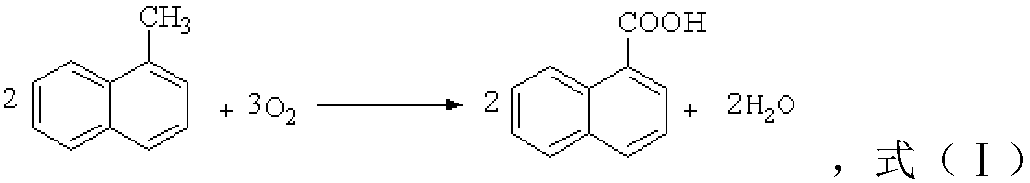

Composition, reaction system and method for preparing 1-naphthoic acid

A reaction system, naphthoic acid technology, applied in the chemical industry, can solve problems such as pollution, large investment in equipment, and many reaction steps, and achieve the effect of simple process, large investment in equipment, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

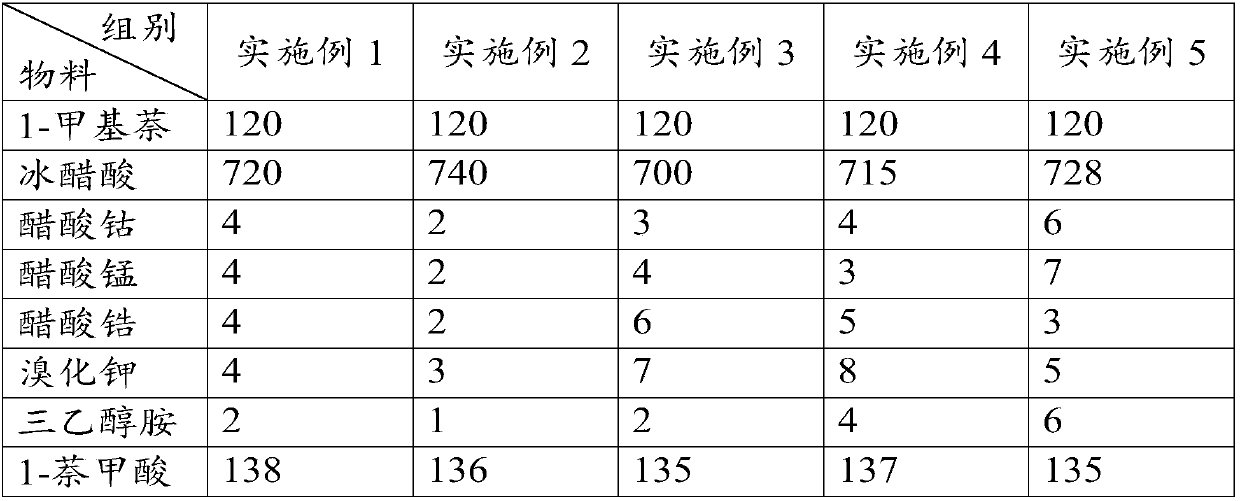

Examples

preparation example Construction

[0043] Preparation methods include:

[0044] Step S101, providing a reaction space continuously fed with oxygen.

[0045] The reaction space is a container for various reagents to react, such as equipment used in various common chemical experiment reactions. The equipment or container may be a general-purpose device used in a laboratory, or a general-purpose device used in industrial mass production, or a device that is appropriately improved to meet the needs of a new production process as required or system.

[0046] For example, in an alternative example, the equipment is primarily a flask, and the reaction space is primarily a space defined by the flask. In addition, glass tubes, stirrers (such as magnetic stirrers), constant pressure dropping funnels, thermometers, reflux condensers, heating jackets, etc. can also be configured in the equipment.

[0047] Step S201, adding 1-methylnaphthalene, glacial acetic acid, cobalt acetate, manganese acetate, zirconium acetate, po...

Embodiment 1

[0062] Put 120g of 1-methylnaphthalene, 720g of glacial acetic acid, 4g of cobalt acetate, 4g of manganese acetate, 4g of bromide Potassium, 4g zirconium acetate, 2g triethanolamine, heat up to reflux and open oxygen 1L / min, maintain the reflux state and react with oxygen for 7 hours, take a sample to detect that the raw material is less than 0.5wt% as the reaction end point, cool and filter to obtain the crude product and mother liquor.

[0063] Among them, the crude product is to be refined to obtain 1-naphthoic acid, and the mother liquor is absorbed by activated carbon and used mechanically.

[0064] The method for the crude product to be refined to obtain 1-naphthoic acid is to add 2500mL water to a 5000mL beaker, and add liquid caustic soda for the crude product (liquid caustic soda is liquid sodium hydroxide, also known as caustic soda, caustic soda, the concentration of liquid caustic soda is usually 30-32% or 40-42%) to adjust the pH value to 8, raise the temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com