Preparation method of modified Beta molecular sieve catalyst and application thereof

A molecular sieve and catalyst technology, applied in the field of preparation of modified Beta molecular sieve catalysts, can solve the problems of cracking and coking reactions, reduce the yield of effective products of the reaction, etc., and achieve the effects of simple preparation process, improved yield, and improved conversion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

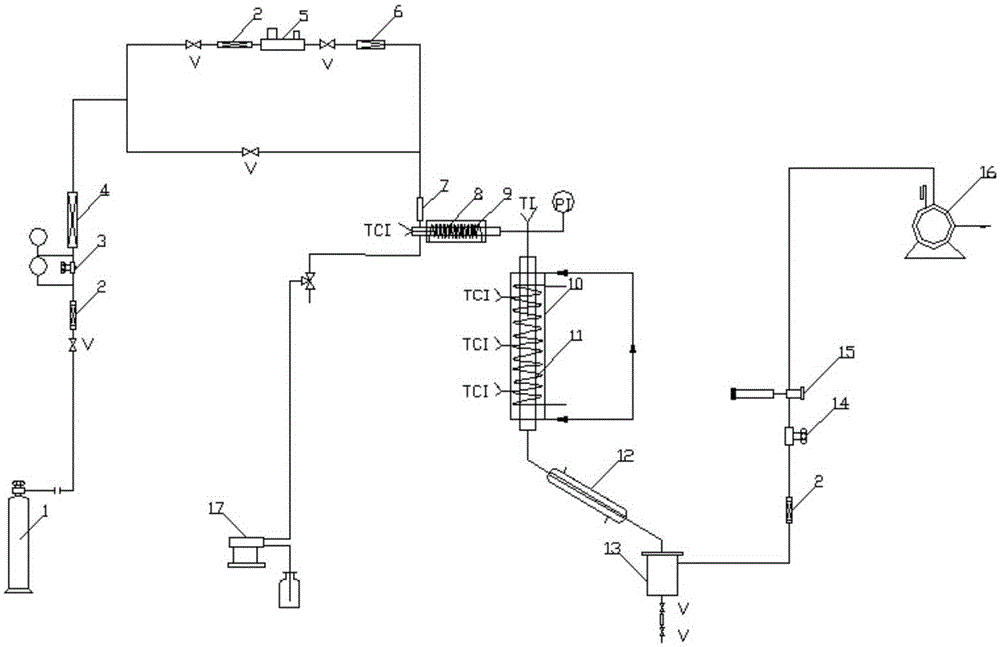

Method used

Image

Examples

Embodiment 1

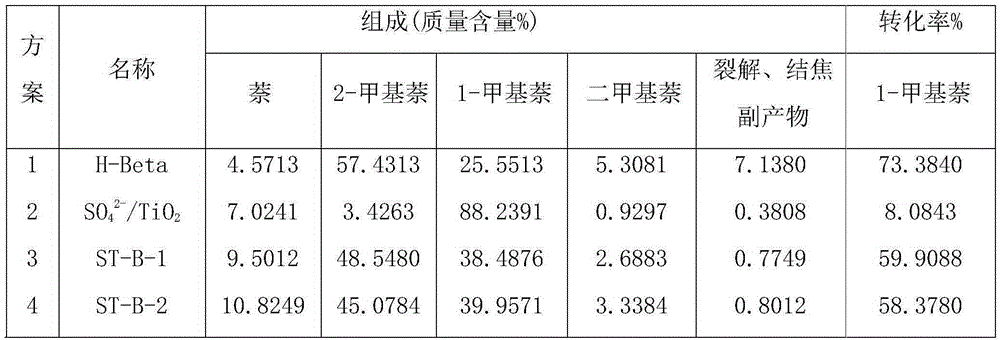

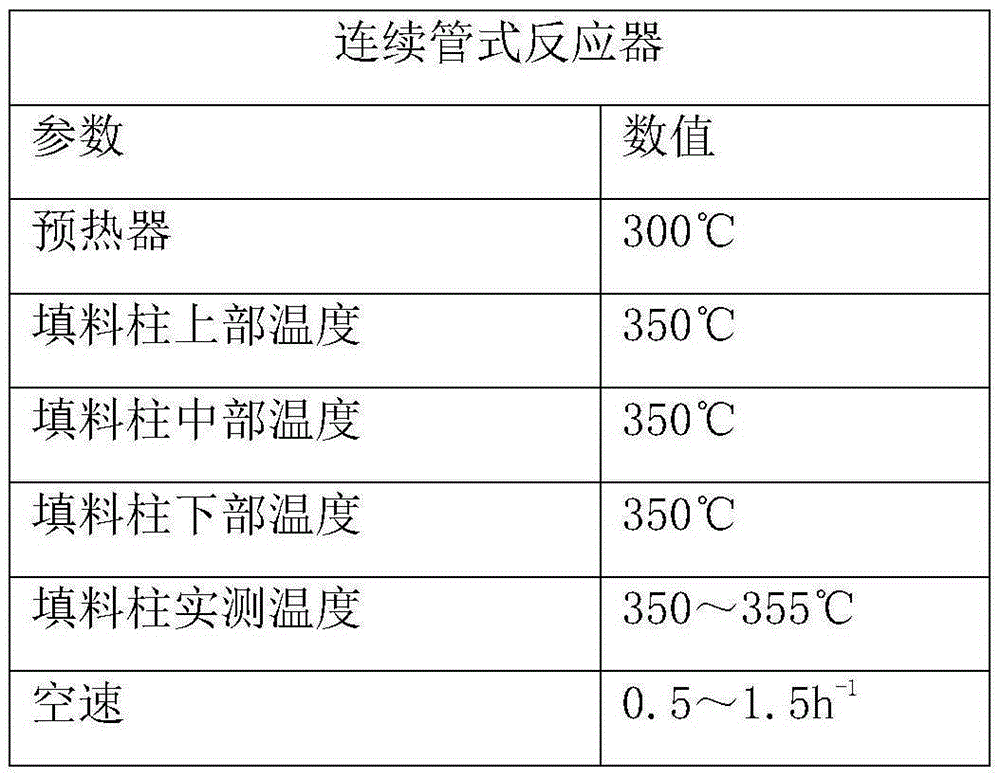

[0028] Prepare ST-B-1 catalyst by titanium sulfate modified Beta molecular sieve method: the specific method is: (1) place the activated Beta molecular sieve in a hydrothermal kettle; (2) configure sulfuric acid with a molar concentration of 0.2mol / l Titanium solution; (3) Under constant temperature and pressure, Beta molecular sieve was completely immersed in titanium sulfate solution for 5 hours, wherein the mass ratio of Ti / Beta molecular sieve = 1:10, vacuum dried for 12 hours, and calcined at 550°C for 7 hours to obtain the modified Beta molecular sieve catalyst ST -B-1.

[0029] The isomerization / disproportionation reaction of 1-methylnaphthalene was carried out in a continuous tubular reactor. The results show that the ST-B-1 catalyst prepared by the titanium sulfate modified Beta molecular sieve method has a conversion rate of 1-methylnaphthalene≥61%, and the selection of effective products (2-methylnaphthalene, naphthalene, dimethylnaphthalene) Property ≥ 98%, the yi...

Embodiment 2

[0031] Using the roasting activation method, the ST-B-1 catalyst in Example 1 was subjected to a cycle experiment. The specific method is: after the ST-B-1 catalyst in the embodiment 1 is continuously used in the continuous tubular reactor for 5 hours (TOS=5hr), it is taken out, screened by the mesh sieve method, and recalcined to activate (vacuum drying for 12h, Calcination at 550° C. for 7 h) to obtain a recycled catalyst sample ST-B-2 catalyst. Pack into continuous tubular reactor and carry out repeated experiment, the conversion rate of 1-methylnaphthalene is 58%, the selectivity 98% of effective product (2-methylnaphthalene, naphthalene, dimethylnaphthalene), effective product (2- The yield of methylnaphthalene, naphthalene, dimethylnaphthalene) is 56%. Compared with the catalyst conversion effect of Example 1, Example 2 is not much different, within the error range, indicating that the effect of the ST-B-2 catalyst prepared by the roasting activation method is basically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com