Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

86results about How to "Useful purpose" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

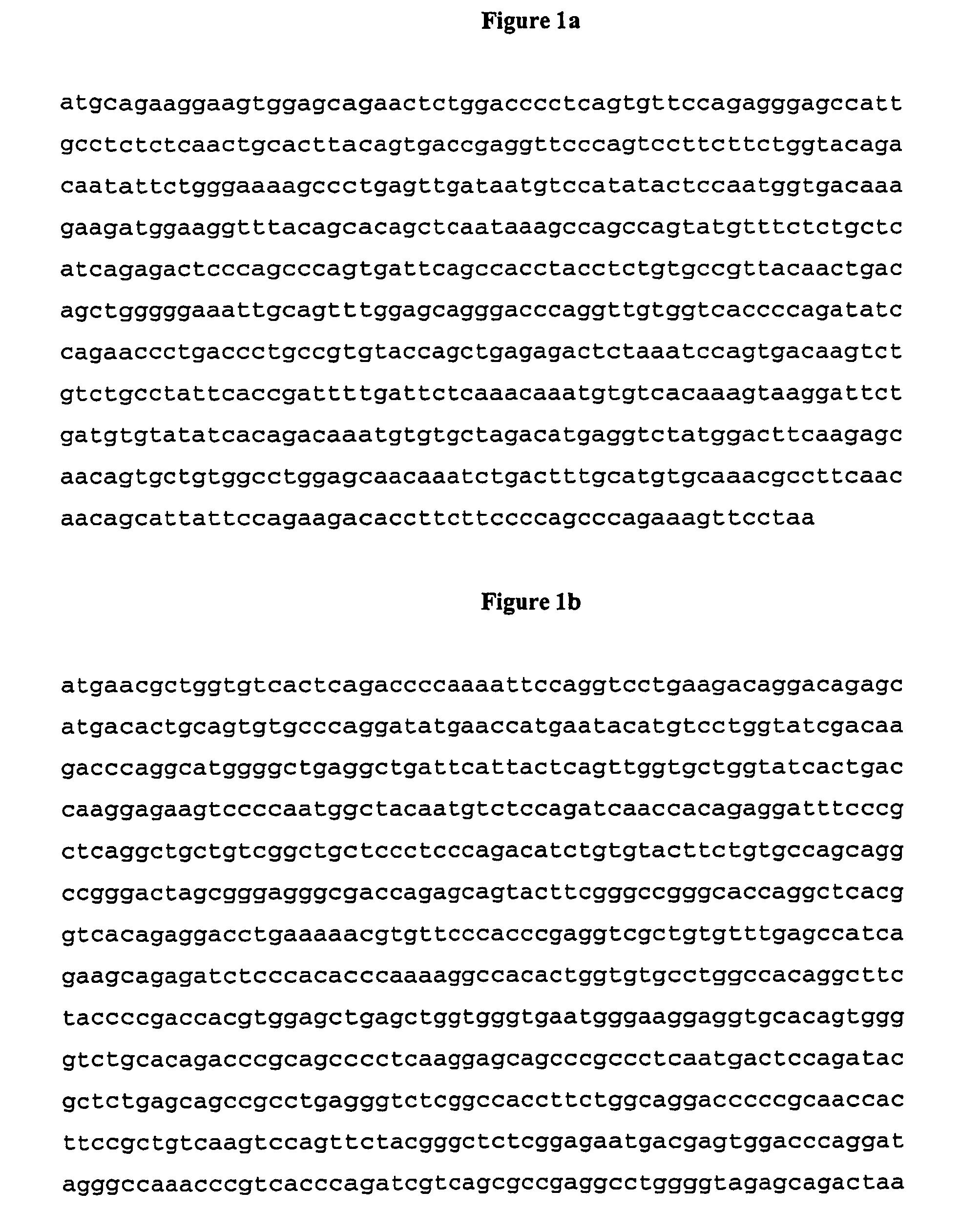

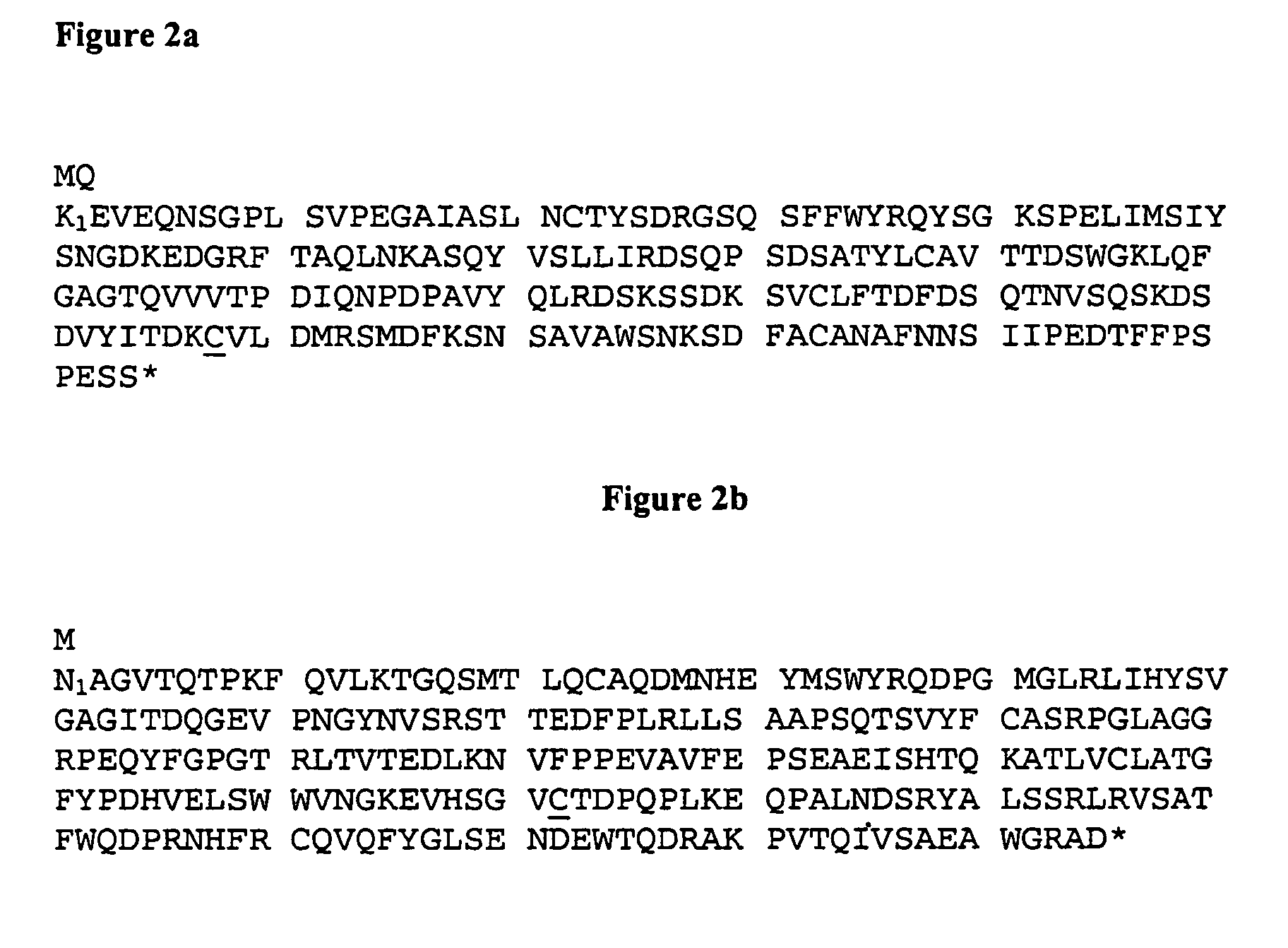

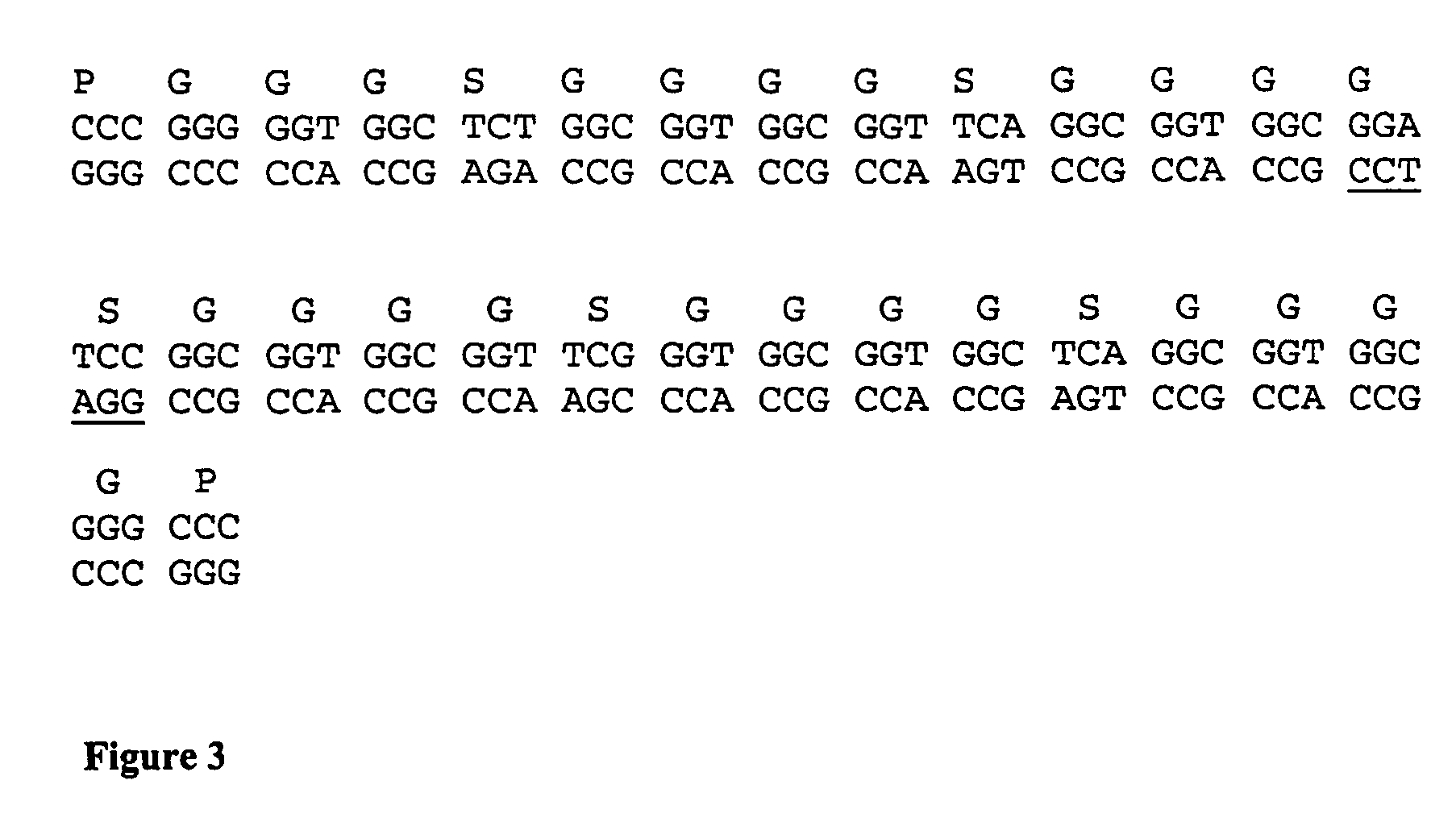

Single chain recombinant T cell receptors

InactiveUS7569664B2Improve stabilityUseful purposeCompound screeningApoptosis detectionExtracellularC-terminus

A single chain T cell receptor (scTCR) comprising an a segment constituted by a TCR α chain variable region sequence fused to the N terminus of a TCR α chain constant region extracellular sequence, a β segment constituted by a TCR β chain variable region fused to the N terminus of a TCR β chain constant region extracellular sequence, and a linker sequence linking the C terminus of the α segment to the N terminus of the β segment, or vice versa, the constant region extracellular sequences of the α and β segments being linked by a disulfide bond, the length of the linker sequence and the position of the disulfide bond being such that the variable region sequences of the α and β segments are mutually orientated substantially as in native αβ T cell receptors. Complexes of two or more such scTCRs, and use of the scTCRs in therapy and in various screening applications are also disclosed.

Owner:IMMUNOCORE LTD +1

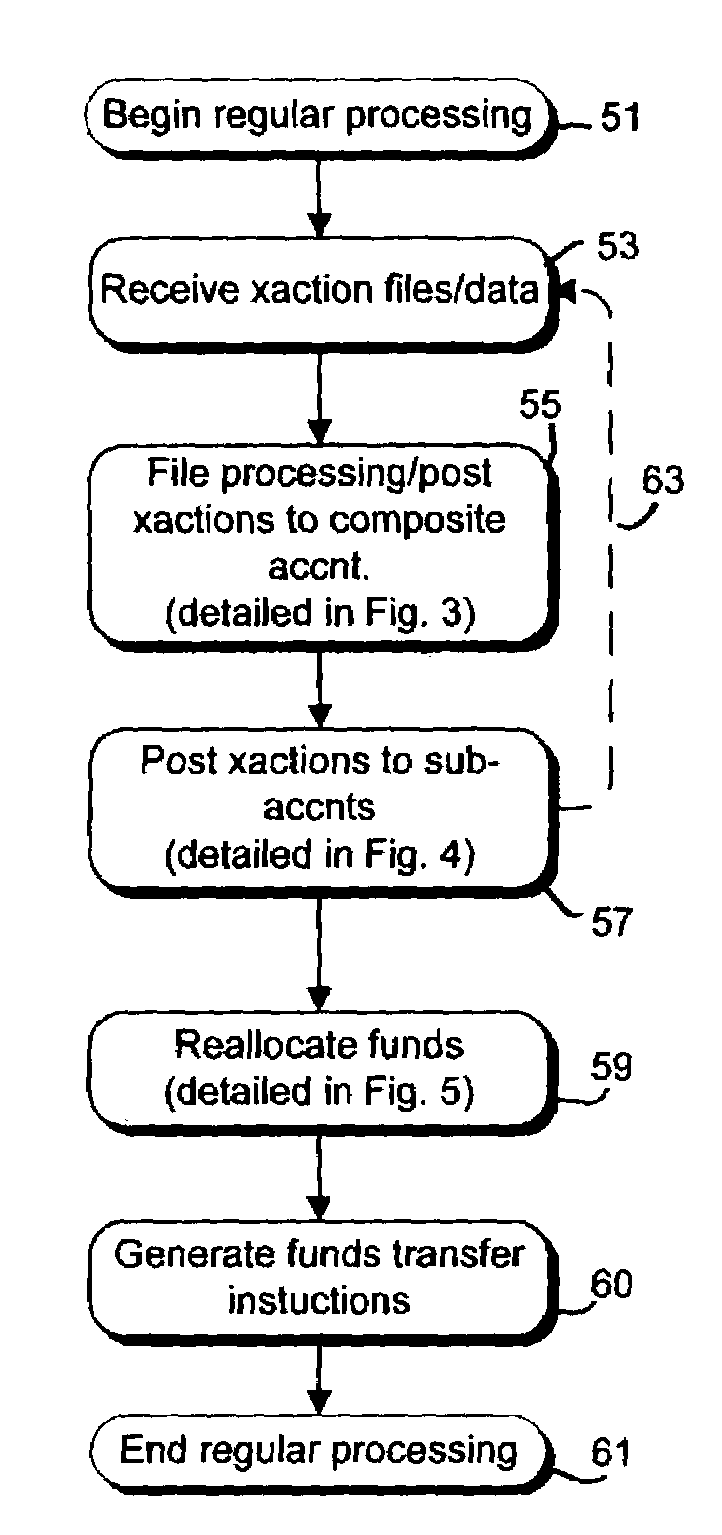

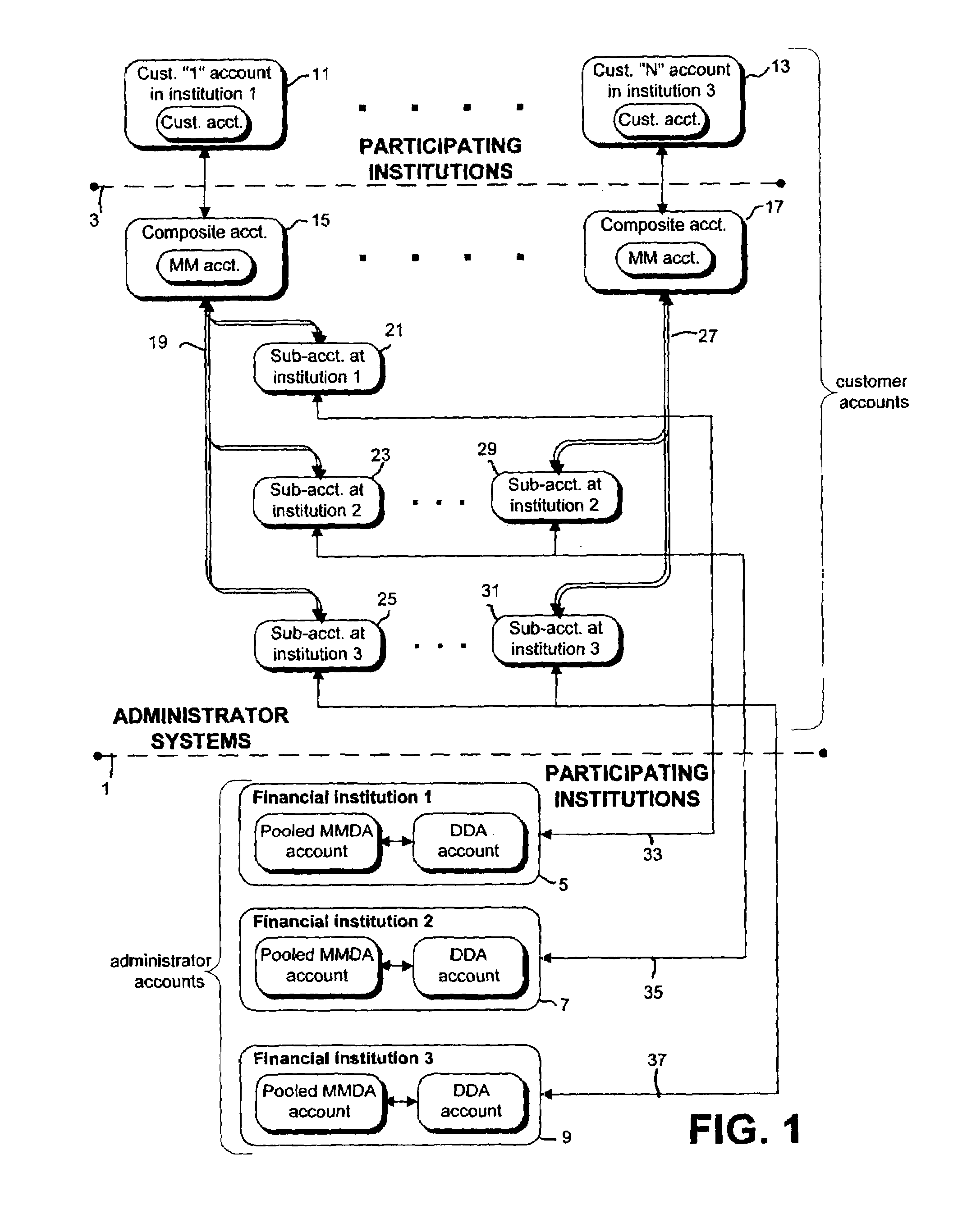

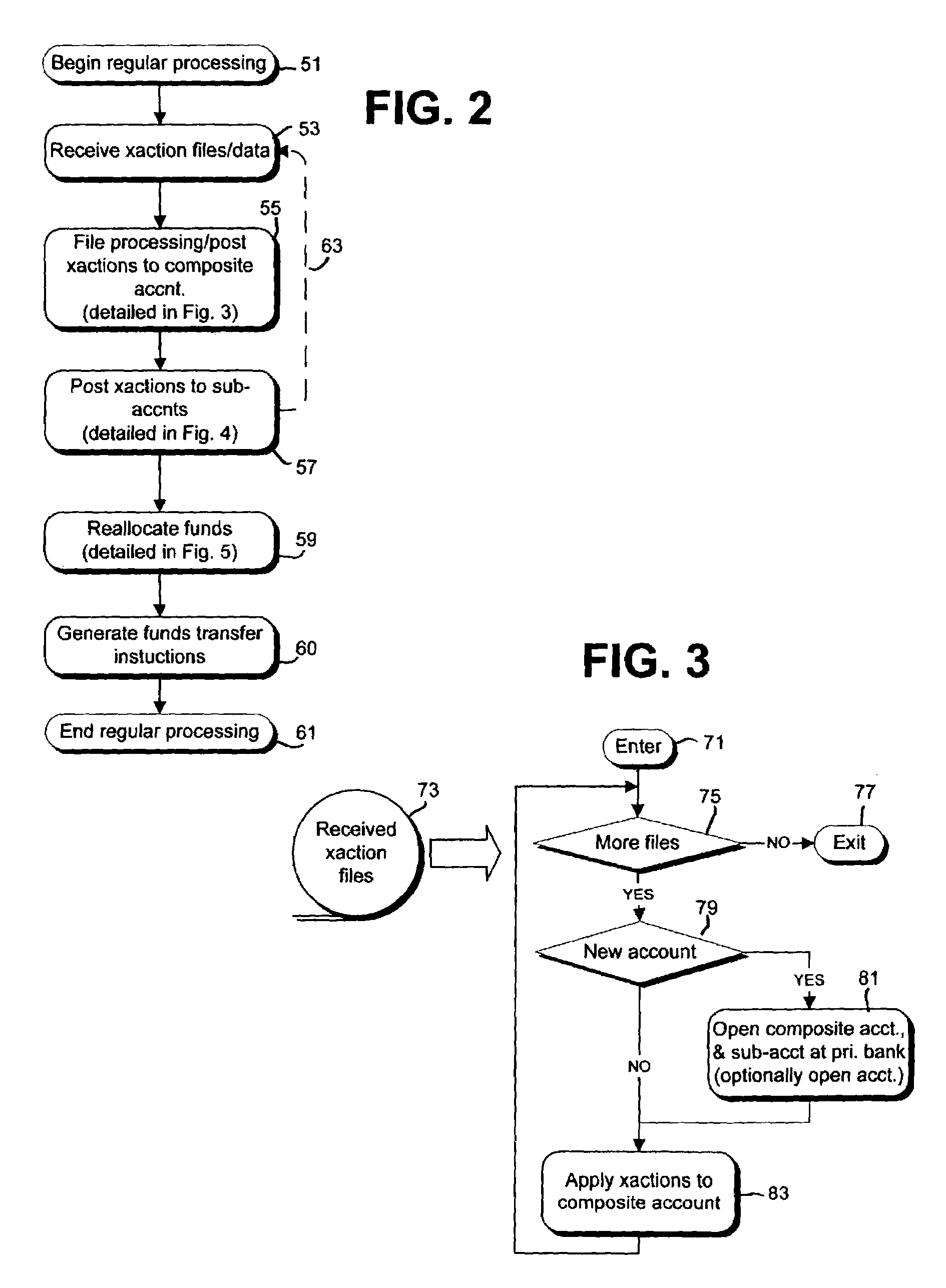

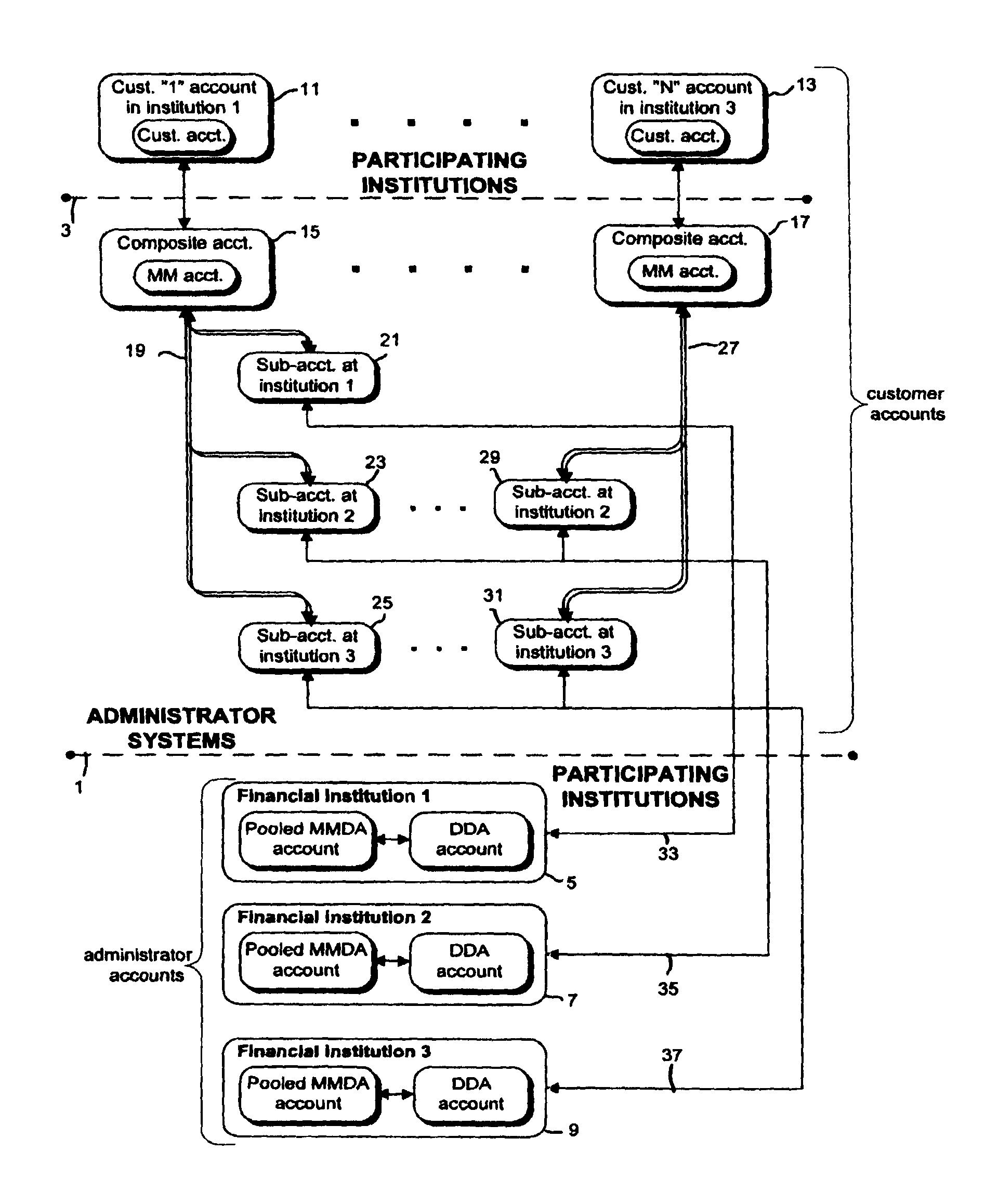

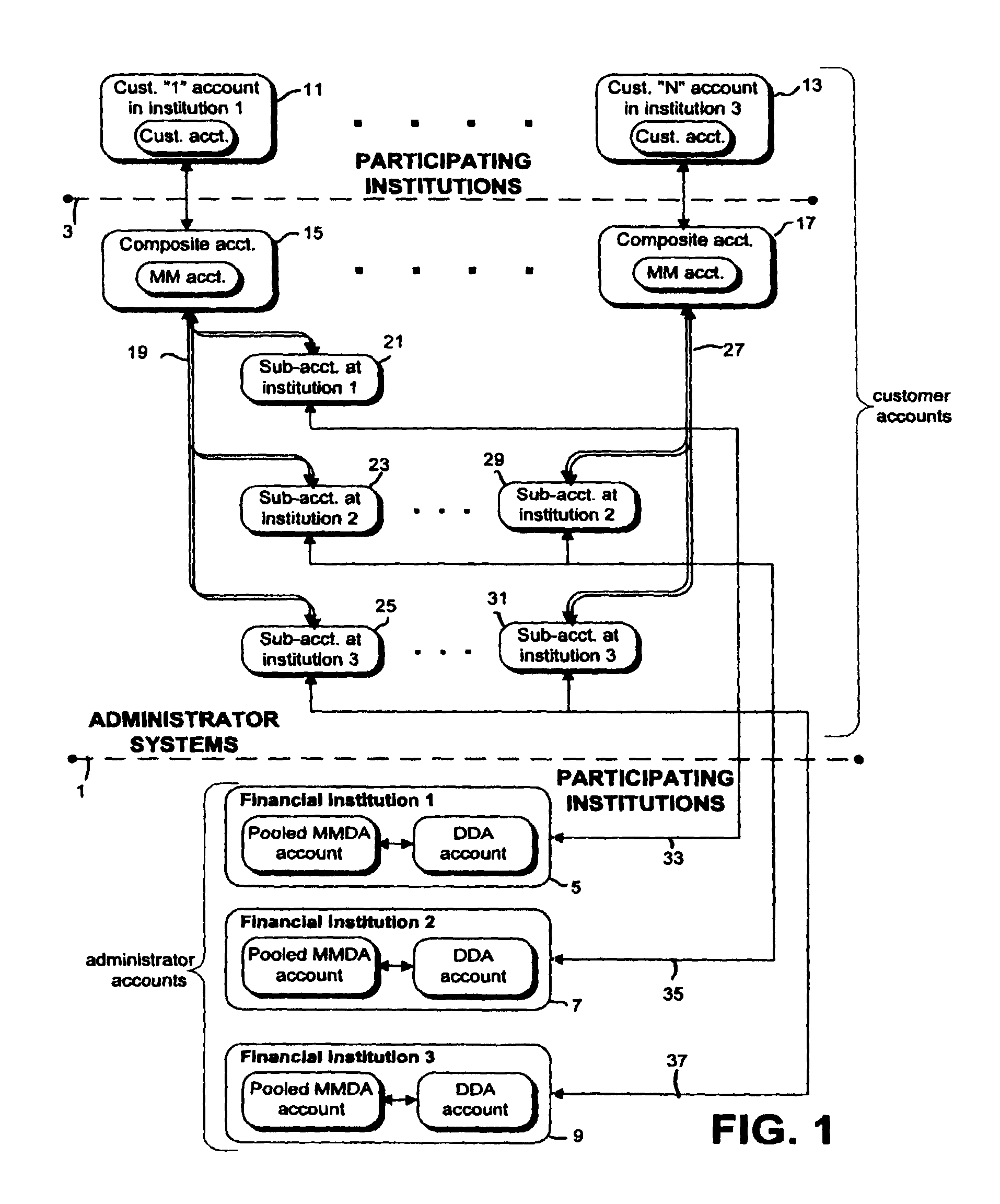

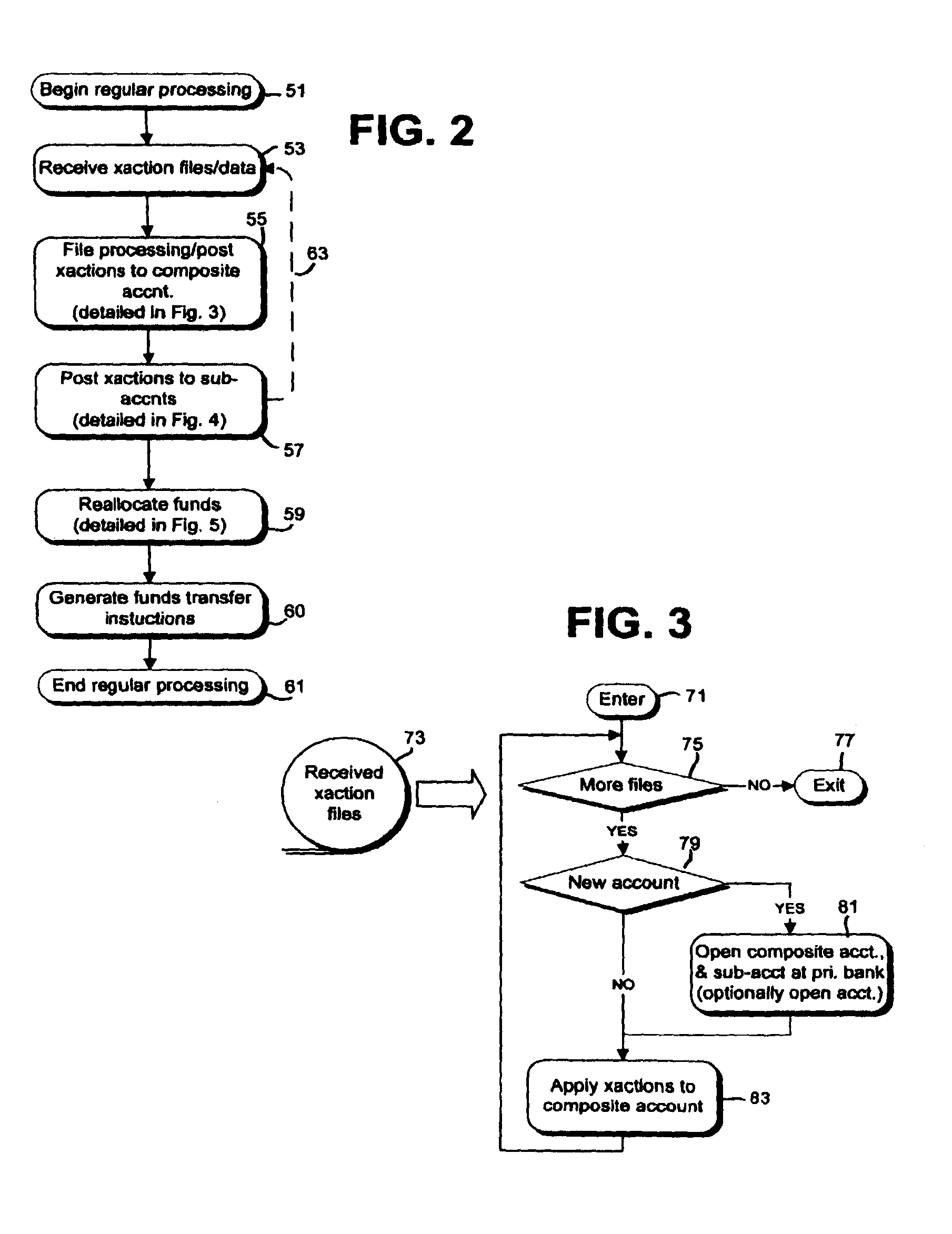

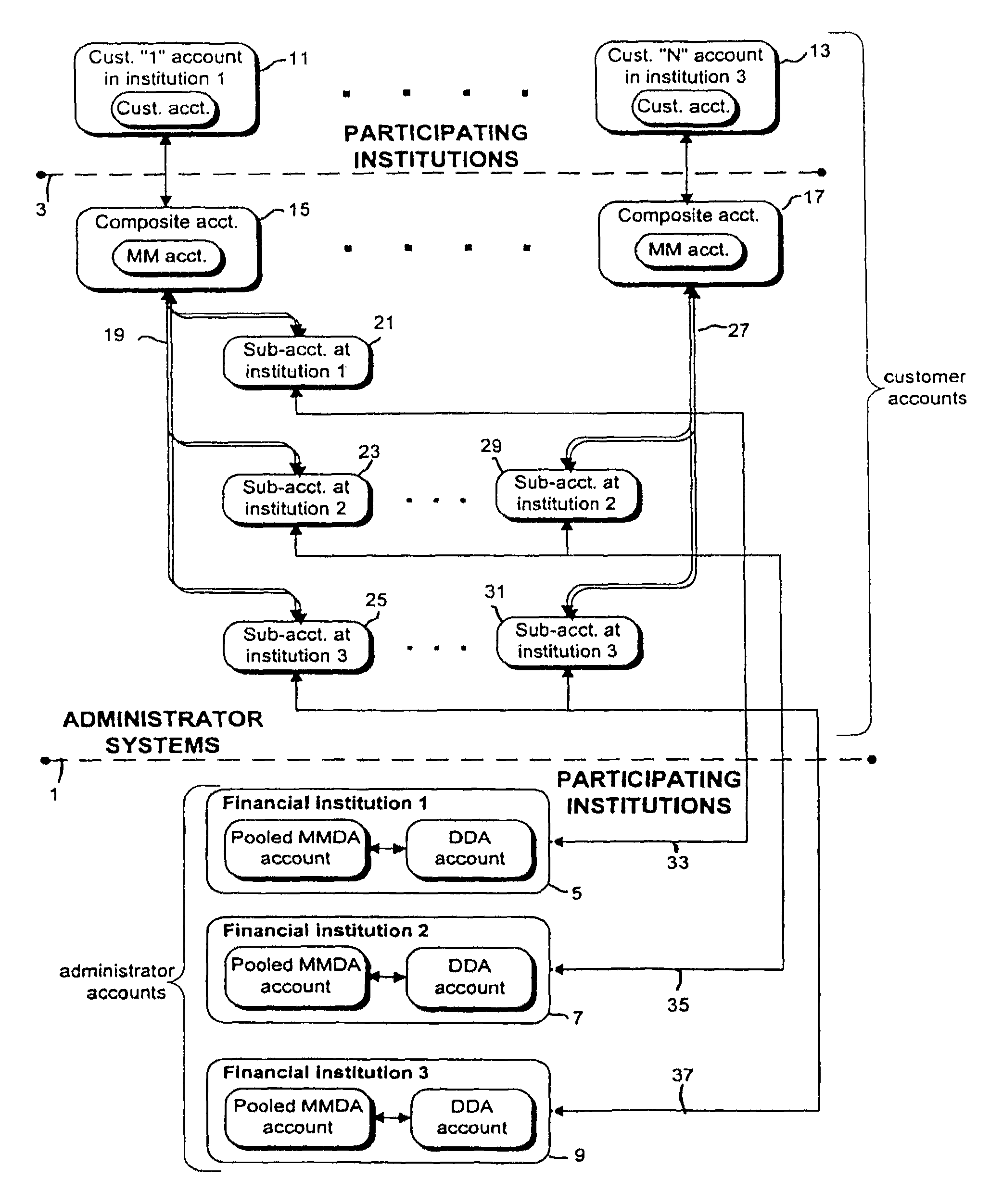

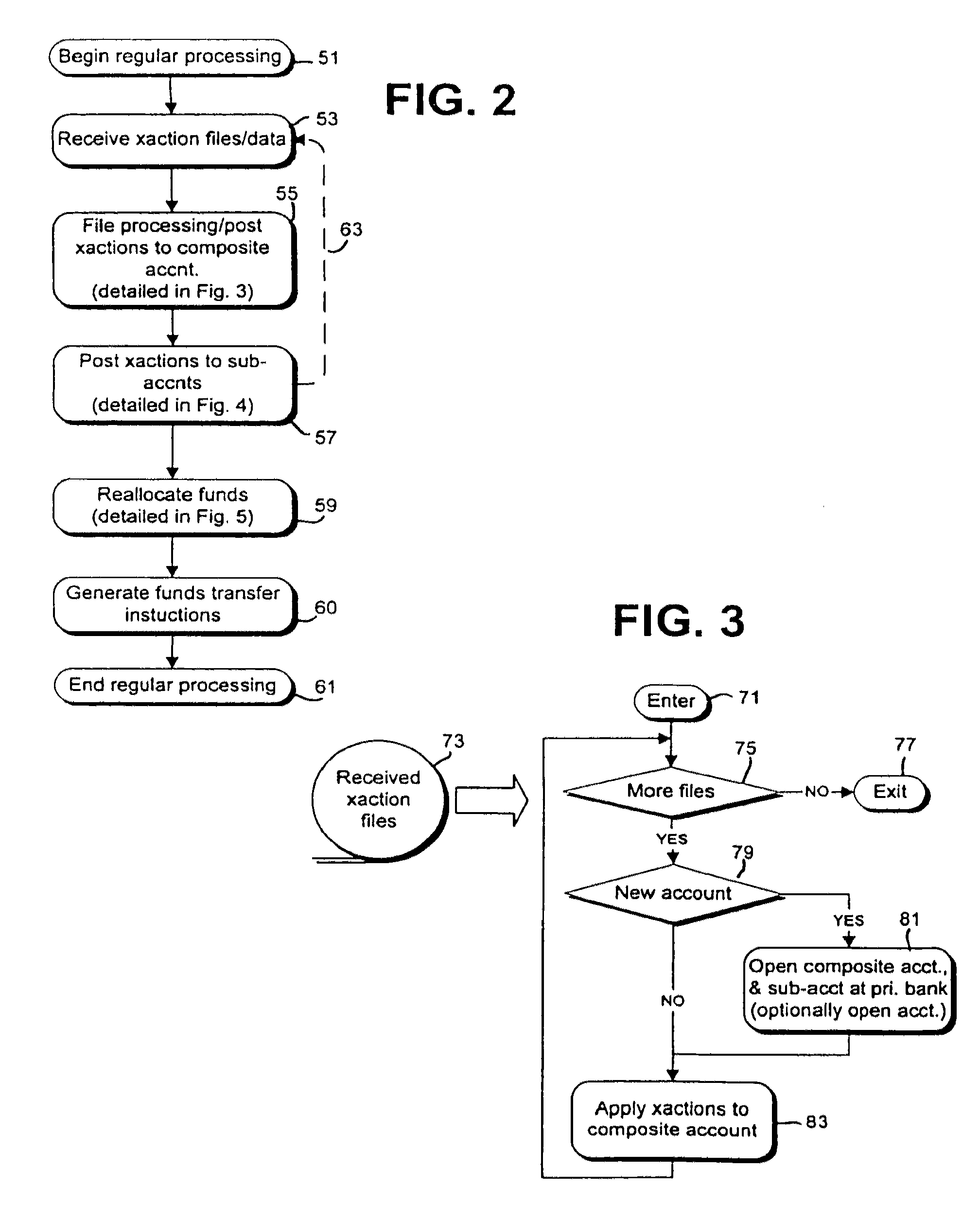

Systems and methods for providing enhanced account management services for multiple banks

This invention includes methods for delivering account management services to multiple financial institutions that provide for customer deposit accounts without transaction but than nevertheless offer interest and receive enhanced deposit insurance. The methods apply at least one customer transaction to that customer's deposit account, and then re-allocate customer-deposited funds among the plurality of financial institutions in order that, for each customer, the risk of loss is not substantially increased, and that, for each financial institution, the amount of customer-deposited funds is not substantially decreased. Preferably, risk of loss is reduced by increasing the fraction of each customer's deposited funds covered by FDIC deposit insurance, and interest and enhanced insurance are available by innovative management of customer transactions and accounts. This invention also includes computer systems for practicing the methods and program products for accordingly configuring such computer systems.

Owner:ISLAND INTPROP

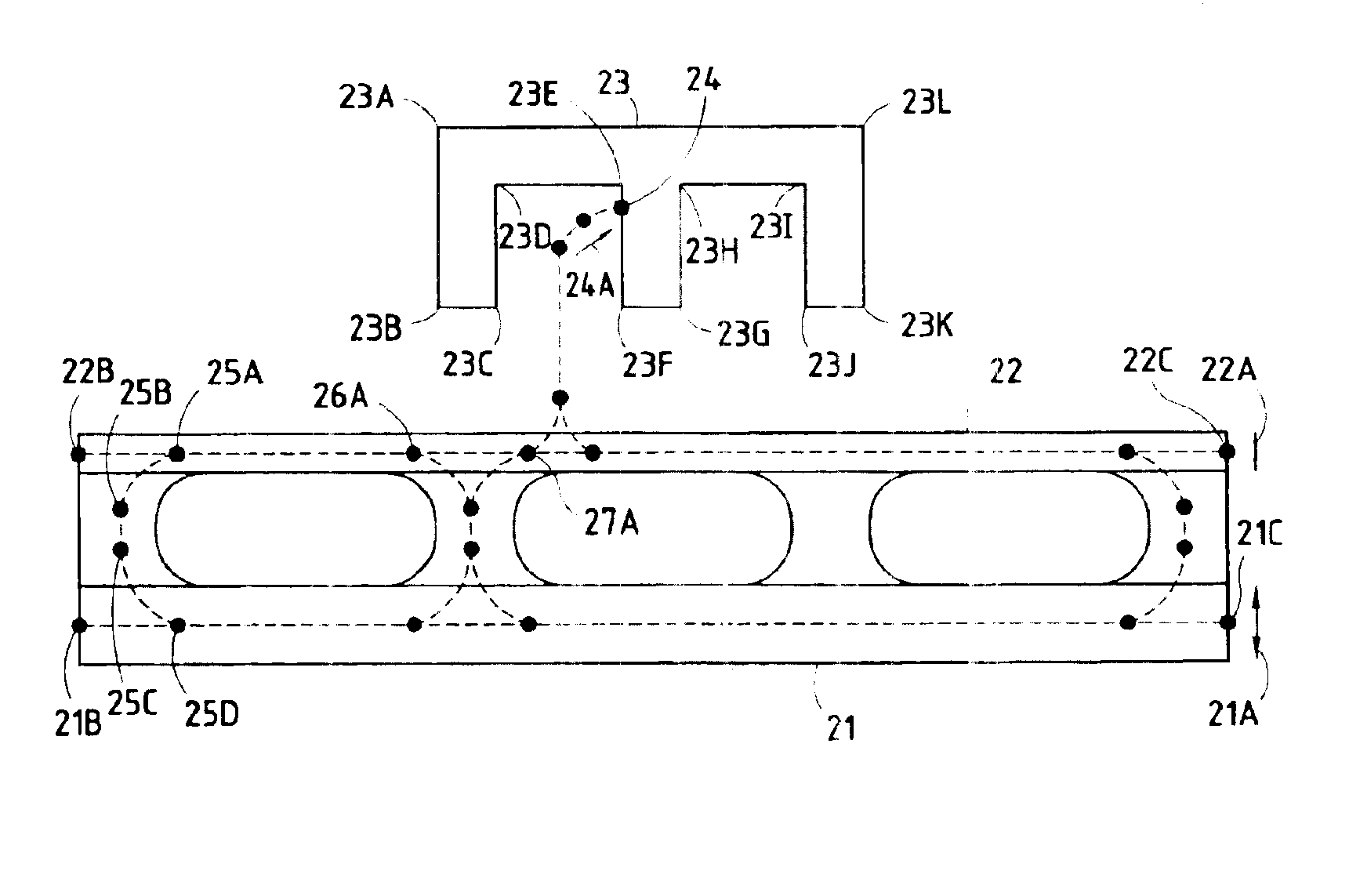

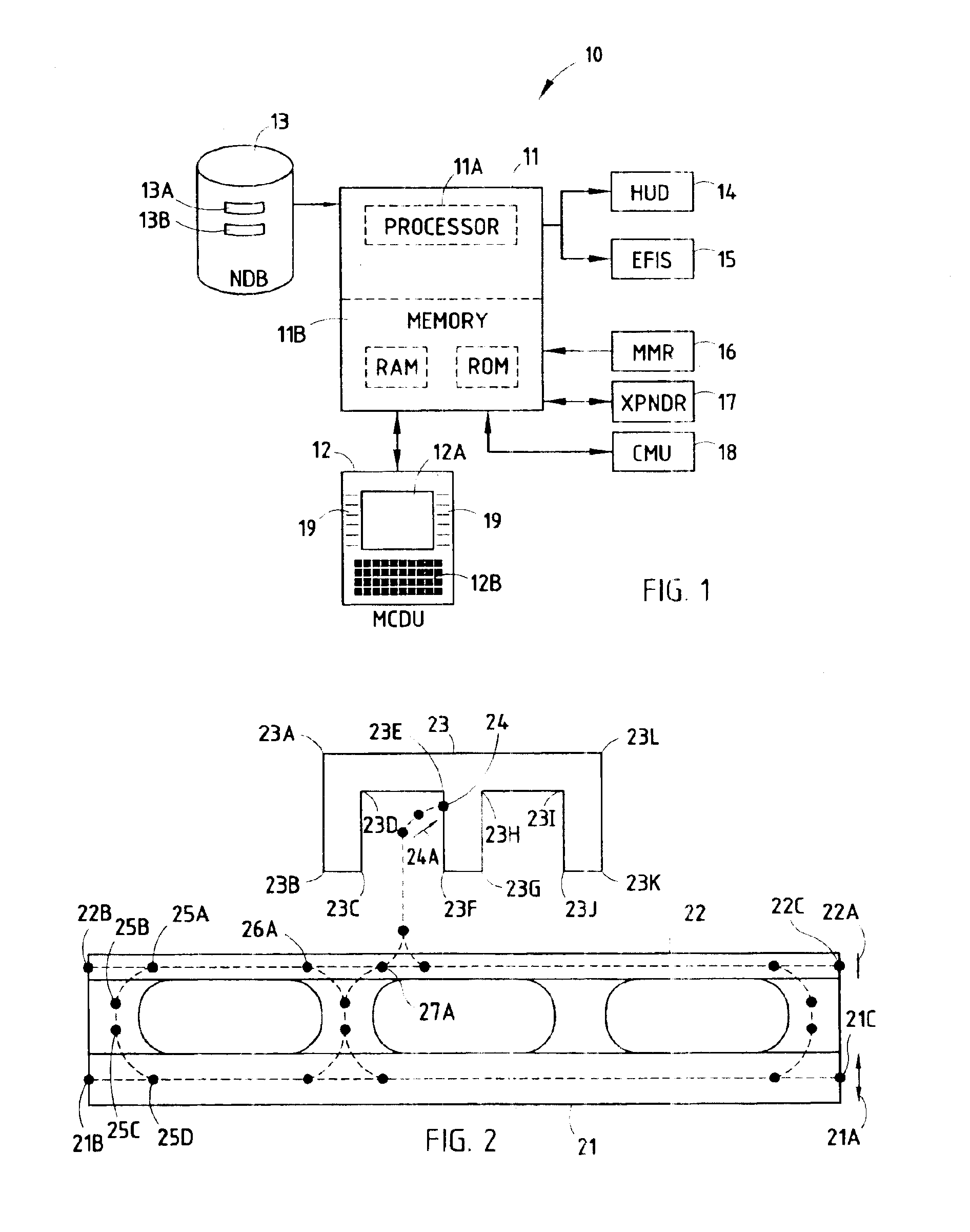

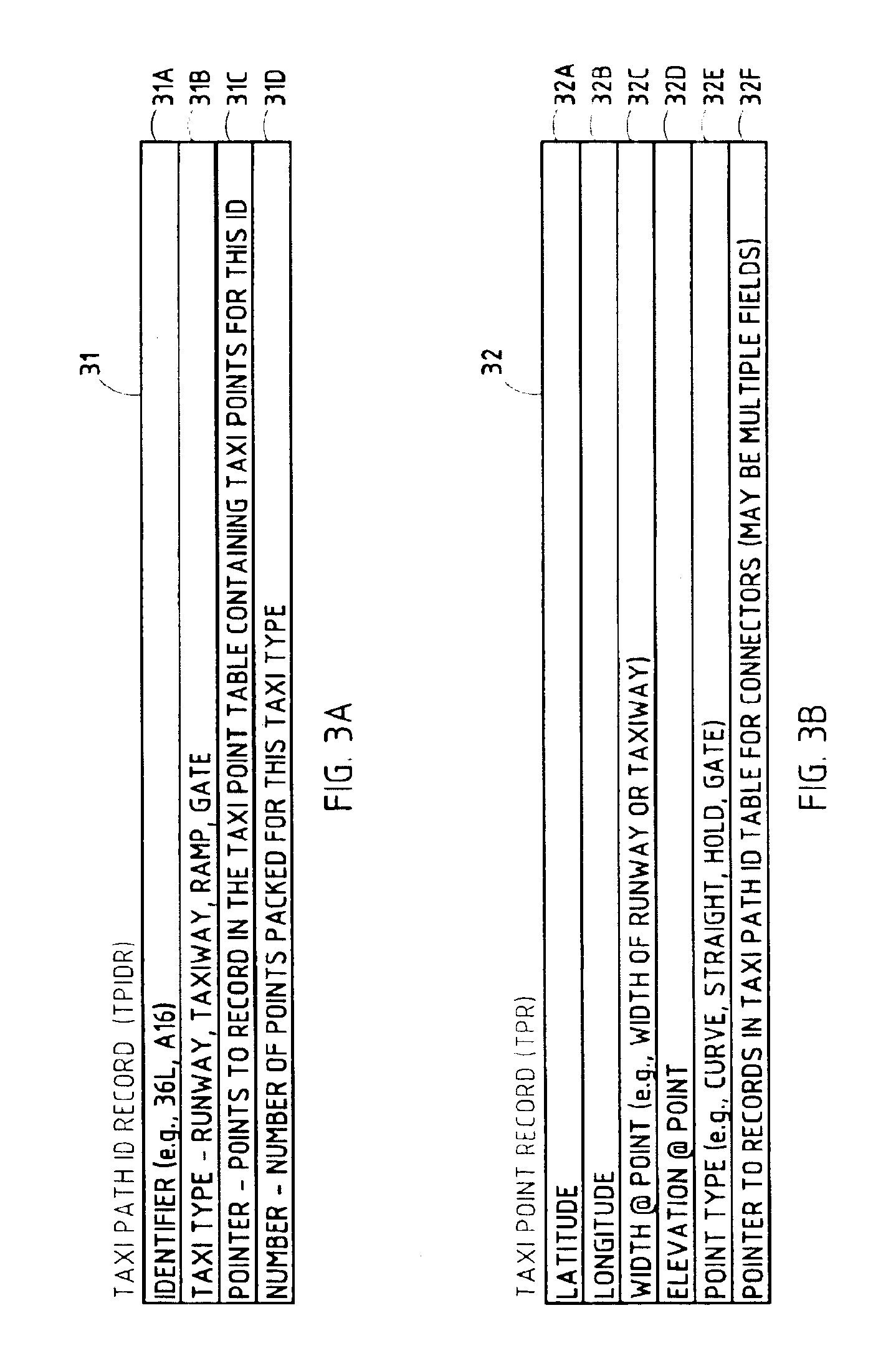

Airport map system with compact feature data storage

InactiveUS6862519B2Reduced space requirementEasily accessAnalogue computers for vehiclesHelicopter landing platformData pointAirplane

An airport map display system for an aircraft displays the airport paved surfaces and structures to a pilot or crew member. The system displays runways, taxiways, connectors, ramps, gates, and buildings. Hold and yield points may also be displayed. A compact set of specific data points and associated pavement width values is used to store unique data for each airport.

Owner:SMITHS AEROSPACE INC

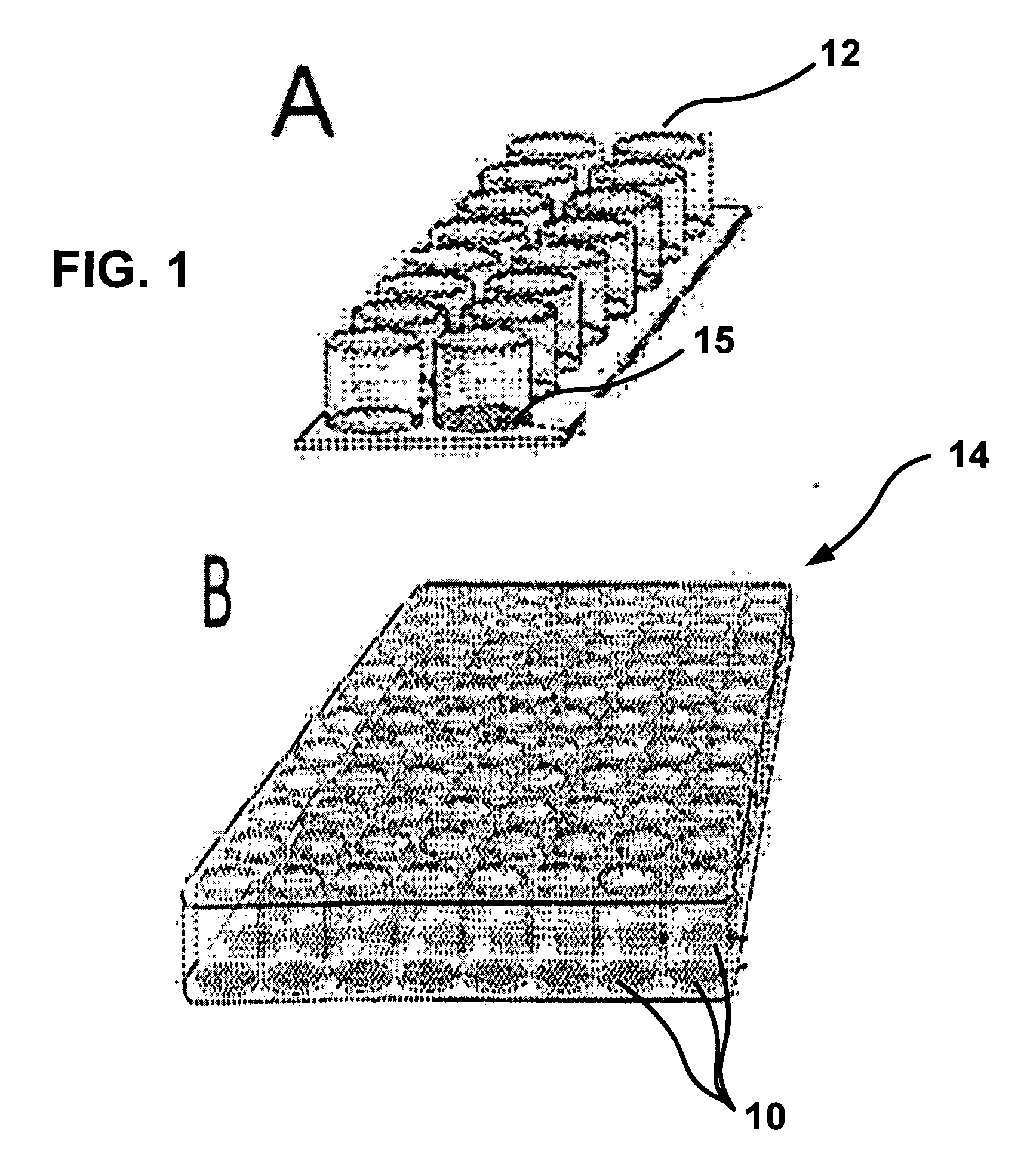

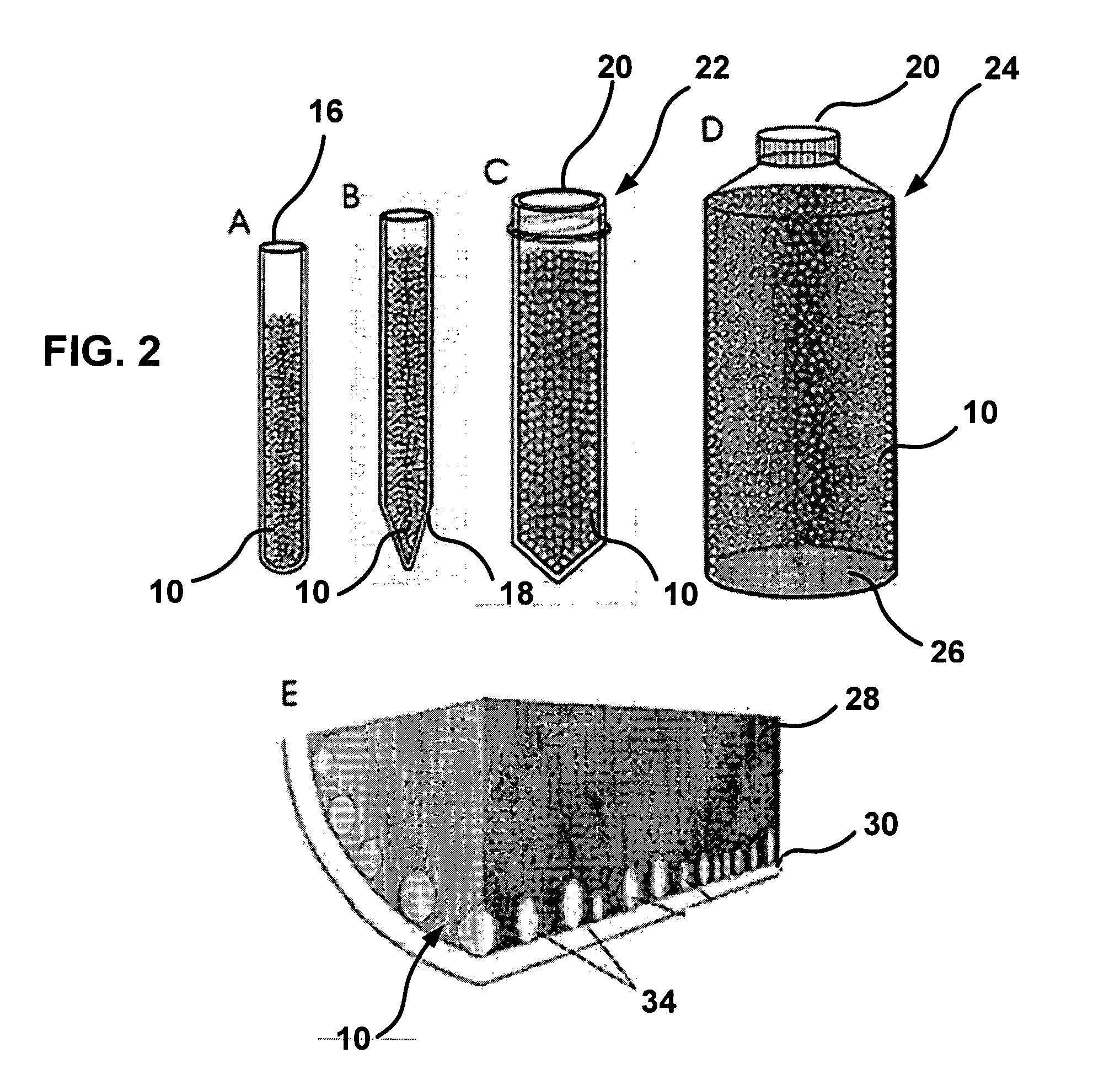

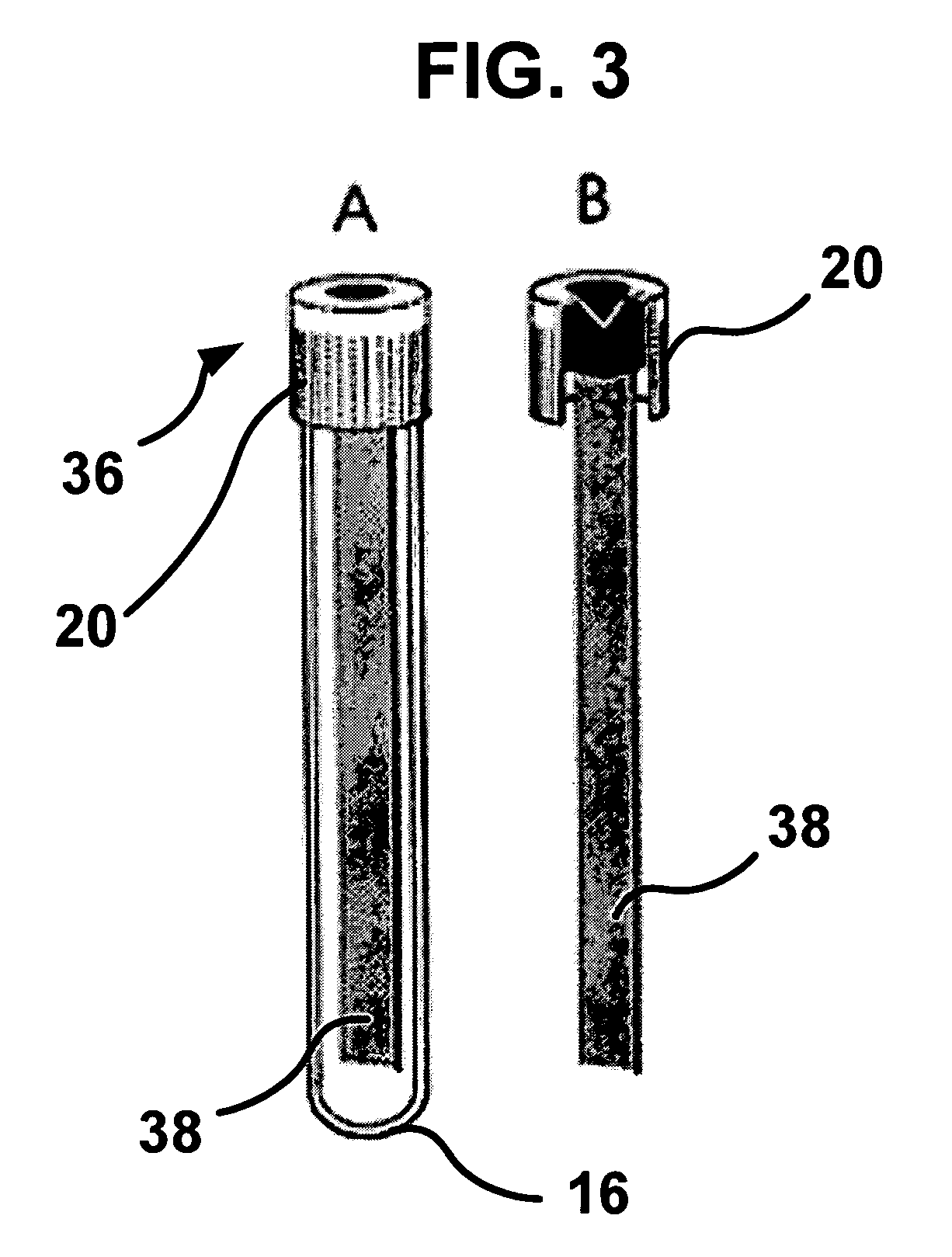

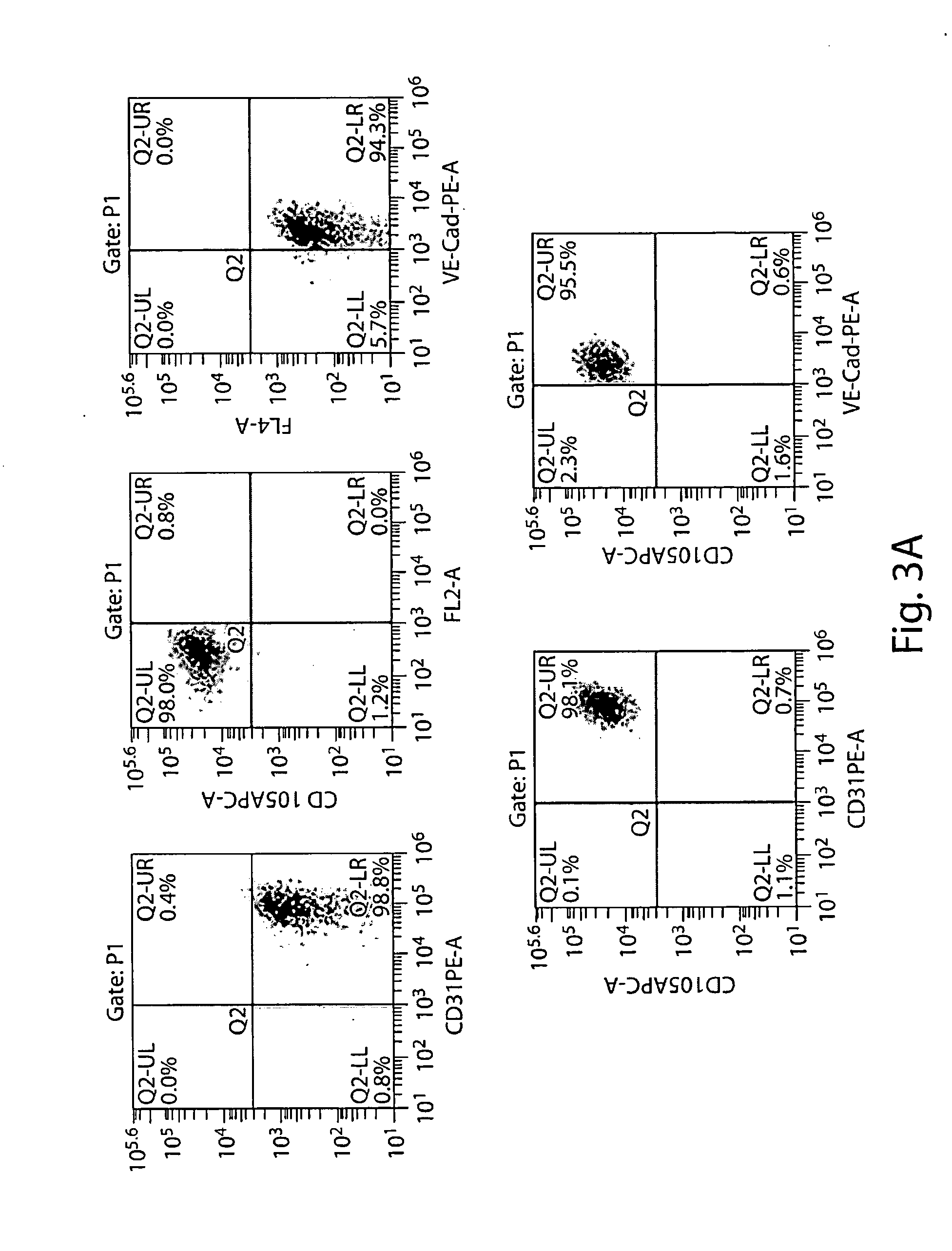

Blood test prototypes and methods for the detection of circulating tumor and endothelial cells

InactiveUS20050244843A1Enhance anti-tumor immune responseDramatic utilityBioreactor/fermenter combinationsBiological substance pretreatmentsAbnormal tissue growthProgenitor

Methods and devices for isolating and diagnosing disease with a cell adhesion matrix system, mimicking a metastatic, cardiovascular or placental environment, are disclosed. The cell adhesion matrix facilitates the enrichment of target cells such as metastatic tumor cells, fetal cells and endothelial progenitor cells from a fluid sample such as blood for diagnostic and therapeutic applications in treating patients afflicted with disease, such as cancerous, cardiovascular and fetal diseases, as well as for research applications in molecular analysis of metastatic, and cardiovascular and fetal diseases. Blood test prototypes and methods for the cell enrichment and detection of circulating tumor and endothelial cells using multiplex molecular analysis are described herein. In addition, methods and compositions for determining host immunity to tumor in subjects with risk of cancer progression and methods for isolating an enriched fraction of fetal cells from pregnant females for prenatal diagnosis are also described herein.

Owner:CHEN WEN TIEN +2

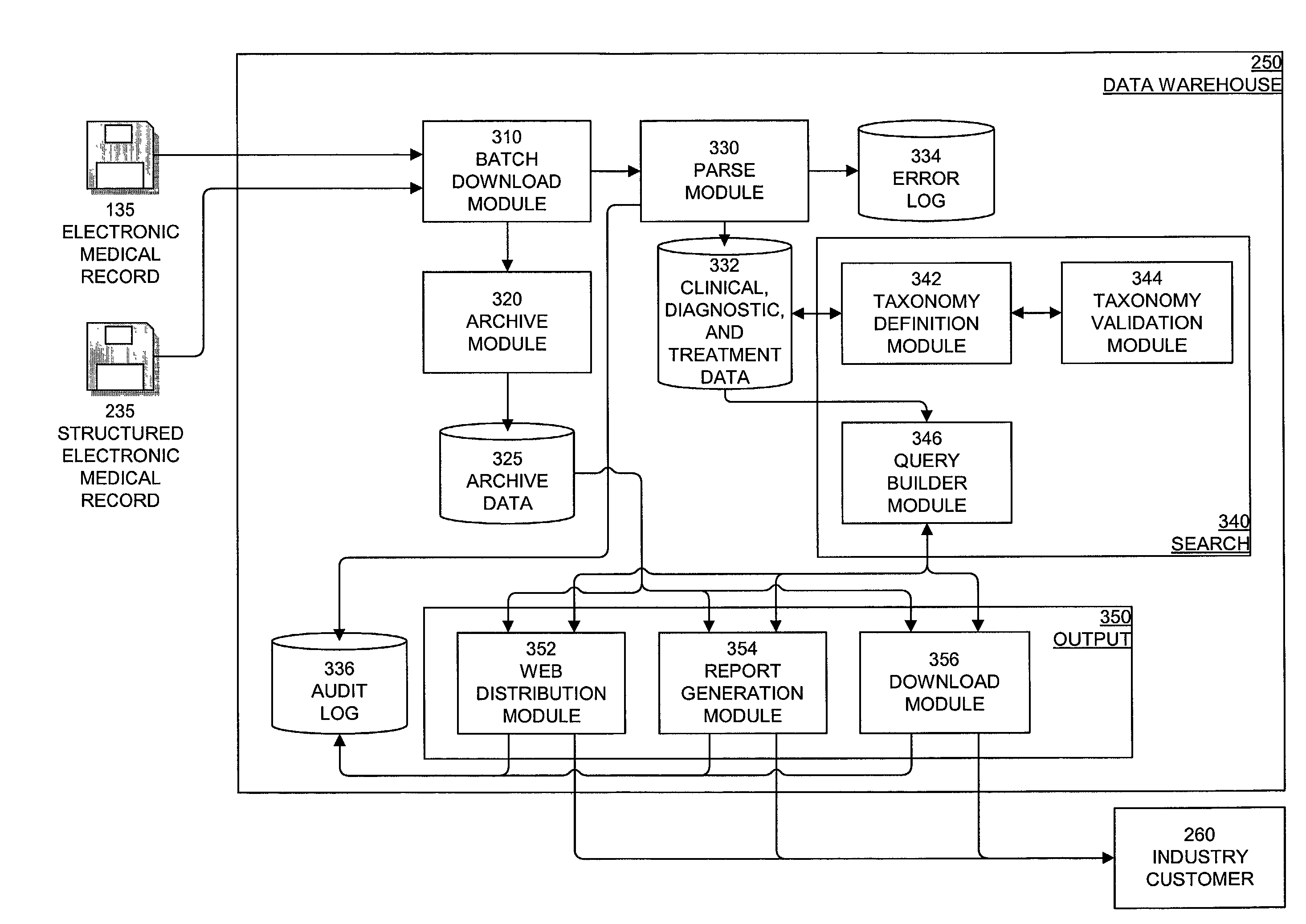

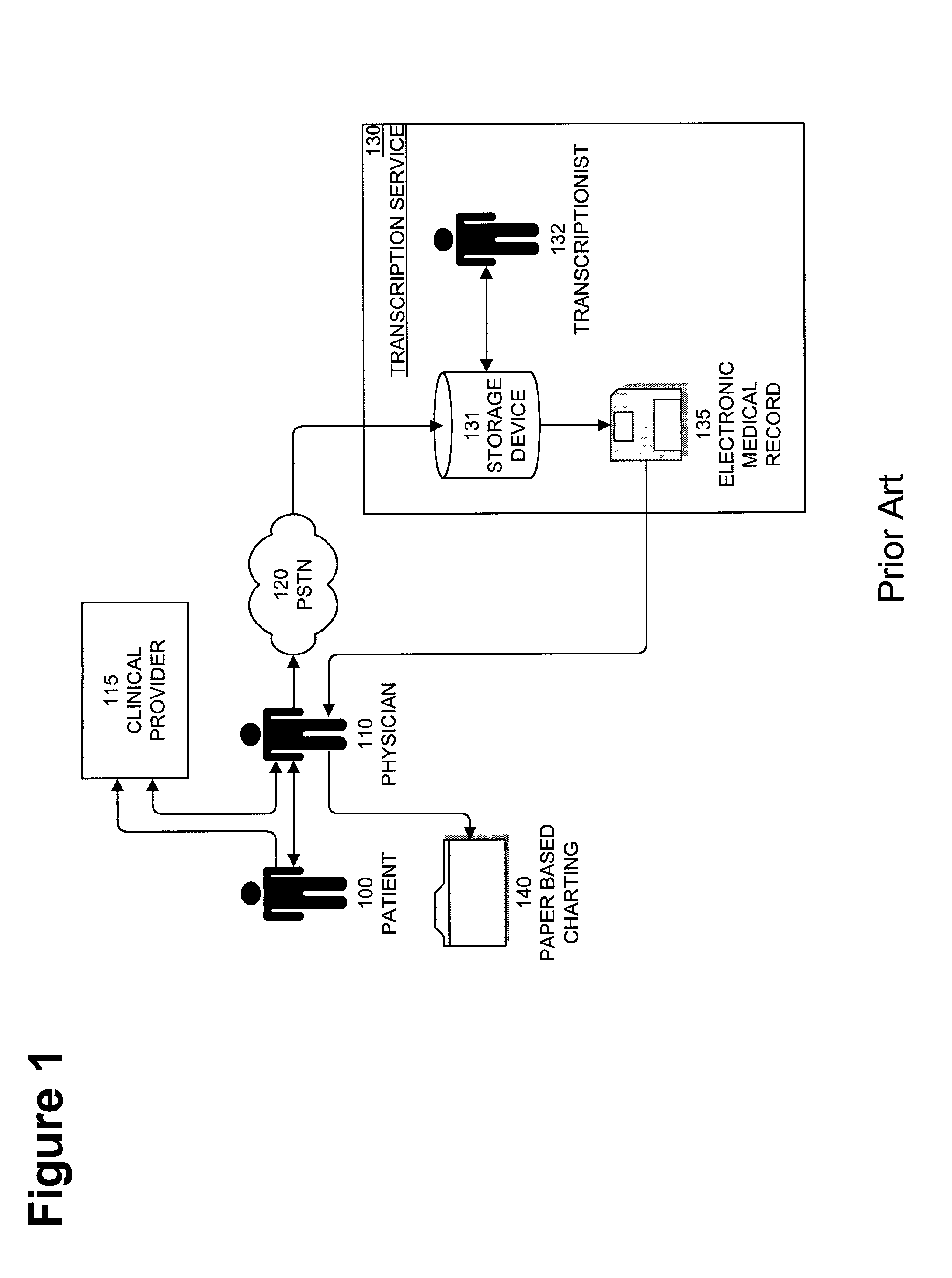

System, method, and apparatus for storing, retrieving, and integrating clinical, diagnostic, genomic, and therapeutic data

InactiveUS7529685B2Useful purposeImprove performanceMedical data miningMedical automated diagnosisClinical researchPatient data

A method, system, and computer program product for storing and retrieving patient data in a database connected to a network is disclosed. The method, system, and computer program product comprises storing clinical data in the database, extracting data from the clinical data, querying the database using a taxonomy that includes inclusive or exclusive search criterion, and receiving a result set. The method, system, and computer program product comprises creating a taxonomy that includes at least one search criterion, sending a query to the database, the query including said at least one search criteria, receiving the result set in response to the query, the result set including at least one result record, and displaying said at least one result record. The method, system, and computer program product can further include a user such as a clinical researcher, a treating physician, or a consulting physician analyzing the result set.

Owner:MD DATACOR

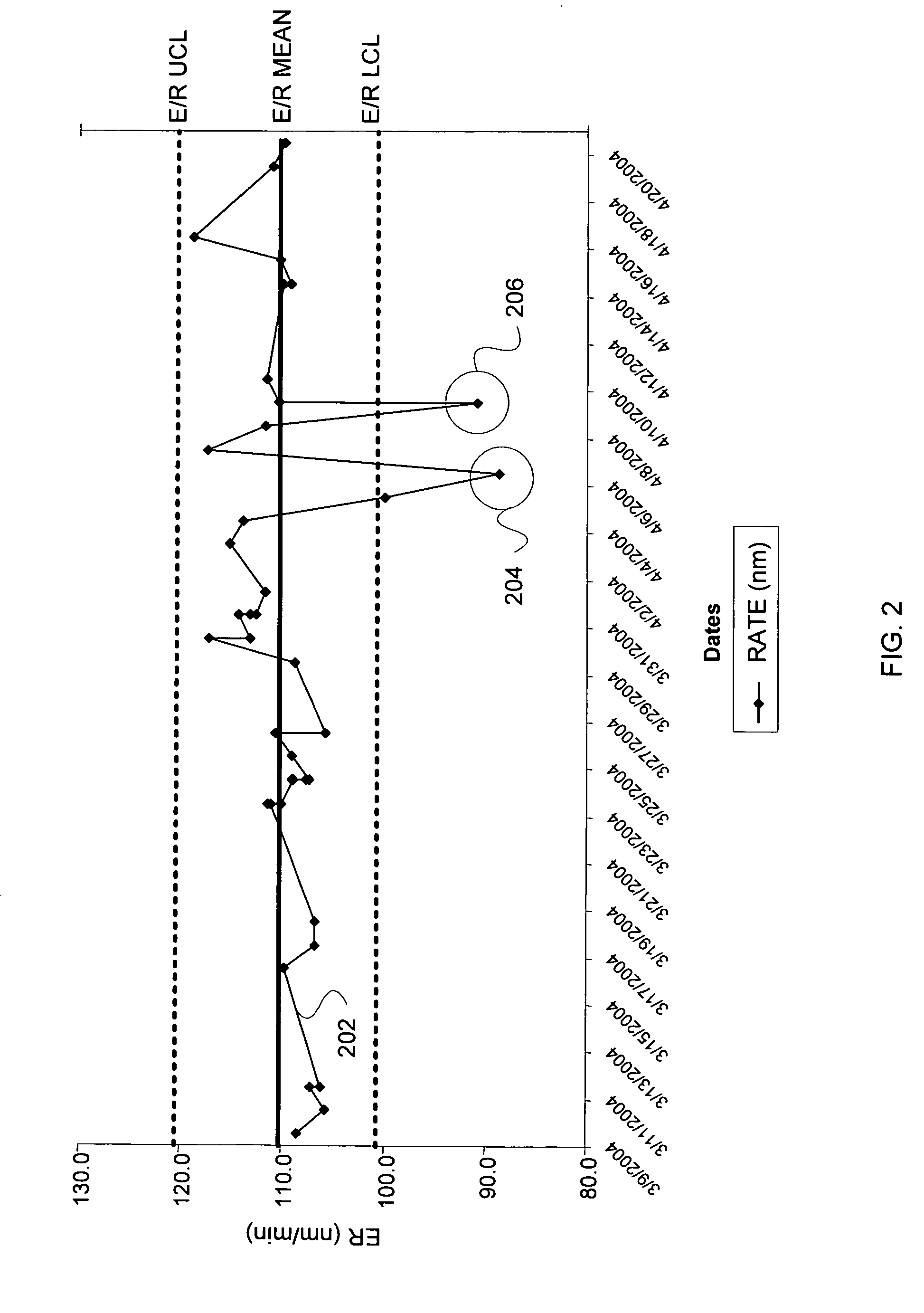

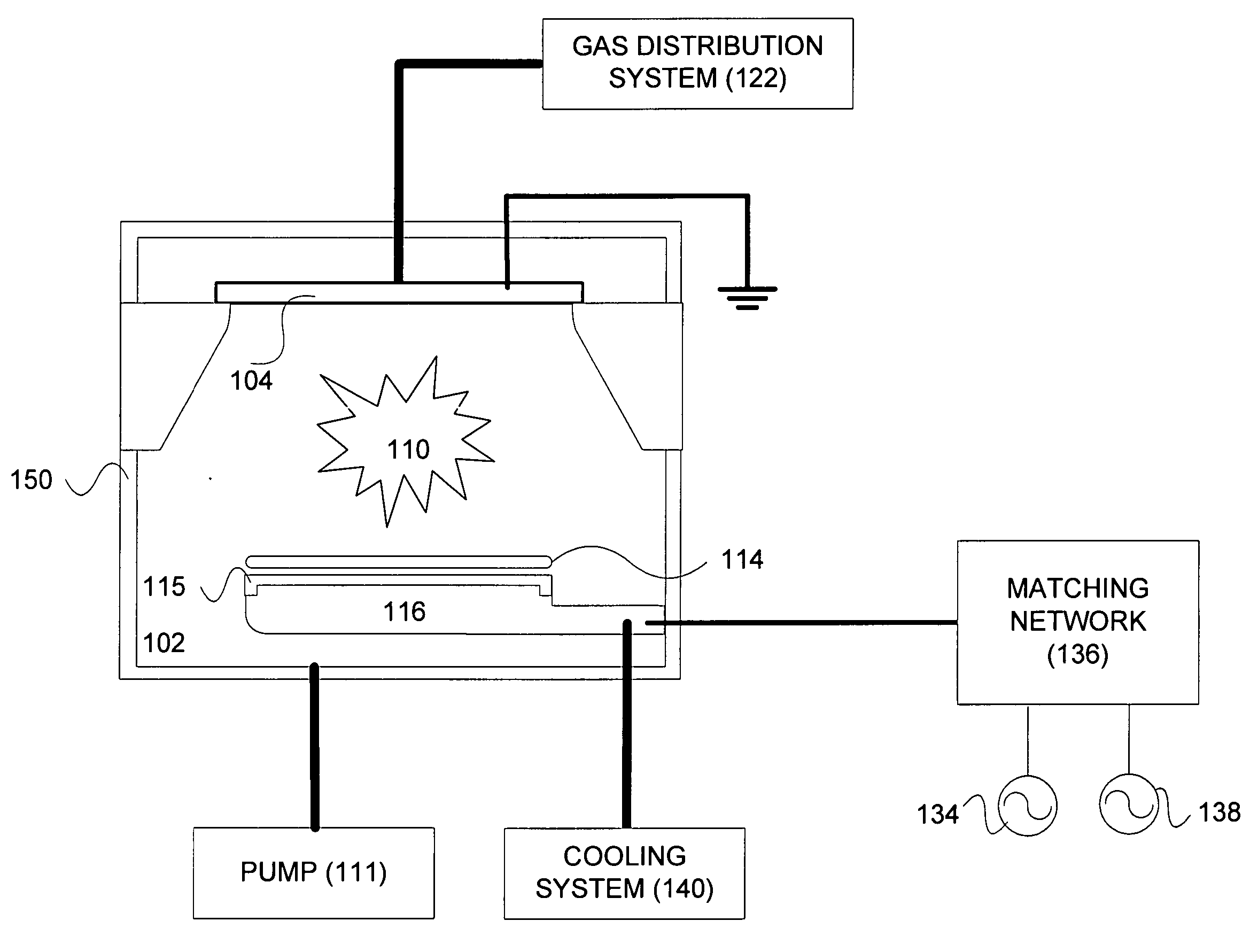

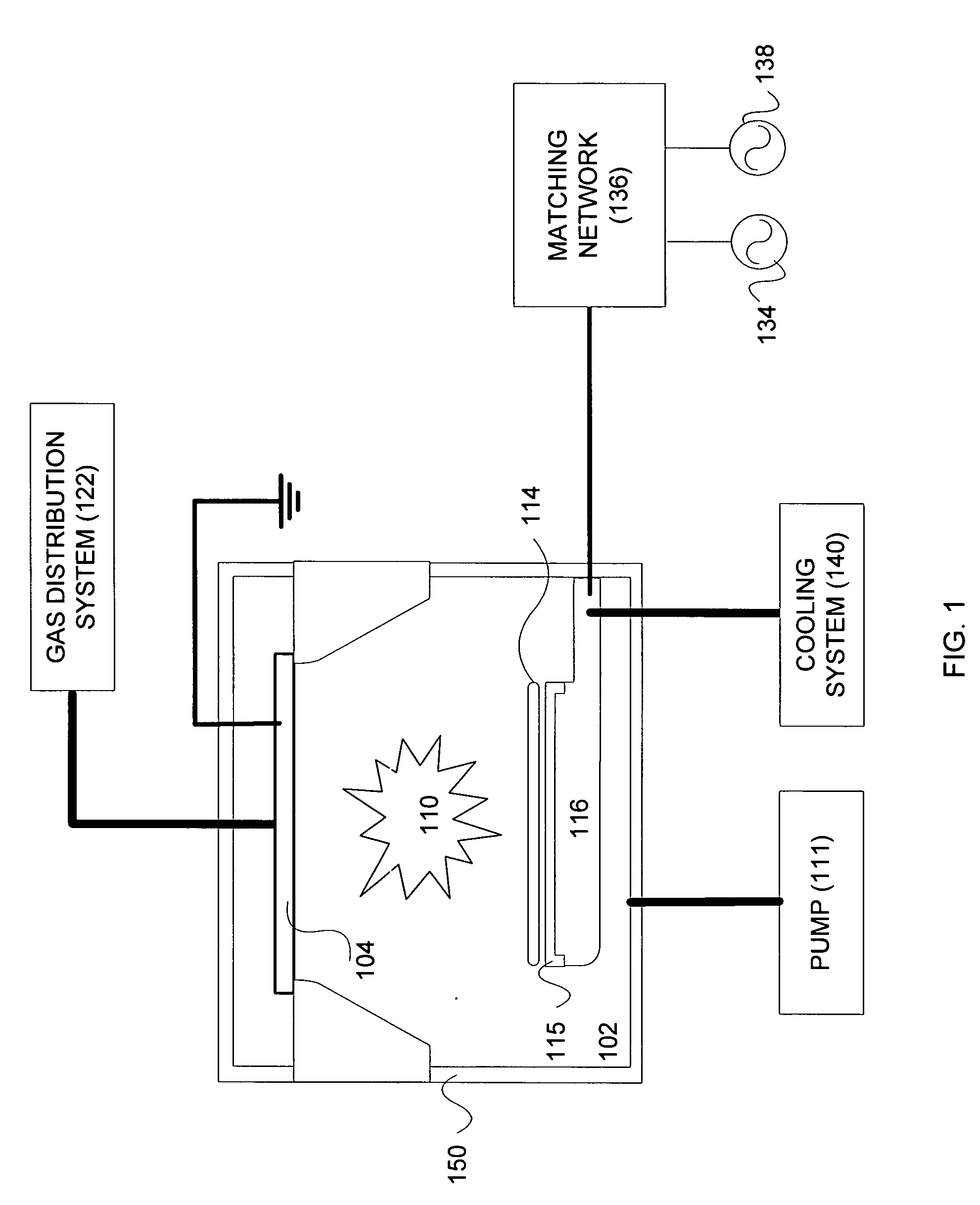

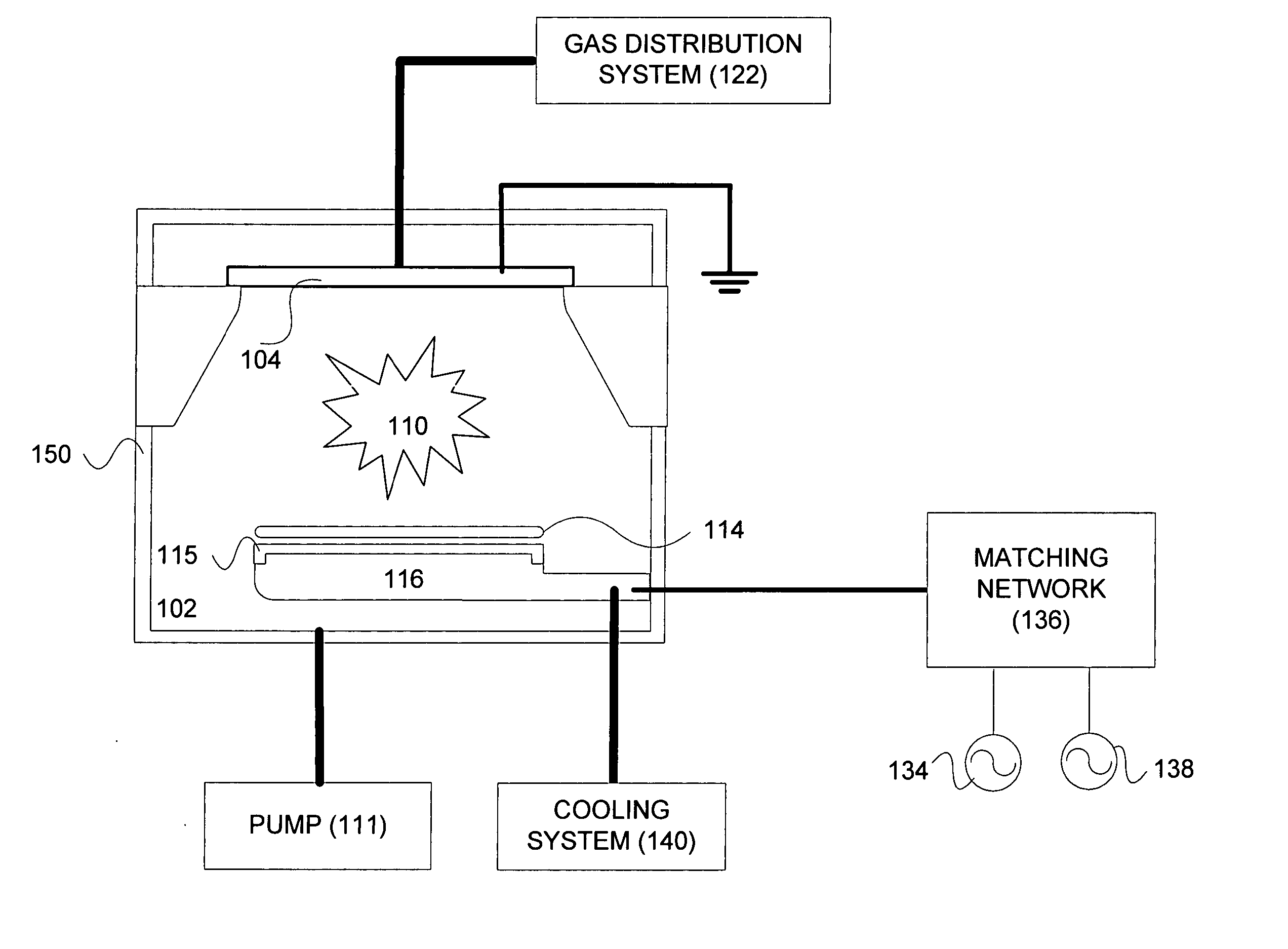

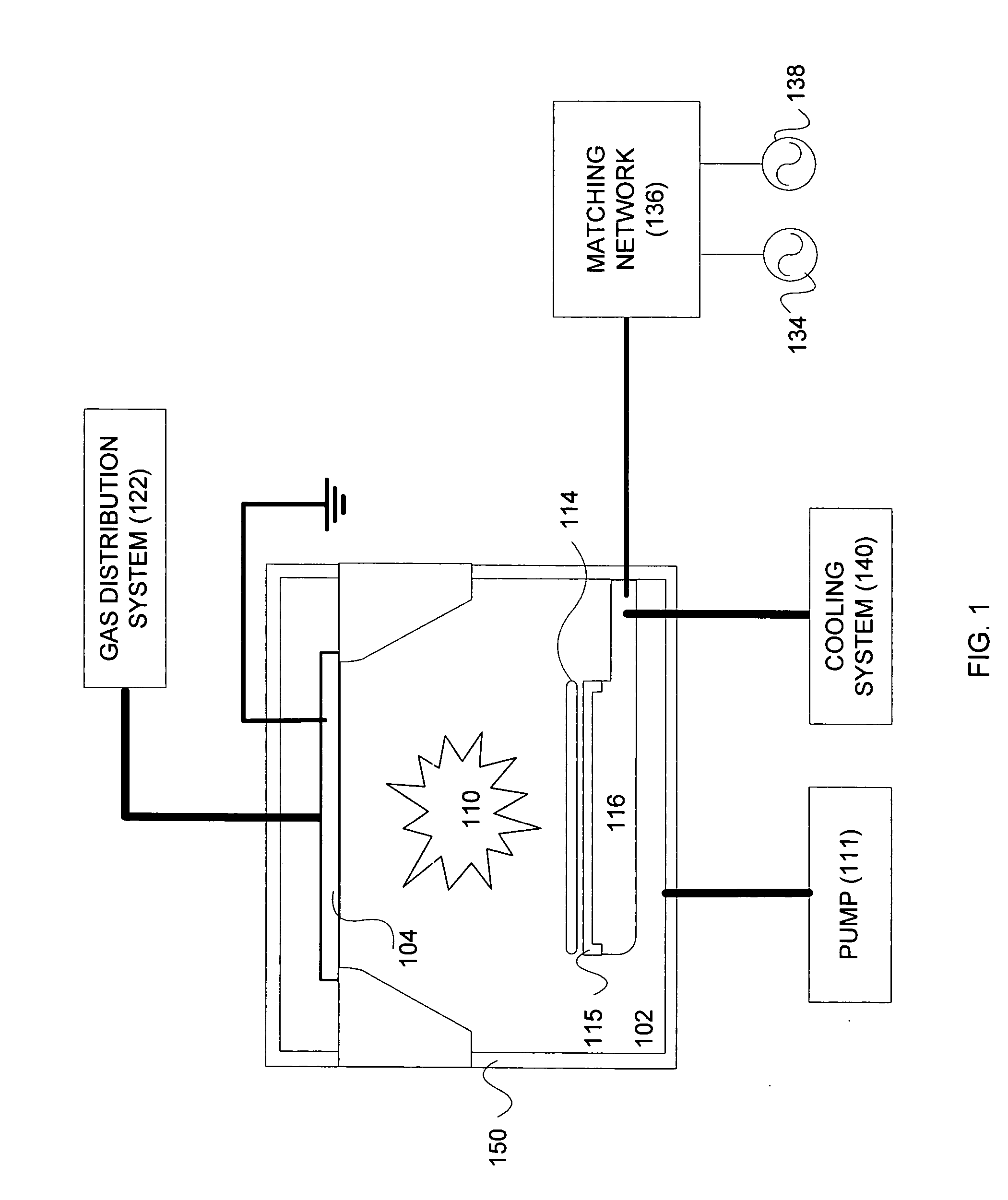

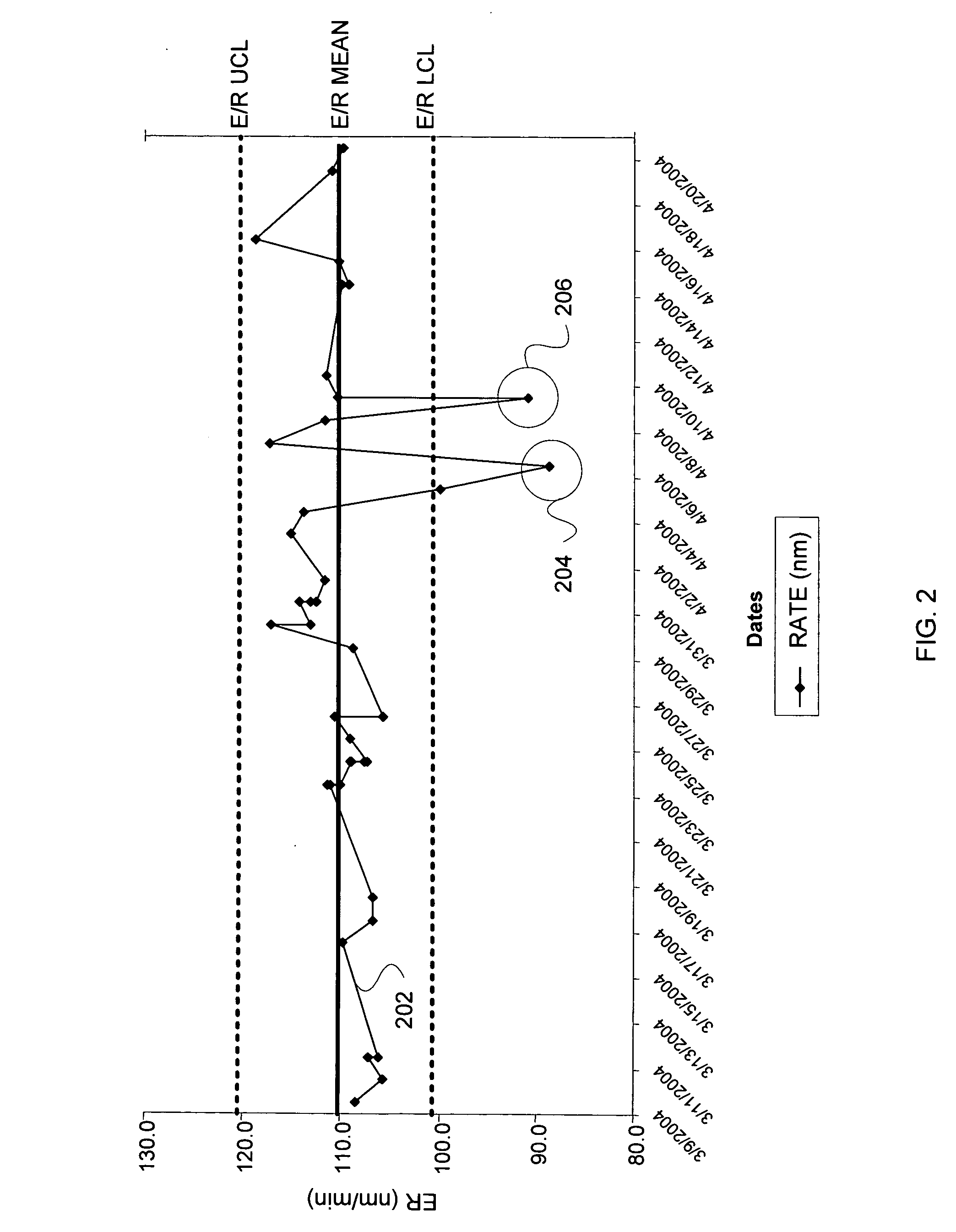

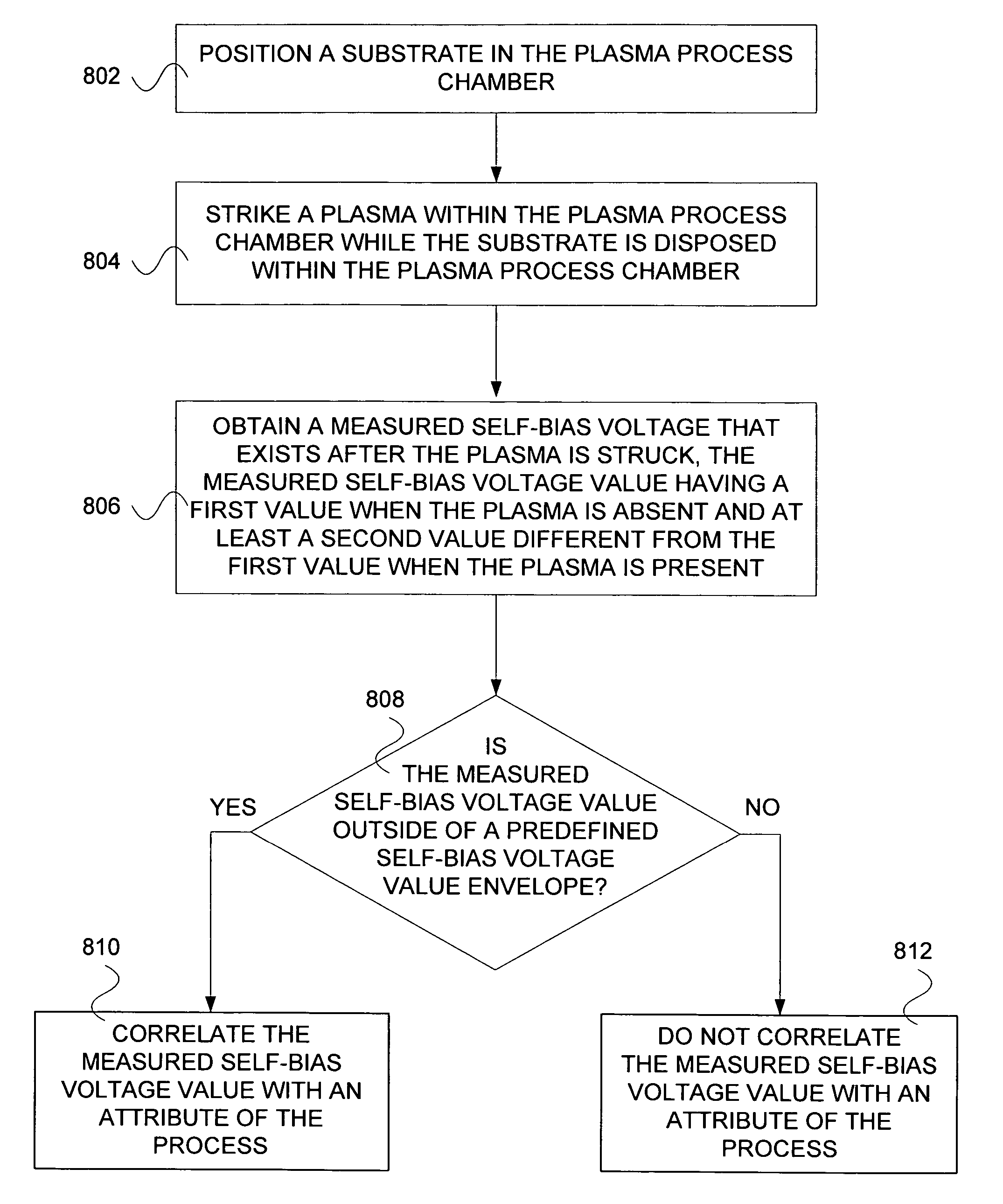

Methods and apparatus for monitoring a process in a plasma processing system by measuring self-bias voltage

ActiveUS20060065623A1Useful purposeSemiconductor/solid-state device testing/measurementElectric discharge tubesEngineeringPlasma processing

A method for in-situ monitoring a process in a plasma processing system having a plasma processing chamber is disclosed. The method includes positioning a substrate in the plasma processing chamber. The method also includes striking a plasma within the plasma processing chamber while the substrate is disposed within the plasma processing chamber. The method further includes obtaining a measured self-bias voltage that exists after the plasma is struck, the measured self-bias voltage value having a first value when the plasma is absent and at least a second value different from the first value when the plasma is present. The method also includes correlating the measured self-bias voltage value with an attribute of the process, if the measured self-bias voltage value is outside of a predefined self-bias voltage value envelope.

Owner:LAM RES CORP

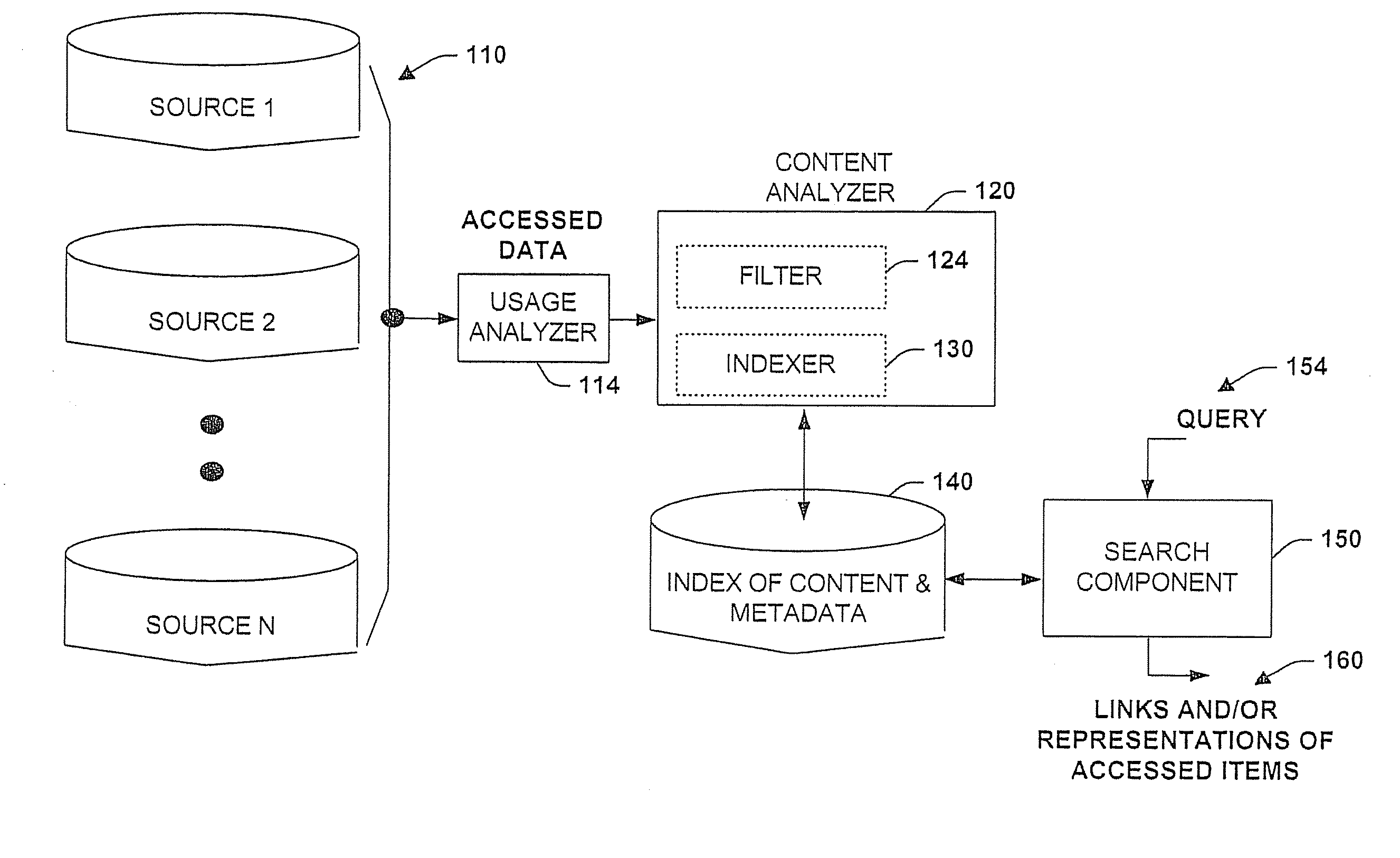

Systems and methods for personal ubiquitous information retrieval and reuse

InactiveUS20070112742A1Facilitate search for informationEasy to reuseData processing applicationsText database indexingData accessContent analytics

Owner:MICROSOFT TECH LICENSING LLC

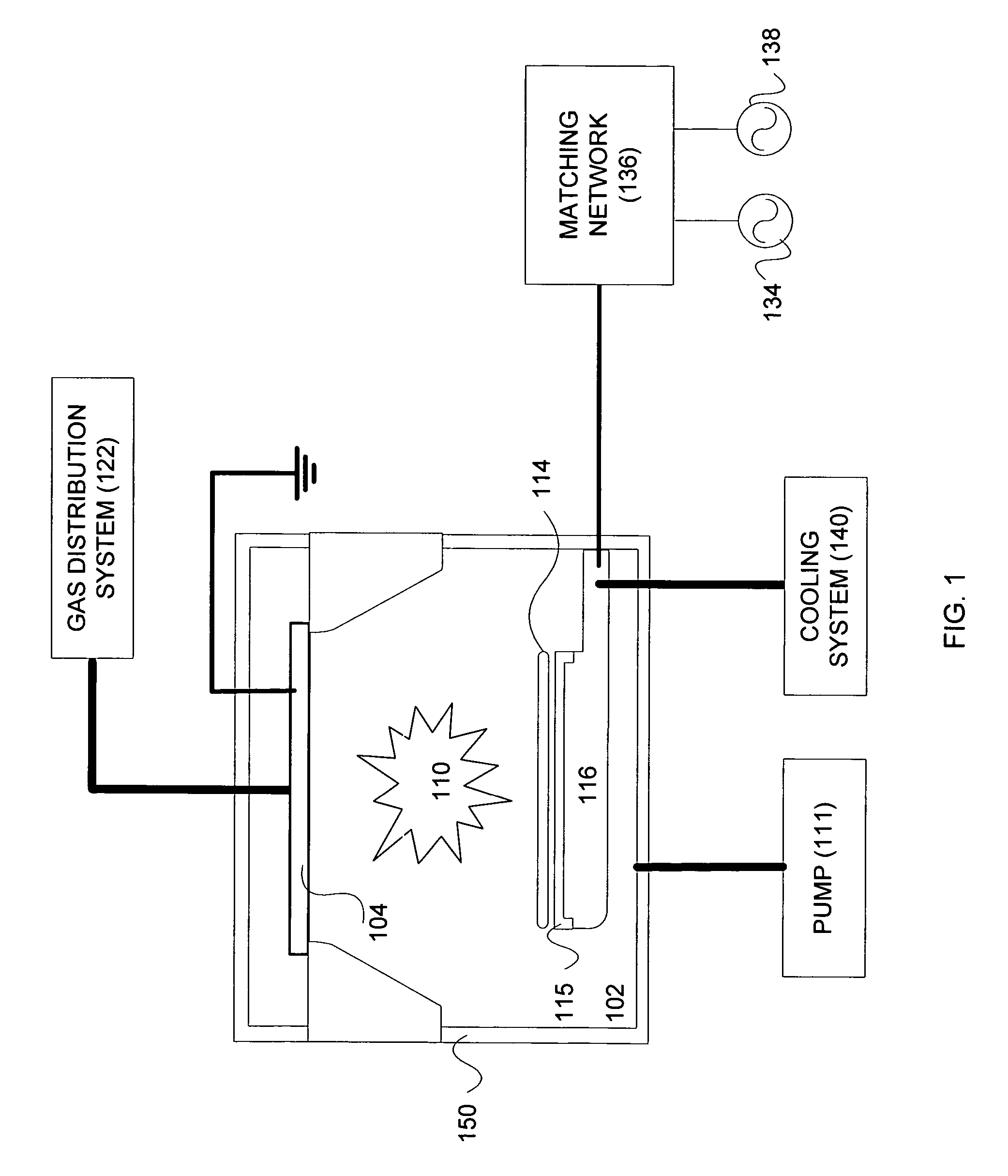

Methods and apparatus for monitoring a process in a plasma processing system by measuring impedance

InactiveUS20060065631A1Useful purposeElectric discharge tubesDecorative surface effectsElectrical impedancePlasma processing

A method for in-situ monitoring a process in a plasma processing system having a plasma processing chamber is disclosed. The method includes positioning a substrate in the plasma processing chamber. The method also includes striking a plasma within the plasma processing chamber while the substrate is disposed within the plasma processing chamber. The method further includes obtaining a measured impedance that exists after the plasma is struck, the measured impedance value having a first value when the plasma is absent and at least a second value different from the first value when the plasma is present. The method also includes correlating the measured impedance value with an attribute of the process, if the measured impedance value is outside of a predefined impedance value envelope.

Owner:LAM RES CORP

Systems and methods for providing enhanced account management services for multiple banks

InactiveUS8290860B1Reduce riskApply evenlyFinancePayment architectureDeposit accountComputerized system

Owner:ISLAND INTPROP

Systems and methods for providing enhanced account management services for multiple banks

InactiveUS8290859B1Reduce riskApply evenlyFinancePayment architectureDeposit accountComputerized system

Owner:ISLAND INTPROP

Systems and methods for providing enhanced account management services for multiple banks

InactiveUS8290861B1Reduce riskApply evenlyFinancePayment architectureDeposit accountTransaction account

A system, method and program product for managing funds, comprising: databases comprising: aggregated transaction account information for plurality of FDIC-insured and interest-bearing aggregated deposit accounts, and client transaction account information; first computation engine for computing respective excess amount by which a balance of funds from that client transaction account exceeds specified amount; first allocation engine allocating respective excess amounts to one or more aggregated deposit accounts in one or more other financial institutions; second computation engine for determining first amount comprising a sum of a plurality excess amounts to one or more aggregated deposit accounts; second allocation engine for allocating to the one financial institution second amount based on a difference between a sum of funds deposited in the one or more aggregated deposit accounts and sum of current balances from the primary client transaction accounts associated with the one financial institution; update engine, and instruction generator.

Owner:ISLAND INTPROP

Methods and apparatus for monitoring a process in a plasma processing system by measuring a plasma frequency

InactiveUS20060065632A1Useful purposeElectric discharge tubesDecorative surface effectsPlasma processingAtomic physics

A method for in-situ monitoring a process in a plasma processing system having a plasma processing chamber is disclosed. The method includes positioning a substrate in the plasma processing chamber. The method also includes striking a plasma within the plasma processing chamber while the substrate is disposed within the plasma processing chamber. The method further includes obtaining a measured plasma frequency that exists after the plasma is struck, the measured plasma frequency value having a first value when the plasma is absent and at least a second value different from the first value when the plasma is present. The method also includes correlating the measured plasma frequency value with an attribute of the process, if the measured plasma frequency value is outside of a predefined plasma frequency value envelope.

Owner:LAM RES CORP

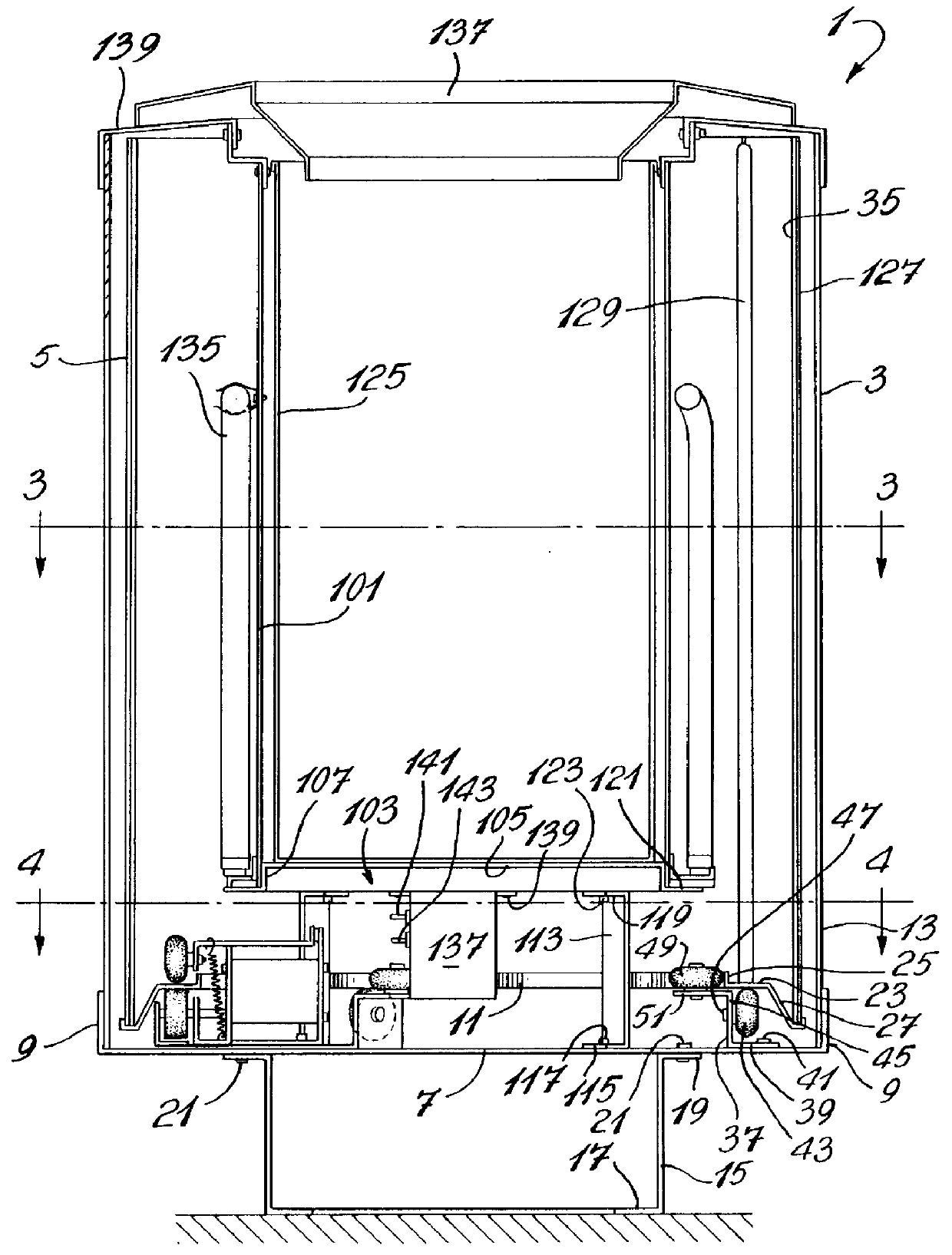

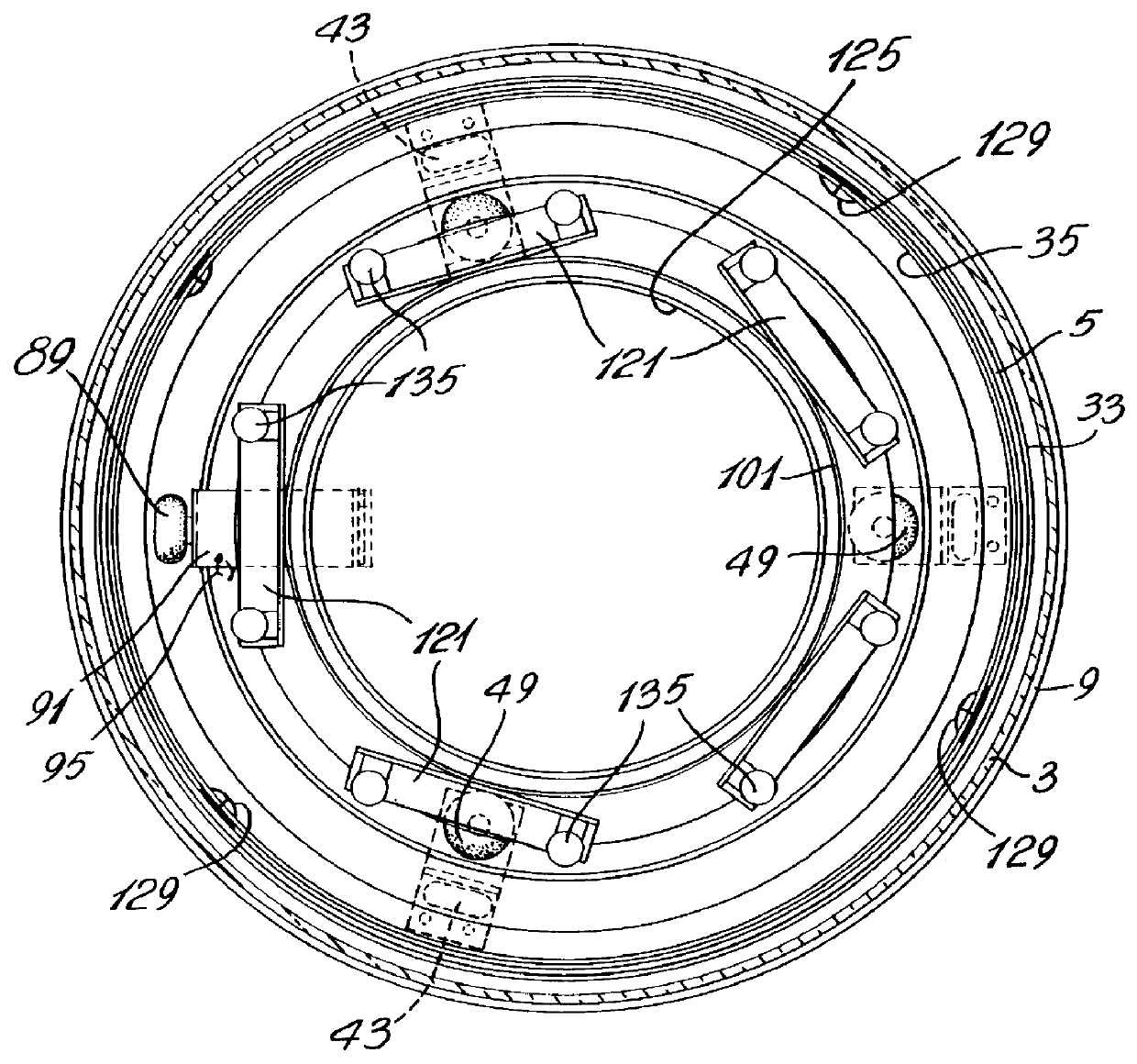

Device for rotatably displaying advertising material

InactiveUS6148552AReduce manufacturing costUseful purposeIlluminated signsBoardsLighting systemMechanical engineering

The device comprises a base member, a transparent outer tubular member which is fixed to the base member. It also comprises a transparent inner tubular member and a revolving inner tubular member holder to mount the inner tubular member in spaced relationship with respect to the outer tubular member. The revolving member is mounted on the base member so as to permit rotation of the revolving inner tubular member holder and of the transparent inner tubular member. Mounting strips or the like are provided to mount translucid advertising sheets on the inner tubular member, and a lighting system is arranged to direct light against the translucid advertising material so as to enable the advertising material to be observed through the transparent tubular member. A container such as a waste box may be placed in the space provided inside the inner tubular member.

Owner:DUMONTIER RAYMOND +1

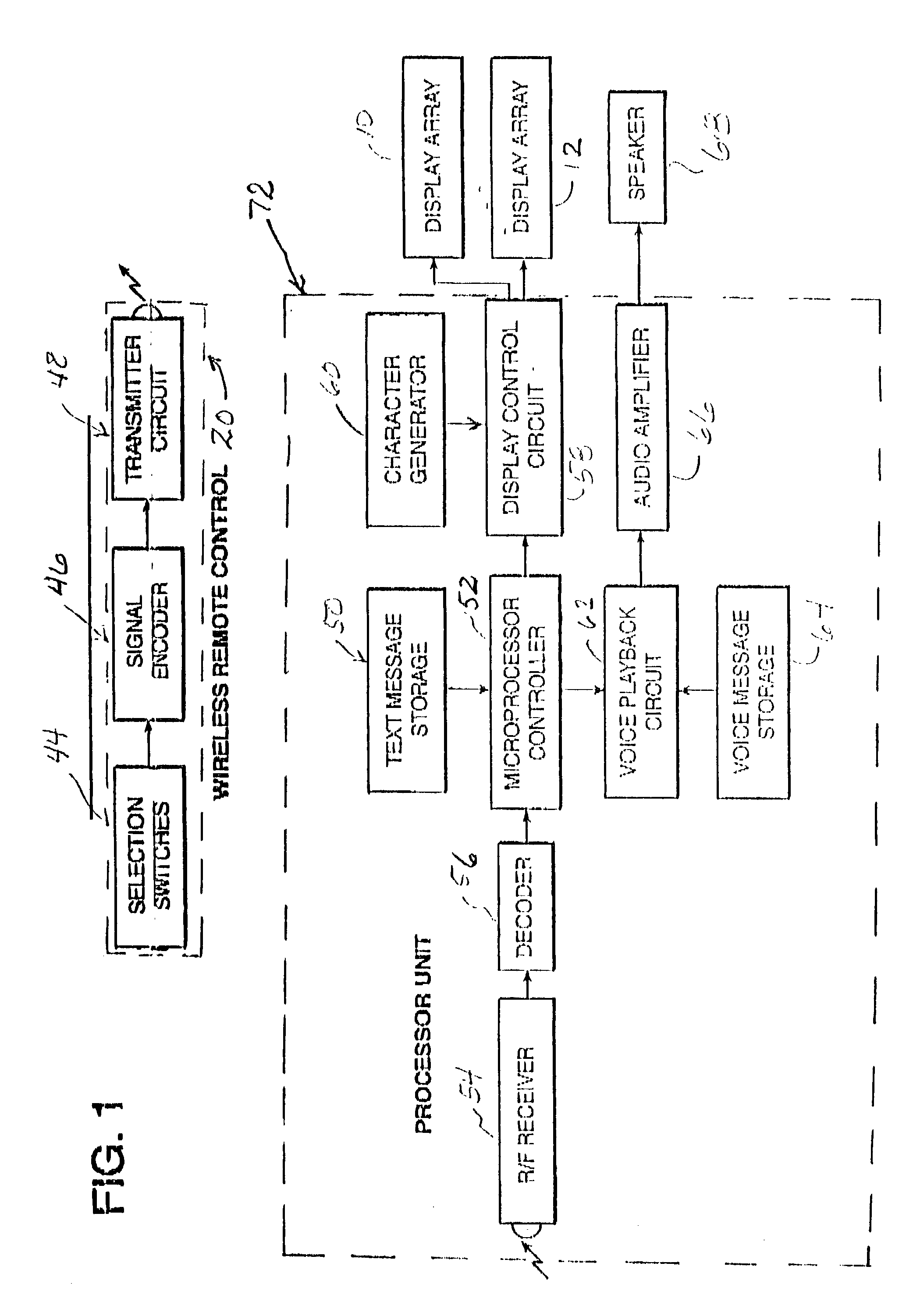

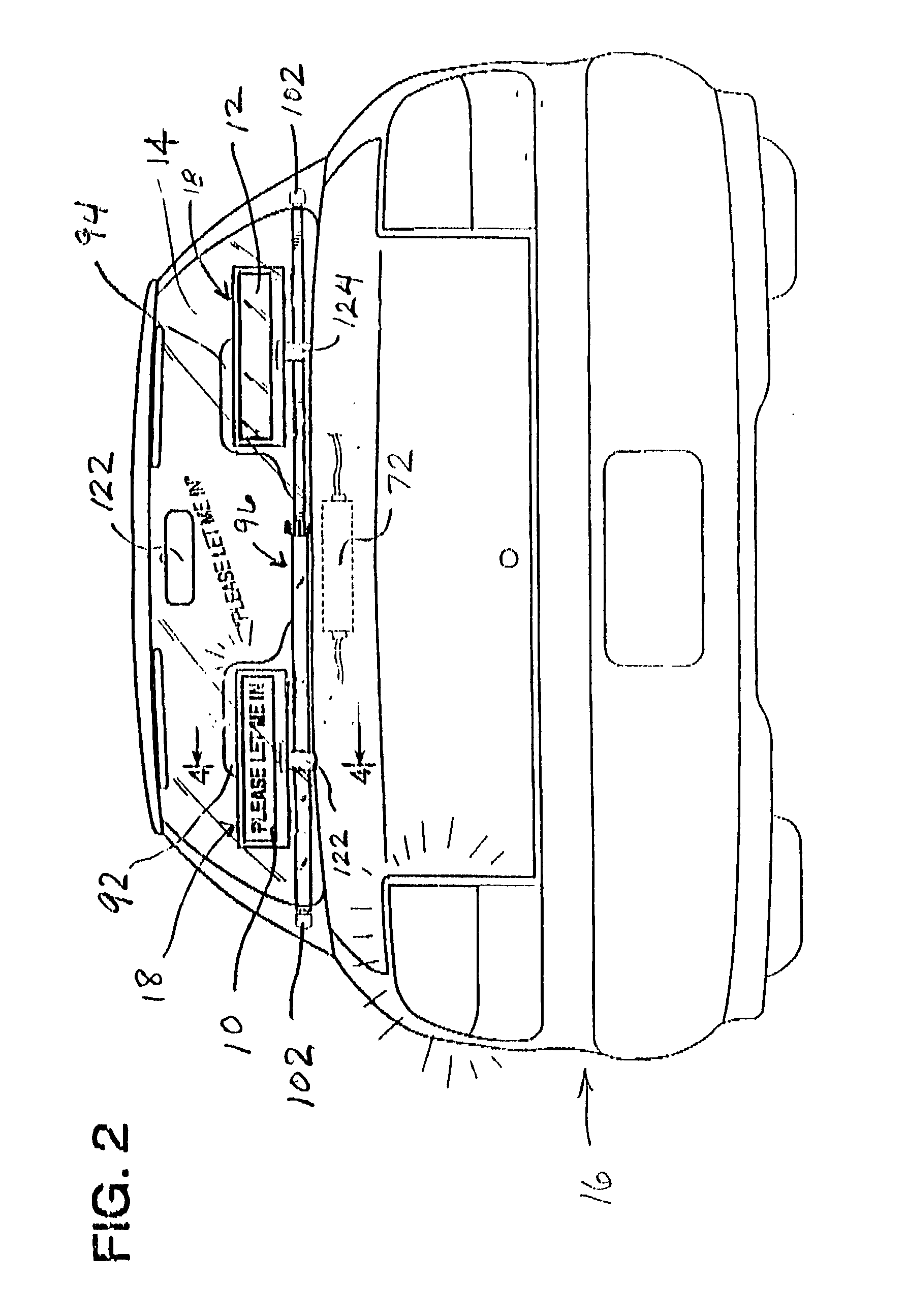

Automotive courtesy display

InactiveUS20030227375A1Reduce road rage among driversLower insurance premiumsOptical signallingWireless controlDriver/operator

An automotive vehicle courtesy message display system allows the driver of a automotive vehicle to visually display courtesy messages to the drivers of vehicles located to the rear. Such messages may be for an occasional urgent request to "cut in" for safe passage. The message display system provides the driver of the vehicle in which the visual display is installed with an audible feedback so that the vehicle driver can verify that the correct message has been selected, without visually distracting the driver's attention. The system includes three main components, namely a wireless control unit located on the vehicle operator's steering wheel, a processor unit containing most of the electronics of the system positioned in an unobtrusive location so as to avoid impairing the drivers view, and one or a pair of display screens which are typically located behind the rear seat headrests of an automotive passenger vehicle. A microprocessor controller withing the microprocessor unit selects a text message corresponding to the particular touch sensor depressed, and transmits it to an appropriate one the display screens. The audible announcement of the message selected by the touch sensor provides the operator with a positive feedback indicating selection of the correct message.

Owner:YONG PETER

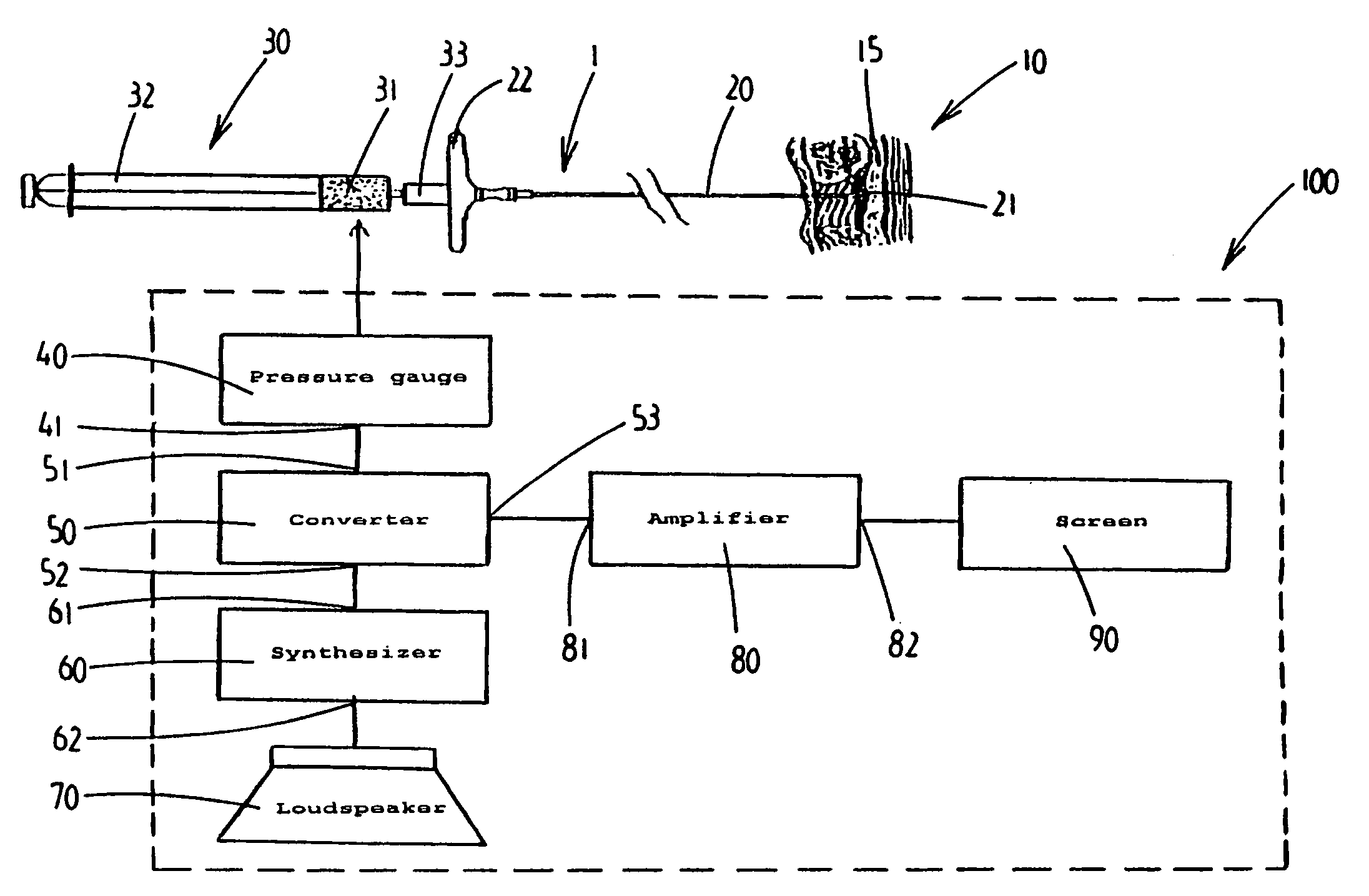

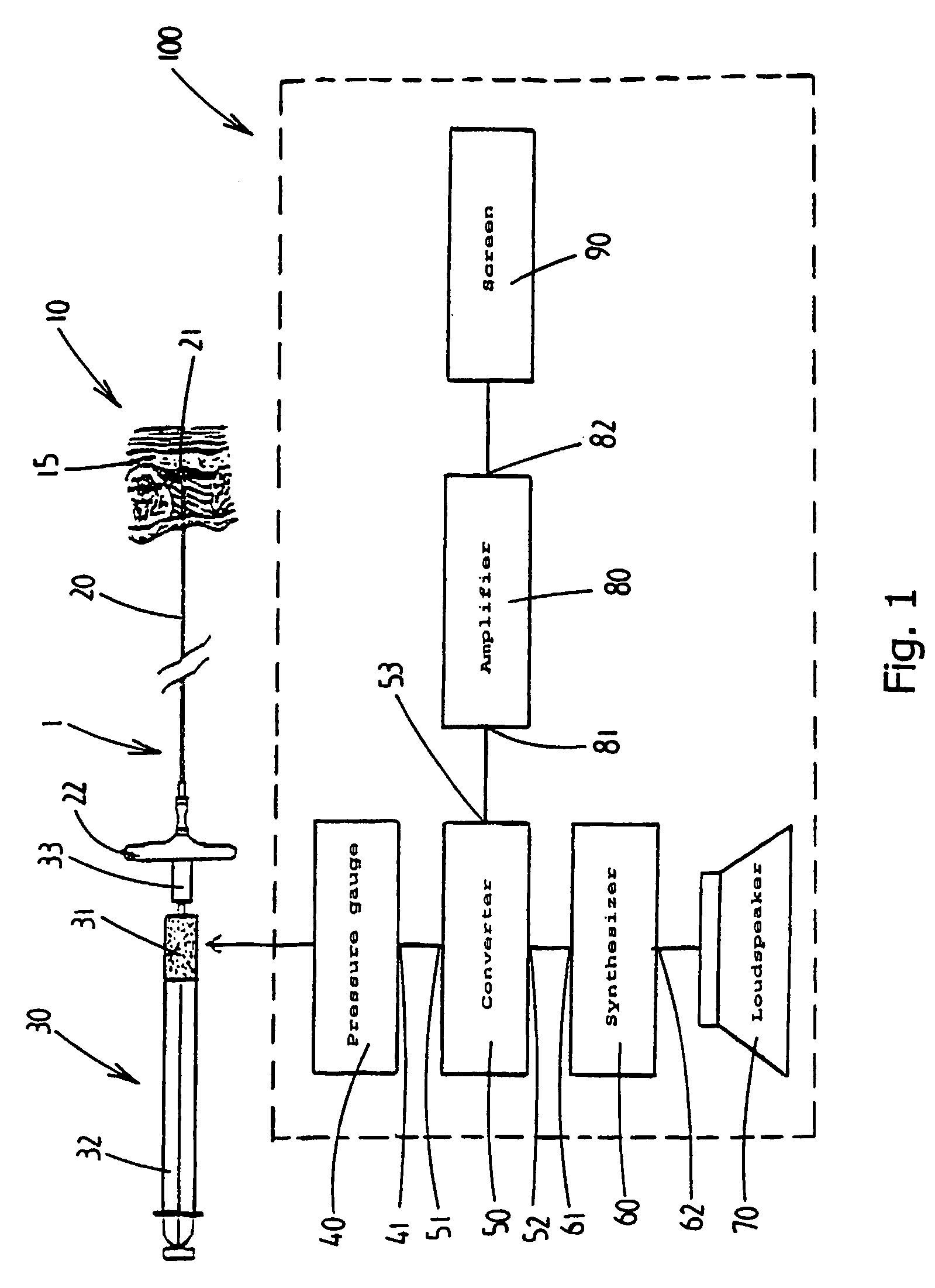

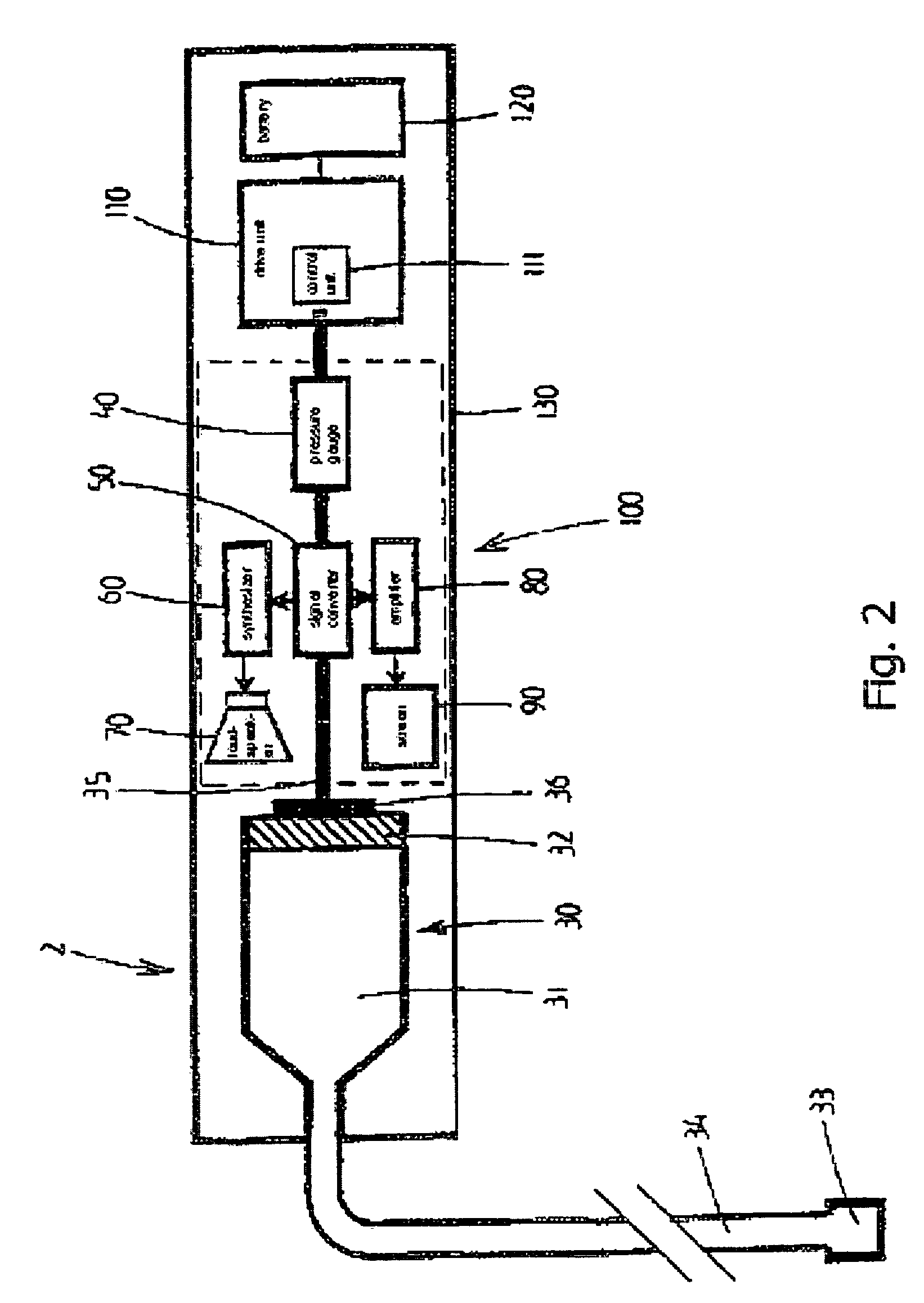

Device and method for locating anatomical cavity in a body

ActiveUS7922689B2Limiting introductionForce can be exertedUltrasonic/sonic/infrasonic diagnosticsSurgical needlesEngineeringPressure measurement

A device (1) is designed for locating a region which is situated in a body (10). The device has a fluid-filled reservoir (30) which is closed off in a sealed manner by a displaceable plunger (32) and is connected to a hollow puncture needle (20). To measure the pressure prevailing in the fluid, the device has a pressure gauge (40). A signal converter (50) is used to convert a continuous pressure-measurement signal provided by the pressure gauge (40) into a form which is suitable for further processing. A synthesizer (60) is designed to process the converted pressure-measurement signal into a continuous sound signal which is representative of the pressure. If, during a displacement of the puncture needle (20), a needle point (21) reaches the anatomical cavity (15), the result is a readily perceptible change in the sound signal. The device records the pressure-measurement signal over the course of time.

Owner:APAD OCTROOI

Methods and apparatus for monitoring a process in a plasma processing system by measuring self-bias voltage

ActiveUS7323116B2Useful purposeSemiconductor/solid-state device testing/measurementElectric discharge tubesEngineeringPlasma processing

A method for in-situ monitoring a process in a plasma processing system having a plasma processing chamber is disclosed. The method includes positioning a substrate in the plasma processing chamber. The method also includes striking a plasma within the plasma processing chamber while the substrate is disposed within the plasma processing chamber. The method further includes obtaining a measured self-bias voltage that exists after the plasma is struck, the measured self-bias voltage value having a first value when the plasma is absent and at least a second value different from the first value when the plasma is present. The method also includes correlating the measured self-bias voltage value with an attribute of the process, if the measured self-bias voltage value is outside of a predefined self-bias voltage value envelope.

Owner:LAM RES CORP

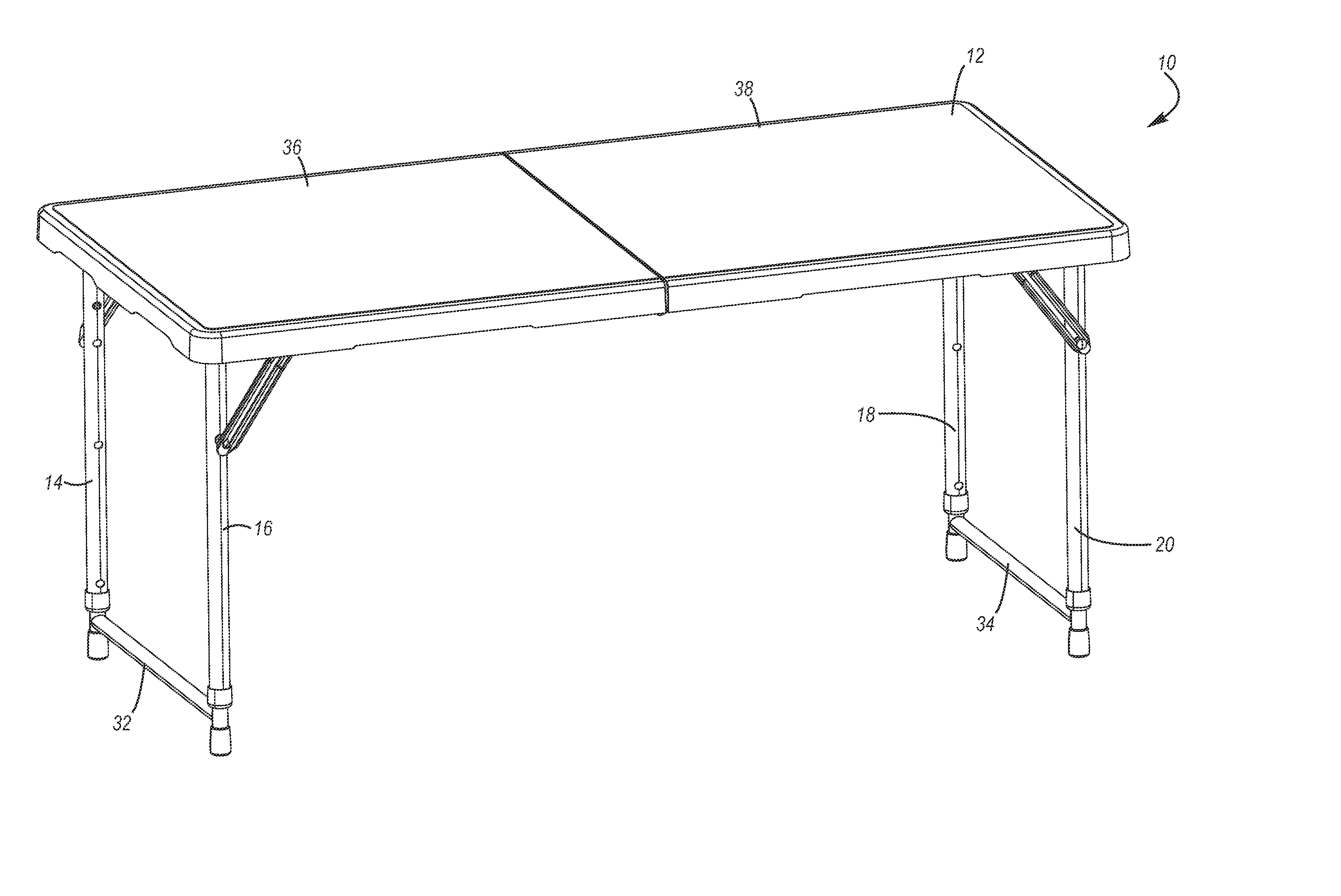

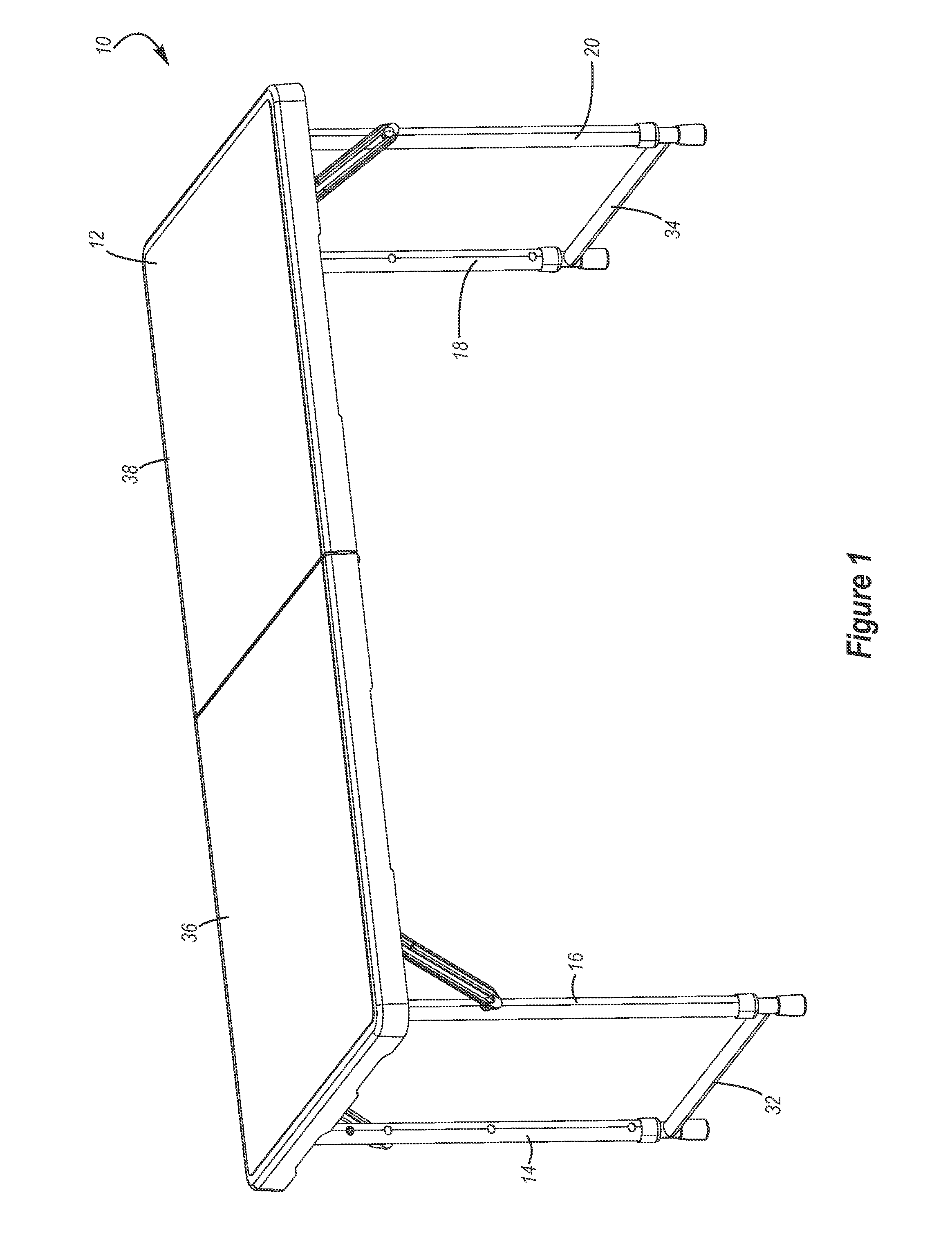

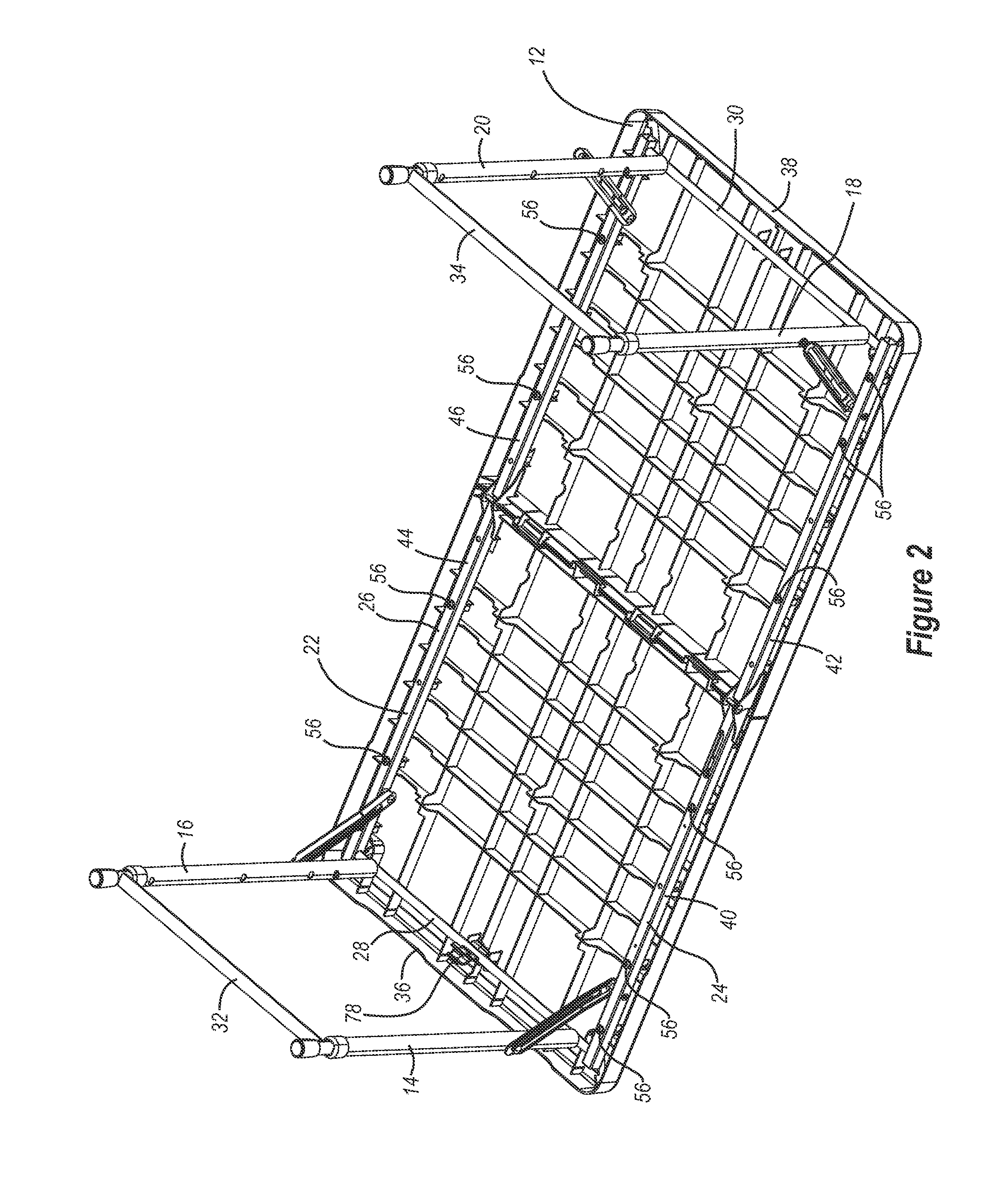

Table

InactiveUS20080078310A1Improve rigidityReduce stressFoldable tablesStowable tablesEngineeringStructural engineering

A table may include a table top, legs, frame and one or more bosses that are sized and configured to allow objects to be attached to the table top. For example, the bosses may be sized and configured to allow the frame to be connected to the table top. The bosses may include a body and reinforcing members that extend outwardly in non-radial directions. The table top may also include ribs that are preferably disposed in a predetermined pattern. For example, a portion of the table top may include a larger number or density of ribs than another portion. In addition, the ribs may be sized and configured to provide a table top with generally uniform characteristics, such as a table top with generally uniform strength and / or rigidity. The table may further be sized and configured to move between a folded position and an unfolded position, and a retainer may be sized and configured to secure the table in the folded position.

Owner:LIFETIME PRODUCTS

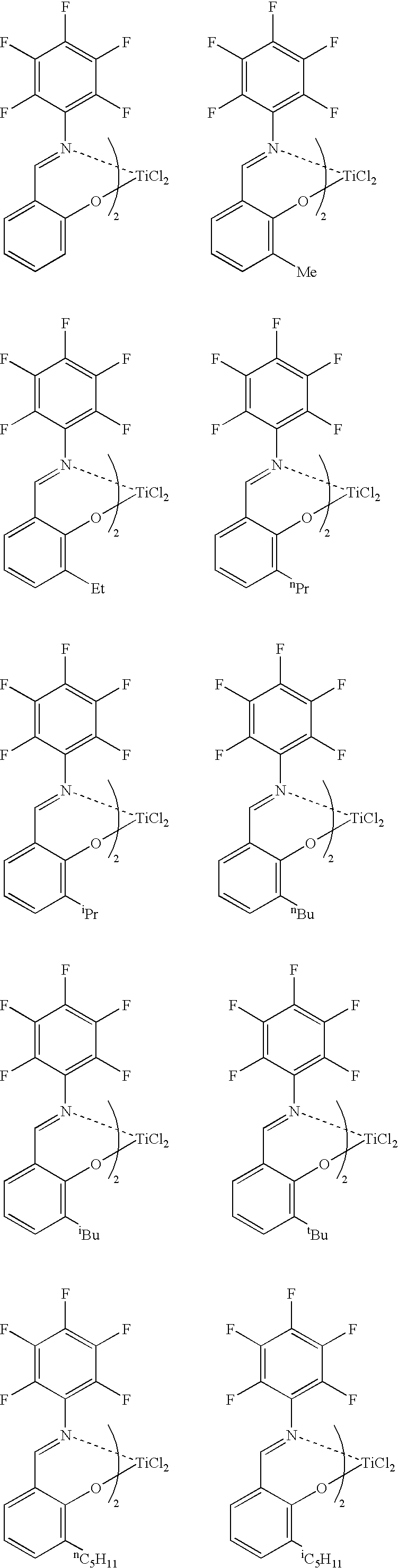

Polyolefin functional at one end

A single-chain-end functionalized polyolefin, which is represented by the following general formula (I): P—X (I) wherein X is a group containing at least one element selected from oxygen, sulfur, nitrogen, phosphorus and halogens, P represents a polymer chain made mainly of an olefin composed only of carbon and hydrogen atoms, and X is bonded to a terminal of P, wherein the molecular weight distribution (Mw / Mn) obtained by gel permeation chromatography (GPC) is from 1.0 to 1.5.

Owner:MITSUI CHEM INC

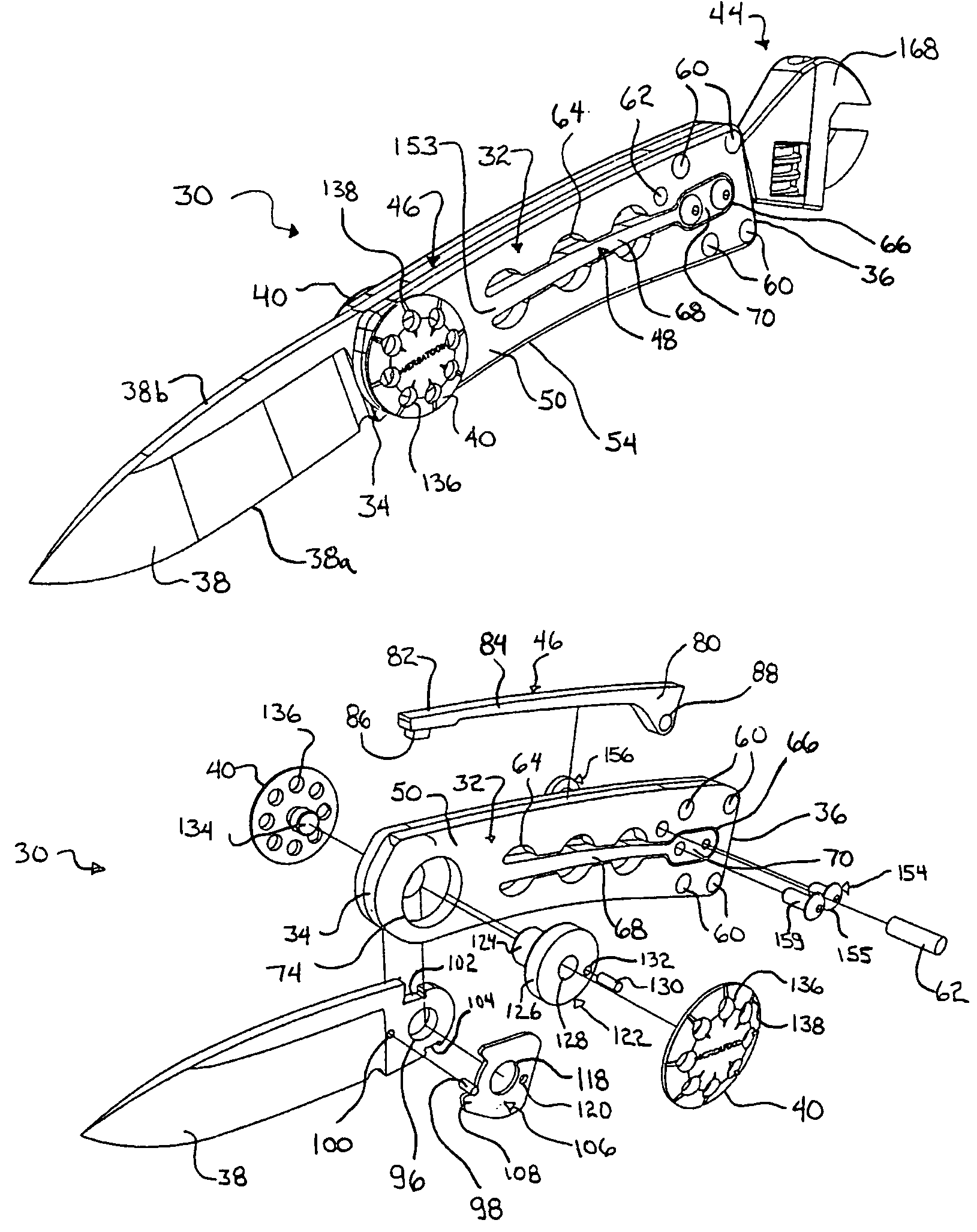

Handheld multi-tool

InactiveUS7174590B1Easy and convenient opening and closingEasy to carryThrusting weaponsWeapon componentsHand heldCam

A multi-tool includes a handle having a blade that is rotatable between open and closed positions by at least one blade rotation member mounted on the side of the handle. The blade includes two locking recesses adapted to receive a locking member mounted to a cantilevered blade lock that extends longitudinally along the handle such that the blade is securely locked in either an open or closed position. The blade rotation members rotate a cam that disengages the blade lock from the blade and imparts rotational motion to the blade by way of a drive pin located on the blade. Preferably, the multi-tool also includes an internal socket located in the handle opposite the blade end, where the socket is adapted to removably receive various tool implements. The tool implements are held in locked engagement with the handle by a cantilevered tool lock located on the handle.

Owner:QUENZI PHILIP J

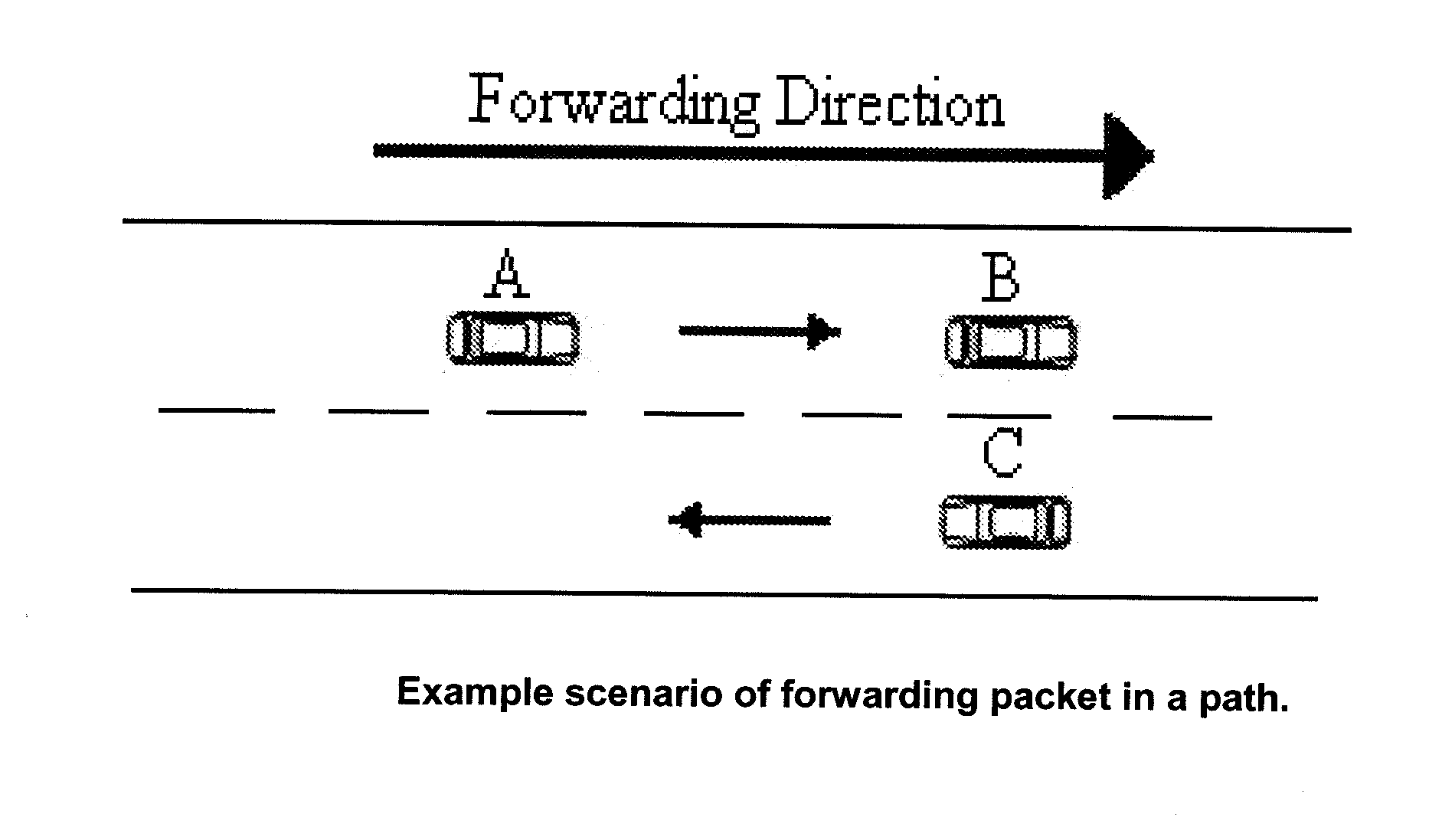

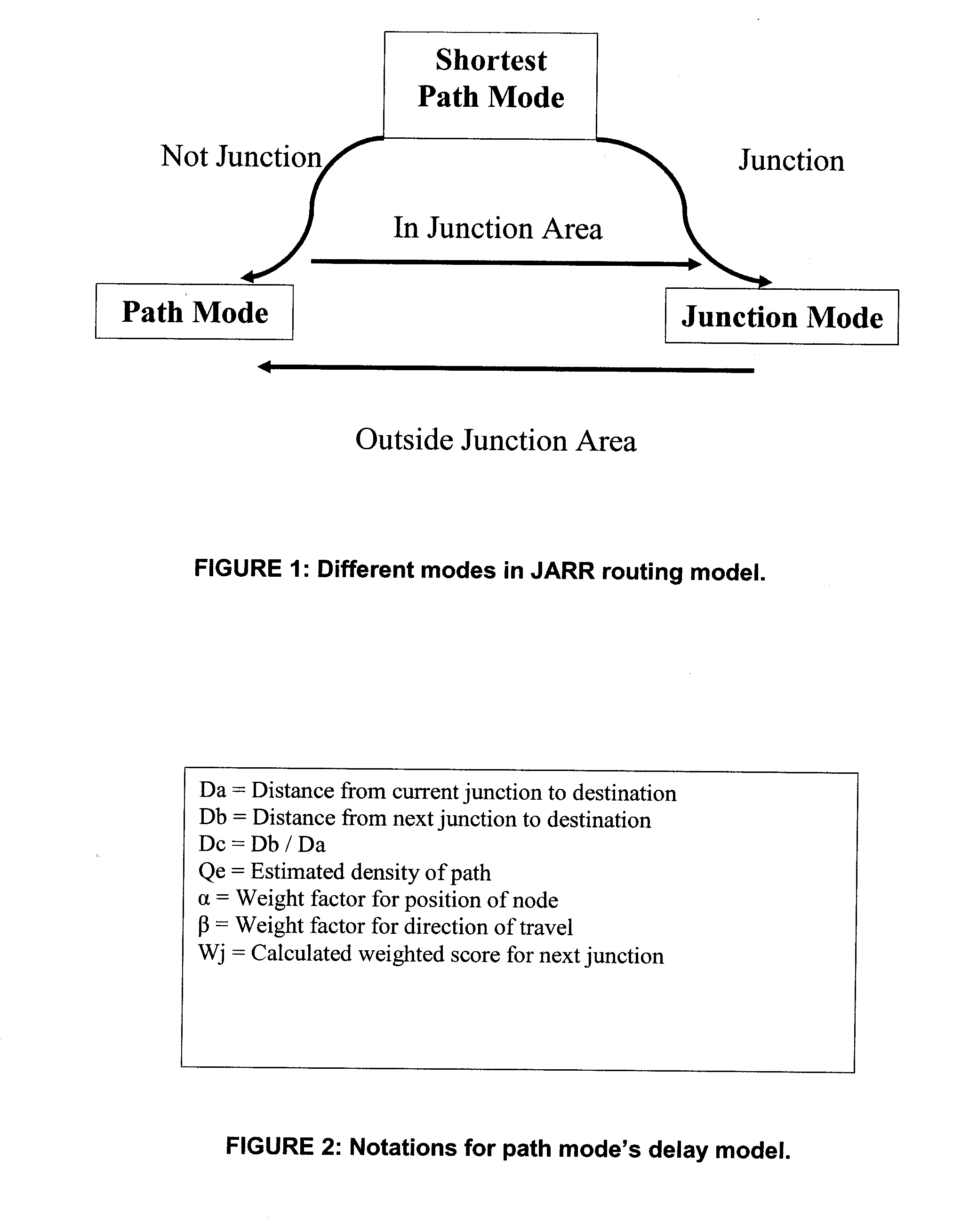

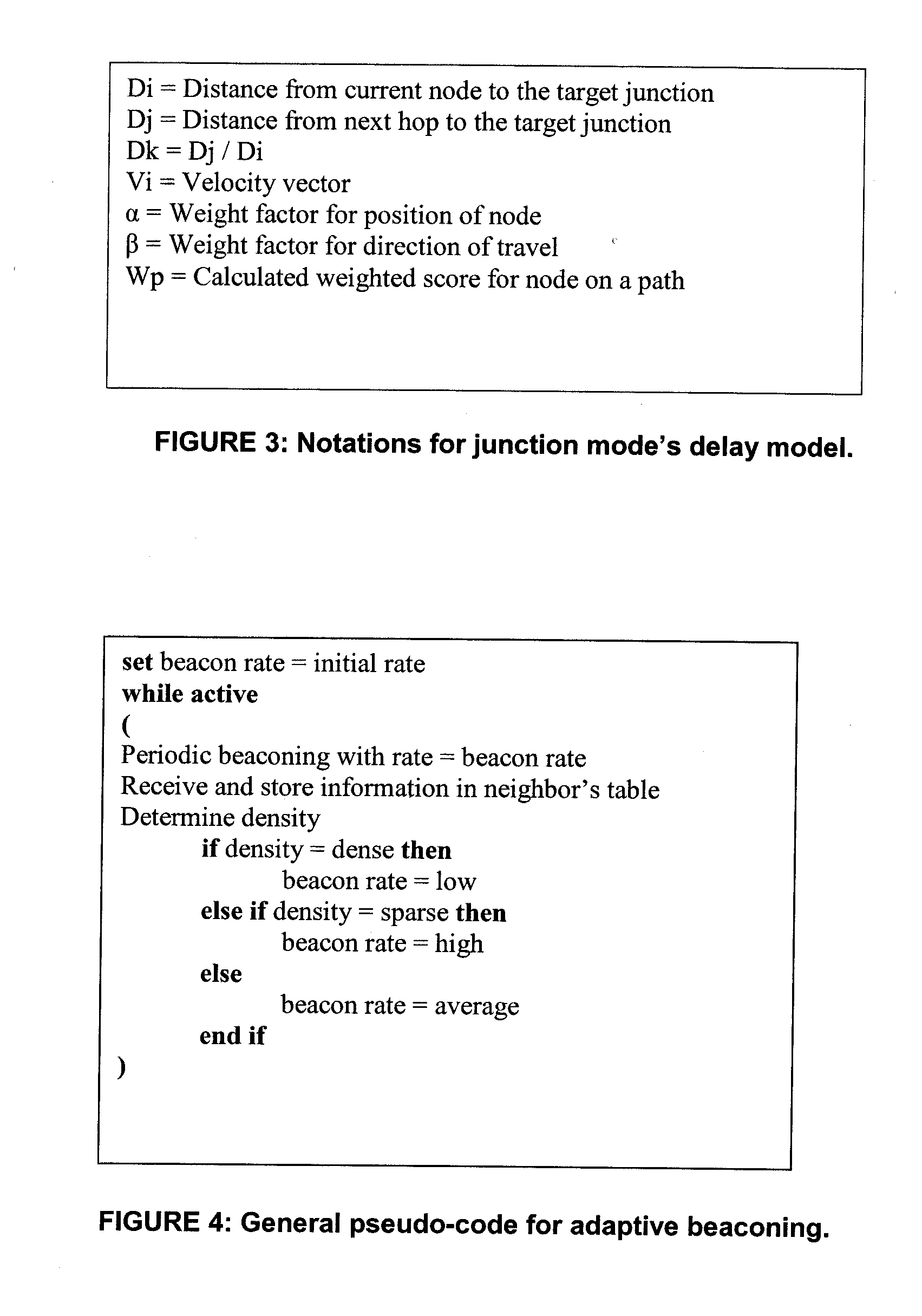

Junction Adaptive Reactive Routing (JARR) Protocol for Vehicular Ad-Hoc Networks in a City Environment

InactiveUS20130282263A1Improve scalabilityShort lifeAnalogue computers for vehiclesInstruments for road network navigationRouting decisionFast path

The routing protocol was designed for VANET in a city environment. The main objective is finding not only the shortest but the most efficient path for a packet to reach its destination. Packets are routed through the fastest paths as opposed to the shortest. Fastest path is defined as the quickest time for a packet to reach a destination irrespective of distance. While the shortest path is still considered, the routing protocol adapts to the network conditions and performs routing reactively. Making use of the city topology, packets are routed from junctions to junctions. This means that routing decisions are made when a packet arrives at a junction, to decide which path to take next in order to reach the next junction. This process continues until the packet reaches its destination.

Owner:TEE CLARENCE AUGUSTINE TECK HUO

Polylactic acid film

InactiveUS20110224342A1High transparencyGood dimensional stabilityGroup 5/15 element organic compoundsNon-linear opticsPolymer sciencePolymer chemistry

The polylactic acid film is obtained by melt extruding polylactic acid (A) prepared by melt kneading together polylactic acid (B) which comprises an L-lactic acid unit as the main ingredient and polylactic acid (C) which comprises a D-lactic acid unit as the main ingredient in a specific weight ratio, wherein the polylactic acid film has:(a) a stereocomplex crystal rate (S) defined by the following equation (i) of 90% or more:S={(ΔHmsc / (ΔHmsc+ΔHmh)}×100 (i)(in the above equation, ΔHmh is the melting enthalpy of a low-melting point crystal melting peak at a temperature lower than 190° C. obtained by differential scanning calorimeter (DSC) measurement and ΔHmsc is the melting enthalpy of a high-melting point crystal melting peak at a temperature of 190° C. or higher obtained by DSC measurement),(b) a haze of 10% or less, and(c) a haze change of 5% or less after it is heated at 140° C. for 10 minutes.

Owner:TEIJIN LTD

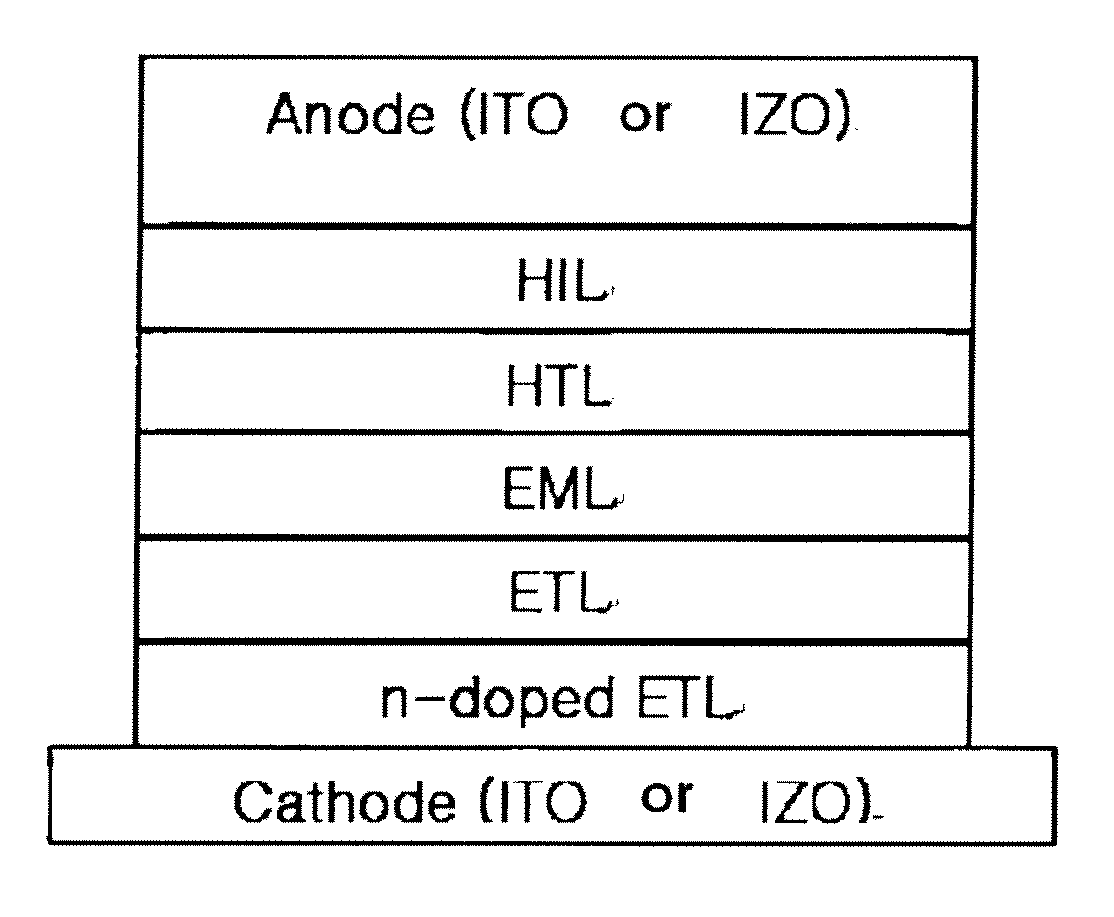

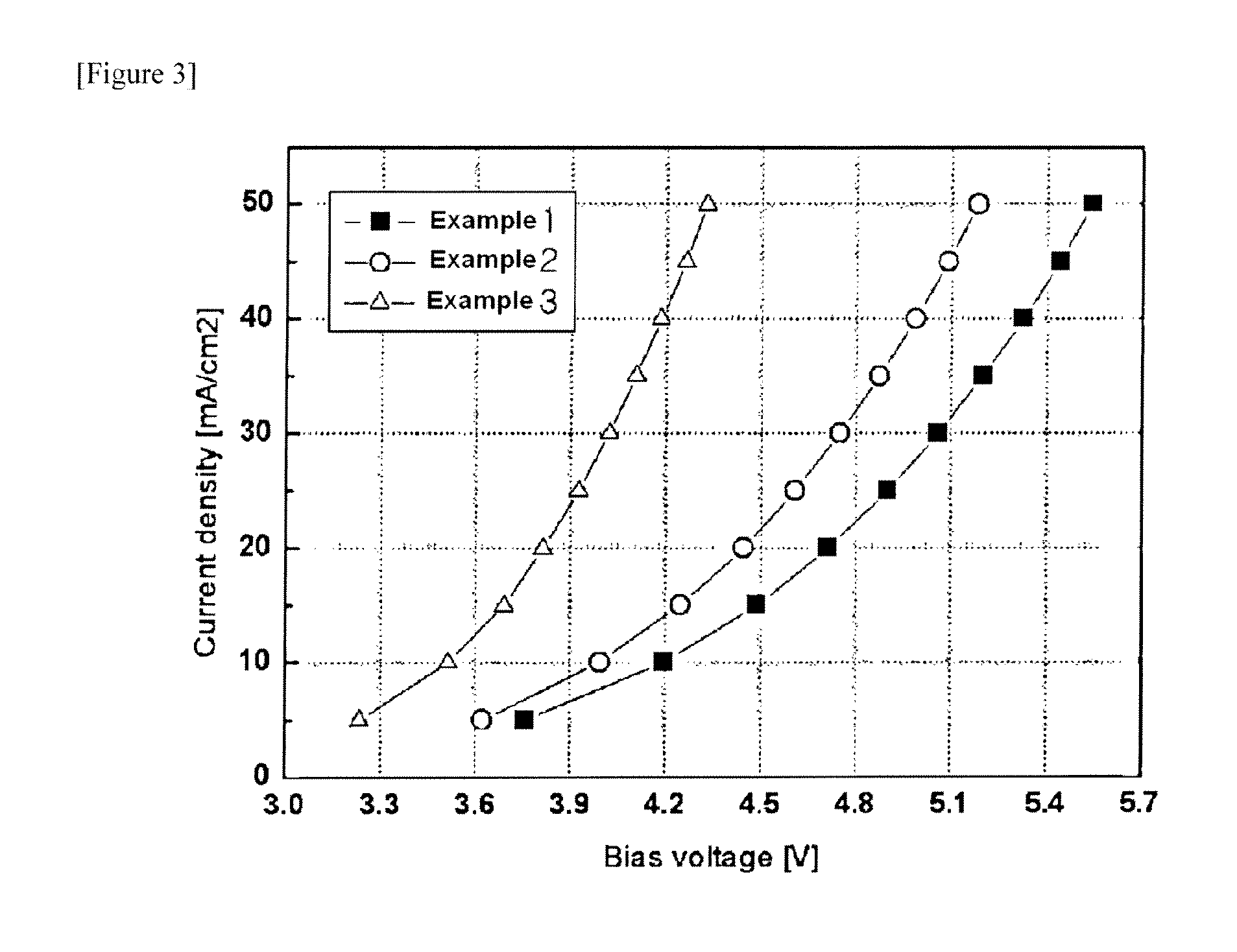

Organic light-emitting diode and method of manufacturing the same

ActiveUS20110180792A1Improve work functionUseful purposeElectroluminescent light sourcesSolid-state devicesDopantElectron transport layer

The present invention provides an organic light emitting diode comprising a substrate; a transparent cathode; an anode; and an organic material layer interposed between the transparent cathode and the anode, wherein the organic material layer comprises a light emitting layer and an n-type doped electron transport layer, the n-type doped electron transport layer includes an electron transport material and an n-type dopant and is disposed between the transparent cathode and the light emitting layer, and a method for manufacturing the same.

Owner:LG DISPLAY CO LTD

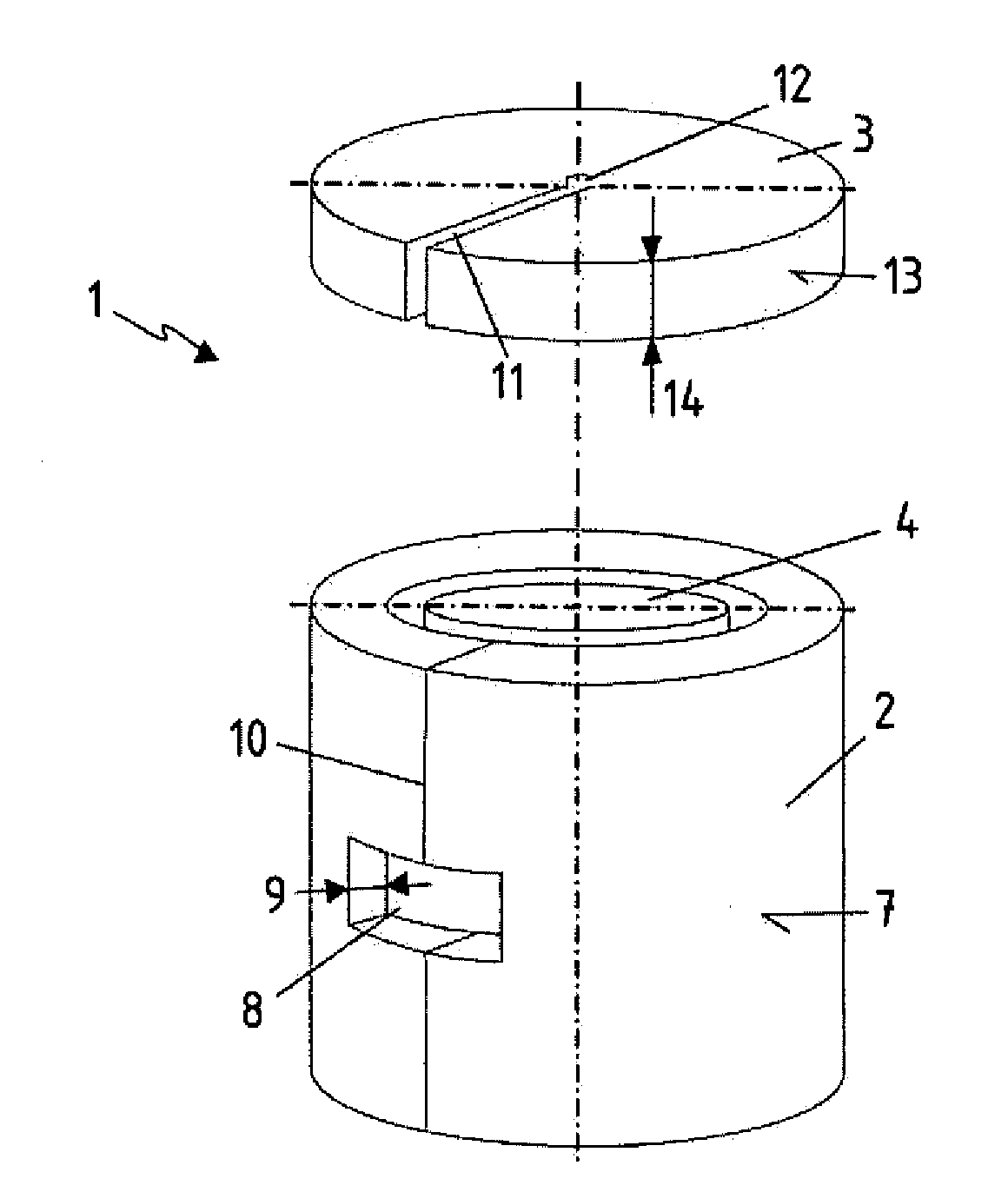

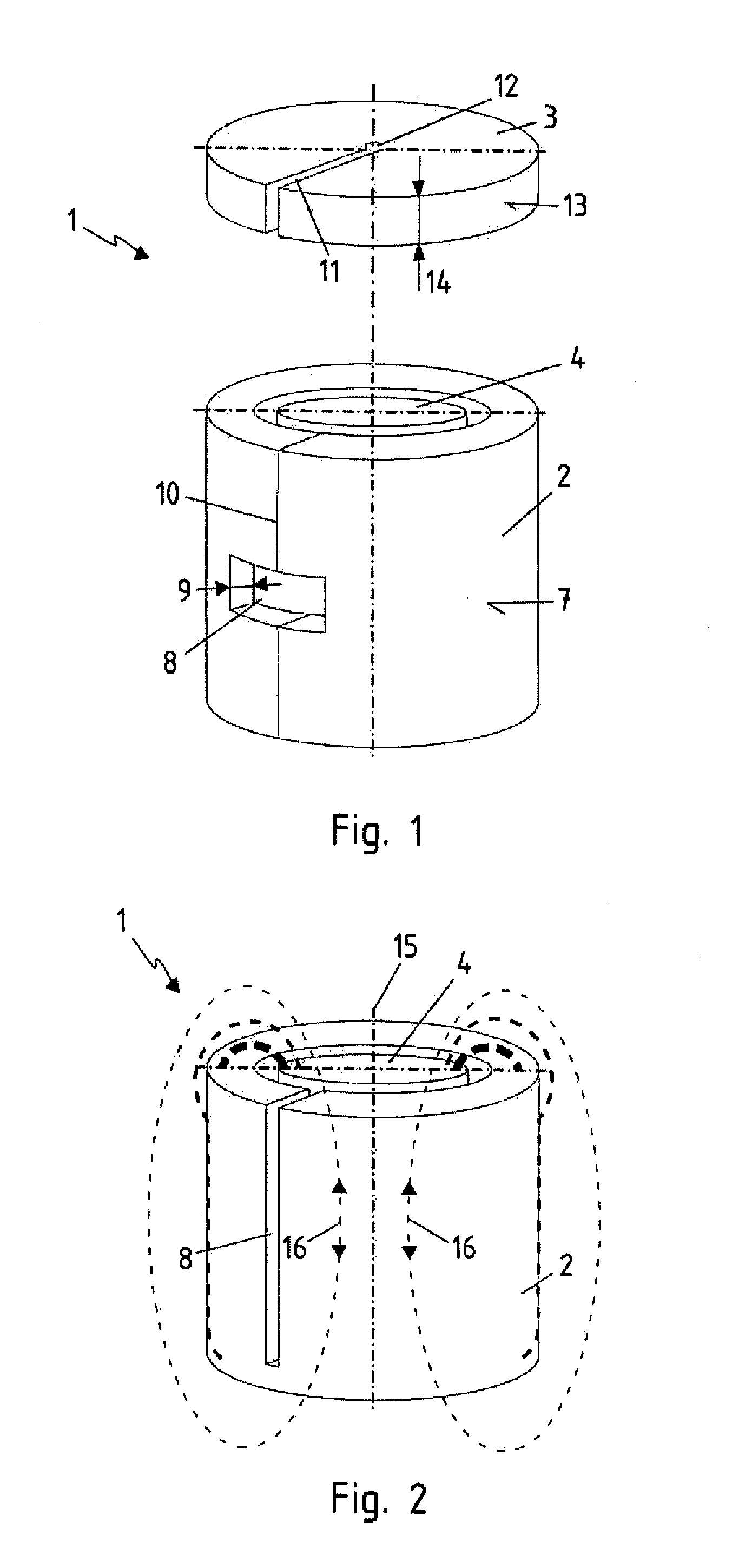

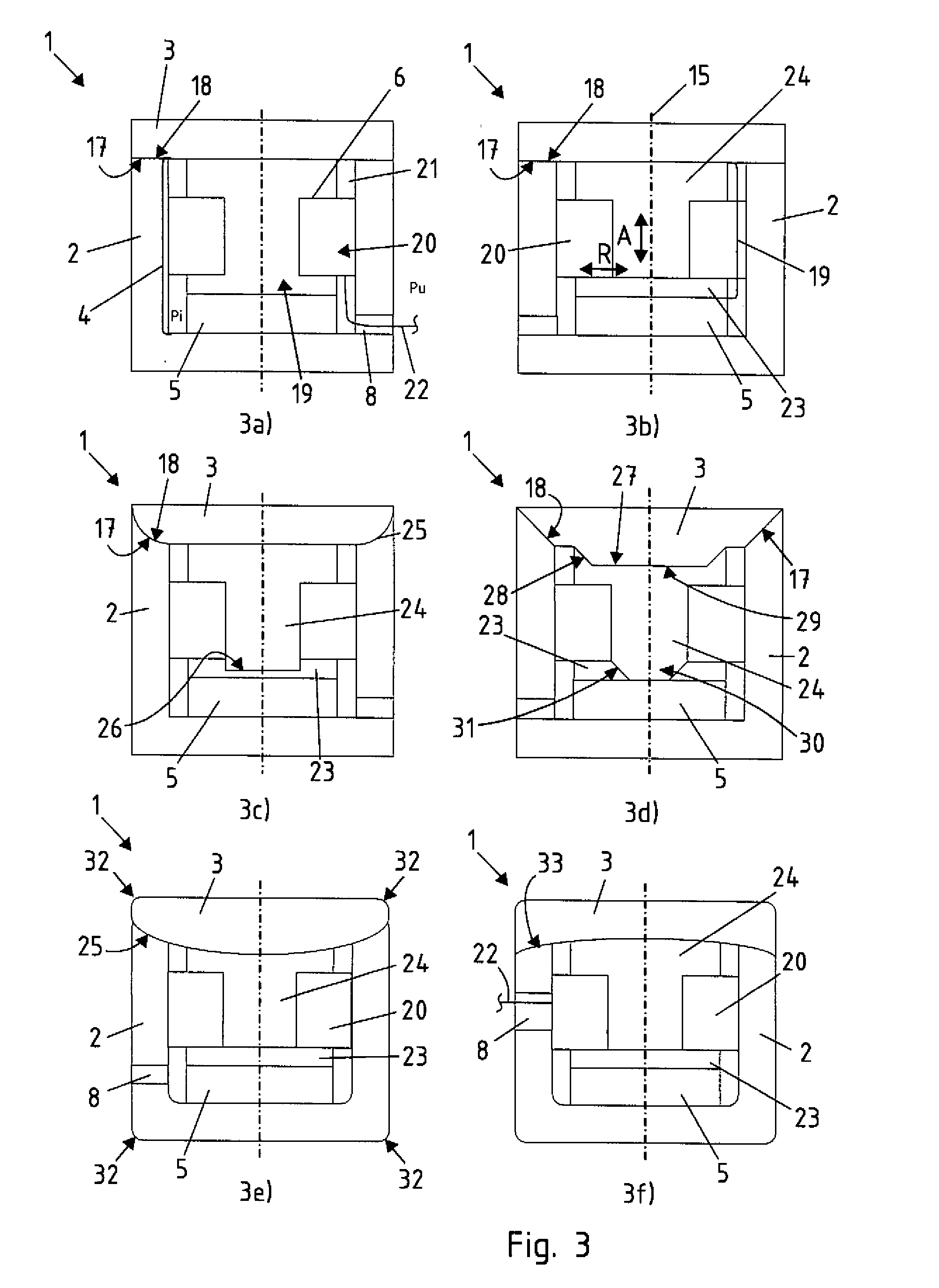

Electromagnetic actuator

InactiveUS20130027833A1Reduce voltageEmission reductionElectric switchesElectromagnetic relay detailsFreewheelInterior space

An electromagnetic actuator operating like a holding magnet includes an anisotropic permanent magnet connected with a ferromagnetic yoke, an electromagnet and a ferromagnetic armature that is movable relative to the electromagnet. The yoke is cup-shaped and has a circular, elliptical or polygonal cross-section to reduce magnetic stray flux. All the aforementioned components are arranged coaxially with respect to a column-shaped core. The periphery of the yoke includes at least one opening configured for passage of the electrical conductors controlling the electromagnet. The opening also enables pressure equalization and vapor diffusion between the interior space of the actuator and the environment. The opening is oriented in the magnetic flux direction and is constructed to reduce eddy currents. The actuator also includes components forming an electrical freewheel circuit or an electrical energy store circuit.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

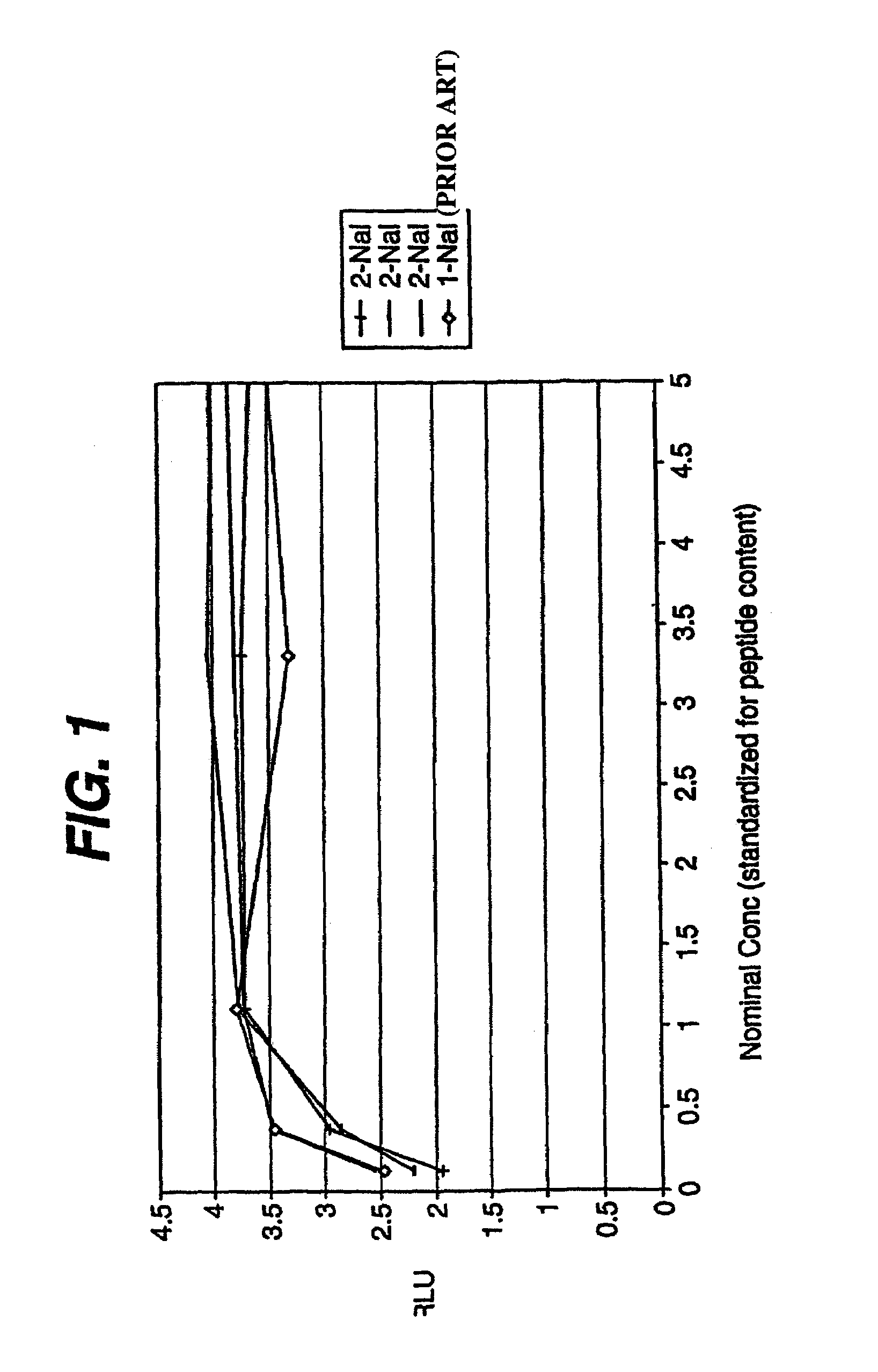

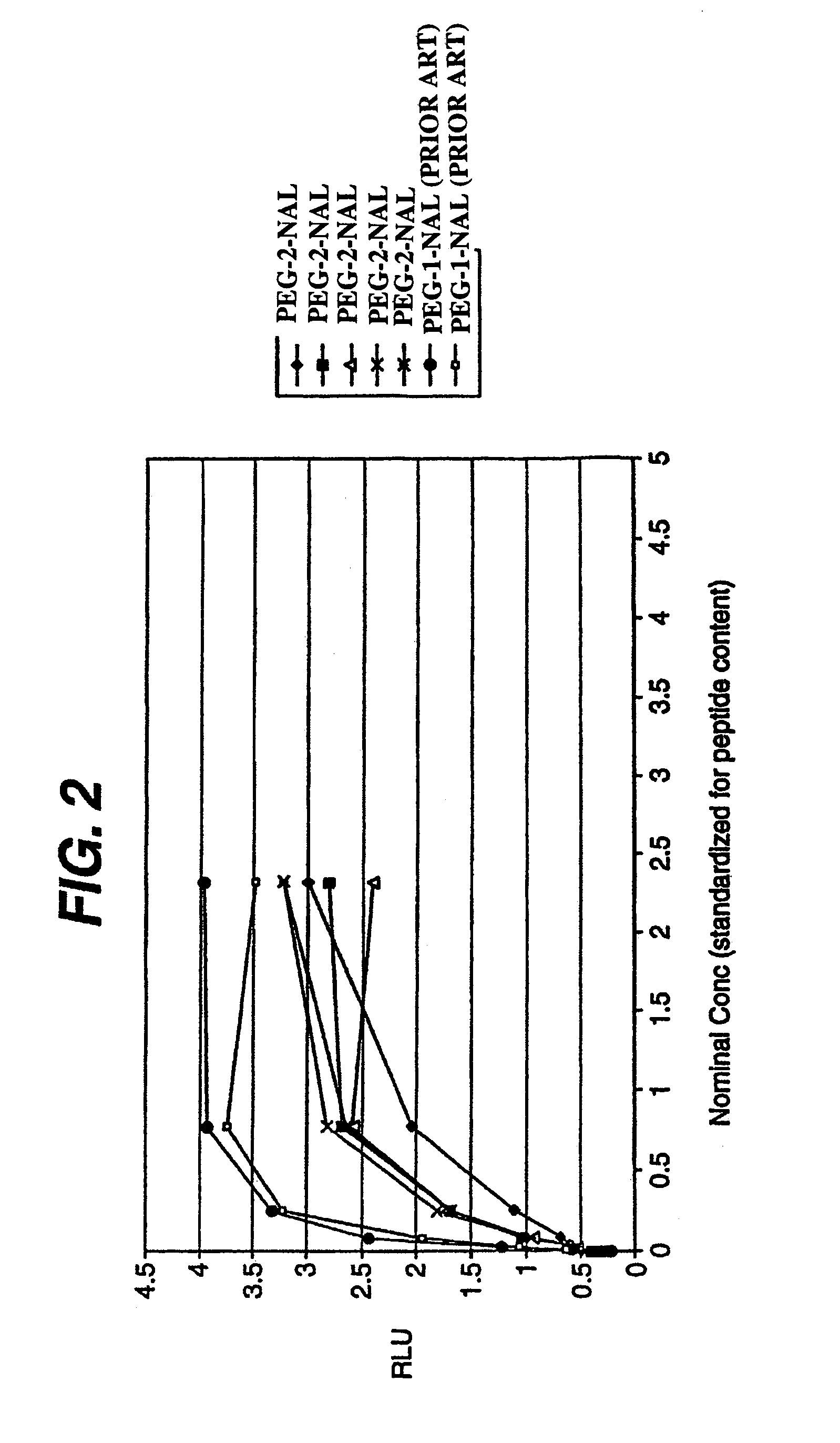

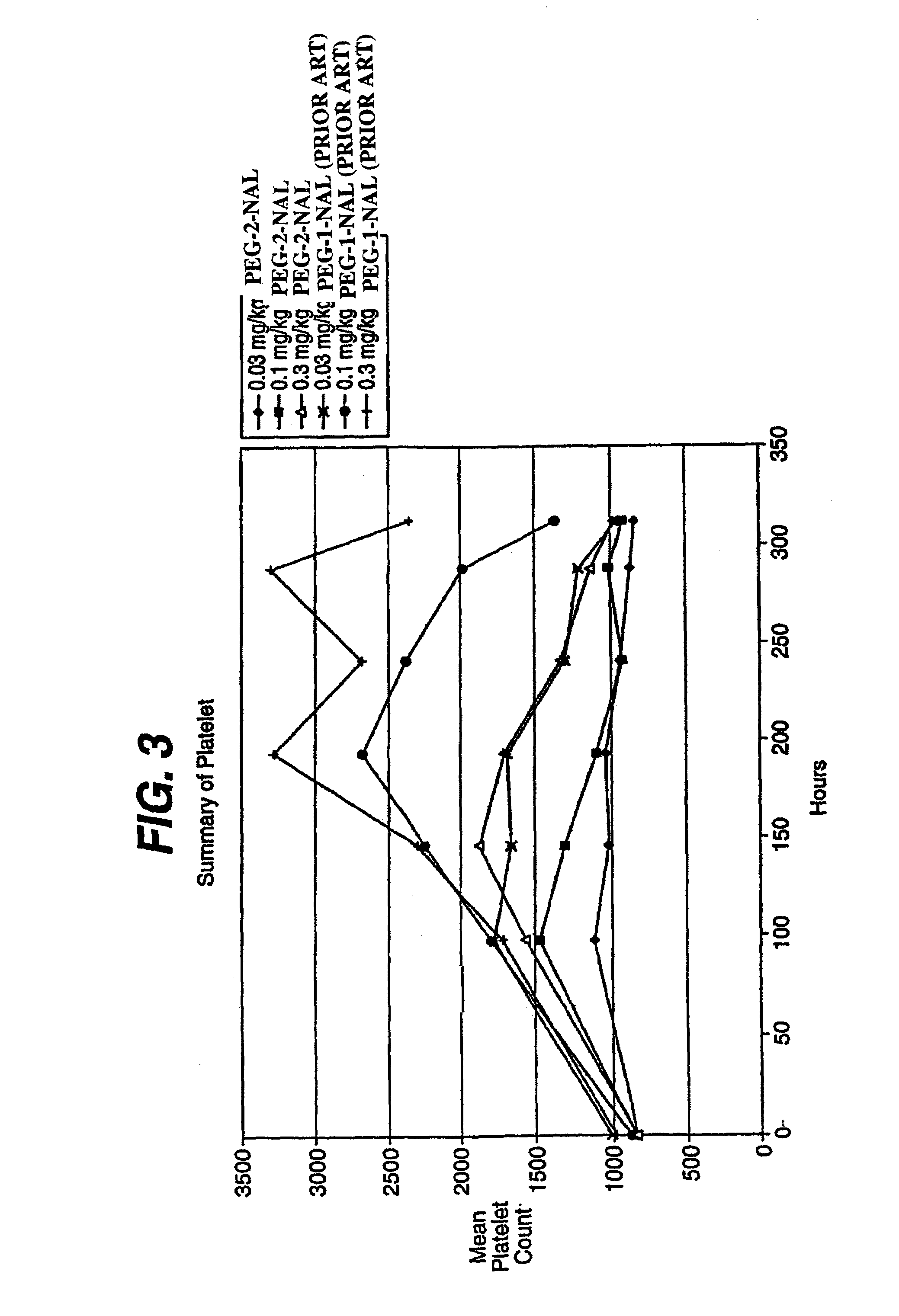

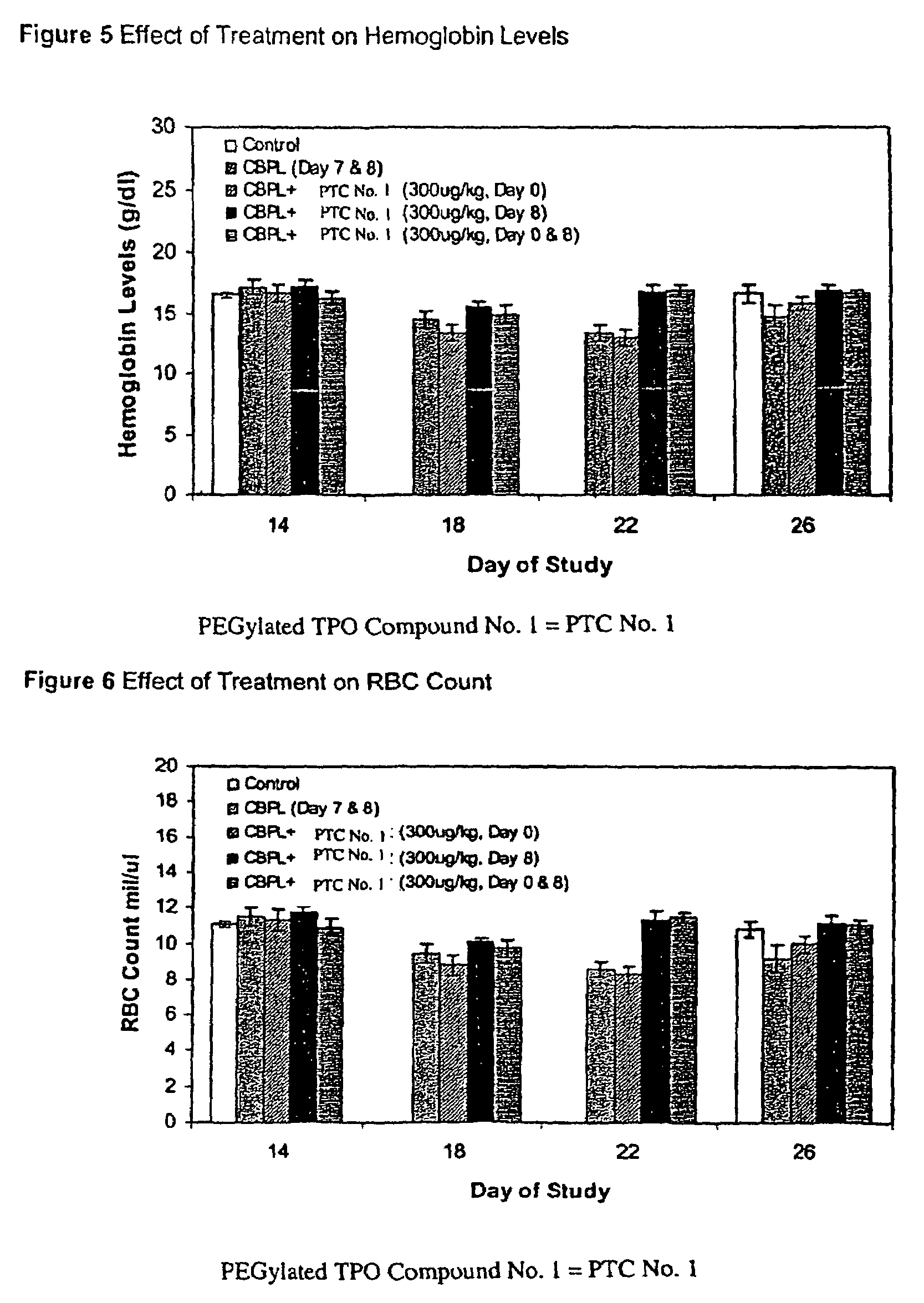

Peptides and compounds that bind to a receptor

ActiveUS7576056B2Eliminate side effectsImprove bindingThrombopoietinPeptide/protein ingredientsAgonistEphA Receptors

Peptide compounds that bind to and activate the thrombopoietin receptor (c-mpl or TPO-R) or otherwise act as a TPO agonist are disclosed.

Owner:JANSSEN PHARMA NV +1

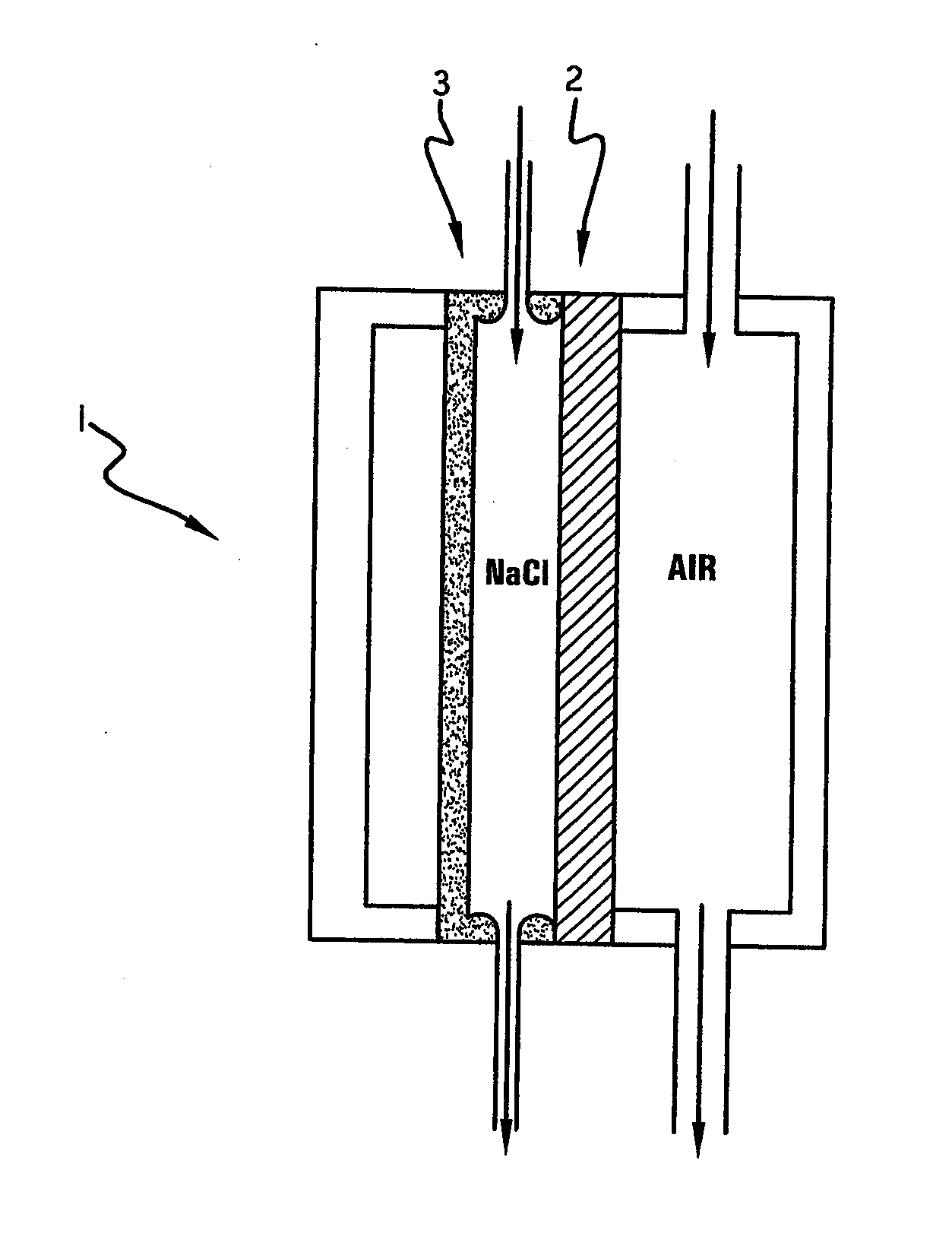

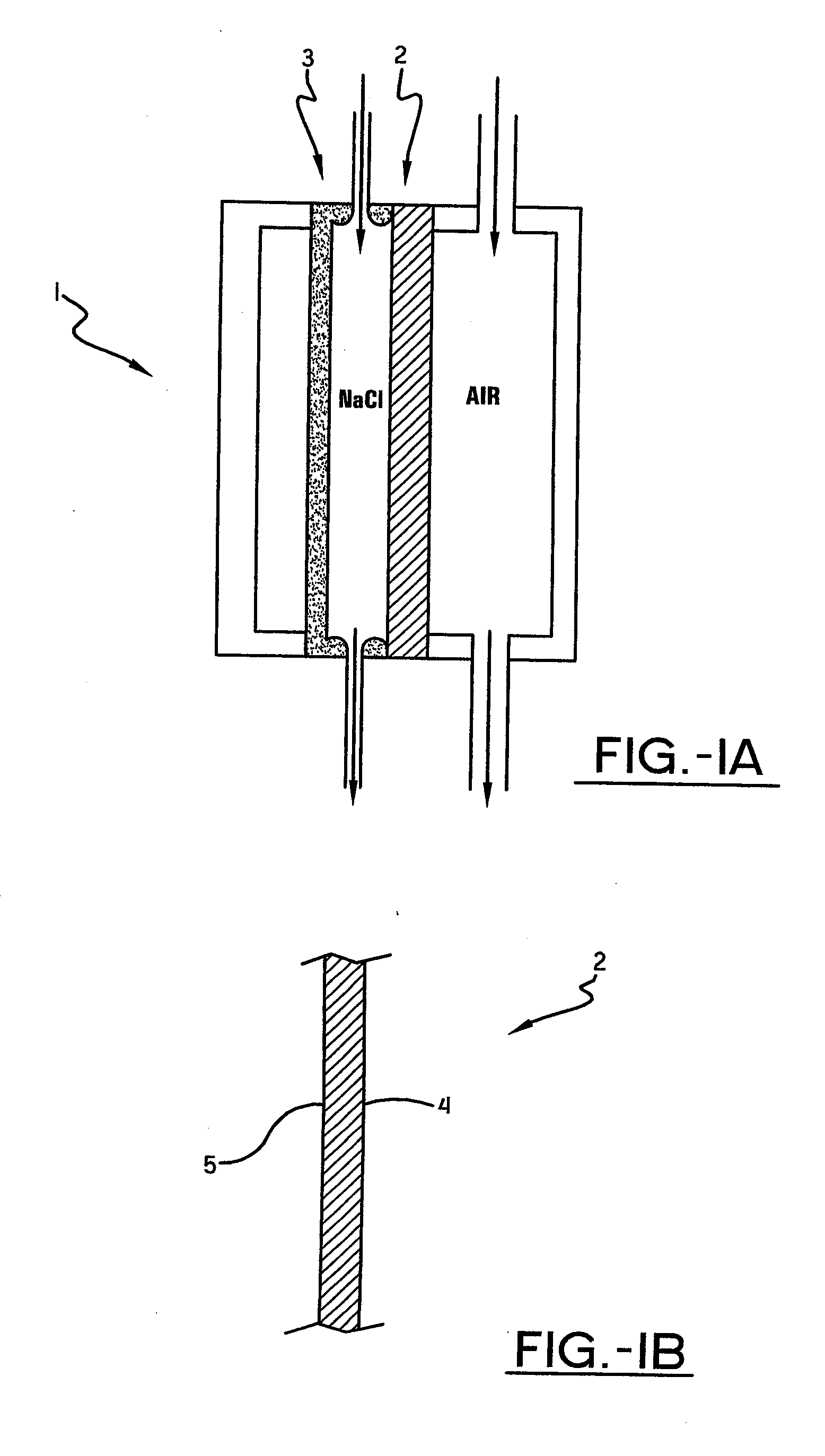

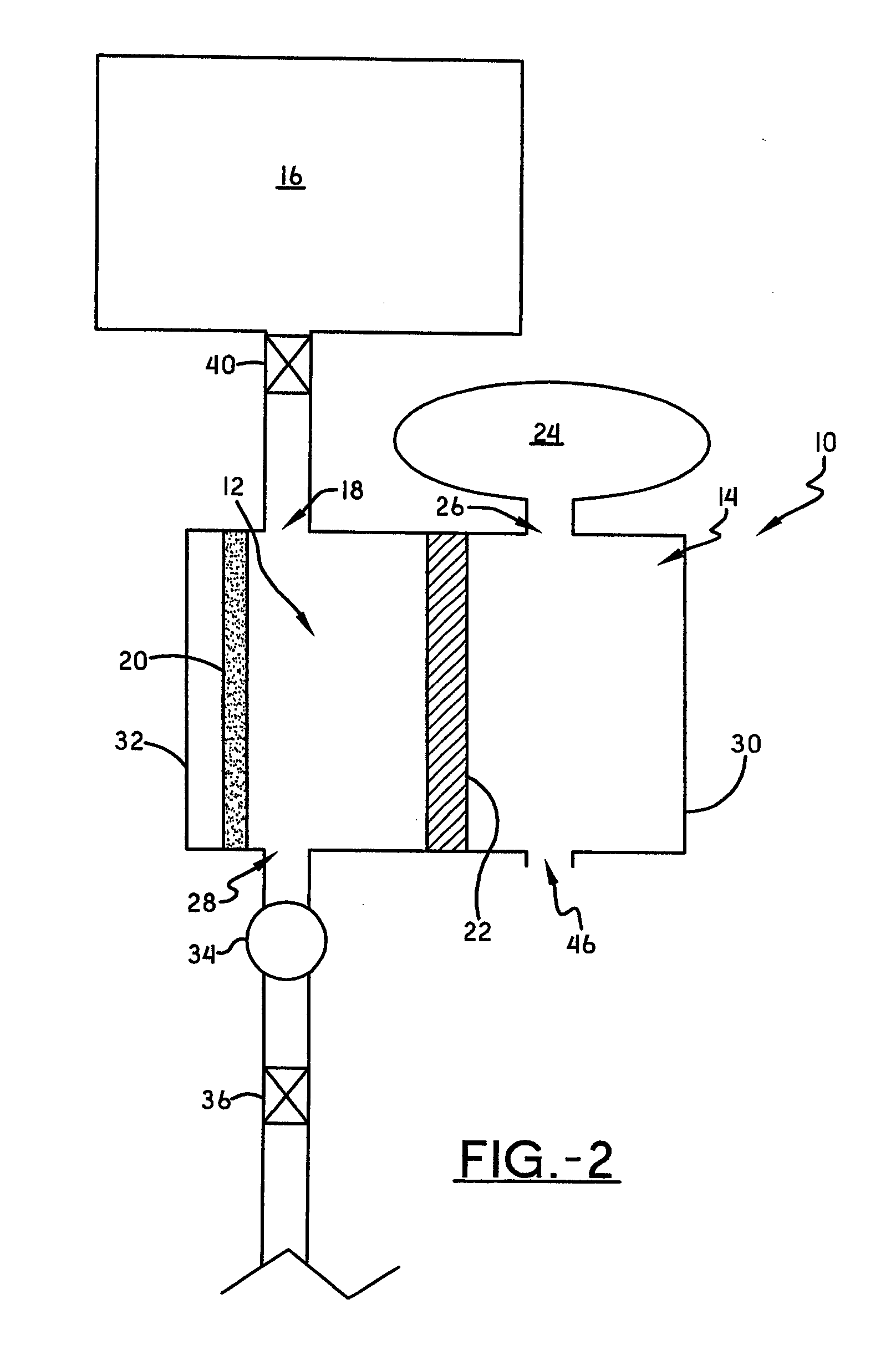

ELECTROLYTIC DEVICE FOR GENERATION OF pH-CONTROLLED HYPOHALOUS ACID AQUEOUS SOLUTIONS FOR DISINFECTANT APPLICATIONS

InactiveUS20130168260A1Economical and safe for handlingUseful purposeCellsPhotography auxillary processesElectrolysisPh control

An electrolytic device for the generation of hypohalous acid in aqueous solutions includes at least a single liquid chamber for receiving an aqueous solution containing halide ions therein, the single liquid chamber having an exterior wall and a solid anode contained within to provide for the oxidation of the halide ions, which, in turn, provides for the formation of hypohalous acid in aqueous solution, and a gas permeable cathode forming a portion of the exterior wall of the single liquid chamber, the cathode providing for the reduction of oxygen to provide hydroxyl ions in solution within the single liquid chamber to mix with the products generated at the anode. An embodiment of the electrolytic device including an anolyte chamber and a catholyte chamber separated by an ionomeric membrane is also described, whereby the anolyte chamber further includes an outlet including a pH control for determining and regulating the pH of the exiting anolyte effluent to between about 4 and 9. The product is suitable for disinfectant applications including as a hand sanitizer.

Owner:GOJO IND INC

Methods for production of platelets from pluripotent stem cells and compositions thereof

ActiveUS20140271590A1Low immunogenicityEliminate pollutionBiocideMammal material medical ingredientsPlateletInducer Cells

Methods for production of platelets from pluripotent stem cells, such as human embryonic stem cells (hESCs) and induced pluripotent stem cells (iPSCs) are provided. These methods may be performed without forming embryoid bodies or clusters of pluripotent stem cells, and may be performed without the use of stromal inducer cells. Additionally, the yield and / or purity can be greater than has been reported for prior methods of producing platelets from pluripotent stem cells. Also provided are compositions and pharmaceutical preparations comprising platelets, preferably produced from pluripotent stem cells.

Owner:ADVANCED CELL TECH INC

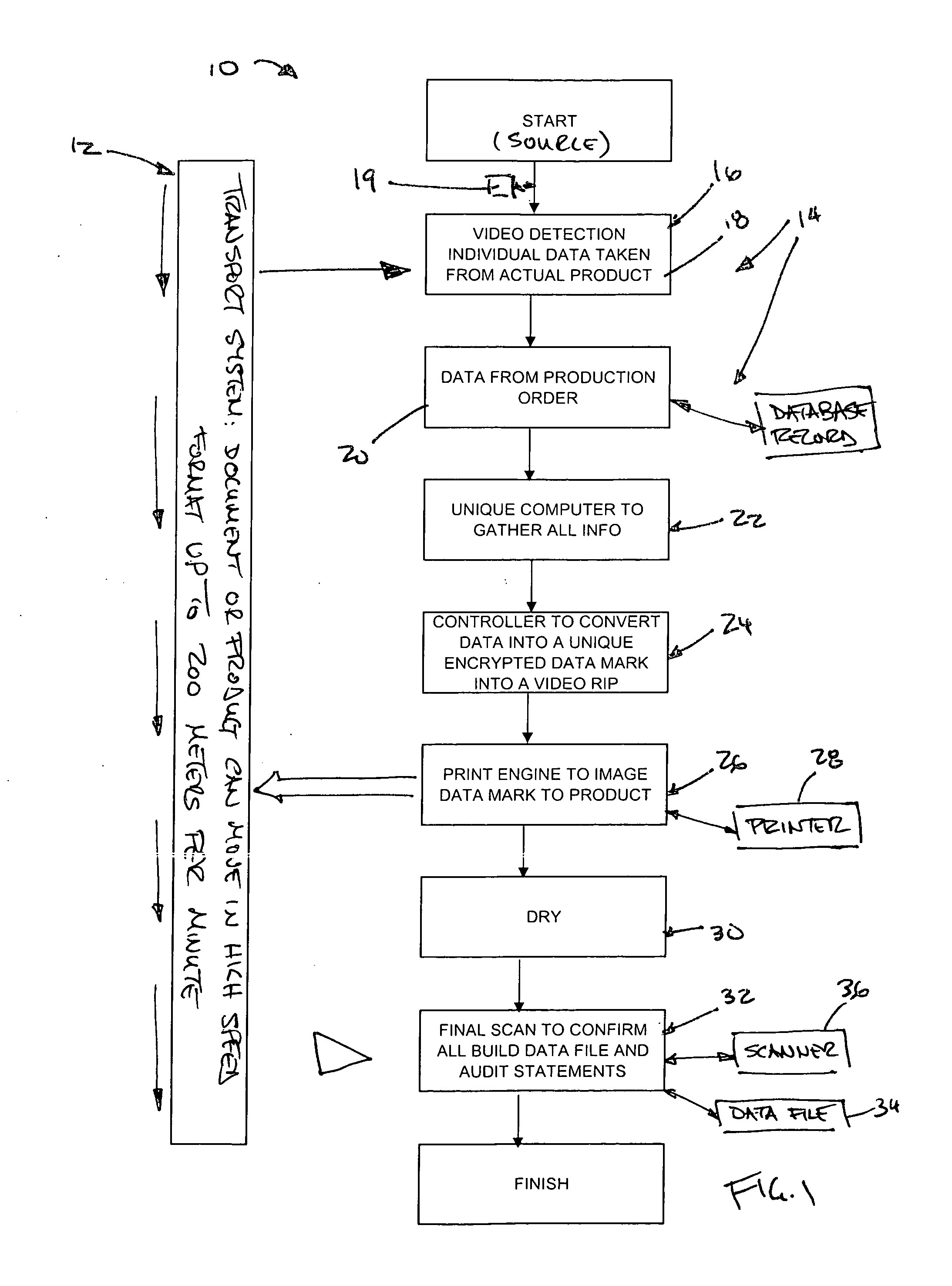

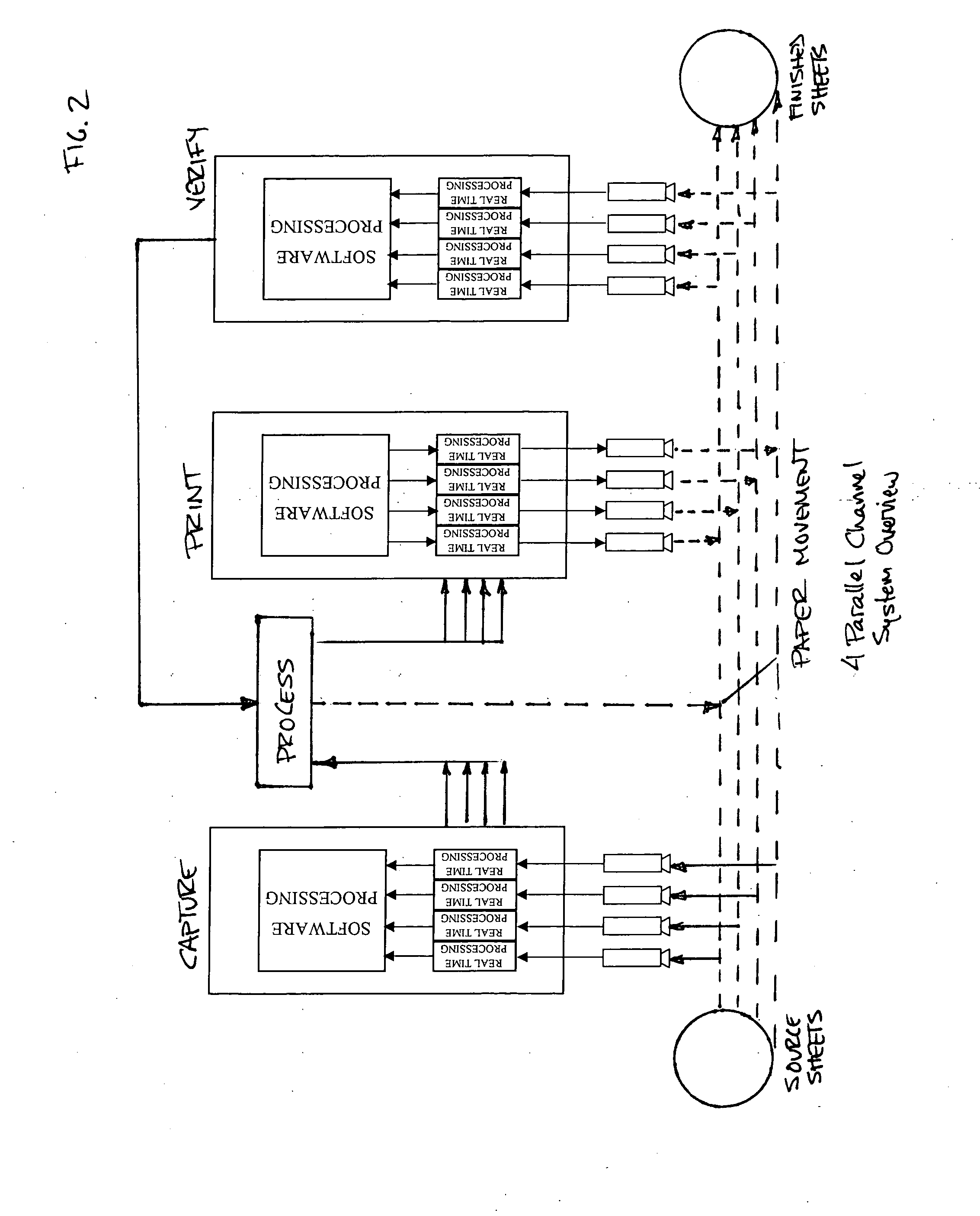

Real-time auditing of covert data marks

A system and method is provided for the real time auditing of covert data marks. Specific information relating to a product or document is entered into an information cell or shell from a product data file. A high definition, high resolution, high speed inline video system is provided to take specific details from the individual product or document, which details are added to the data cell or shell. Details are then inspected, quality checked, matched in the event there are multiple identifiers (e.g., currency would normally carry two matching sequential numbers), and verified to the product order. This cell or shell is passed to the special design computer / controller through a high speed electronic interface. Information entering the computer / controller is once again verified and matched to the original data as well as the product or document. The cell or shell is converted into a specially created 2-dimensional bar code which is encrypted by the computer / controller and then transformed into a video rip. This video rip is sent to high quality / high resolution production print engines. The encrypted 2-dimensional bar code is imaged directly to the product or document as it is carried past the print imaging engines. The ink also is specially designed and manufactured for this system and process. It is an invisible ink which is unique, durable, permanent and not available commercially (covered under trade secrets). These special inks are well suited for delivery using inkjet technology to efficiently make well formed invisible images at slow to high speed production schemes. The product or document is then sent instantly into a drying scheme (this can be air, forced air, heat, UV Dryer, depending on the printing system selected). After drying there is a final scanning. This scanning equipment is the same scanner design which will be used in the field so that each product or document will be verified with the actual scanning device and programs which will be used in the field. From this final scanning of the 2-dimensional data bar code, a final audited product or document profile is created, as is a database which will be the point of reference in the infrastructure during the life of the product or document. Each time any product or document is scanned at a transaction point, the database will be updated, either in real-time or downloaded from a data collection scanning device. This will build a complete history from the point of manufacture to the moment it is removed from service.

Owner:COVERT SECURITY SOLUTIONS

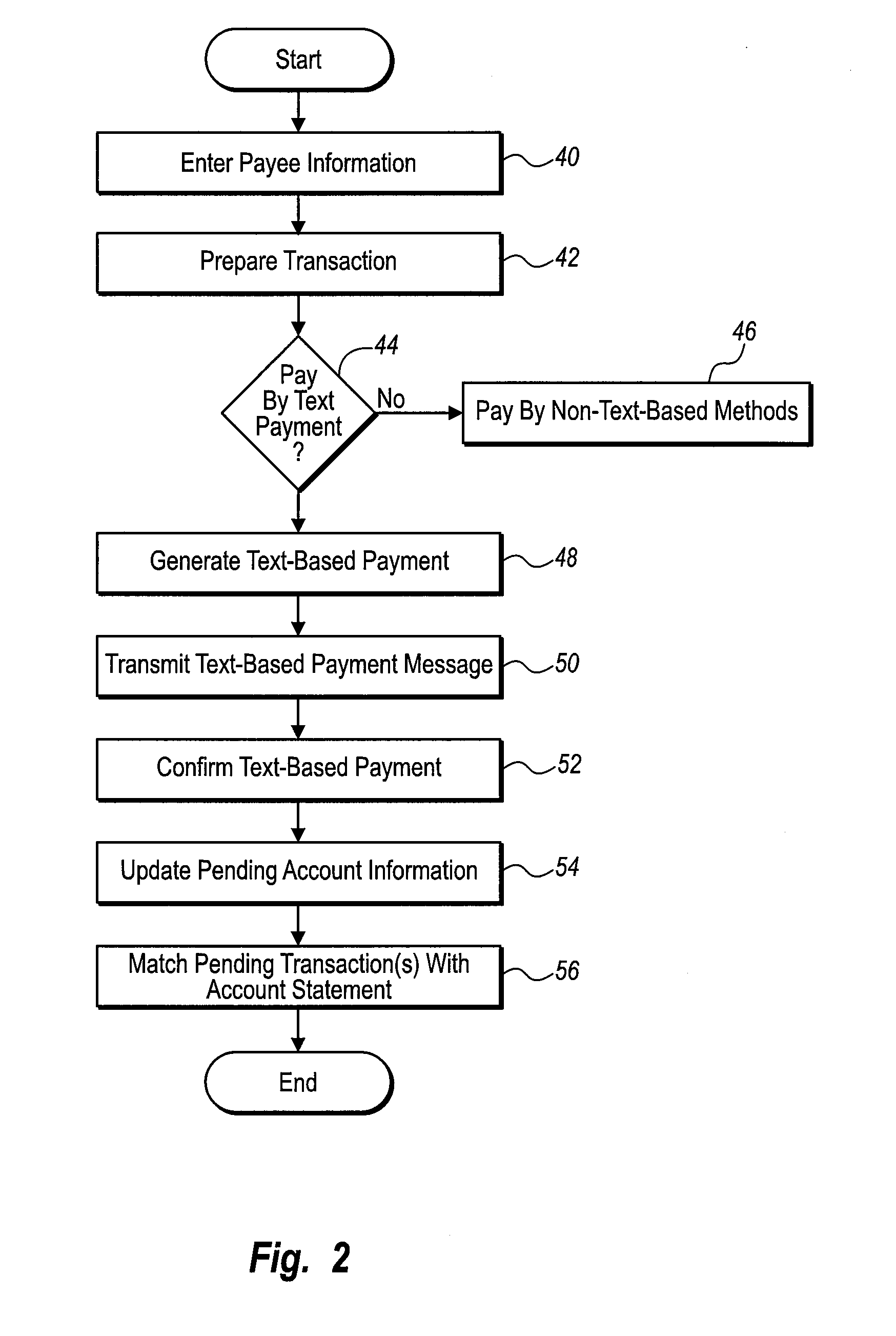

Web-based payments on text-to-pay SMS networks

A web-based financial software application that emulates short message service (SMS) based text payment. The software allows entry of financial transactions in detailed form to allow for normal budgeting, accounting, and tracking methods, then translates the pending transaction from the detailed form into a text-based format compatible with the SMS payment network and transmits and confirms the payment as would normally be done via a mobile device. Optionally, the transmission of the text-based payment may occur through a secure link to simplify the payment process. The software also permits entry of transactions in the SMS-compatible format and translates these entries into a detailed form to allow for budgeting, accounting, and tracking. The software then searches for corresponding payees, and allows the user to select from found matching payees to automatically fill in the remaining payee information, or permits the user to manually enter additional information.

Owner:IN2M CORP

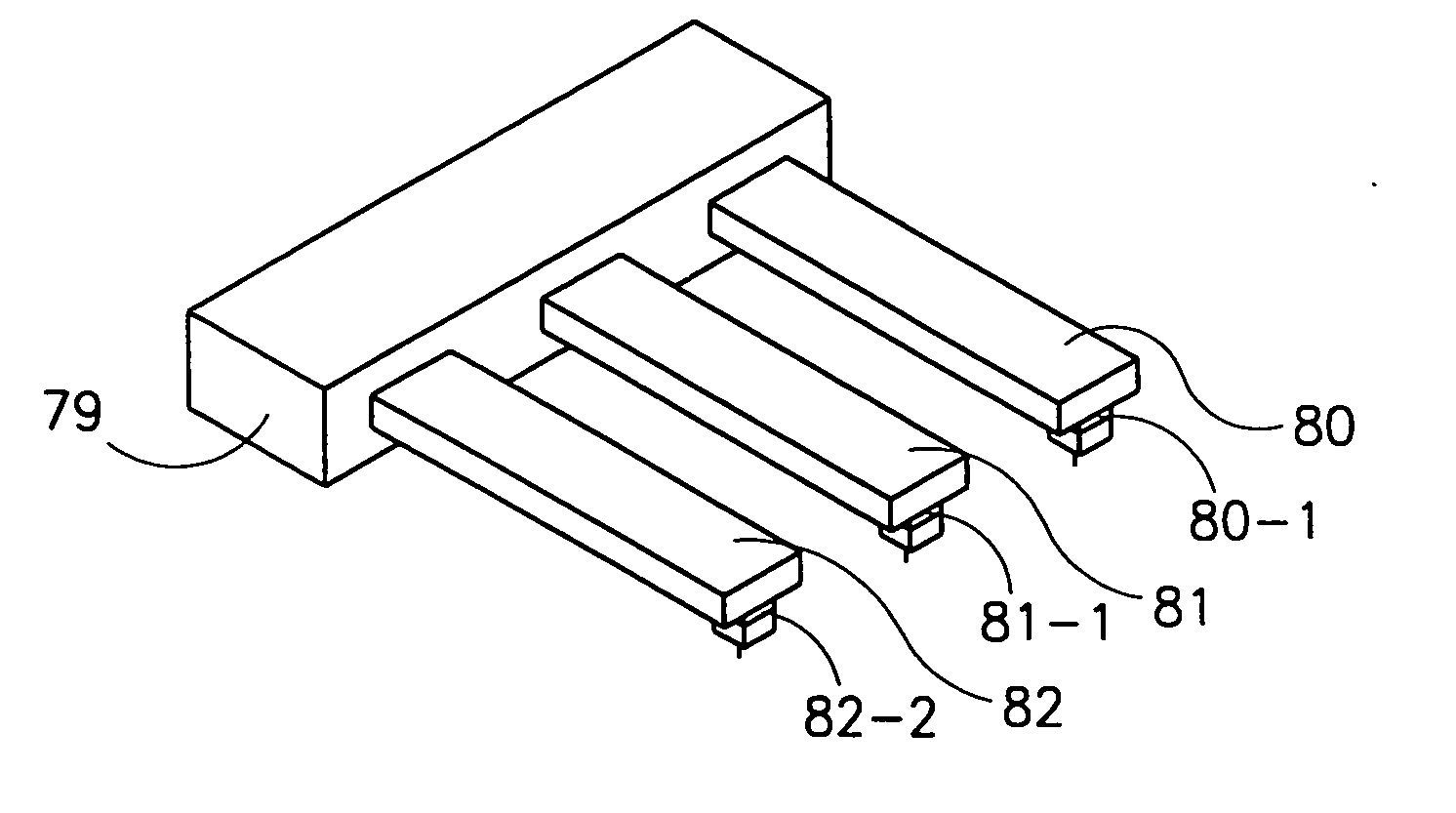

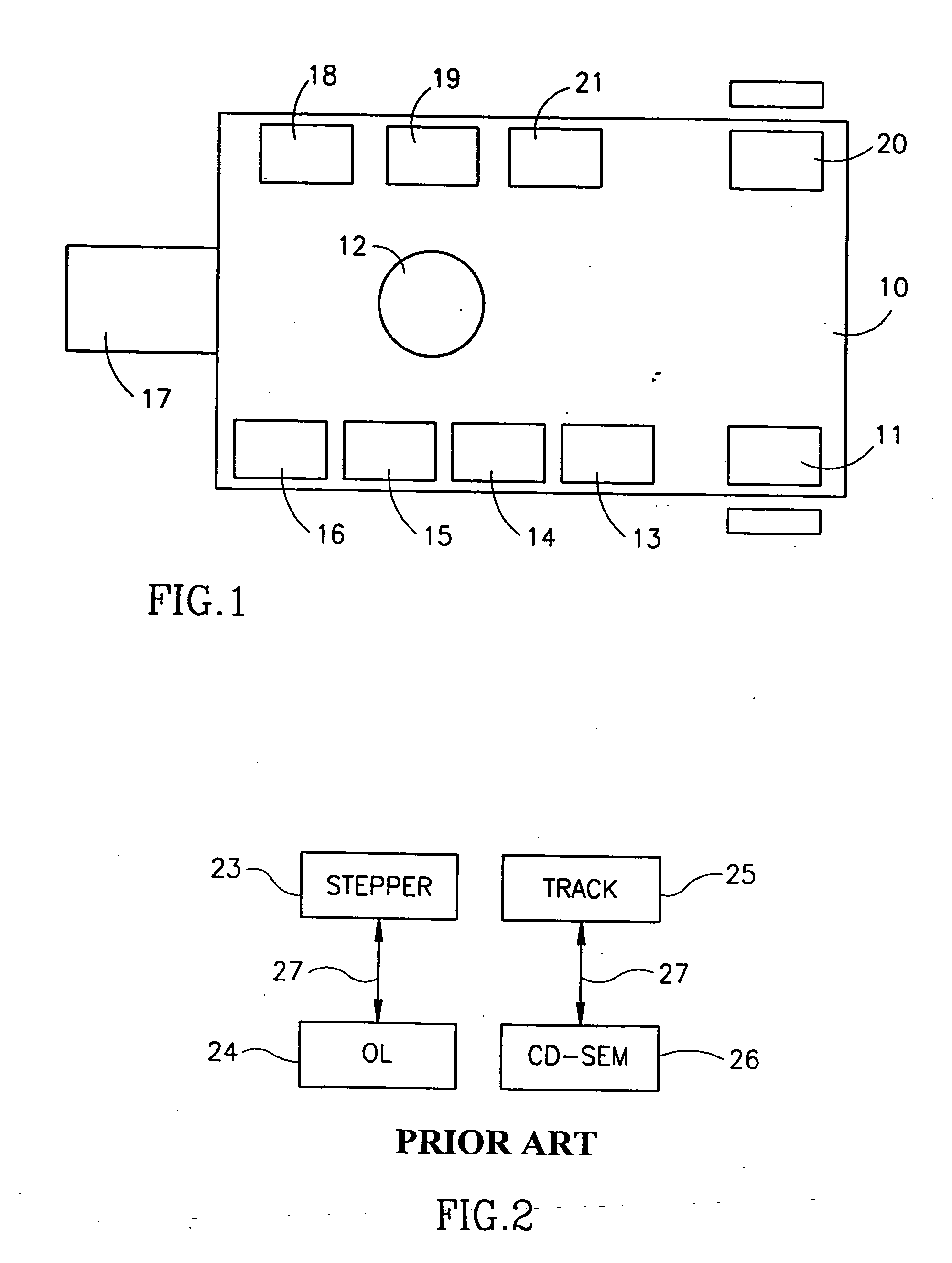

AFM-based lithography metrology tool

InactiveUS20050205776A1Small sizePrecious space is savedNanoinformaticsMaterial analysis by optical meansCooking & bakingMetrology

A photolithographic track system and method for semiconductor wafer manufacture having a plurality of stations for receiving a wafer for sequential processing, including a first group of stations for performing at least a part of a photolithography process. A metrology station is provided in a position of the track system after the first group of stations, for determining whether the processed wafer is within tolerance for at least one critical dimension. If not within tolerance, the wafer is moved by the track system to a stripping station for removal of at least one layer and a return to the beginning of the first group of stations for repeating the performance of a photolithography process. Parameters may also be adjusted for purposes of the repeated performance of the process. If within tolerance, the wafer may be moved for further processing, for example, baking or off loading.

Owner:APPLIED MATERIALS INC

TPO peptide compounds for treatment of anemia

ActiveUS7615533B2Improve bindingEliminate side effectsThrombopoietinPeptide/protein ingredientsAgonistAnemia

Peptide compounds that bind to and activate the thrombopoietin receptor (c-mpl or TPO-R) or otherwise act as a TPO agonist are disclosed.

Owner:JANSSEN PHARMA NV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com