A method of decomposing phosphate rock to produce phosphoric acid

A phosphate rock and phosphoric acid technology, applied in the direction of phosphoric acid, phosphorus oxyacids, chemical instruments and methods, etc., can solve the problems of low decomposition conversion rate of phosphate rock and affect the decomposition conversion rate of phosphate rock, and achieve high decomposition rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

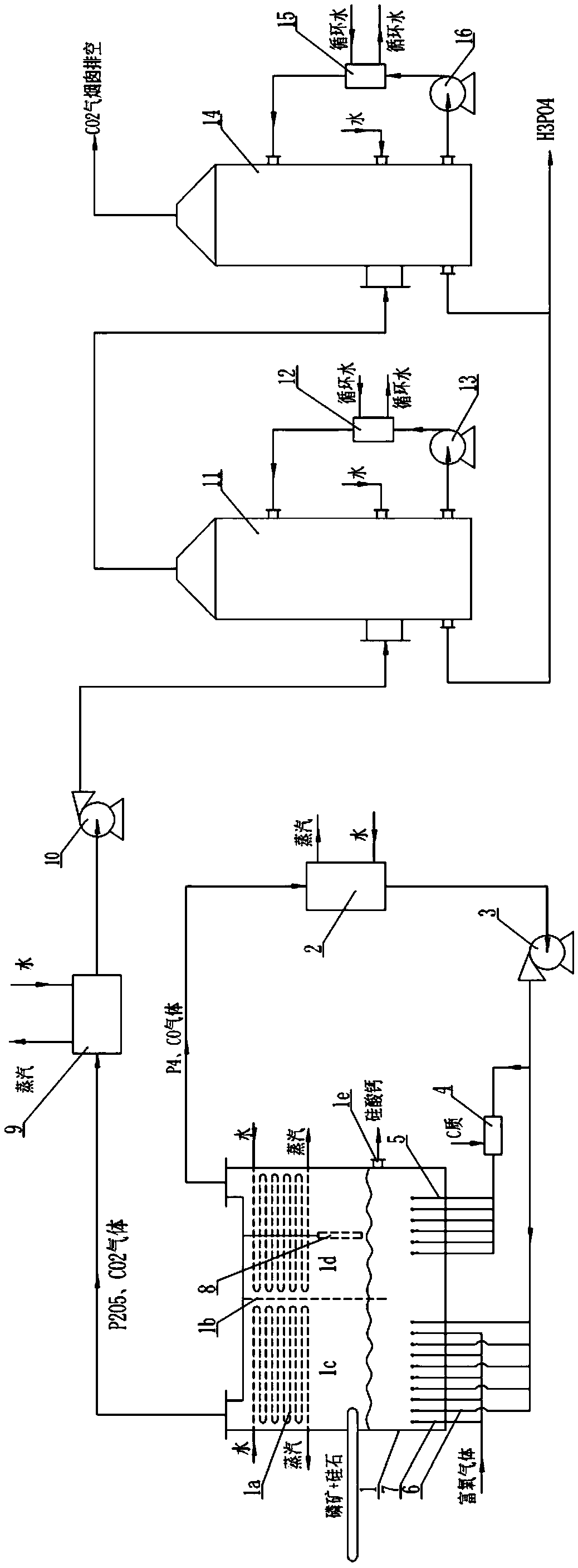

[0036] Such as figure 1 As shown, the system for producing phosphoric acid in this embodiment consists of the following: side blowing furnace 1, water wall 1a, reduction zone economizer 2, booster fan 3, injection device 4, P 4 And CO and C quality spray gun 5, P 4 And CO spray gun 6, oxygen-enriched gas spray gun 7, heating electrode 8, oxidation zone economizer 9, conveying fan 10, primary absorption tower 11, primary phosphoric acid cooler 12, primary phosphoric acid circulation pump 13, secondary absorption tower 14. Secondary phosphoric acid cooler 15. Secondary phosphoric acid circulation pump 16.

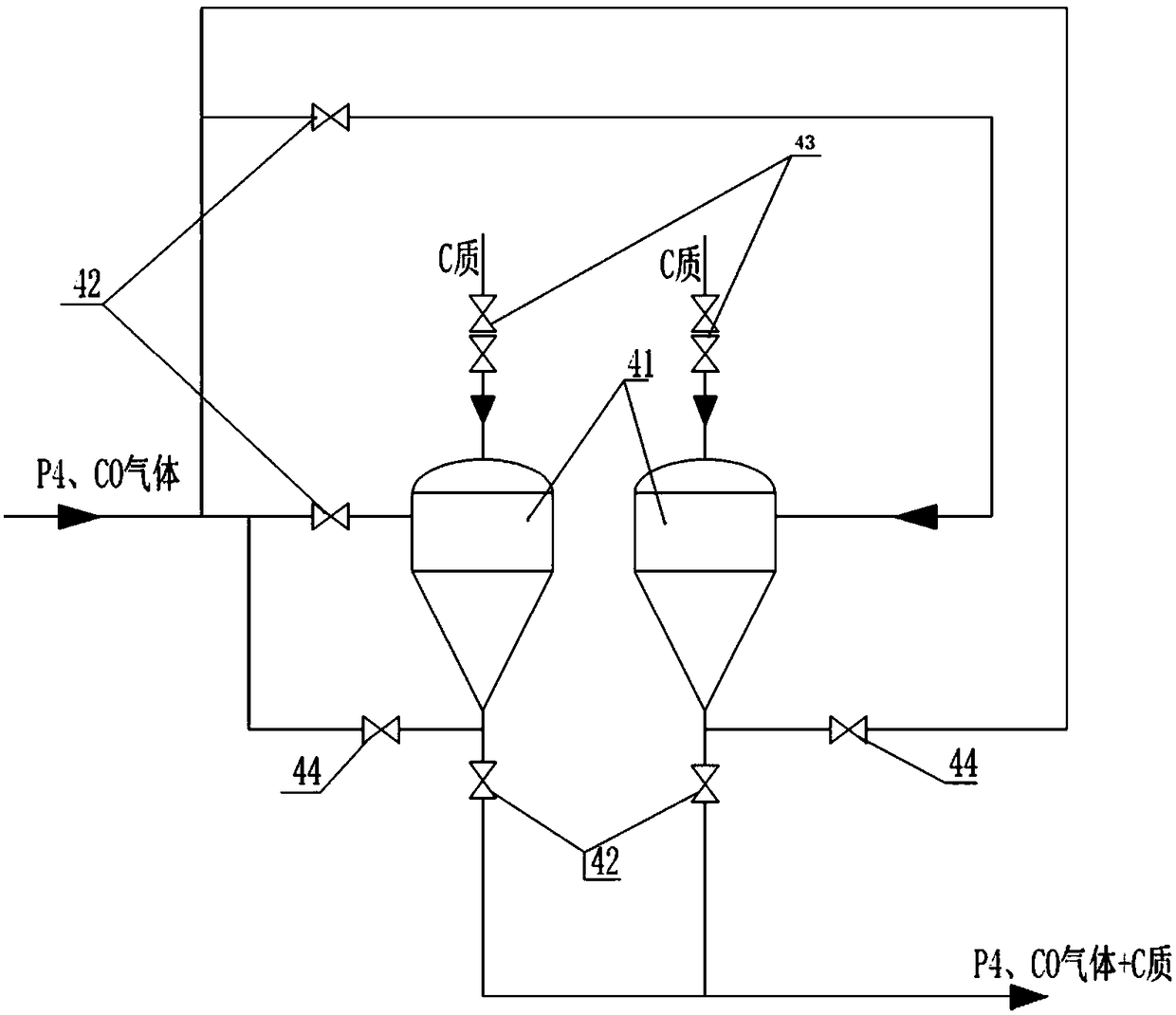

[0037] Such as figure 2 As shown, the injection device 4 includes two parallel injection tanks 41, C substance is added from the upper end of the injection tank 41, and the P 4 The mixed gas with CO is sent into the spray tank 41 respectively in two pipelines, and the gas delivery switch valve 42 is connected respectively on the two pipelines, and the P 4 Mixed gas with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com