Diesel oil pour point depressant cosolvent composition and preparation method thereof

A diesel pour point depressant and co-solvent technology, which is applied in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., can solve the problems of poor solubility and dispersibility, and the decrease of the pour point depressant effect of diesel oil, so as to improve the dispersibility , Enhanced pour point depressing effect, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

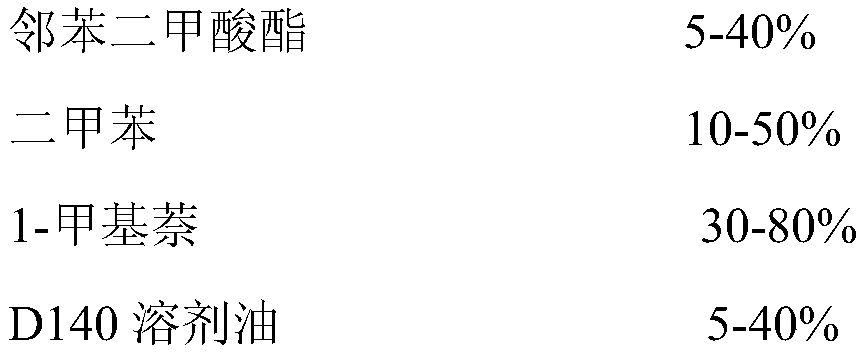

[0027] A diesel oil pour point depressant co-solvent composition, which is composed of phthalate, xylene, 1-methylnaphthalene and D140 solvent oil. The composition and content of the raw materials are as follows:

[0028]

[0029] The preparation method of the above-mentioned a kind of diesel oil pour point depressant co-solvent composition is as follows: the various raw material components are mixed according to the predetermined mass ratio at room temperature and 100 rpm / min, and after 15 minutes of stirring evenly, the described co-solvent combination.

[0030] Mix the co-solvent composition and T1804 pour point depressant obtained above with a mass ratio of 1:2, and add the composite pour point depressant to 100g of Songjiang 0# diesel oil at a mass ratio of 0.1%. After stirring for 10 minutes at the rotation speed of / min, it dissolves quickly. After testing, the cold filter point and condensation point of Songjiang 0# diesel oil after adding the additive are reduced b...

Embodiment 2

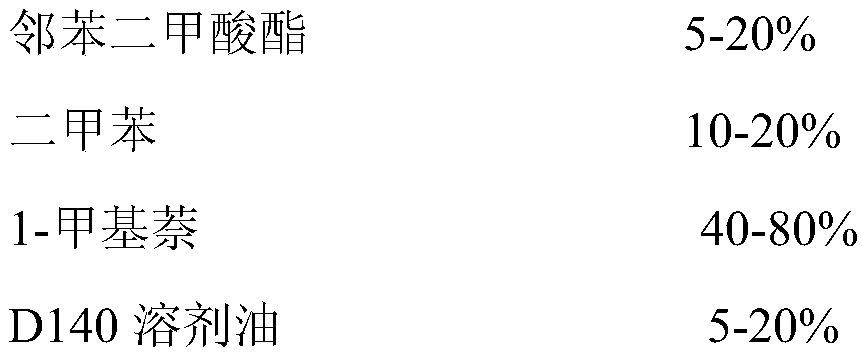

[0032] A diesel oil pour point depressant co-solvent composition, which is composed of phthalate, xylene, 1-methylnaphthalene and D140 solvent oil. The composition and content of the raw materials are as follows:

[0033]

[0034] The preparation method of the above-mentioned a kind of diesel oil pour point depressant co-solvent composition is as follows: the various raw material components are mixed according to the predetermined mass ratio at room temperature and 100 rpm / min, and after 15 minutes of stirring evenly, the described co-solvent combination.

[0035] Mix the co-solvent composition obtained above with T1804 pour point depressant at a ratio of 1:2, add the composite pour point depressant to 100g Songjiang 0# diesel oil at a mass ratio of 0.1%, and stir at room temperature and 100rpm / min After 10 minutes, it dissolves quickly. After testing, the cold filter point and condensation point of Songjiang 0# diesel oil after adding the additive are respectively reduced ...

Embodiment 3

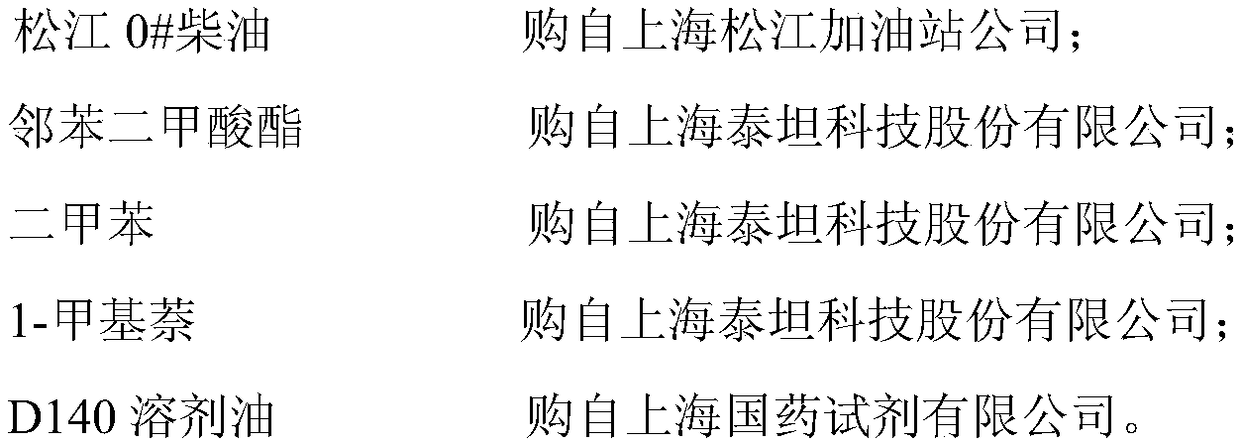

[0037] A diesel oil pour point depressant co-solvent composition, which is composed of phthalate, xylene, 1-methylnaphthalene and D140 solvent oil. The composition and content of the raw materials are as follows:

[0038]

[0039]

[0040] The preparation method of the above-mentioned a kind of diesel oil pour point depressant co-solvent composition is as follows: the various raw material components are mixed according to the predetermined mass ratio at room temperature and 100 rpm / min, and after 15 minutes of stirring evenly, the described co-solvent combination.

[0041] Mix the co-solvent composition obtained above with T1804 pour point depressant at a ratio of 1:2, and add the composite pour point depressant to 100g of Songjiang 0# diesel oil at a mass ratio of 0.1%. After stirring for 10 minutes, it dissolves quickly. After testing, the cold filter point and condensation point of Songjiang 0# diesel after adding the additive are respectively reduced by 7°C and 21°C....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com