Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31 results about "1-Methylnaphthalene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

1-Methylnaphthalene is an organic compound with the formula CH₃C₁₀H₇. It is a colorless liquid. It is isomeric with 2-methylnaphthalene.

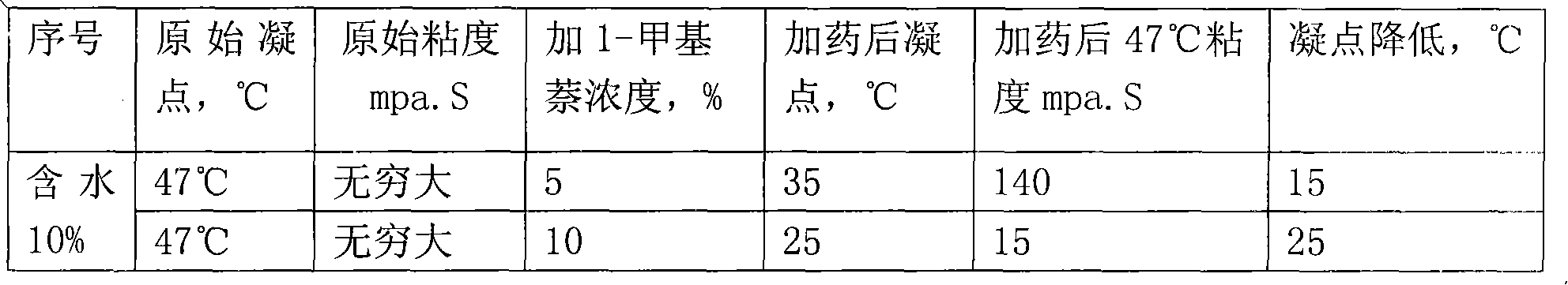

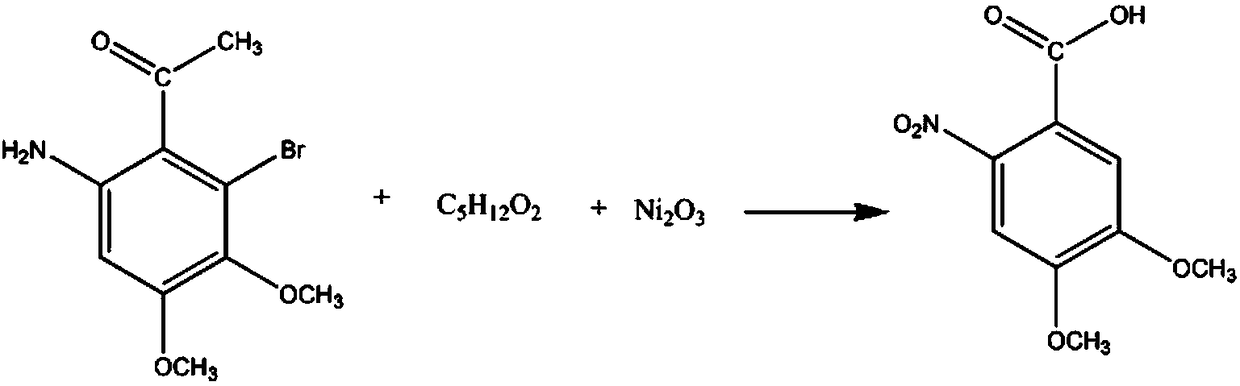

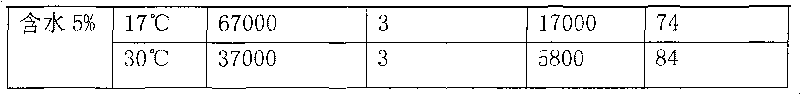

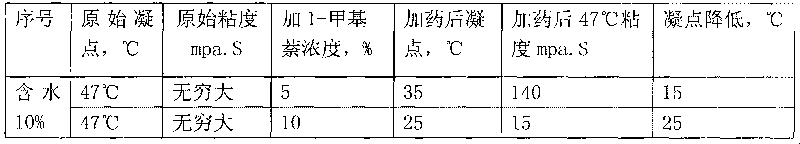

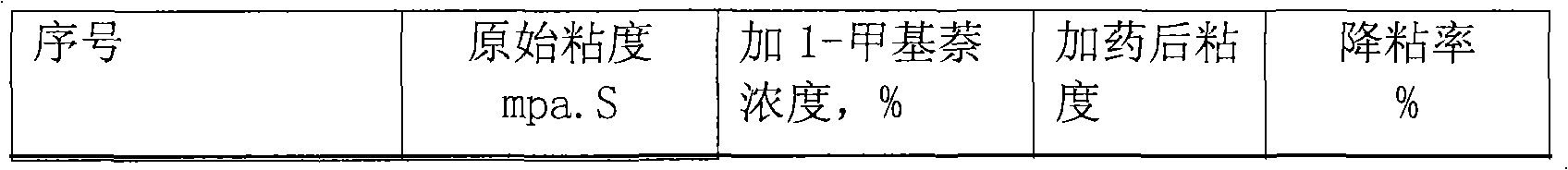

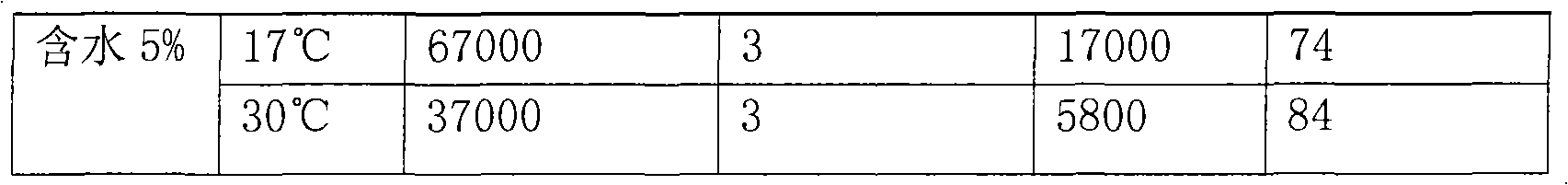

Application of methylnaphthalene in lowering viscosity of thickened oil

ActiveCN101717626ALow viscositySpeed up the flowFluid dynamicsFluid removalOil viscosityHigh surface

The invention discloses application of methylnaphthalene in lowering viscosity of thickened oil, which comprises application of 1-methylnaphthalene in lowering viscosity of thickened oil and the specific implementation steps, 2-methylnaphthalene in lowering viscosity of thickened oil and the specific implementation steps and mixed methylnaphthalene in lowering viscosity of thickened oil and the specific implementation steps. The invention enlarges the application method of methylnaphthalene, clearly demonstrates the specific application method of using methylnaphthalene to lower viscosity of thickened oil, solves the problems of great load and power consumption, frequent machinery accidents, high surface line return pressure, and the like of an oil extractor during extracting and outwards transporting thickened oil in the background art, and can effectively lower viscosity of thickened oil and reduce extraction and outward transportation cost of thickened oil.

Owner:盘锦河升大地石油科技有限公司

Method for quickly pyrolyzing sludge to prepare bio-oil and soil improver by microwave assisted catalysis

ActiveCN105087036AIncrease contentImprove fertilitySludge treatment by pyrolysisByproduct vaporizationLiquid productSludge

The invention relates to a method for quickly pyrolyzing sludge to prepare bio-oil and a soil improver by microwave assisted catalysis. The method comprises the following steps: (1) weighing silicon carbide spherical particles and a HZSM-5 spherical catalyst in a mass ratio of 1: 1 to 1: 2, and uniformly mixing and adding the mixture into a quartz reaction kettle; (2) putting the quartz reaction kettle in a microwave splitting instrument, heating the quartz reaction kettle to 450-600 DEG C, stirring the mixture at a rate of 60-100 r / minute, gradually adding dried sludge powder into the quartz reaction kettle and condensing the generated steam to obtain a brown liquid product bio-oil, and collecting solid residues as the soil improver. The method provided by the invention is simple in process and quick to split, and the obtained split fuel is high in hydrocarbon content which can reach over 55%. The obtained split fuel comprises important chemical raw materials such as naphthalene, p-xylene, 1,3,5-trimethylbenzene, 1-methylnaphthalene, indene and the like. The obtained solid residues are very high in content of P, Ca, K and Mg and can be used as the soil improver to improve the soil fertility.

Owner:NANCHANG UNIV

Cyanide-free silver plating solution additive

The invention relates to a cyanide-free silver plating solution additive which comprises the following components by ratio: 0.1-10g / l of brightener, 5-10g / l of leveling agent, 100-600g / l of complexing agent and the balance of plasma water, wherein the brightener is one or mixture of more in nitrogen-containing compound, triazole, benzotriazole, 2-hydroxypyridine, pyridine, 22 dipyridyl, 1, 10-phenanthroline, triethylene tetramine and diethylene triamine according to any ratio; the leveling agent is one or mixture of more in aromatic hydrocarbon compounds, naphthalene, 1-methylnaphthalene, 1, 4-naphthoquinone and 1-naphthol according to any ratio; the complexing agent is one or mixture of more in disodium ethylenediamine tetraacetate, niacin, aminosulfonic acid and potassium pyrophosphate according to any ratio. The cyanide-free silver plating solution additive has the beneficial effects that the plating solution is stable, low in toxicity and good in dispersing ability; the obtained plating layer is bright and fine as well as good in binding force; the technology adopts the environment-friendly organic additive which does not contain heavy metal and sulfide; the plating layer is good in corrosion resistance. Furthermore, the cyanide-free silver plating solution additive can be directly used for parts such as brass, copper, chemical nickel and the like, preplating is not needed, and the binding force is also guaranteed.

Owner:HANGZHOU WIN WIN TECH CO LTD

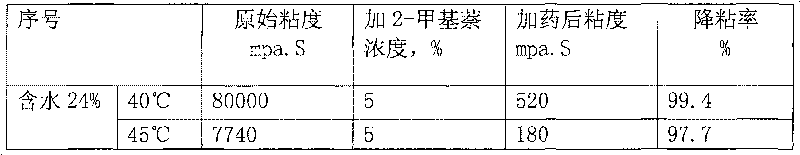

Oil-washing deep processing technology of coal tar

InactiveCN101899313AHigh economic valueReduce manufacturing costTar working-up by distillationDistillationDibenzofuran

The invention relates to an oil-washing deep processing technology of coal tar. An oil-washing fraction is a distillate with the distillation range of 230 to 300 DEG C, the oil-washing fraction sequentially passes through a washing tower (1), a naphthalene washing separation tower (2), a methyl naphthalene tower (3), a methyl naphthalene separation tower (4), an indole and biphenyl tower (5), a dimethyl naphthalene tower (6), an acenaphthene tower (7), a dibenzofuran tower (8) and a fluorene tower (9); and eight substances of 1-methyl naphthalene, 2-methyl naphthalene, and the like are separated to obtain the 1-methyl naphthalene with the mass percentage of more than 96 percent, the 2-methyl naphthalene with the purity of more than 98 percent, naphthalene with the purity of more than 99 percent, 2,6-dimethyl naphthalene, acenaphthene, dibenzofuran, fluorene, and other high value-added products.

Owner:BAOSHUN TECH CO LTD +1

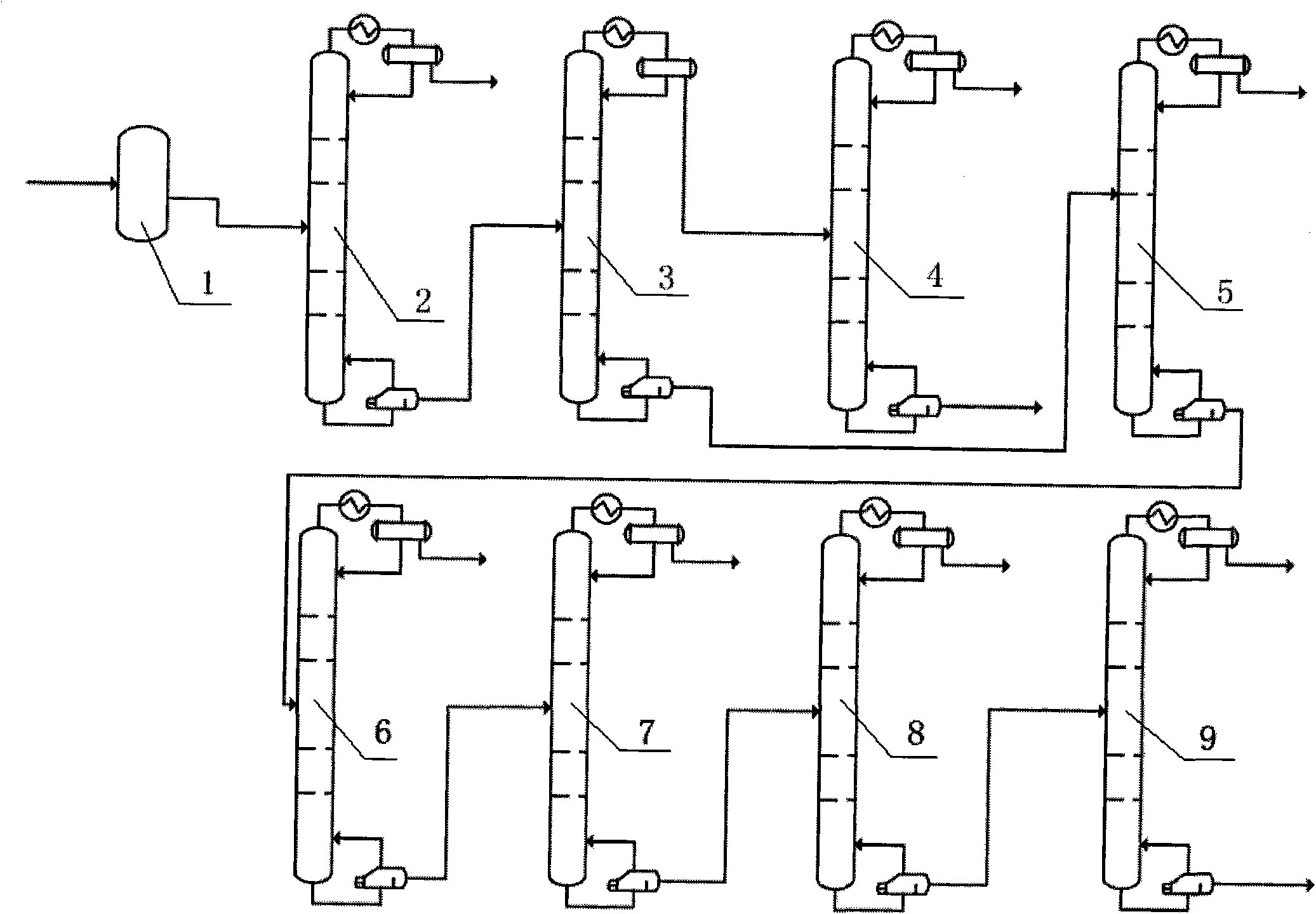

Wide-spectrum diesel pour point depressant composition, preparation method thereof and application of composition

InactiveCN109135846AIncrease polarityImprove solubilityLiquid carbonaceous fuelsFuel additivesPolymer scienceNitrogen

The invention discloses a wide-spectrum diesel pour point depressant composition, a preparation method thereof and an application of the composition. The pour point depressant composition comprises, in weight percent, 30-80% of benzyl methacrylate-methacrylic acid tetradecyl ester copolymers, 10-40% of arene oil, 5-50% of 1-methylnaphthalene and 5-30% of polar nitrogen-containing compounds. The raw materials are uniformly mixed according to predetermined weight percent to obtain the composition. The diesel pour point depressant composition can be rapidly dissolved in diesel oil, is high in spectrum and has remarkable pour point declining effect when being applied to different diesel, and a condensation point and a cold filter plugging point are reduced by 21-26 DEG C and 8-12 DEG C.

Owner:SHANGHAI INST OF TECH

Pour point depressant for crude oil

ActiveCN101735788ALower the freezing point of crude oilSatisfy depressing needsDrilling compositionDepressantMethyl group

The invention discloses a pour point depressant for crude oil. The depressant is prepared from methylnaphthalene, wherein the methylnaphthalene is 1-methylnaphthalene, any one in mixed methylnaphthalene or a mixture of 1-methylnaphthalene and mixed methylnaphthalene in any ratio; or the methylnaphthalene is a mixture prepared from 2-methylnaphthalene dissolved in 1-methylnaphthalene or mixed methylnaphthalene at normal temperature and pressure or a mixture prepared from 2-methylnaphthalene dissolved in a mixed solution of 1-methylnaphthalene and mixed methylnaphthalene in any ratio under normal temperature and pressure, and the maximum content of the 2-methylnaphthalene in the mixture is not more than the saturation concentration of the 2-methylnaphthalene in the solution at normal temperature and pressure. The invention can greatly decrease the pour point of crude oil in different oil fields, can be widely used for solving the problem of depressing the pour point of crude oil in various phases of oil recovery, gathering and storage and transportation in different oil fields, can lower the cost for depressing the pour point of crude oil, and has the advantages of less toxic and side effects, high safety, simple production, low cost, strong applicability, easy popularization and application and the like.

Owner:盘锦河升大地石油科技有限公司

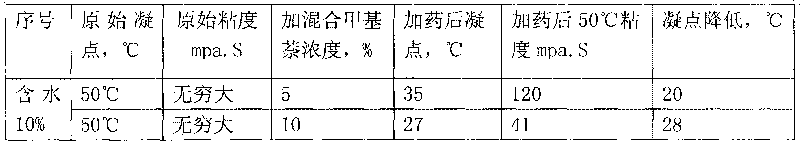

a-OLEFIN / VINYL PYRROLIDINONE COPOLYMERS AS ASPHALTENE DISPERSANTS

InactiveUS20120220807A1Prevent precipitationDistillation purification/separationHydrocarbonsPyrrolidinones1-hexadecene

An additive comprising, dissolved in a solvent, an asphaltene dispersant selected from the group consisting of α-olefin / vinyl pyrrolidinone copolymers. The copolymer can comprise at least one α-olefin selected from the group consisting of mono-α-olefins, at least one α-olefin selected from the group consisting of linear α-olefins and / or at least one α-olefin is selected from the group consisting of 1-hexadecene, 1-octadecene, 1-eicosene, 1-docosene, 1-tetracosene, 1-hexacosene, 1-octacosene and 1-triacontene. The additive can comprise a copolymer of 2-pyrrolidinone, 1-ethenyl monomer. The copolymer can have a Hansen Solubility Parameter (HSP), δ, of greater than 16, 17 or 18 MPa1 / 2. The solvent can be selected from the group consisting of aromatic solvents, such as 1-methyl naphthalene, bis-(m-phenoxyphenyl)ether, o-xylene, toluene and heavy aromatic solvents. Also provided is a method of inhibiting asphaltene precipitation in a fluid by introducing into the fluid an asphaltene dispersant selected from the group consisting of α-olefin / vinyl pyrrolidinone copolymers.

Owner:SHRIEVE CHEM PRODS

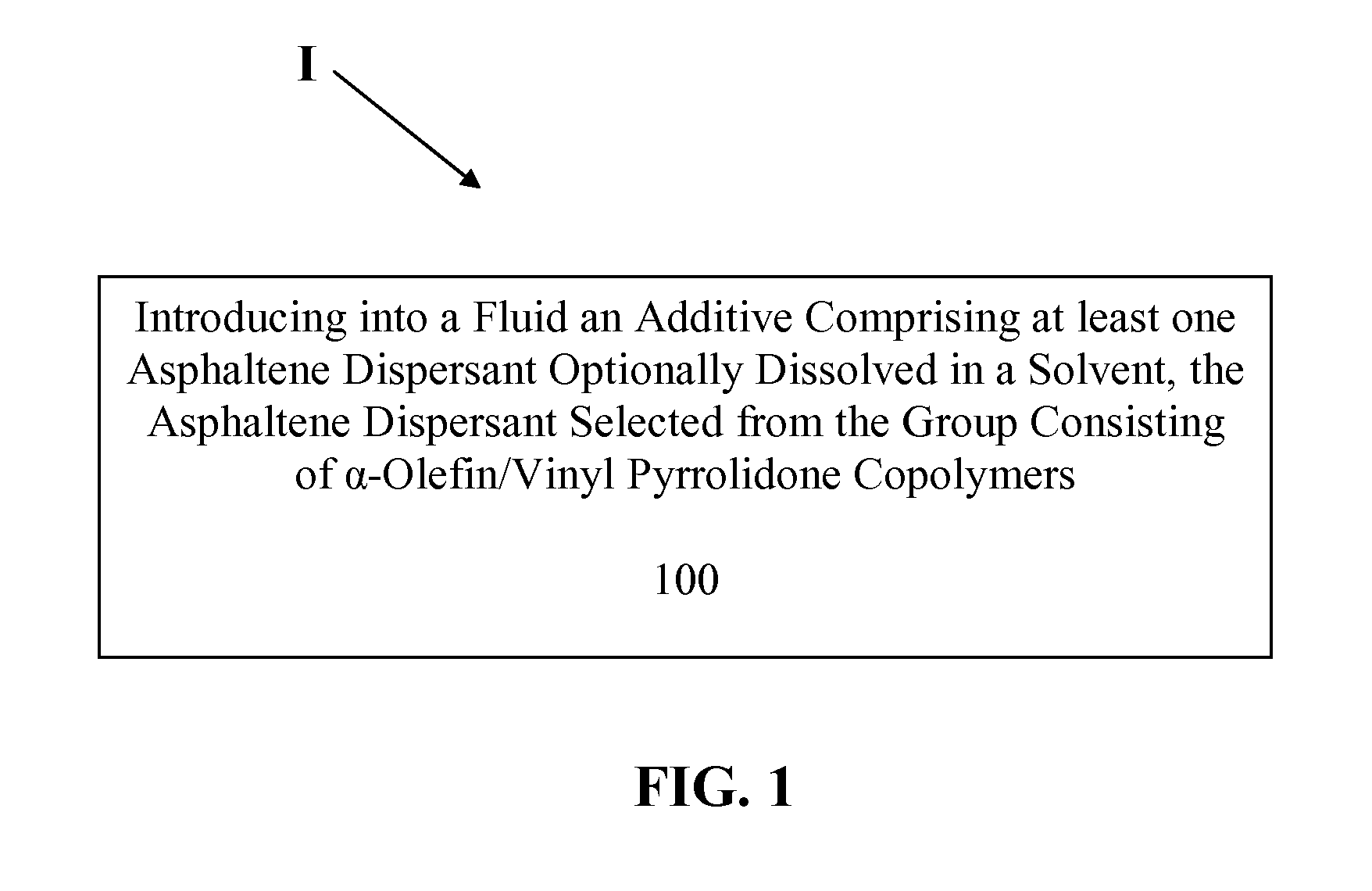

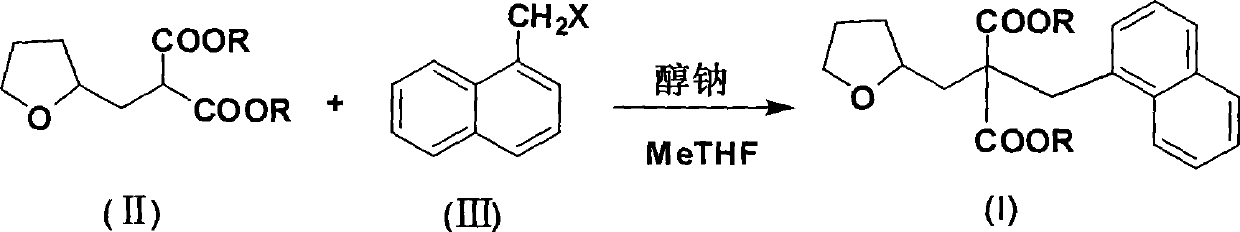

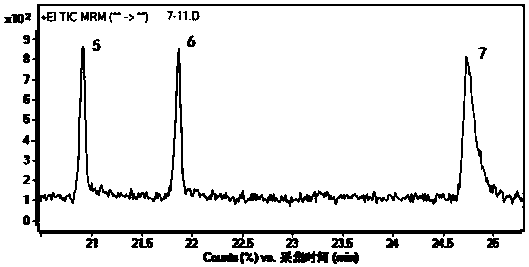

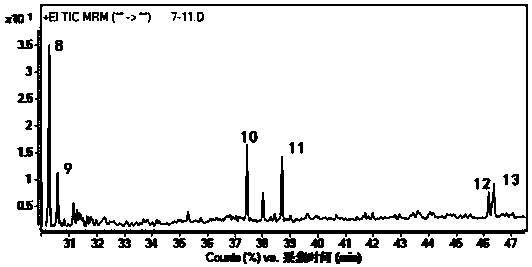

Method for detecting polycyclic aromatic hydrocarbon content in smokeless tobacco products

ActiveCN106645444AGood effectLow requirements for matrix purityComponent separationAcenaphthyleneGas chromatography–mass spectrometry

The invention discloses a method for detecting polycyclic aromatic hydrocarbon content in smokeless tobacco products. The method includes the steps: extracting the smokeless tobacco products by the aid of extraction agents; detecting filtered extraction solution by the aid of a GC-MS / MS (gas chromatography-mass spectrometry). The method can simultaneously measure content of indene, naphthalene, 1-methylnaphthalene, 2-methylnaphthalene, acenaphthylene, acenaphthene, fluorine, phenanthrene, anthracene, fluoranthene, pyrene, benzo [a] anthracene, chrysene, benzo [b] fluoranthene, benzo [k] fluoranthene, benzo [j] fluoranthene, benzo [e] pyrene, benzo [a] pyrene, perylene, indene [1, 2, 3-cd] pyrene, diphenyl [a, h] anthracene, benzo [g, h, i] pyrene and the like in the smokeless tobacco products. The method fills in gaps of the prior art and has the advantages that the method is simple, convenient and rapid in sample pretreatment, goof in detection accuracy and repeatability and high in analytical test flux, and the method is applicable to rapid analysis of large-batch samples.

Owner:YUNNAN TOBACCO QUALITY SUPERVISION MONITORING STATION

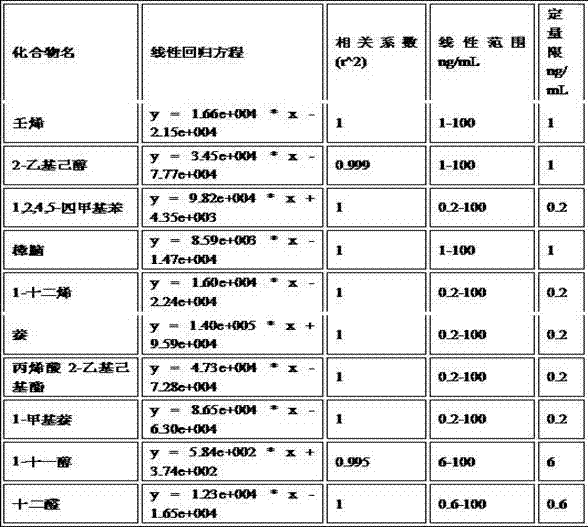

Method for determining migration quantity of volatile organic compounds in adhesive sticker for food label in water-based food simulating object

ActiveCN103575848AOvercome the disadvantage of not being able to directly enter water samplesHigh detection sensitivityComponent separationWater basedMass spectrometry detector

The invention discloses a method for determining the migration quantity of volatile organic compounds in an adhesive sticker for a food label in a water-based food simulating object. The method comprises the following steps: performing a direct or indirect migration test on the adhesive sticker for the food label through a water-based food simulating solution; sampling the water-based food simulating solution through purging and trapping; separating 10 volatile organic compounds through HP-5ms or chromatographic columns with similar properties; performing detection through a mass spectrometry detector; performing quantification through an external standard method, wherein the 10 volatile organic compounds include nonene, 2-ethylhexanol, 1,2,4,5-tetramethylbenzene, camphor, 1-dodecene, naphthalene, 2-ethylhexyl acrylate, 1-methylnaphthalene, 1-undecanol and dodecyl aldehyde. The method is accurate in test, easy to operate, high in efficiency, quick, high in sensitivity and high in practicality, is applicable to qualitative and quantitative determination on the volatile organic compounds in the adhesive sticker for the food label through a manufacturing enterprise of the adhesive sticker for the food label and relevant government supervision departments, and can be used for avoiding harm to the physical health of a consumer caused by over-large migration quantity of the volatile organic compounds.

Owner:厦门佰能检验技术服务有限公司

Method for simultaneously detecting content of 22 polycyclic aromatic hydrocarbon matters in cigarette smoke

ActiveCN106248835AGood effectLow requirements for matrix purityComponent separationAcenaphthyleneTrapping

The invention discloses a method for simultaneously detecting content of 22 polycyclic aromatic hydrocarbon matters in cigarette smoke. The method comprises the following steps: trapping total particular matters in cigarette main stream smoke by adopting a filter; extracting the trapping filter by utilizing an extraction agent; and detecting the filtered extract liquor by adopting gas chromatography-tandem mass spectrum (GC-MS / MS), and simultaneously detecting the contents of 22 polycyclic aromatic hydrocarbon matters, including indene, naphthalene, 1-methylnaphthalene, 2-methylnaphthalene, acenaphthylene, acenaphthene, fluorene, phenanthrene, anthracene, fluoranthene, pyrene, benzo [a] anthracene, chrysene, benzo [b] fluoranthene, benzo [k] fluoranthene, benzo [j] fluoranthene, benzo [e] pyrene, benzo [a] pyrene, perylene, indene [1,2,3-cd] perylene, dibenzo [a, h] anthracene, benzo [g, h, i] pyrene, and the like, in cigarette main stream smoke. The method fills the blank of the prior art, has the characteristics of simple, convenient and quick sample pretreatment, high detection accuracy and repeatability and large analysis test flux and is fit for quick analysis of mass samples.

Owner:YUNNAN TOBACCO QUALITY SUPERVISION MONITORING STATION

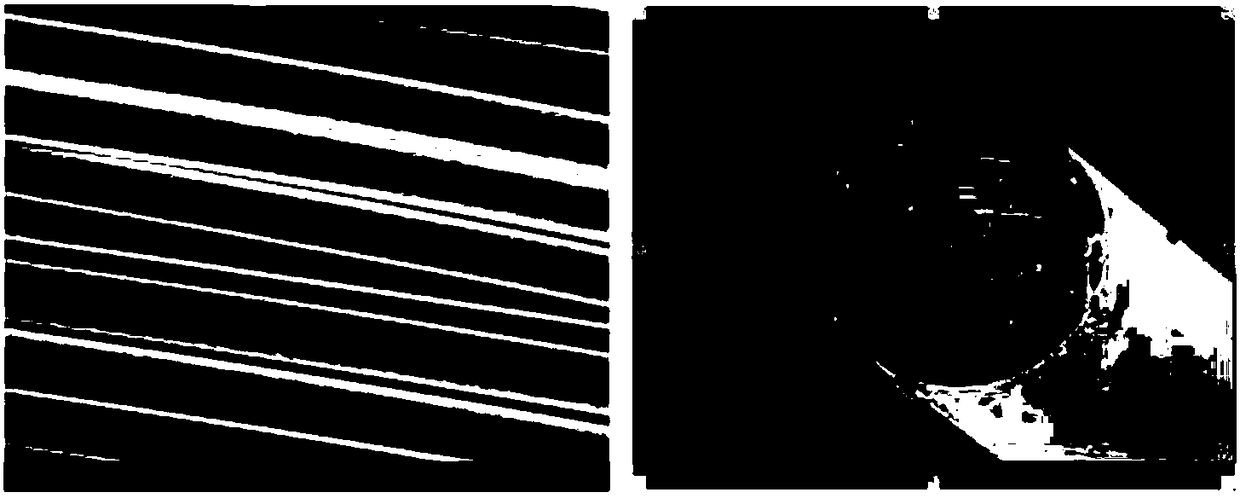

Preparation method of high-strength coal series isotropic asphalt base carbon fiber

ActiveCN108560082AExcellent performance indexImprove performanceFibre chemical featuresCarbon fibersEvaporation

The invention discloses a production method of a high-strength coal series isotropic asphalt base carbon fiber. The production method comprises the following steps: taking ashless coal as an asphalt precursor, removing volatile components of the ashless coal by adopting a thin layer evaporation method, and controlling a softening point of asphalt at a temperature of 180 to 260 DEG C to obtain spinning alphalt; then obtaining a carbon fiber by a melt spinning technology, a preoxidizing technology, a carbonization technology and the like; mixing coal with 1-methylnaphthalene according to the ratio of 1-2 to 1-10, carrying out solvent extraction reaction at the temperature of 350 to 410 DEG C and the pressure of 1 to 5MPa, and then carrying out solid-liquid separation, hot press filtering andsolvent recovery to obtain the ashless coal; finally, preparing the carbon fiber of the ashless coal by the melt spinning technology, the preoxidizing technology, the carbonization technology and thelike. According to the production method disclosed by the invention, coal is used as a raw material for producing a general asphalt base carbon fiber with excellent performance indexes; tensile strength of the general asphalt base carbon fiber is as high as 1500MPa; the general asphalt base carbon fiber has a broader market prospect and economic benefits.

Owner:HUNAN UNIV

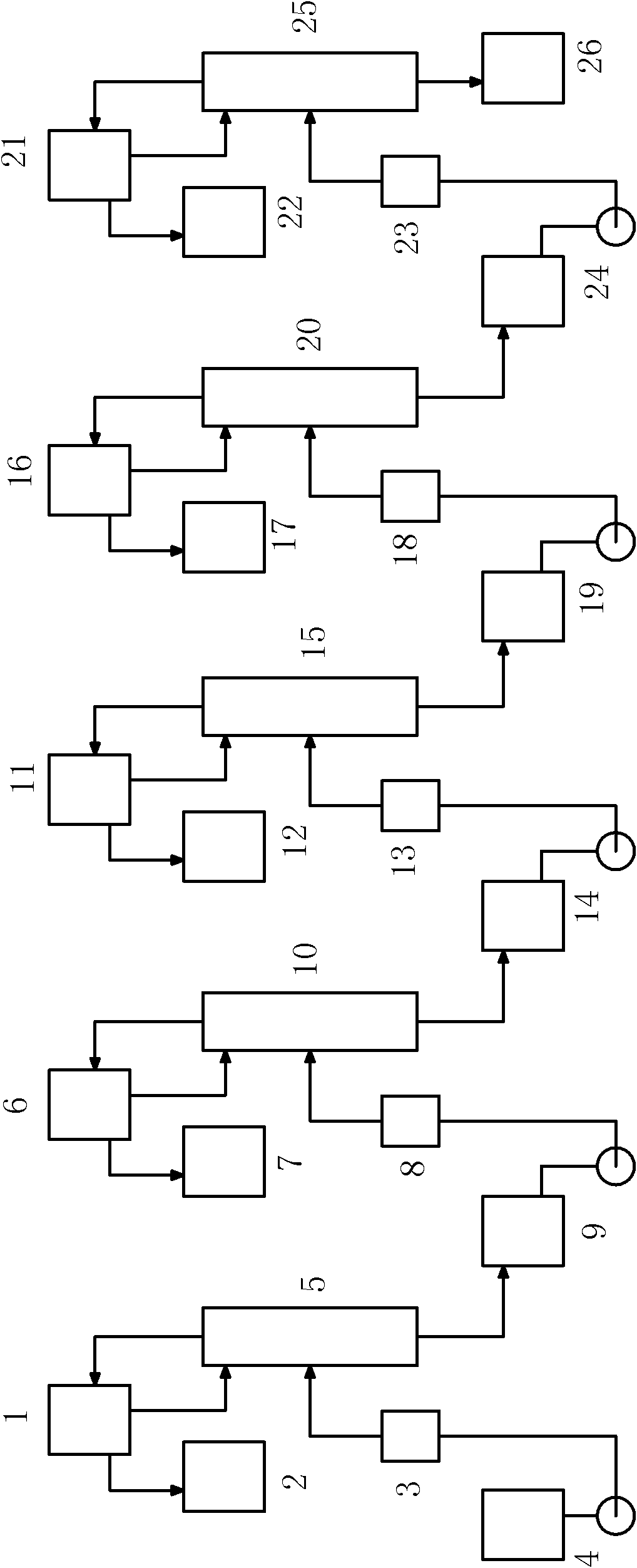

Method for extracting naphthalene, 1-methylnaphthalene and 2-methylnaphthalene from ethylene tar

ActiveCN102134500AIncrease contentImprove protectionTar working-up by distillationBenzeneBoiling point

The invention discloses a method for extracting naphthalene, 1-methylnaphthalene and 2-methylnaphthalene from ethylene tar. The method comprises the following steps of: adding ethylene cracking tar with the total content of naphthalene and methylnaphthalene of not less than 30 percent from the middle of a first rectifying tower (5) under certain conditions; recovering materials of which light components are removed by the first rectifying tower at the bottom of the tower; adding from the middle of a second rectifying tower (10), and obtaining the naphthalene with the purity of not less than 95 percent on the top of the tower; adding the materials of which the naphthalene is removed at the bottom of the second rectifying tower from the middle of a third rectifying tower (15), and removing tetramethyl benzene and other components of which the boiling point is lower than that of the 2-methylnaphthalene at the top of the tower; recovering the materials of which the light fraction is removed by the third rectifying tower at the bottom of the tower, adding from the middle of a fourth rectifying tower (20), and obtaining the 2-methylnaphthalene with the purity of not less than 98 percenton the top of the tower; and recovering the materials of which the 2-methylnaphthalene is removed by the fourth rectifying tower at the bottom of the tower, adding from the middle of a fifth rectifying tower (25), and obtaining the 1-methylnaphthalene with the purity of not less than 98 percent. By the method, wastewater and waste residue are not generated and extraction efficiency is high.

Owner:广东新华粤石化集团股份公司 +2

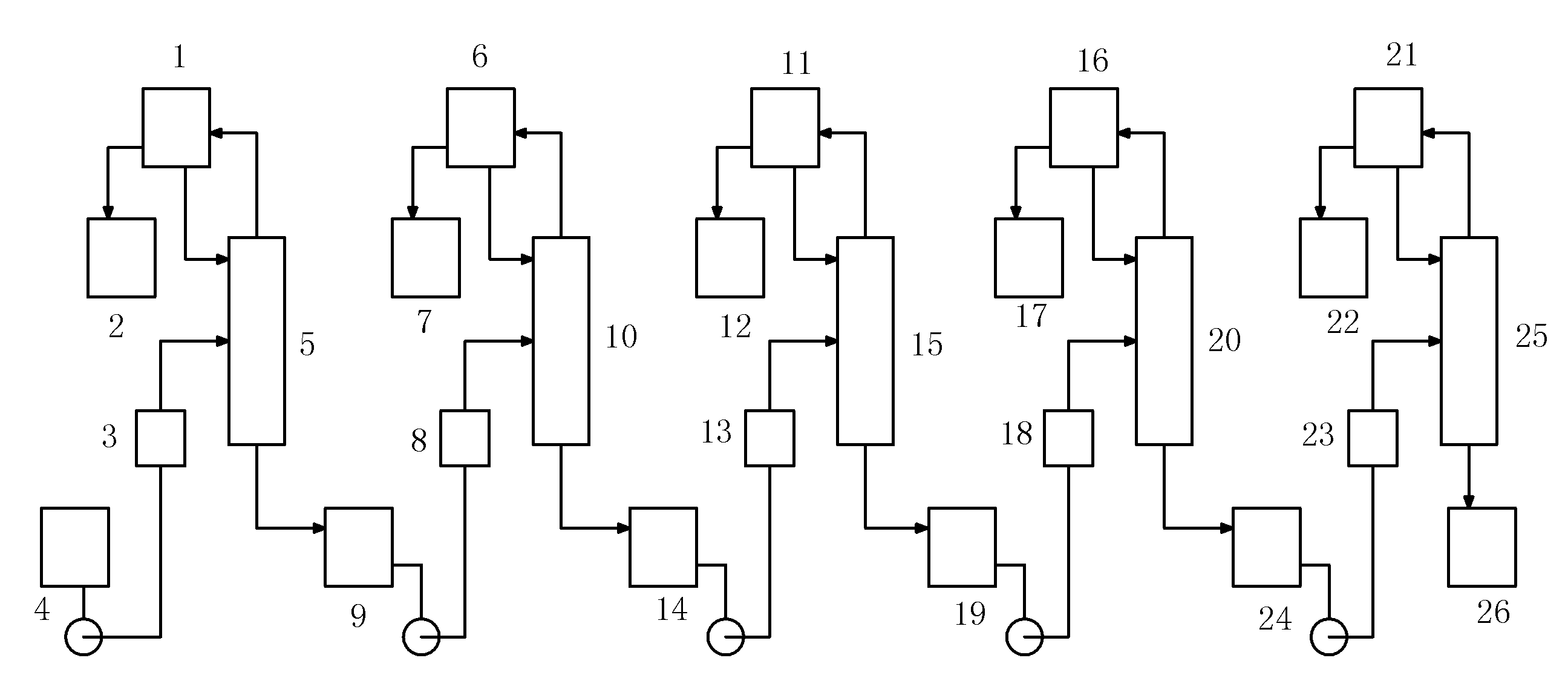

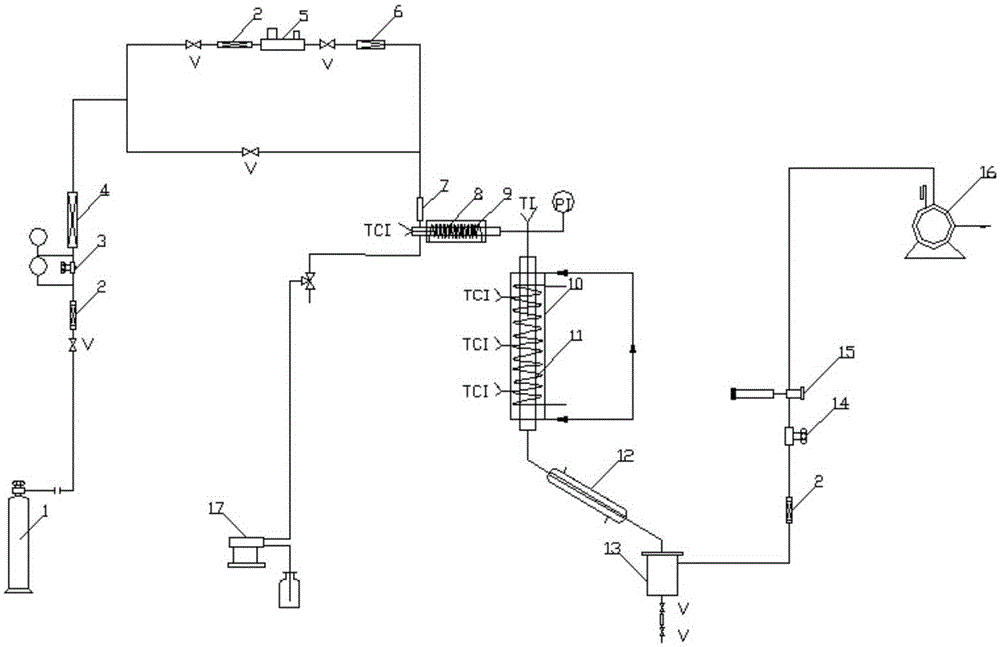

Preparation method of modified Beta molecular sieve catalyst and application thereof

InactiveCN105396612ALarge specific surface areaEasy to makeHydrocarbon by isomerisationMolecular sieve catalystsMolecular sieveIsomerization

The invention discloses a preparation method of a titanous sulfate modified Beta molecular sieve catalyst and application thereof. The method comprises the following steps: (1) putting a roasted and activated Beta molecular sieve into a hydrothermal kettle; (2) preparing a titanous sulfate solution with the mole concentration of 0.1-0.3mol / l; (3) soaking the Beta molecular sieve completely in the titanous sulfate solution at constant temperature and constant pressure, carrying out vacuum drying, and roasting so as to prepare the modified Beta molecular sieve catalyst. The catalyst disclosed by the invention is applied to isomerization and disproportionation of 1-methylnaphthalene; the conversion rate of 1-methylnaphthalene is about 60%, and the selectivity of active products (2-methylnaphthalene, naphthalene and dimethylnaphthalene) is not less than 98%; the modified Beta molecular sieve catalyst can be synthesized by a one-step process; the technology is simple, and the preparation method is suitable for large-scale industrial production; the prepared catalyst can be used for multiple times repeatedly, is high in catalytic activity and selectivity, is long in service life, and is low in cost.

Owner:NANJING NORMAL UNIVERSITY

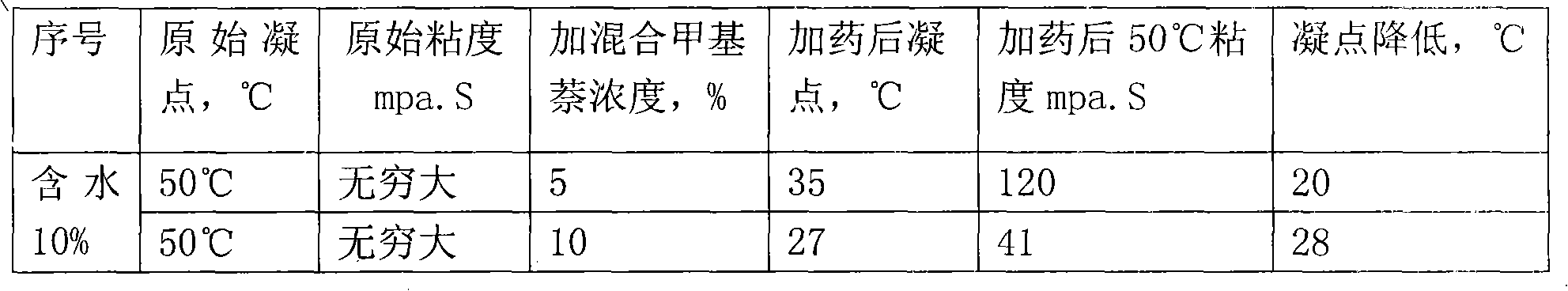

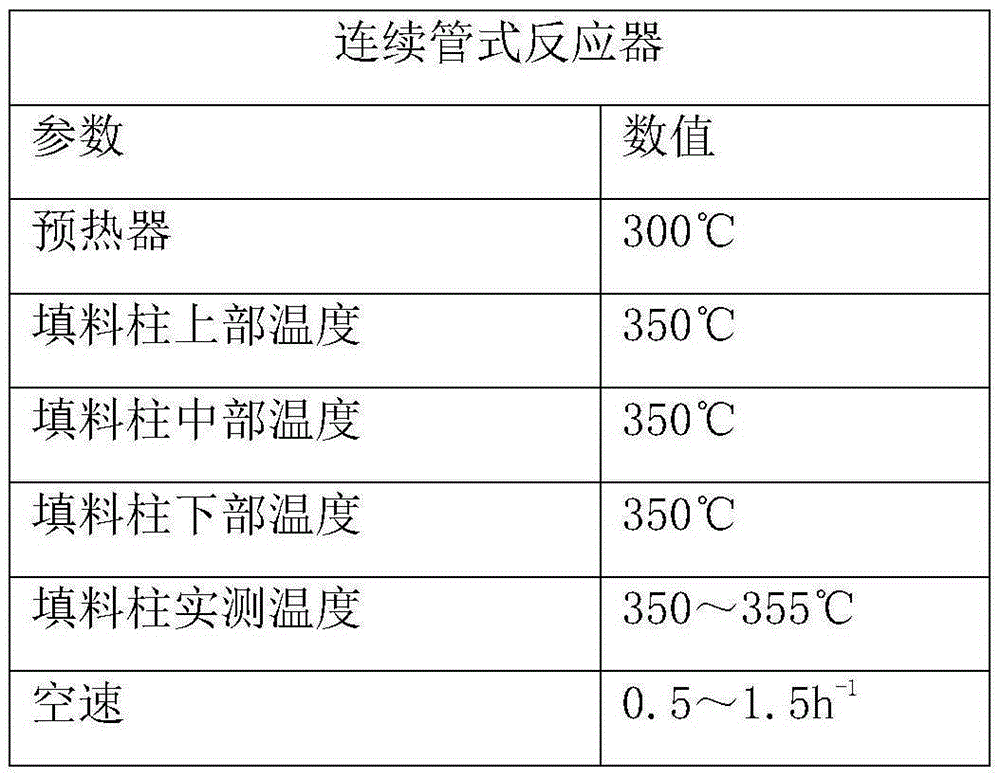

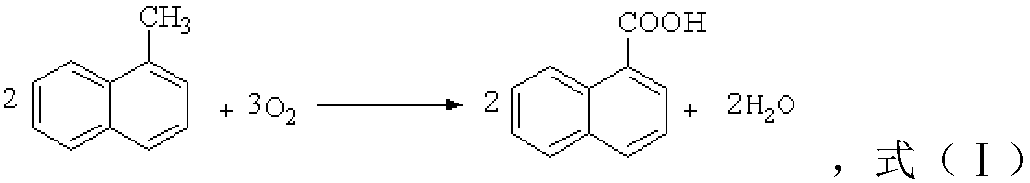

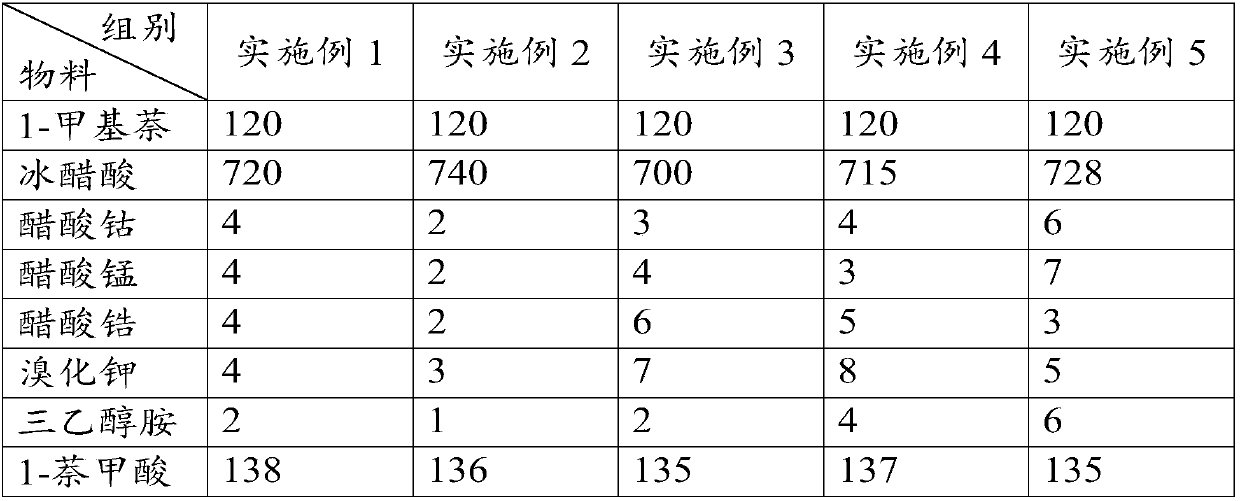

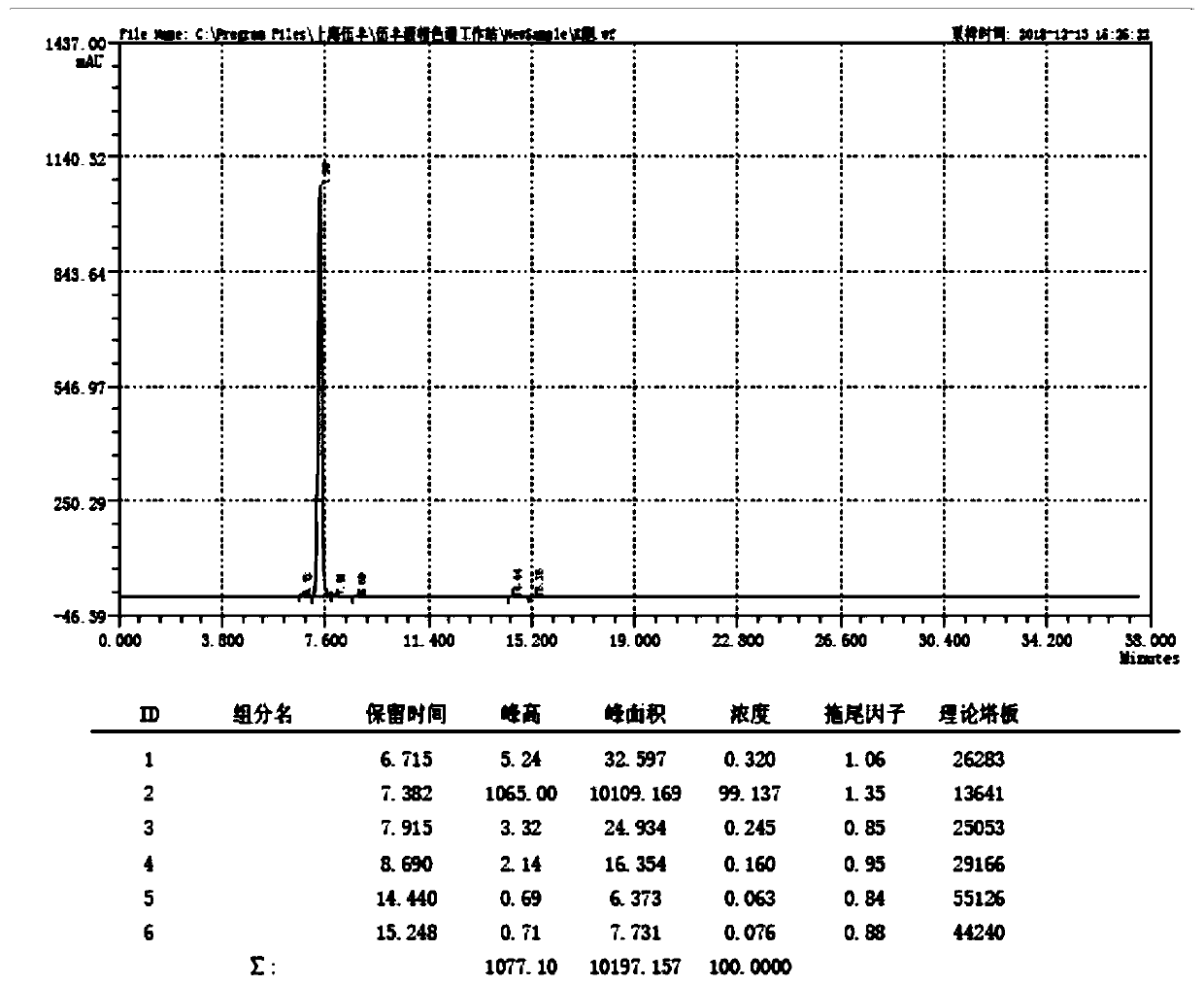

Composition, reaction system and method for preparing 1-naphthoic acid

InactiveCN107586258AReduce pollutantsSimple processOrganic compound preparationCarboxylic compound preparationChemical industryMANGANESE ACETATE

The invention provides a composition, a reaction system and a method for preparing 1-naphthoic acid, and belongs to the field of chemical industry. The composition is characterized in that 1-methylnaphthalene is treated as an initiator, and methyl of 1-methylnaphthalene is oxidized as carboxyl to be used for preparing 1-naphthoic acid, wherein the composition comprises glacial acetic acid, cobaltacetate, manganese acetate, zirconium acetate, potassium bromide and triethanolamine. The method for preparing 1-naphthoic acid is simple in processes, high in yield, small in production period, and low in pollution in process.

Owner:黄石市利福达医药化工有限公司

Method for purifying 4-acetyl-1-methyl naphthalene in acetyl methyl naphthalene mixture

ActiveCN109761775AHigh purityHigh yieldCarbonyl compound separation/purificationNaphthaleneCrystallization

The invention relates to a method for purifying 4-acetyl-1-methyl naphthalene in an acetyl methyl naphthalene mixture. The melting point difference between 4-acetyl-1-methyl naphthalene and other acetyl methyl naphthalene is adopted to obtain the 4-acetyl-1-methyl naphthalene with high purity. The acetyl methyl naphthalene mixture is put into a melting crystallization device, and the temperature is reduced from normal temperature to 10-15 DEG C, a mother solution without crystallization is released, and then the crystallized solid is started to heat up and sweat from 10-15 DEG C, the sweatingtemperature is 15-37 DEG C, after the end point of sweating is reached, sweating is stopped, and sweat is discharged; and finally, the crystalline solid in the melting crystallization device is heatedand melted to obtain the 4-acetyl-1-methyl naphthalene. According to the method for purifying the 4-acetyl-1-methyl naphthalene in the acetyl methyl naphthalene mixture, under the condition of not reducing the productive rate, the 4-acetyl-1-methyl naphthalene with the purity larger than 99.0% is obtained, and the operation is easy to operate.

Owner:湖北海力环保科技股份有限公司

Process for extracting 1-methylnaphthalene and 2-methylnaphthalene from tar

InactiveCN100393677CSimple processEasy to automateDistillation purification/separationAlkyl transferDistillation

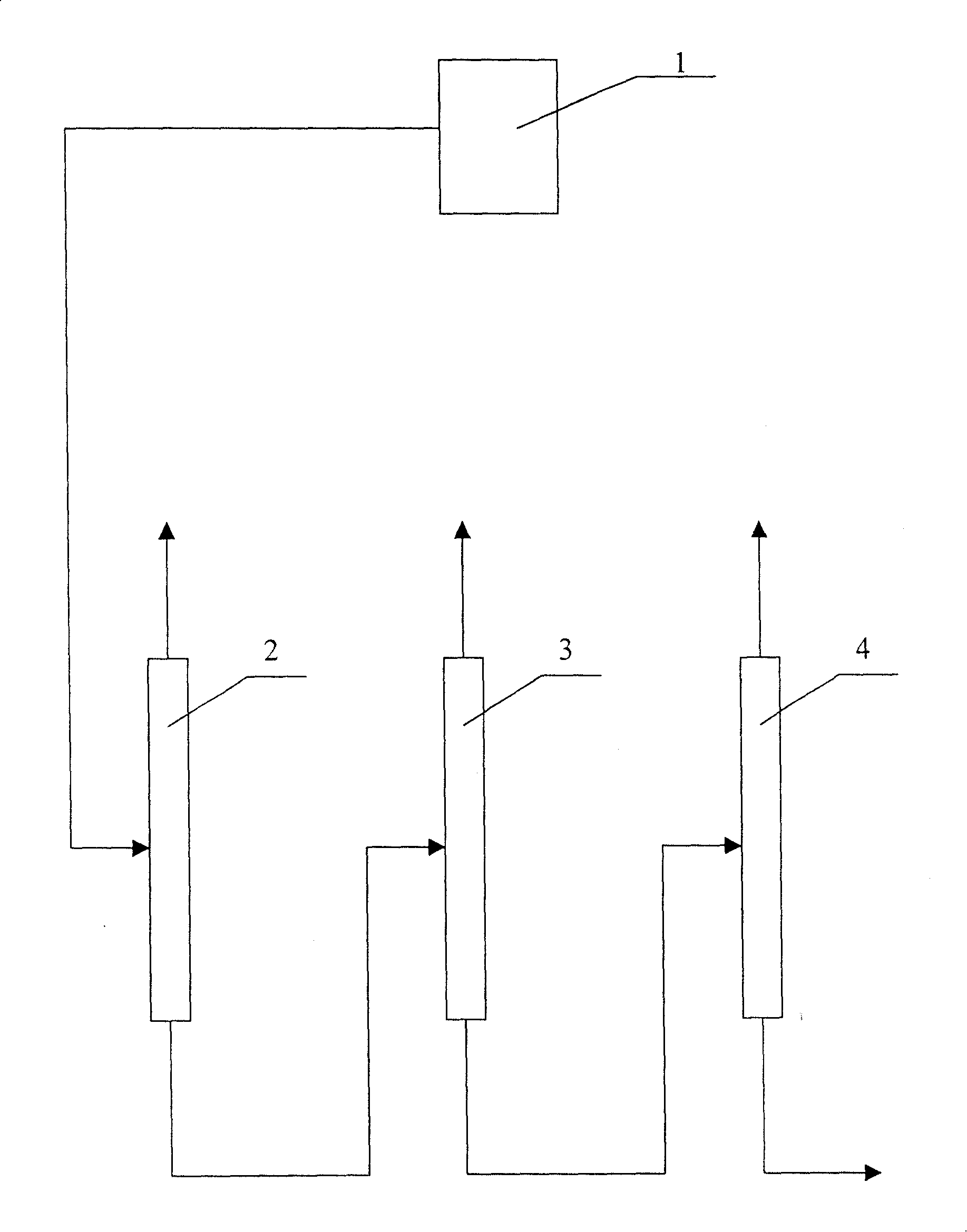

The method of extracting 1-methyl naphthalene and 2-methyl naphthalene from tar includes adopting the production apparatus comprising one alkylating polymerization reactor and three serially connected rectification towers, and the production process, which comprises the alkylating polymerization reaction of material with methyl naphthalene content not lower than 60 %, solid acid and / or liquid acid catalyst and alkylation agent in 70-90 deg.c and 95-115 deg.c separately; the separation of the alkylating polymerization product in the first rectification tower to eliminate light distillation fraction from the tower top; the further separation in the second rectification tower to obtain 2-methyl naphthalene of 95 % over purity from the tower top; and the further separation in the third rectification tower to obtain 1-methyl naphthalene of 95 % over purity from the tower top. The present invention makes it possible to treat both tar scrubbing oil and coal tar scrubbing oil in the same apparatus.

Owner:TIANJIN UNIV

Method for reducing content of impurities in 2-methylnaphthalene

ActiveCN101575262AQuality improvementHigh recovery rateCrystallisation purification/separationMetallurgyCoal tar

The invention discloses a method for reducing the content of impurities in 2-methylnaphthalene. 2-methylnaphthalene which is extracted from coal tar and has the content not lower than 96 percent is used as the raw material. A melt crystallization method is adopted, and the method comprises the following steps: (1) adding the 2-methylnaphthalene raw material in a crystallizer, and gradually raising the temperature of the 2-methylnaphthalene raw material by heating and raising the temperature of the crystallizer to 60-70 DEG C so that the 2-methylnaphthalene raw material in the crystallizer is thoroughly melted;(2) slowly lowering the temperature of the 2-methylnaphthalene raw material after the 2-methylnaphthalene raw material in the crystallizer is thoroughly melted, and cooling the crystallizer to 30-31 DEG C, wherein the whole cooling crystallization process lasts for 3-4.5h; and (3) discharging substances which are not crystallized in the crystallizer, wherein the remaining crystal is the purified 2-methylnaphthalene. The method can effectively reduce the content of such impurities as 1-methylnaphthalene, indole, 2-methyldibenzothiophene, 5-methyldibenzothiophene, and the like in the 2-methylnaphthalene, achieves higher recovery rate and is clean and environment-friendly.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD

Method used of high efficiency separation and purification of 1-methylnaphthalene

ActiveCN109289930AEasy to operateLow equipment requirementsOrganic-compounds/hydrides/coordination-complexes catalystsDistillation purification/separationDistillationFractionation

The invention discloses a method used for high efficiency separation and purification of 1-methylnaphthalene. The method comprises following steps: firstly, magnesium-based hydrotalcite is taken as araw material, polyethylene glycol is adopted for surface modification, sodium ethylene diamine tetracetate and zinc chloride are added for modification so as to obtain a catalyst; naphthalene oil fractions are subjected to sulphur removing and primary distillation, and 230 to 270 DEG C fractions are collected, the catalyst is added into the collected fractions for reaction, and an obtained filtrate is collected; the filtrate is subjected to intermittent vacuum rectification, and 237 to 241 DEG C crystallizable fractions and 241 to 245 DEG C noncrystallizable fractions are collected; the collected crystallizable fractions are refrigerated to -10 to -20 DEG C, and are subjected to centrifugation processing, and an obtained filtered solution is collected; the filtered solution and the noncrystallizable fractions are mixed, and are washed with concentrated sulfuric acid with a mass concentration of 95 to 98%, alkali neutralization is carried out, washing and removing of water are carried out, fractionation is carried out in a distillation column, and 241 DEG C lower fractions are collected, and are subjected to low temperature refrigeration to remove crystals so as to obtain 1-methylnaphthalene. The method is simple in operation, and high in product yield and purity.

Owner:PENG CHEN NEW MATERIALS TECH CO LTD

Application of methylnaphthalene in lowering viscosity of thickened oil

ActiveCN101717626BEfficient developmentGood viscosity reductionFluid dynamicsFluid removalHigh surfaceOil viscosity

Owner:盘锦河升大地石油科技有限公司

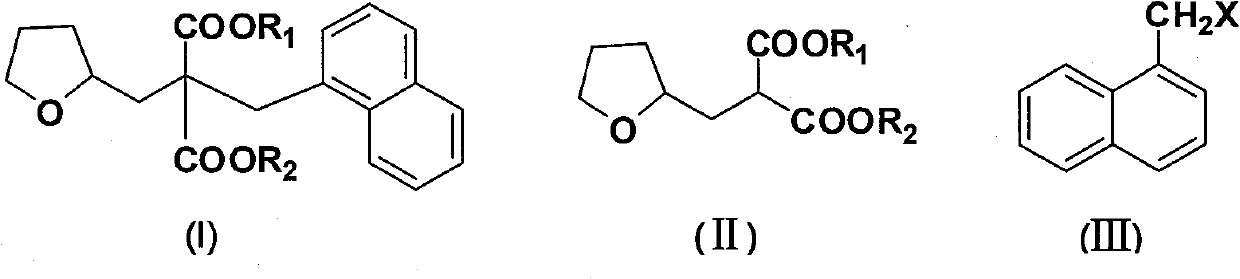

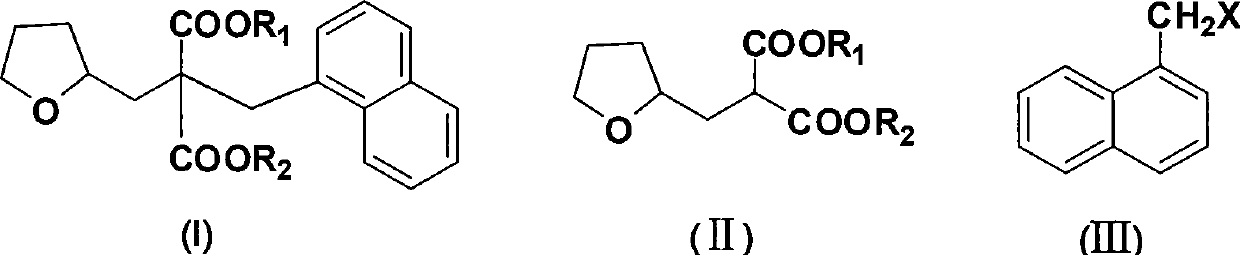

Synthetic method of diethyl naphthylmethyl-tetrahydrofurfurylmalonate

Owner:浙江清和新材料科技有限公司

Method for simultaneous detection of 22 kinds of polycyclic aromatic hydrocarbons in cigarette smoke

ActiveCN106248835BLow requirements for matrix purityGood choiceComponent separationAcenaphthyleneTrapping

Owner:YUNNAN TOBACCO QUALITY SUPERVISION MONITORING STATION

Method for reducing content of impurities in 2-methylnaphthalene

ActiveCN101575262BQuality improvementHigh recovery rateCrystallisation purification/separationMetallurgyCoal tar

The invention discloses a method for reducing the content of impurities in 2-methylnaphthalene. 2-methylnaphthalene which is extracted from coal tar and has the content not lower than 96 percent is used as the raw material. A melt crystallization method is adopted, and the method comprises the following steps: (1) adding the 2-methylnaphthalene raw material in a crystallizer, and gradually raising the temperature of the 2-methylnaphthalene raw material by heating and raising the temperature of the crystallizer to 60-70 DEG C so that the 2-methylnaphthalene raw material in the crystallizer is thoroughly melted;(2) slowly lowering the temperature of the 2-methylnaphthalene raw material after the 2-methylnaphthalene raw material in the crystallizer is thoroughly melted, and cooling the crystallizer to 30-31 DEG C, wherein the whole cooling crystallization process lasts for 3-4.5h; and (3) discharging substances which are not crystallized in the crystallizer, wherein the remaining crystal is the purified 2-methylnaphthalene. The method can effectively reduce the content of such impurities as 1-methylnaphthalene, indole, 2-methyldibenzothiophene, 5-methyldibenzothiophene, and the like in the 2-methylnaphthalene, achieves higher recovery rate and is clean and environment-friendly.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD

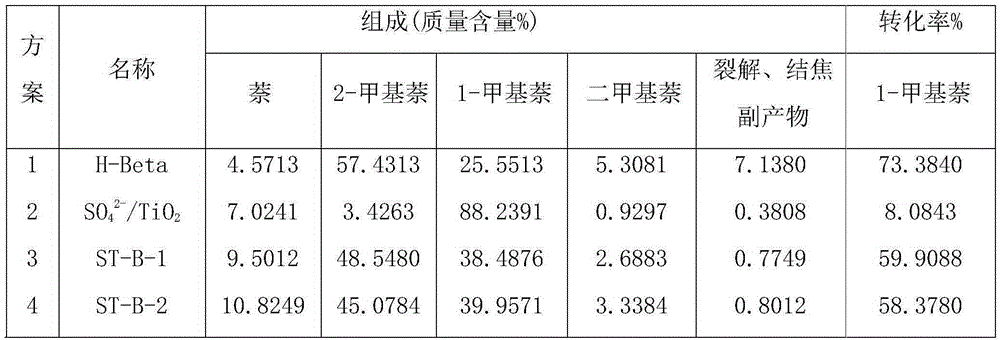

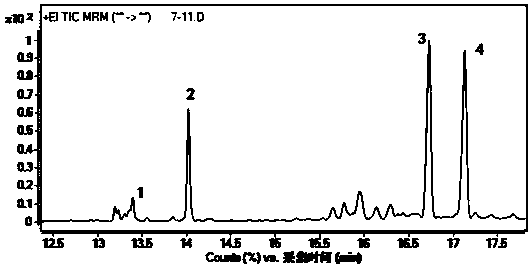

1-methyl-4[4-(n,n-p-methylphenyl amido)styryl]naphthyl and method of manufacturing the same and application thereof

InactiveCN100596295CEasy to manufactureMild reaction conditionsAmino preparation from aminesSolid-state devicesTriethylphosphitePhosphoric acid

The invention discloses a 1- methyl-4-[4-(N, N-p-Methyl-phenyl-amino) styryl] naphthol and the preparation method and application, which belongs to the technology field of photoelectric materials. Thestructural formula of the component refers to the drawing and the preparation process of the component comprises that: 1-methylnaphthalene reacts with paraformaldehyde and hydrochloric acid under thecatalysis of the phosphoric acid to prepare 1- methyl-4-chloromethyl naphthalene and then reacts with triethyl phosphate to prepare the wittig reagent; the produced wittig reagent reacts with 4-(N, N-2 p-Methyl-phenyl-amino) aminotenzaldehyde under the action of alkali to gain the starting material. The component mixes with bisphenol A Pc resin or bisphenol Z Pc resin to prepare the hole-transporting layer thin film of the organic photoconductor of function separated type. The invention has moderate reaction conditions and has high photosensitivity of the organic photoconductor appliance as the hole-transporting material.

Owner:TIANJIN UNIV

1-methyl-4[4-(n,n-p-methylphenyl amido)styryl]naphthyl and method of manufacturing the same and application thereof

InactiveCN101108808AEasy to manufactureMild reaction conditionsAmino preparation from aminesSolid-state devicesTriethylphosphitePhosphoric acid

The invention discloses a 1- methyl-4-[4-(N, N-p-Methyl-phenyl-amino) styryl] naphthol and the preparation method and application, which belongs to the technology field of photoelectric materials. The structural formula of the component refers to the drawing and the preparation process of the component comprises that: 1-methylnaphthalene reacts with paraformaldehyde and hydrochloric acid under the catalysis of the phosphoric acid to prepare 1- methyl-4-chloromethyl naphthalene and then reacts with triethyl phosphate to prepare the wittig reagent; the produced wittig reagent reacts with 4-(N, N-2 p-Methyl-phenyl-amino) aminotenzaldehyde under the action of alkali to gain the starting material. The component mixes with bisphenol A Pc resin or bisphenol Z Pc resin to prepare the hole-transporting layer thin film of the organic photoconductor of function separated type. The invention has moderate reaction conditions and has high photosensitivity of the organic photoconductor appliance as the hole-transporting material.

Owner:TIANJIN UNIV

Crude oil pour-point depressant

InactiveCN104694098ALowering the freezing pointLower pour point depressing costsPipeline systemsDrilling compositionDepressantMethyl group

The invention discloses a crude oil pour-point depressant, which is composed of methylnaphthalene. The methylnaphthalene is one of 1-methylnaphthalene' and mixed methylnaphthalene' or a mixture of 1-methylnaphthalene' and mixed methylnaphthalene' according to any proportion; or the methylnaphthalene is a mixture of 2-methylnaphthalene dissolved in 1-methylnaphthalene or mixed methylnaphthalene' under normal temperature and normal pressure, or a mixture of 2-methylnaphthalene dissolved in 1-methylnaphthalene or mixed methylnaphthalene' according to any proportion under normal temperature and normal pressure, and highest content of 2-methylnaphthalene in the mixture is less than saturation concentration of 2-methylnaphthalene in a solution under normal temperature and normal pressure. The crude oil pour-point depressant can greatly reduce the crude oil condensation points of different oil fields, can widely used for solving the crude oil pour point reduction problem of oil extraction, gathering and transportation, and storage and transportation phases of different oil fields, can reduce the crude oil pour point reduction cost, and has the beneficial effects of little toxic and side effect, high security, simple production, low cost, strong applicability, and easy popularization and application.

Owner:QINGDAO HUICHENG PETROCHEM TECH

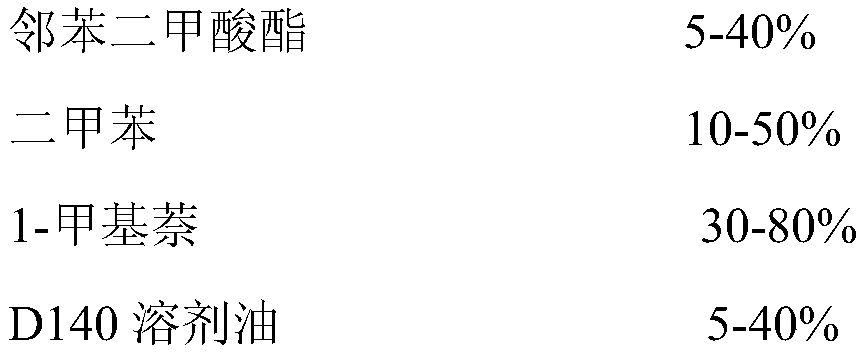

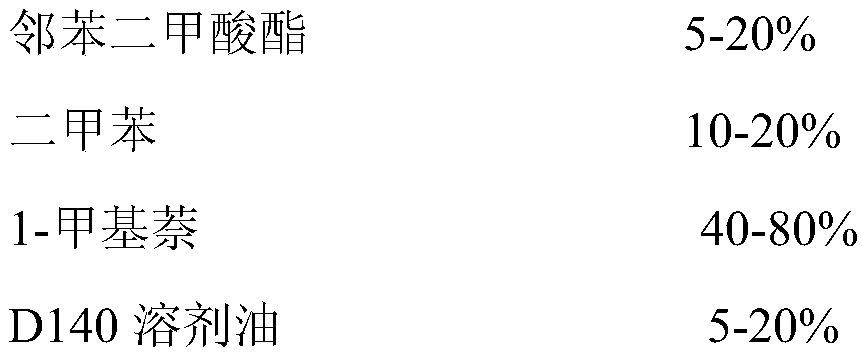

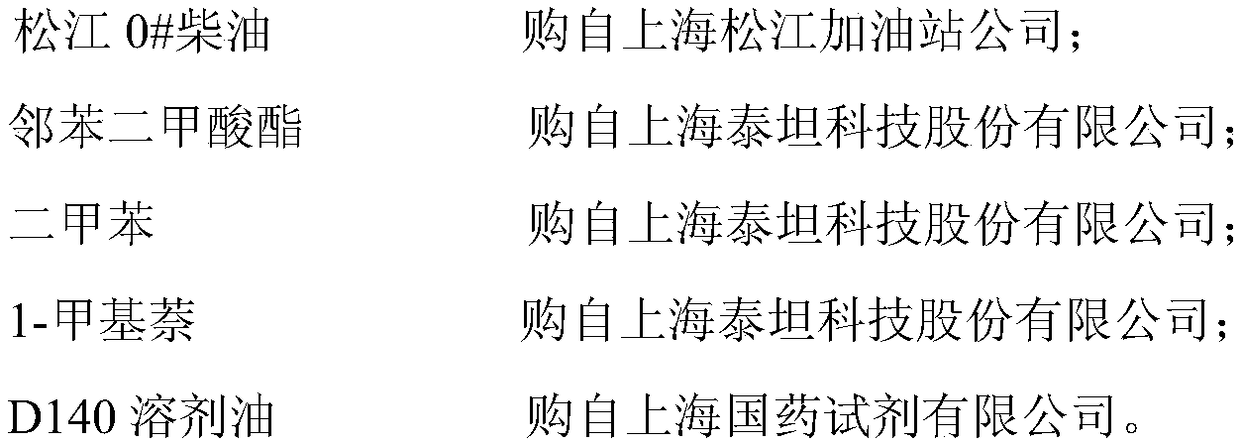

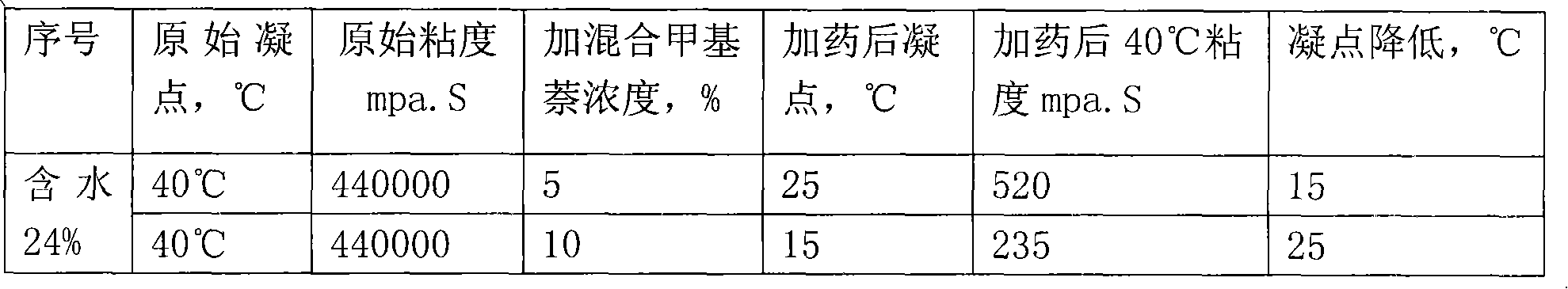

Diesel oil pour point depressant cosolvent composition and preparation method thereof

ActiveCN109135848AImprove solubilityImprove ease of useLiquid carbonaceous fuelsFuel additivesSolubilityDispersity

The invention discloses a diesel oil pour point depressant cosolvent composition and a preparation method thereof. The cosolvent composition comprises, by mass percentage, 5-40% of phthalate, 10-50% of xylene, 30-80% of 1-methylnaphthalene and 5-40% of D140 solvent oil. The cosolvent composition is prepared by evenly mixing the components above according to the proportion. The cosolvent composition can effectively enhance the solubility and dispersity of a pour point depressant in diesel oil. When the composition is used along with the pour point depressant, the pour point depressant can be evenly dispersed into the diesel oil in short time without heating. By the composition, the pour point lowering effect of the equivalent pour point depressant is further enhanced on the basis that the cost of the pour point depressant is lowered and the use convenience of the pour point depressant is increased.

Owner:SHANGHAI INST OF TECH

Pour point depressant for crude oil

ActiveCN101735788BImprove pour point depressing effectLowering the freezing pointDrilling compositionDepressantMethyl group

The invention discloses a pour point depressant for crude oil. The depressant is prepared from methylnaphthalene, wherein the methylnaphthalene is 1-methylnaphthalene, any one in mixed methylnaphthalene or a mixture of 1-methylnaphthalene and mixed methylnaphthalene in any ratio; or the methylnaphthalene is a mixture prepared from 2-methylnaphthalene dissolved in 1-methylnaphthalene or mixed methylnaphthalene at normal temperature and pressure or a mixture prepared from 2-methylnaphthalene dissolved in a mixed solution of 1-methylnaphthalene and mixed methylnaphthalene in any ratio under normal temperature and pressure, and the maximum content of the 2-methylnaphthalene in the mixture is not more than the saturation concentration of the 2-methylnaphthalene in the solution at normal temperature and pressure. The invention can greatly decrease the pour point of crude oil in different oil fields, can be widely used for solving the problem of depressing the pour point of crude oil in various phases of oil recovery, gathering and storage and transportation in different oil fields, can lower the cost for depressing the pour point of crude oil, and has the advantages of less toxic and side effects, high safety, simple production, low cost, strong applicability, easy popularization and application and the like.

Owner:盘锦河升大地石油科技有限公司

A method for preparing bio-oil and soil conditioner by microwave-assisted catalytic fast pyrolysis sludge

ActiveCN105087036BIncrease contentImprove fertilitySludge treatment by pyrolysisByproduct vaporizationLiquid productSludge

The invention relates to a method for quickly pyrolyzing sludge to prepare bio-oil and a soil improver by microwave assisted catalysis. The method comprises the following steps: (1) weighing silicon carbide spherical particles and a HZSM-5 spherical catalyst in a mass ratio of 1: 1 to 1: 2, and uniformly mixing and adding the mixture into a quartz reaction kettle; (2) putting the quartz reaction kettle in a microwave splitting instrument, heating the quartz reaction kettle to 450-600 DEG C, stirring the mixture at a rate of 60-100 r / minute, gradually adding dried sludge powder into the quartz reaction kettle and condensing the generated steam to obtain a brown liquid product bio-oil, and collecting solid residues as the soil improver. The method provided by the invention is simple in process and quick to split, and the obtained split fuel is high in hydrocarbon content which can reach over 55%. The obtained split fuel comprises important chemical raw materials such as naphthalene, p-xylene, 1,3,5-trimethylbenzene, 1-methylnaphthalene, indene and the like. The obtained solid residues are very high in content of P, Ca, K and Mg and can be used as the soil improver to improve the soil fertility.

Owner:NANCHANG UNIV

A kind of cyanide-free silver plating solution additive

The invention relates to a cyanide-free silver plating solution additive which comprises the following components by ratio: 0.1-10g / l of brightener, 5-10g / l of leveling agent, 100-600g / l of complexing agent and the balance of plasma water, wherein the brightener is one or mixture of more in nitrogen-containing compound, triazole, benzotriazole, 2-hydroxypyridine, pyridine, 22 dipyridyl, 1, 10-phenanthroline, triethylene tetramine and diethylene triamine according to any ratio; the leveling agent is one or mixture of more in aromatic hydrocarbon compounds, naphthalene, 1-methylnaphthalene, 1, 4-naphthoquinone and 1-naphthol according to any ratio; the complexing agent is one or mixture of more in disodium ethylenediamine tetraacetate, niacin, aminosulfonic acid and potassium pyrophosphate according to any ratio. The cyanide-free silver plating solution additive has the beneficial effects that the plating solution is stable, low in toxicity and good in dispersing ability; the obtained plating layer is bright and fine as well as good in binding force; the technology adopts the environment-friendly organic additive which does not contain heavy metal and sulfide; the plating layer is good in corrosion resistance. Furthermore, the cyanide-free silver plating solution additive can be directly used for parts such as brass, copper, chemical nickel and the like, preplating is not needed, and the binding force is also guaranteed.

Owner:HANGZHOU WIN WIN TECH CO LTD

Pharmaceutical intermediate 3,4-dimethoxy-6-nitrobenzoic acid synthesis method

InactiveCN108238890AReduce intermediate linksShort reaction timeOrganic compound preparationCarboxylic compound preparationM-aminoacetophenoneHydrogen Sulfate

The invention relates to a pharmaceutical intermediate 3,4-dimethoxy-6-nitrobenzoic acid synthesis method, which mainly comprises: adding 3 mol 2-bromo-3,4-dimethoxy-6-aminoacetophenone and 6-8 mol 1,5-pentanediol solution into a reaction container, controlling the stirring speed at 210-250 rpm, maintaining for 30-40 min, adding 600 ml of a potassium carbonate solution, adjusting the pH value to 8-9, increasing the solution temperature to 60-70 DEG C, adding 3-5 mol nickel oxide, continuously carrying out the reaction for 30-40 min, adding a potassium hydrogen sulfate solution, adjusting the pH value to 2-3, reducing the solution temperature to 10-15 DEG C, washing with a sodium sulfate solution, washing with a methylcyclohexanone solution, washing with a 1-methylnaphthalene solution, re-crystallizing in a 2-methyl-3-pentanol solution, and dehydrating with a dehydrating agent to obtain the finished product 3,4-dimethoxy-6-nitrobenzoic acid.

Owner:CHENGDU DONG DIAN AI ER TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![1-methyl-4[4-(n,n-p-methylphenyl amido)styryl]naphthyl and method of manufacturing the same and application thereof 1-methyl-4[4-(n,n-p-methylphenyl amido)styryl]naphthyl and method of manufacturing the same and application thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/3e006608-5c43-491d-8f1a-8df5c0d2a4b5/C2007100580260002C1.PNG)

![1-methyl-4[4-(n,n-p-methylphenyl amido)styryl]naphthyl and method of manufacturing the same and application thereof 1-methyl-4[4-(n,n-p-methylphenyl amido)styryl]naphthyl and method of manufacturing the same and application thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/3e006608-5c43-491d-8f1a-8df5c0d2a4b5/C2007100580260002C2.PNG)

![1-methyl-4[4-(n,n-p-methylphenyl amido)styryl]naphthyl and method of manufacturing the same and application thereof 1-methyl-4[4-(n,n-p-methylphenyl amido)styryl]naphthyl and method of manufacturing the same and application thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/3e006608-5c43-491d-8f1a-8df5c0d2a4b5/C20071005802600041.PNG)

![1-methyl-4[4-(n,n-p-methylphenyl amido)styryl]naphthyl and method of manufacturing the same and application thereof 1-methyl-4[4-(n,n-p-methylphenyl amido)styryl]naphthyl and method of manufacturing the same and application thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/5490b347-69a8-47e2-b418-ea6a1d4732a5/A2007100580260002C1.PNG)

![1-methyl-4[4-(n,n-p-methylphenyl amido)styryl]naphthyl and method of manufacturing the same and application thereof 1-methyl-4[4-(n,n-p-methylphenyl amido)styryl]naphthyl and method of manufacturing the same and application thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/5490b347-69a8-47e2-b418-ea6a1d4732a5/A2007100580260002C2.PNG)

![1-methyl-4[4-(n,n-p-methylphenyl amido)styryl]naphthyl and method of manufacturing the same and application thereof 1-methyl-4[4-(n,n-p-methylphenyl amido)styryl]naphthyl and method of manufacturing the same and application thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/5490b347-69a8-47e2-b418-ea6a1d4732a5/A20071005802600041.PNG)