Pour point depressant for crude oil

A crude oil pour point depressant, a special technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of high toxicity, high manufacturing cost and market price, and ineffectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

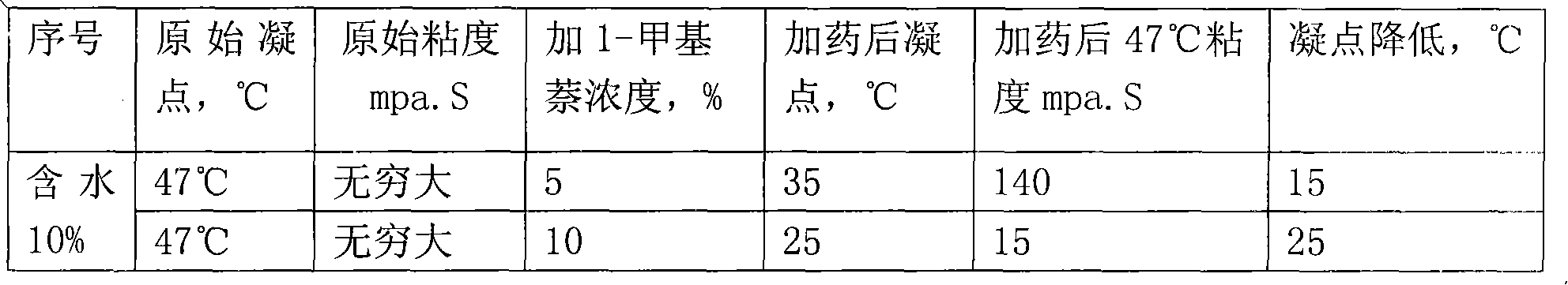

[0111] A crude oil pour point depressant is composed of 1-methylnaphthalene. The experimental effects of the pour point depressant of this embodiment are shown in Tables 2, 4 and 6.

Embodiment 2

[0113] A crude oil pour point depressant, which is a mixed solution formed by dissolving 2-methylnaphthalene in 1-methylnaphthalene, "mixed methylnaphthalene" or mixing them in any proportion at normal temperature and pressure, and 2-methylnaphthalene The maximum content of naphthalene in the mixed solution does not exceed its saturation concentration in the solution at normal temperature and pressure. In order to achieve the aforementioned goals, those skilled in the art can determine the maximum concentration or content of 2-methylnaphthalene in the mixed solution through existing methods.

Embodiment 3

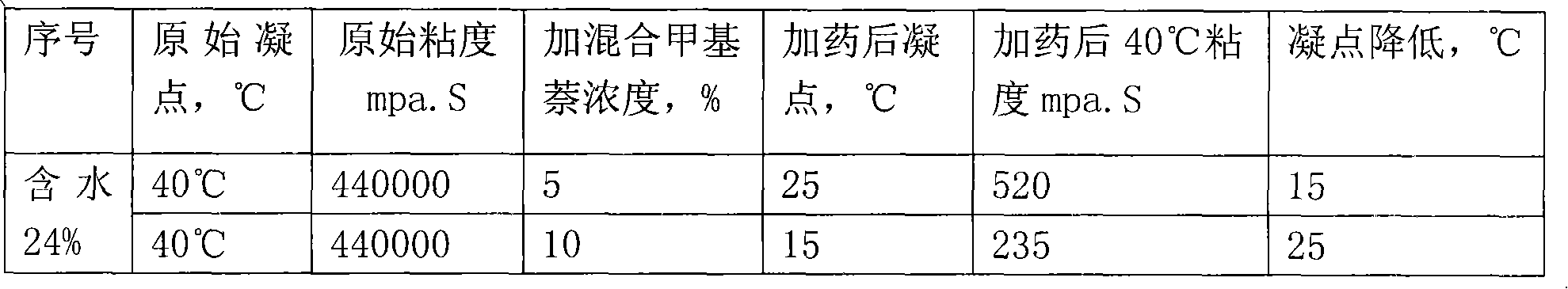

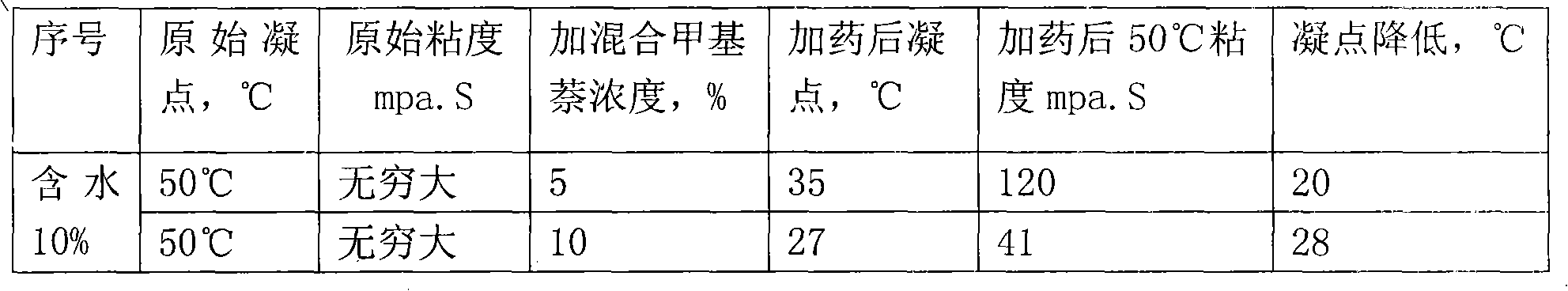

[0115] A crude oil pour point depressant, which is composed of "mixed methyl naphthalene". The results of the pour point depressing experiment in this embodiment are shown in Tables 1, 3, 5 and 7.

[0116] The public market price in 2009 shows that the tax-included market price of "mixed methylnaphthalene" is less than 30% of the tax-included market price of sodium dodecylbenzenesulfonate in the same period, and less than the tax-included market price of polyacrylate 40% of the price;

[0117] From the last 3-4 lines on page 255 of "Oilfield Chemistry" printed for the first time in the first edition of China University of Petroleum Press in July 2000, it can be known that polyacrylate belongs to a typical polymer type crude oil pour point depressant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dew point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com