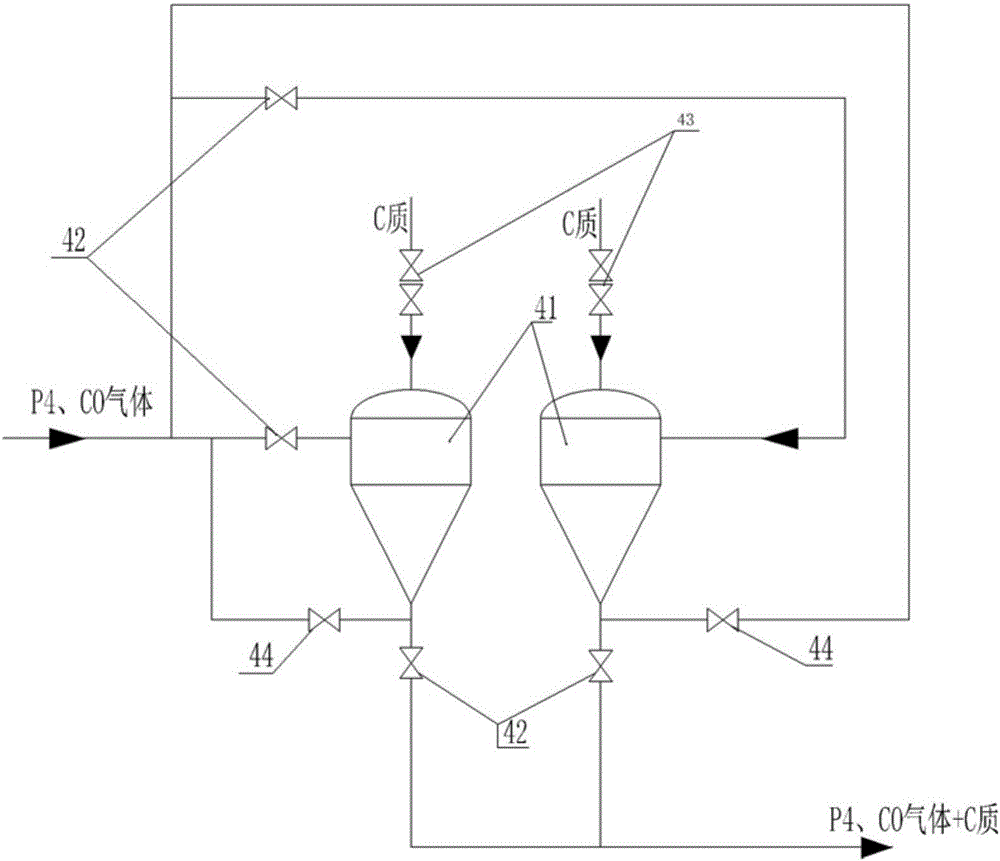

A method of decomposing phosphate rock to produce phosphoric acid

The invention discloses a method for producing phosphoric acid by decomposing phosphate ore. A side-blown furnace is taken as a phosphate ore decomposition furnace and is divided into two parts including an oxidation zone and a reduction zone, wherein gas phase sections of the two parts are completely isolated by a partition wall, and the partition wall only goes deep into a liquid surface of a melt; gas for an oxidation reaction and C substances for a reduction reaction in the side-blown furnace are sprayed into the melt from two sides of the side-blown furnace respectively, a carbon heat reaction reduction zone and a P4 and CO mixed gas oxidation reaction zone are completely separated, P4 and CO mixed gas produced by the reduction zone is introduced into the oxidation zone of the melt section for cyclic utilization, heat can be directly transferred between the oxidation reaction and the reduction reaction of the melt section, so that heat during the oxidation reaction can be transferred as fully as possible and counteracts consumption heat of the reduction reaction to decompose the phosphate ore through own reaction heat and guarantee a higher phosphate ore decomposition rate, and the yield of a phosphoric acid product is increased while energy is saved.

Owner:CINF ENG CO LTD

A kind of iron manganese vanadium phosphate precursor, iron manganese vanadium lithium/carbon cathode material and preparation method

ActiveCN106486668BHigh purityImprove electrochemical performanceCell electrodesSecondary cellsDivalentCarbothermic reaction

The invention discloses an iron manganese vanadium phosphate precursor, an iron manganese vanadium lithium phosphate / carbon anode material and a preparation method. The preparation method includes following steps: 1), preparing a mixed solution of ferric iron source, manganous source, pentavalent vanadium source and phosphor source, and preparing an ammonia water solution; 2), mixing the mixed solution with the ammonia water solution according to a set proportion for co-precipitation reaction to obtain a precipitation product; 3), subjecting the precipitation product to washing, drying and pre-sintering to obtain an iron manganese vanadium phosphate precursor material, well mixing the iron manganese vanadium phosphate precursor material with a lithium source and a carbon source, drying, and calcining in an inert atmosphere to obtain the iron manganese vanadium lithium phosphate / carbon anode material. The iron manganese vanadium phosphate precursor is prepared firstly, a ferric iron compound is used as an iron source in the process of preparation, control on valence state changing of iron is unique, ferric iron can be ensured to be reduced into ferrous in the subsequent carbothermic reaction step, and then the LiFe1-xMn2x / 3Vx / 3PO4 material high in both purity and electrochemical performance is obtained.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI +1

Bio-based silicon carbide ceramic cotton cloth and preparation method thereof

PendingCN114085085ALow thermal conductivitySmall bulk densityHeating/cooling textile fabricsCarbide siliconFiber

The invention discloses bio-based silicon carbide ceramic cotton cloth and a preparation method thereof. The method comprises the following steps that cotton cloth serves as a template, the temperature is slowly increased to the pyrolysis temperature in the inert atmosphere, and then the cotton cloth is pyrolyzed into flexible carbon fiber cotton cloth at the pyrolysis temperature; a silicon source reactant is slowly heated to a gaseous state in the presence of inert gas, and then is subjected to a carbon thermal reaction with the carbon fiber cotton cloth to generate the silicon carbide ceramic cotton cloth. The method is simple, the prepared silicon carbide ceramic cotton cloth is resistant to high temperature, acid and alkali corrosion and oxidation, low in thermal conductivity, small in volume density and extremely high in porosity and has good flexibility and mechanical strength, the method is a novel method for preparing the ceramic cotton cloth, and the problems that an existing flexible ceramic cotton cloth preparation method is complex and high in cost are solved.

Owner:广东盛唐新材料技术有限公司

All-single-walled carbon nanotube field effect transistor and preparation method thereof

ActiveCN102903747BHigh reactivityPrecise Width ControlNanoinformaticsSemiconductor/solid-state device manufacturingCarbon nanotubeCarbon nanotube field-effect transistor

The invention relates to the field of single-walled carbon nanotubes, in particular to an all-single-walled carbon nanotube field effect transistor and a preparation method thereof. Semiconductor single-walled carbon nanotubes are utilized as channels of field effect transistors, and metallic / semiconductor single-walled carbon nanotube mixtures are used as source and drain electrodes. Metallic oxide and the single-walled carbon nanotubes can be in carbon heat reaction at proper temperature, and high-chemical-activity metallic single-walled carbon nanotubes are selectively etched to obtain semiconductor single-walled carbon nanotubes. A metal film is deposited on a Si / SiO2 substrate by using photolithography, and is pre-oxidized to obtain a metallic oxide film. Only the semiconductor single-walled carbon nanotubes are reserved in the single-walled carbon nanotube film and a reaction region which is in contact with metal oxide and are used as the channels of the field effect transistors, and the single-walled carbon nanotubes which are unaffected and are positioned out of the channels are utilized as the source and drain electrodes. Metal electrodes are not required to be deposited; and the all-single-walled carbon nanotube field effect transistor can be used for flexible devices, has the characteristics of cleanness and high efficiency, and can be used for manufacturing large-scale all-carbon integrated circuits possibly.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

A method for manufacturing a steel ingot

A method for manufacturing a steel ingot in a casting arrangement (100) comprising a vacuum vessel (110); an ingot mold (120) arranged within the vacuum vessel and a stirrer (130) arranged to stir liquid steel in the ingot mold, comprising: -providing (1000) a liquid steel melt; filling (2000) the ingot mold (100) with the liquid steel melt; applying (3000) a reduced pressure within the vacuum vessel (110); allowing the liquid steel melt to solidify into an ingot; allowing the liquid steel melt to solidify under stirring within the ingot mold at a reduced pressure during solidification of the steel melt; wherein, the liquid steel melt comprises a predetermined amount of carbon and; incidental impurity elements in the form of oxides, wherein during stirring the oxides are reduced by carbothermic reaction in which oxygen in the oxides and carbon in the steel melt form carbon-monoxide.

Owner:OVAKO SWEDEN AB

Method for producing phosphoric acid by decomposing phosphate ore

ActiveCN106744758AImprove decomposition rateHigh yieldChemical industryPhosphoric acidHigh phosphateDecomposition

The invention discloses a method for producing phosphoric acid by decomposing phosphate ore. A side-blown furnace is taken as a phosphate ore decomposition furnace and is divided into two parts including an oxidation zone and a reduction zone, wherein gas phase sections of the two parts are completely isolated by a partition wall, and the partition wall only goes deep into a liquid surface of a melt; gas for an oxidation reaction and C substances for a reduction reaction in the side-blown furnace are sprayed into the melt from two sides of the side-blown furnace respectively, a carbon heat reaction reduction zone and a P4 and CO mixed gas oxidation reaction zone are completely separated, P4 and CO mixed gas produced by the reduction zone is introduced into the oxidation zone of the melt section for cyclic utilization, heat can be directly transferred between the oxidation reaction and the reduction reaction of the melt section, so that heat during the oxidation reaction can be transferred as fully as possible and counteracts consumption heat of the reduction reaction to decompose the phosphate ore through own reaction heat and guarantee a higher phosphate ore decomposition rate, and the yield of a phosphoric acid product is increased while energy is saved.

Owner:CINF ENG CO LTD

Nano (ti,m)c solid solution whiskers and preparation method thereof

ActiveCN106087060BWell mixedLower reaction synthesis temperaturePolycrystalline material growthFrom solid stateDistilled waterWhiskers

The invention discloses a nano (Ti, M) C solid solution crystal whisker and a preparation method thereof. The nano (Ti, M) C solid solution crystal whisker is prepared from the following components: 40-79.9% of Ti, 0.1-40% of M and the balance of C, wherein M is at least one of W, Mo, V, Cr, Ta and Nb. Preparation raw materials comprise a component precursor of (Ti, M) C, a halogenating agent and a catalyst. The preparation method comprises the following steps: preparing a precursor mixed solution from all raw materials with distilled water, and drying so as to obtain precursor mixed powder; putting the precursor mixed powder into a reaction furnace, performing carbon-thermal reaction at 1100-1300 DEG C, firing the obtained nano (Ti, M) C solid solution crystal whisker for 4-6 hours at 350-400 DEG C in the presence of air for decarbonization, washing, performing eccentric separation, and finally drying, thereby obtaining the nano (Ti, M) C solid solution crystal whisker. The nano (Ti, M) C solid solution crystal whisker can be used as a nano ceramic phase crystal whisker toughening reinforcing metal based and ceramic based composite material, and is in good interface combination with a substrate.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com