Method for efficiently preparing titanium-based-carbon three-dimensional crimped nano fibers

A nanofiber and three-dimensional crimping technology, which is applied in the fields of fiber chemical characteristics, rayon manufacturing, textiles and papermaking, etc., can solve problems such as unfavorable development of nano-preparation methods, achieve field improvement, facilitate large-scale industrial production, and expand the scope of application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

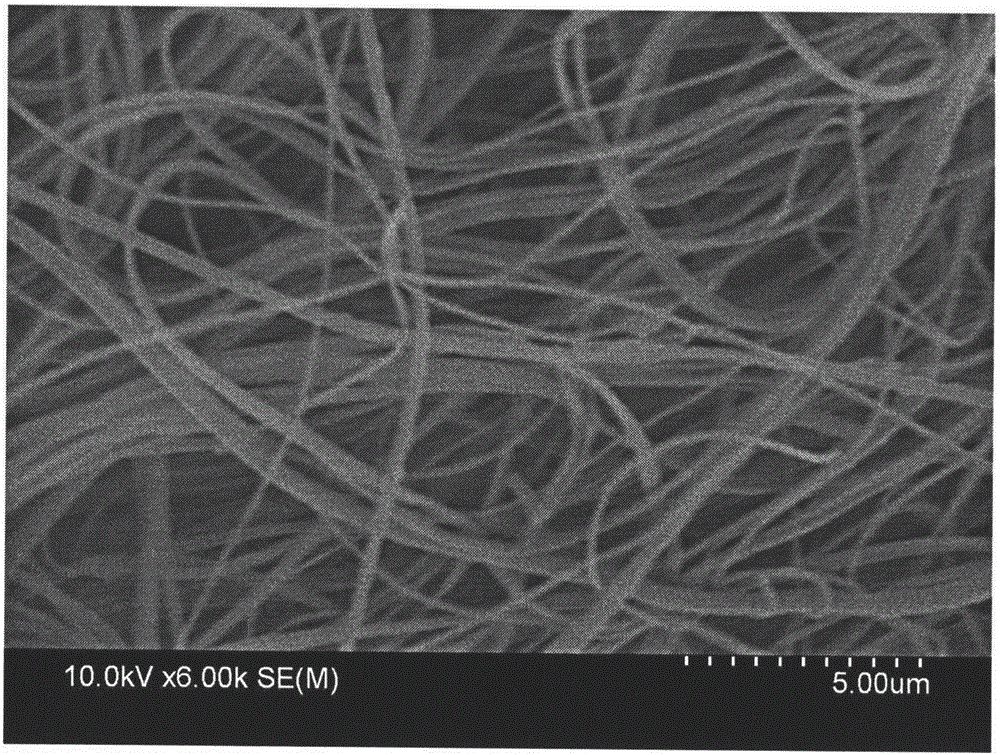

[0031] A high-efficiency preparation of TiO 2 -C three-dimensional crimped nanofiber method, comprising the steps:

[0032] (1) Add polyvinylpyrrolidone polymer to the solvent, dissolve at 0-100°C for 2-8 hours, add glacial acetic acid and tetrabutyl titanate solution to the polymer solution, and obtain polyvinylpyrrolidone / TiO 2 polymer solution.

[0033] (2) the polyvinylpyrrolidone / TiO obtained in step (1) 2 Polymer solution, in the solution jet spinning technology, the apparent viscosity of the solution is 4512mPa s, the airflow temperature is 90°C, the diameter of the spinneret hole is 0.5mm, the airflow slit is 0.3mm, and the air flow rate of the air inlet is 900m 3 / h, the air flow at the exhaust port is 1800m 3 / h, the propulsion speed is 20ml / h, the spinning air pressure is 0.12MPa, and the receiving distance is 50cm. Polyvinylpyrrolidone / TiO prepared by solution jet spinning 2 Fiber felt.

[0034] (3) Polyvinylpyrrolidone / TiO obtained in step (2) 2 On the basi...

Embodiment 2

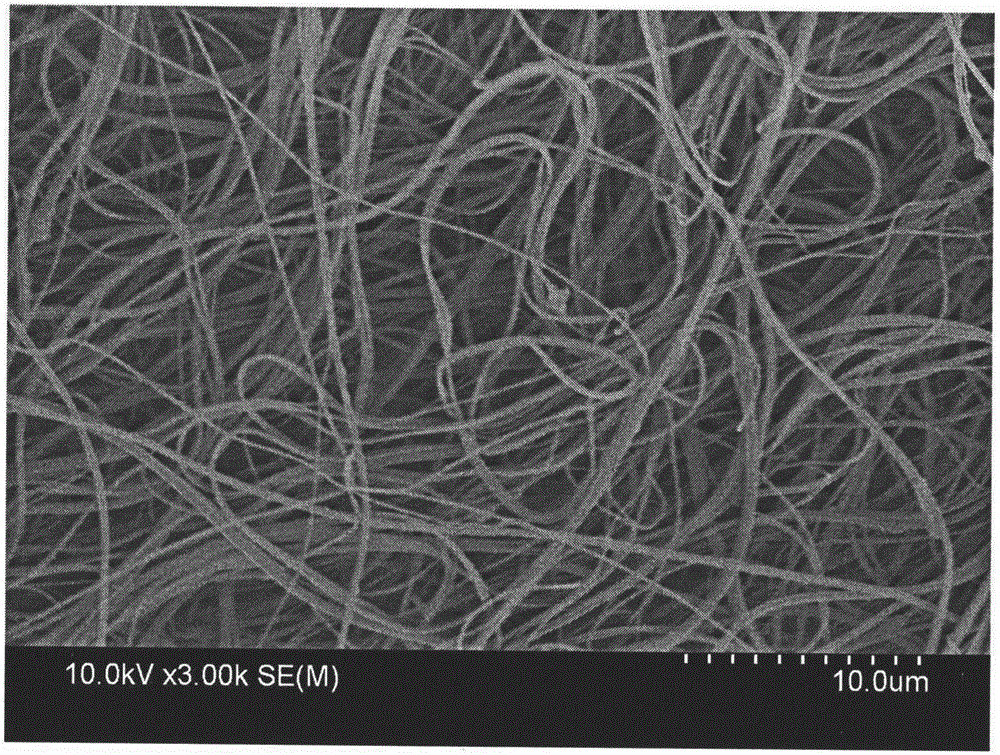

[0037] A method for efficiently preparing TiC-C three-dimensional curled nanofibers, comprising the steps of:

[0038] (1) Add polyacrylonitrile to the organic solvent N,N-dimethylformamide, dissolve at 80°C for 1 hour, add glacial acetic acid and tetrabutyl titanate to obtain polyacrylonitrile / TiO 2 solution.

[0039] (2) the polyacrylonitrile / TiO that step (1) obtains 2 solution, prepared to the range of spinnable concentration, and the optimized polyacrylonitrile / TiO was prepared by solution jet spinning technology 2 nanofiber felt. In the solution jet spinning technology, the apparent viscosity of the solution is 4512mPa s, the airflow temperature is 90°C, the diameter of the spinneret hole is 0.5mm, the airflow slit is 0.3mm, and the gas flow rate of the air inlet is 900m 3 / h, the air flow at the exhaust port is 1800m 3 / h, the propulsion speed is 15ml / h, the spinning air pressure is 0.12MPa, and the receiving distance is 50cm.

[0040] (3) polyacrylonitrile / TiO obt...

Embodiment 3

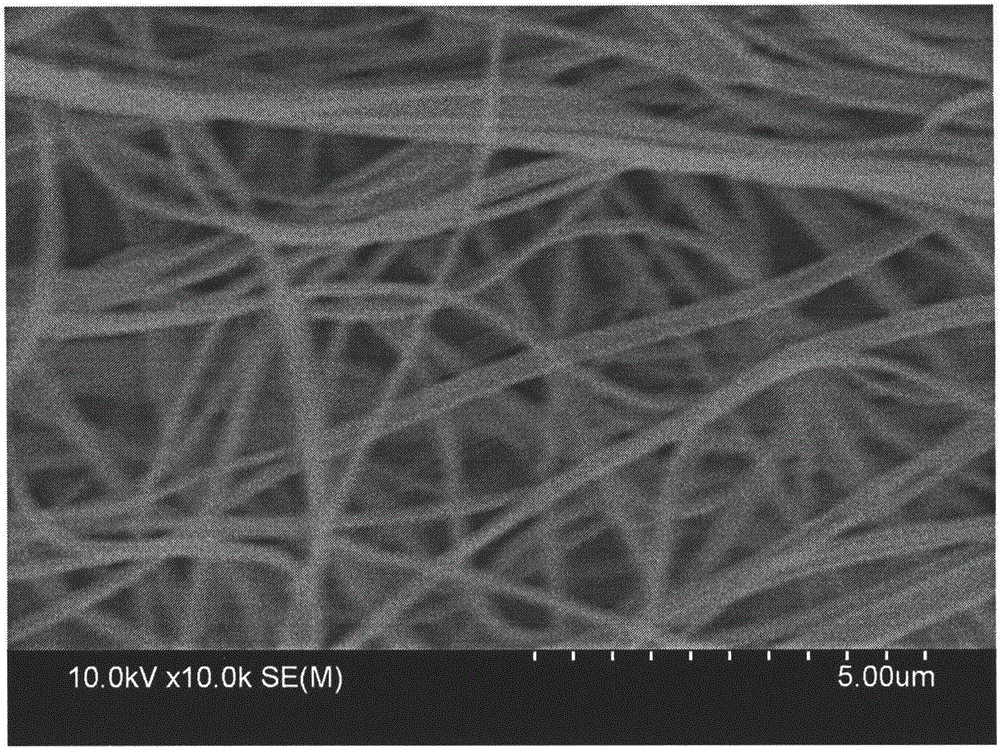

[0045] A preparation of high-efficiency Ti(C 1-X N X )-C three-dimensional crimped nanofiber method, comprising the steps:

[0046] (1) Add polyacrylonitrile to the organic solvent N,N-dimethylformamide, dissolve at 80°C for 1 hour, add glacial acetic acid and tetrabutyl titanate to obtain polyacrylonitrile / TiO 2 solution.

[0047] (2) the polyacrylonitrile / TiO that step (1) obtains 2 solutions, formulated to a range of spinnable concentrations, and optimized polyacrylonitrile / TiO 2 nanofiber felt. In solution jet spinning and electrospinning technology, the apparent viscosity of the solution is 4512mPa s, the airflow temperature is 90°C, the diameter of the spinneret hole is 0.5mm, the airflow slit is 0.3mm, and the air flow rate of the air inlet is 900m 3 / h, the air flow at the exhaust port is 1800m 3 / h, the propulsion speed is 10ml / h, the spinning air pressure is 0.12MPa, the voltage is 25KV, and the receiving distance is 50cm.

[0048] (3) polyacrylonitrile / TiO ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com