Magnesium ammonium phosphate-phosphorus fertilizer slow-release fertilizer and preparation method thereof

A technology of magnesium ammonium phosphate and slow-release fertilizer, applied in the field of comprehensive utilization of resources, can solve the problem of high production cost of wrapped slow/controlled-release fertilizer, low phosphorus content of magnesium ammonium phosphate slow-release fertilizer, uneven spraying of binder solution, etc. problem, to achieve the effect of reducing the cost of medicine, slowing the release effect, and slowing the release rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

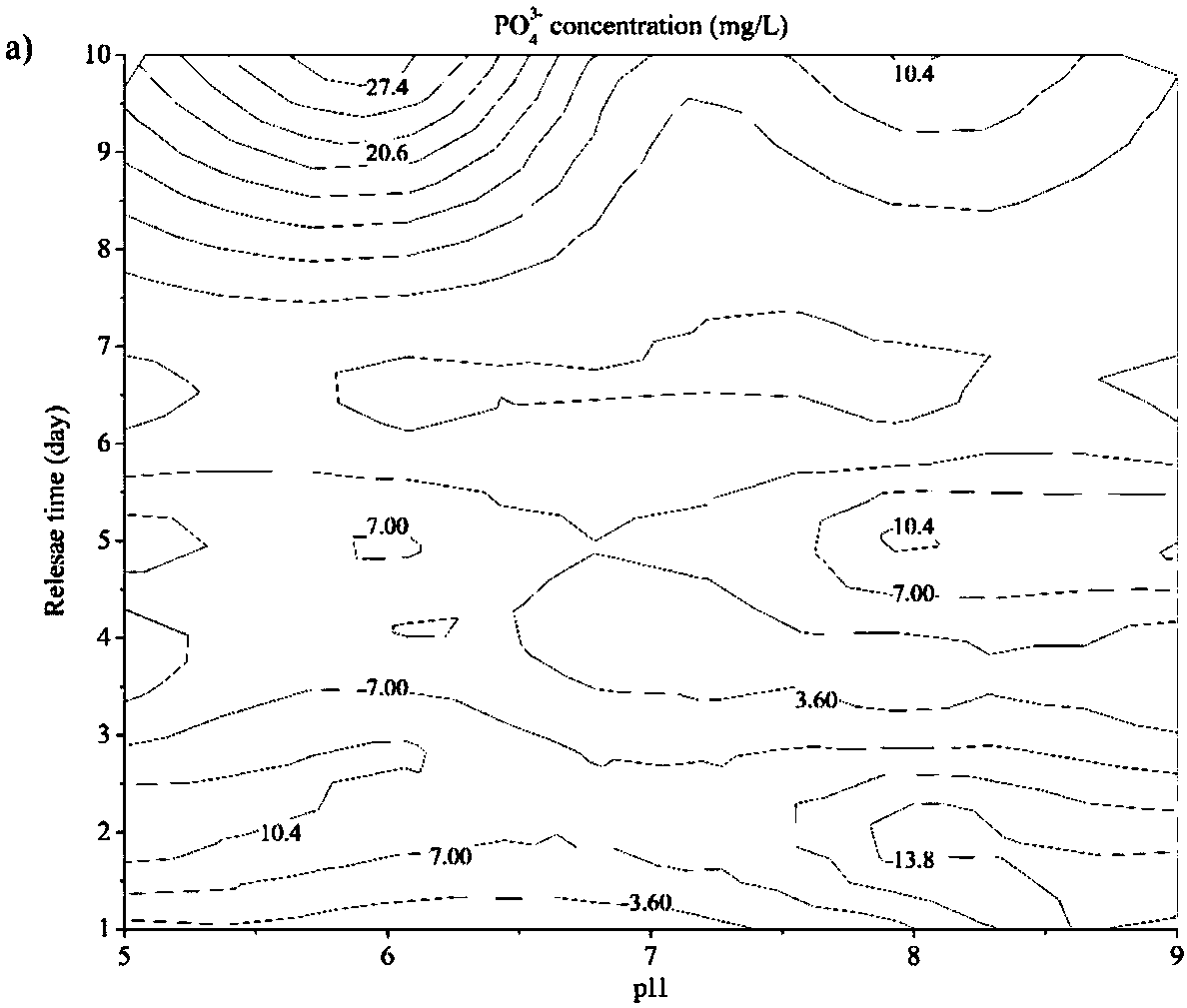

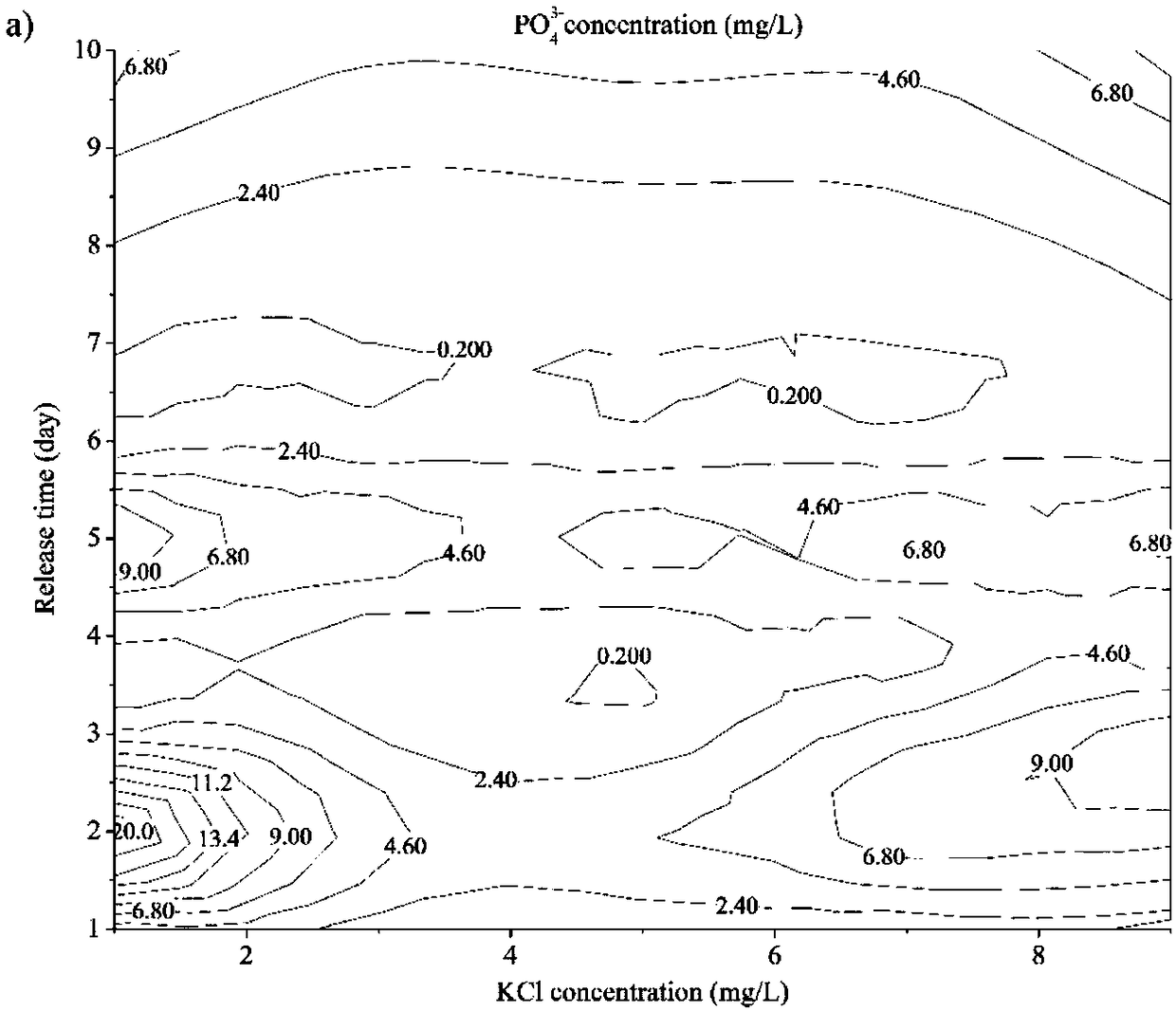

Image

Examples

Embodiment 1

[0061] Raw materials: 1000g magnesium ammonium phosphate, 50g modified starch, 1000g phosphate fertilizer.

[0062] A preparation method of magnesium ammonium phosphate-phosphate slow-release fertilizer, comprising the following steps:

[0063] 1) Grind 1000g of magnesium ammonium phosphate and 50g of modified starch into small particles of about 1 μm, and mix well;

[0064] 2) Take 5% of the mixture in step 1), and place it in a disc granulator;

[0065] 3) Spray water on the rotating magnesium ammonium phosphate and modified starch granules by means of atomization;

[0066] 4) Slowly add 100 g (i.e. 10% of the total amount of phosphate fertilizer) phosphate fertilizer that is ground into small particles of about 1 μm in the magnesium ammonium phosphate and modified starch materials described in step 3);

[0067] 5) water spray granulation;

[0068] 6) After the material is converted into particles of about 1mm, repeat step 2) to step 5) in a slow adding manner, wherein th...

Embodiment 2

[0077] Raw materials: 2000g magnesium ammonium phosphate, 200g modified starch, 1000g phosphate fertilizer.

[0078] A preparation method of magnesium ammonium phosphate-phosphate slow-release fertilizer, comprising the following steps:

[0079] 1) Grind 2000g of magnesium ammonium phosphate and 200g of modified starch into small particles of 100 μm and 20 μm respectively, and mix well;

[0080] 2) Take 10% of the mixture in step 1), and place it in a disc granulator;

[0081] 3) Spray water on the rotating magnesium ammonium phosphate and modified starch granules by means of atomization;

[0082] 4) Slowly add 150 g (i.e. 15% of the total amount of phosphate fertilizer) of phosphate fertilizer that is ground into 100 μm small particles into the magnesium ammonium phosphate and modified starch materials described in step 3);

[0083] 5) water spray granulation;

[0084] 6) After the material is converted into particles of about 1 mm, repeat step 2) to step 5) in a slow addi...

Embodiment 3

[0092] Raw materials: 3000g magnesium ammonium phosphate, 240g modified starch, 1000g phosphate fertilizer.

[0093] A preparation method of magnesium ammonium phosphate-phosphate slow-release fertilizer, comprising the following steps:

[0094] 1) Grind 3000g of magnesium ammonium phosphate and 240g of modified starch into small particles of 200 μm and 50 μm respectively, and mix well;

[0095] 2) Take 8% of the mixture in step 1), and place it in a disc granulator;

[0096] 3) Spray water on the rotating magnesium ammonium phosphate and modified starch granules by means of atomization;

[0097] 4) Slowly add 140g (i.e. 14% of the total amount of phosphate fertilizer) phosphate fertilizer that is ground into 200 μm small particles in the magnesium ammonium phosphate and the modified starch material in step 3);

[0098] 5) water spray granulation;

[0099] 6) After the material is converted into particles of about 1 mm, repeat step 2) to step 5) in a slowly adding manner, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com