Transmission electron microscope technology for in-situ study of three-dimensional distribution structure of nanoparticles

A technology of nanoparticle and three-dimensional distribution, which is applied in individual particle analysis, particle and sedimentation analysis, and preparation of test samples. It can solve problems such as poor dispersion, large particle size of metal catalysts, and difficult size control, and achieve high performance. , to avoid the effect of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] The method for in-situ researching the sintering phenomenon and the three-dimensional distribution of the multi-component alloy nanoparticles loaded on the carbon nanofiber under the action of the electric field under the transmission electron microscope comprises the following steps:

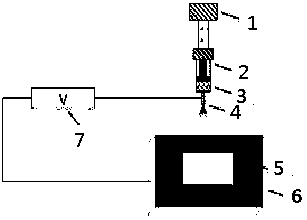

[0064] 1. In order to obtain carbon nanofibers, we use the method of electrospinning. in accordance with figure 1 The schematic diagram of electrospinning shown in the figure shows that before spinning, polyacrylonitrile (PAN) and dimethylformamide (DMF) are mixed according to a certain ratio to form a polymer solution and then loaded into the injector. Then place a substrate for carrying carbon nanofibers at a suitable position on the receiving screen directly opposite the injection port. Choose copper foil or carbon paper as the substrate, but according to experimental experience, due to the relatively high strength of copper foil compared with carbon paper, and weaker bonding with ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com