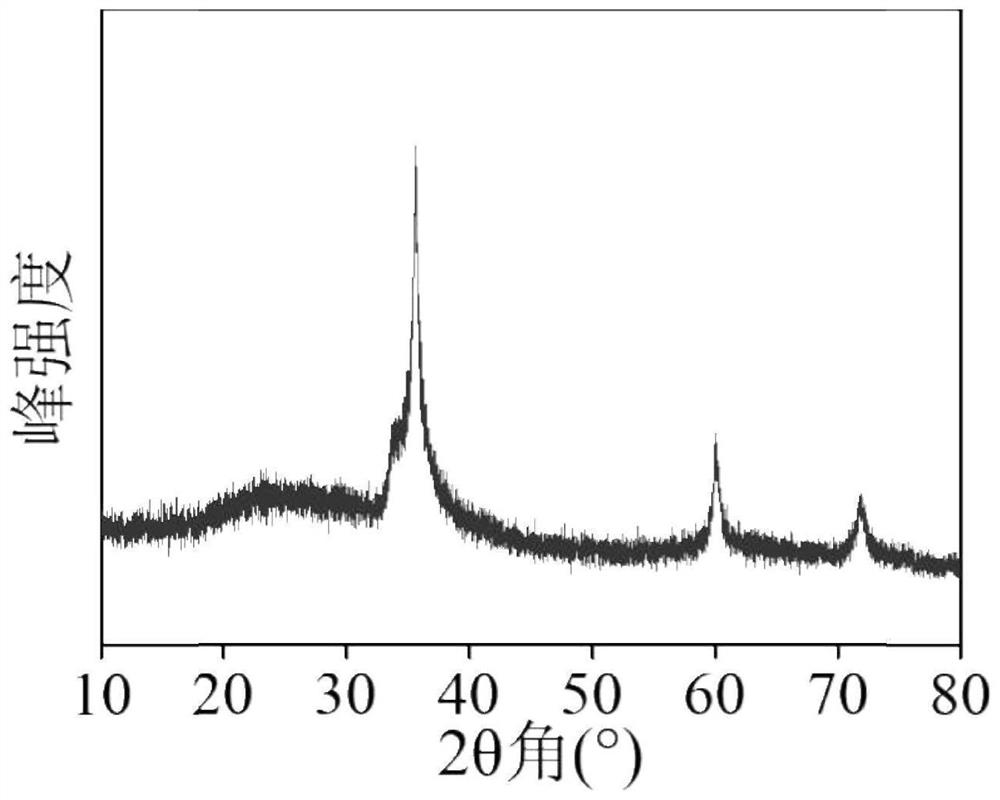

Bio-based silicon carbide ceramic cotton cloth and preparation method thereof

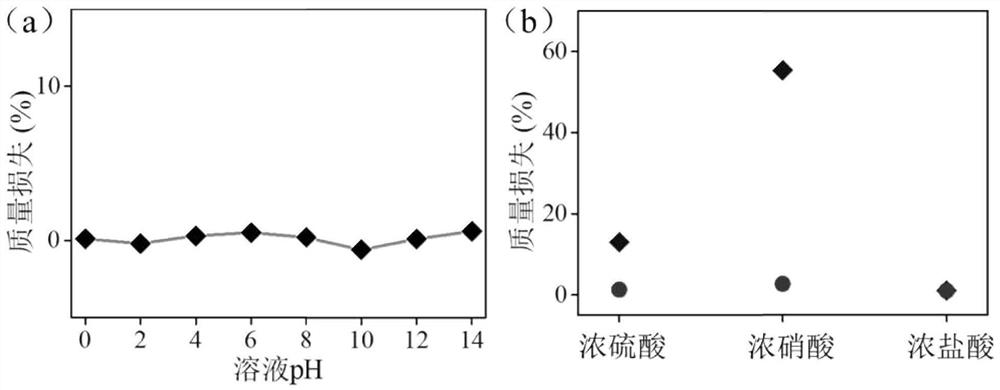

A silicon carbide ceramic, bio-based technology, applied in fabric surface trimming, heating/cooling fabrics, textiles and papermaking, etc., can solve the problems of high price, poor strength, high brittleness, etc., and achieve simple methods, low thermal conductivity, and porosity high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific embodiments.

[0031] Step S1, put the cleaned and dried biomass fiber cotton cloth into a high-temperature furnace, place it in a corundum crucible, put the crucible into a pyrolysis device, feed an inert gas at a flow rate of 60ssm, and heat it to T1°C at a heating rate of V1 Keep warm for t1 hour, then cool naturally to room temperature, wash the obtained carbon fiber cotton cloth with ethanol to remove adsorbed small organic molecules, dry at 60°C, and cool naturally.

[0032] Step S2, arrange the carbon fiber cotton obtained in step S1 in a corundum crucible, place a silicon source reactant under or around the carbon fiber cotton cloth, and cover the crucible to prevent excessive escape of reactant gas obtained by sublimation or evaporation. Put the corundum crucible together with the lid into a high-temperature furnace, pass in an inert gas with a flow rate of 60ssm, heat it to T2°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com