Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Uniform air permeability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

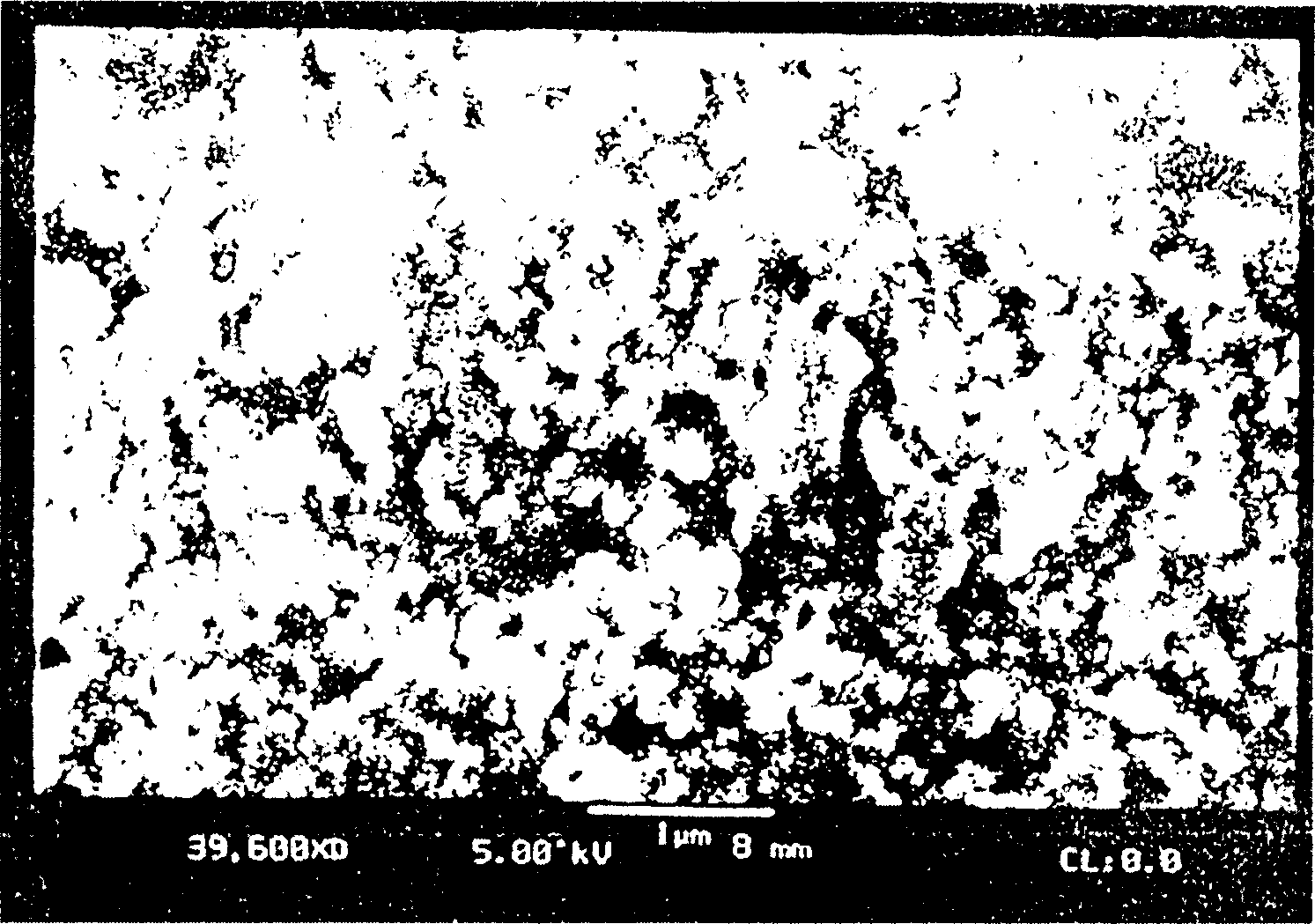

Microporous membrane, preparing method and use

InactiveCN1552757AProtection against erosionWaterproof, breathable and moisture permeablePolymer scienceSolvent

A millipore film is prepared from synthetic resin, thermoplastic elastomer, inorganic powder, lubricant and antibacterial agent through proportional mixing, filming and pore forming in solvent. It can be used for virus preventing clothing, diving suit, mountaineering wear, etc. Its advantages are high weight, good heat insulation, high air and moisture permeability, and high tension strength.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Polylactic acid forming paper and preparation method

ActiveCN102877355AGood compatibilityNon-irritatingPaper/cardboardRetention agents additionPolyesterFiber

The invention provides polylactic acid forming paper adopting polylatic acid fibers as a raw material and a preparation method thereof so as to solve the vices of hair slip and powder drop of the conventional forming paper and reduce excessive consumption of production of the conventional forming paper on resources to a certain extent. The invention adopts the following technical means: the polylactic acid forming paper comprises the following components in parts by weight: 15-65 parts of polylactic acid fibers, 15-20 parts of hardwood fibers with whiteness of 80-85% and 10-15 parts of polyester fibers, wherein the polylactic fibers are 4-6 mm long, and the fineness is 1-5 D; the polyester fibers are 4-10 mm long and the fineness is 0.5-1.4 D; the ratio of the forming paper is 10-50 g and the air permeability is 500-50000 um / pa.s.

Owner:HONGTA TOBACCO GRP +1

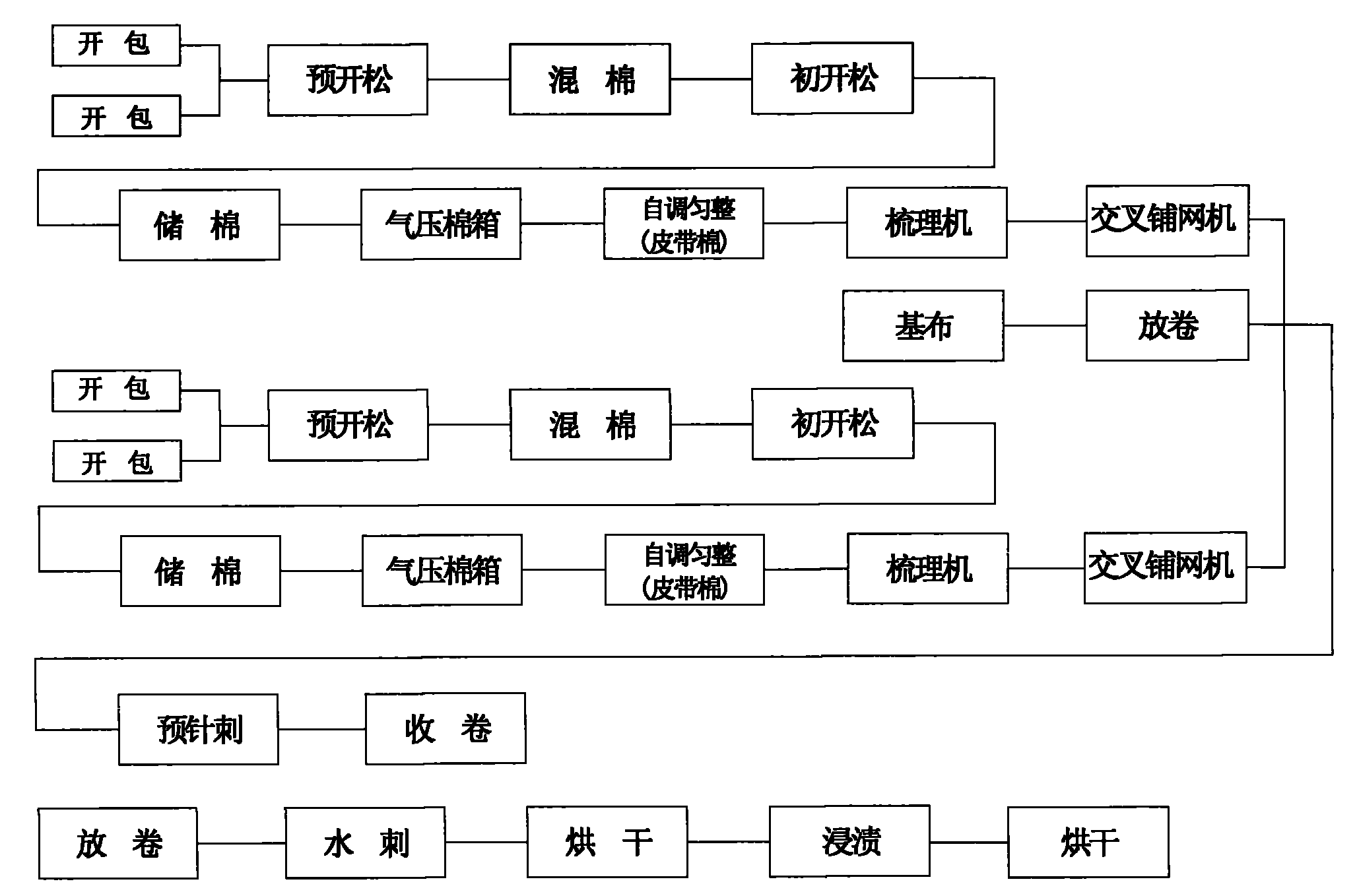

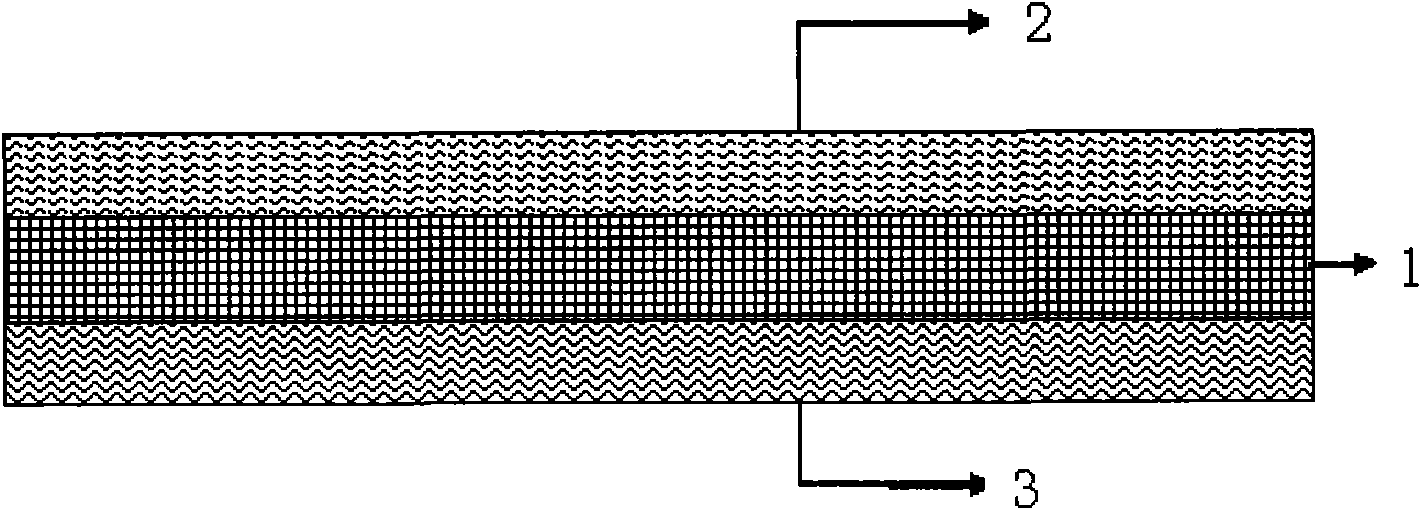

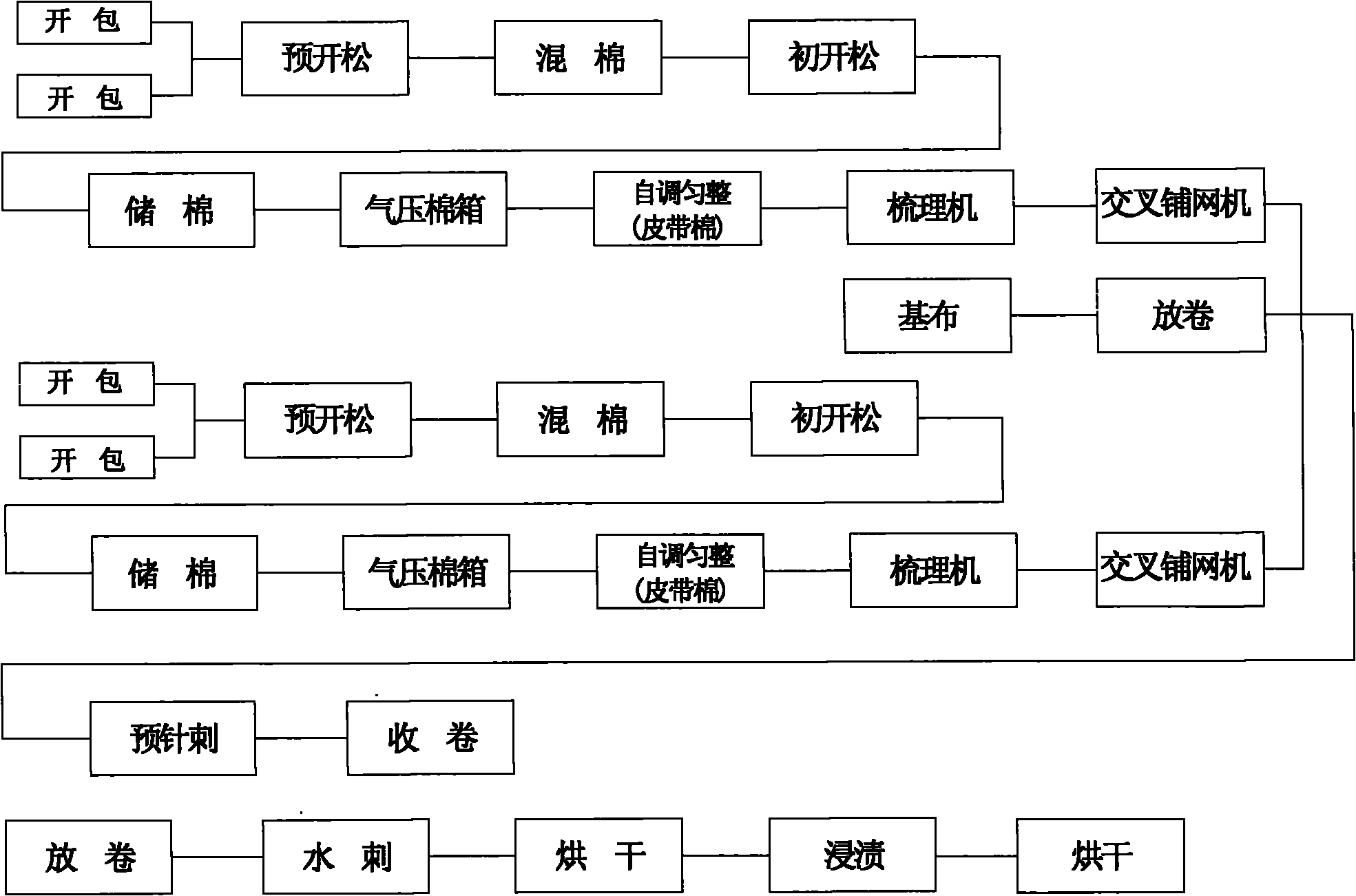

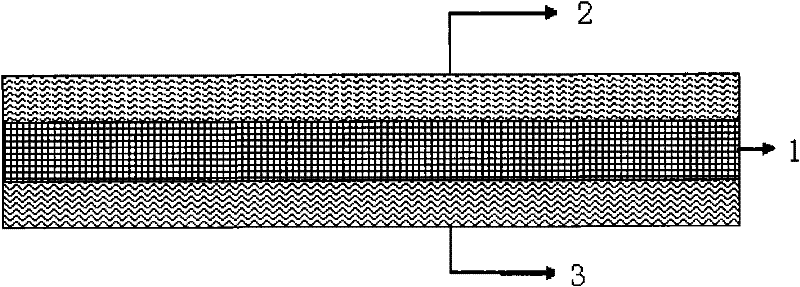

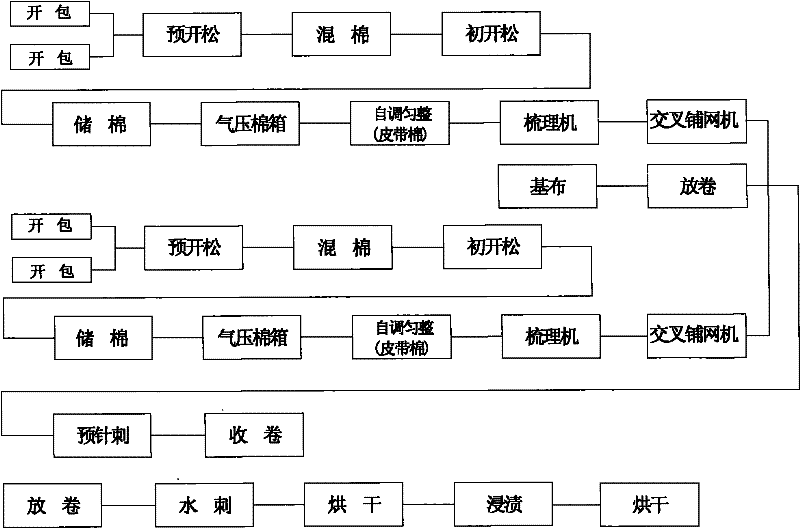

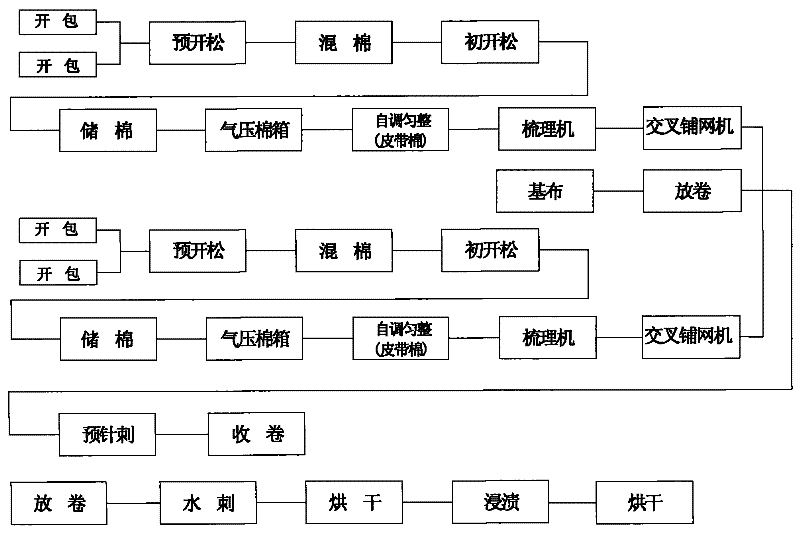

Preparation method of PBO composite ultra-high temperature filter material

ActiveCN101810971AImprove breathabilityHigh filtration precisionLayered productsFiltration separationFlue gasSolvent

The invention discloses a preparation method of a PBO composite ultra-high temperature filter material, which comprises the following steps that: a plain blanket is formed through an acupuncture and spunlaced composite process, and then soaked in chemical solvent to prepare the ultra-high temperature filter material, the dust facing surface in the prepared filter material comprises PBO and basalt fibers which are blended, wherein the weight proportion of the PBO fibers is 10 to 15 percent; base cloth comprises PBO long filaments and basalt filaments which are interwoven; and a bottom layer adopts 100 percent basalt fibers. The preparation method of the PBO composite ultra-high temperature filter material effectively reduces the damage of the fibers, improves the strong force of the filter material, meets the need of ultra high temperature flue gas treatment, and is applicable to a bag-type dust collector for ultra high temperature flue gas treatment at above 500DEG C.

Owner:南京际华三五二一环保科技有限公司

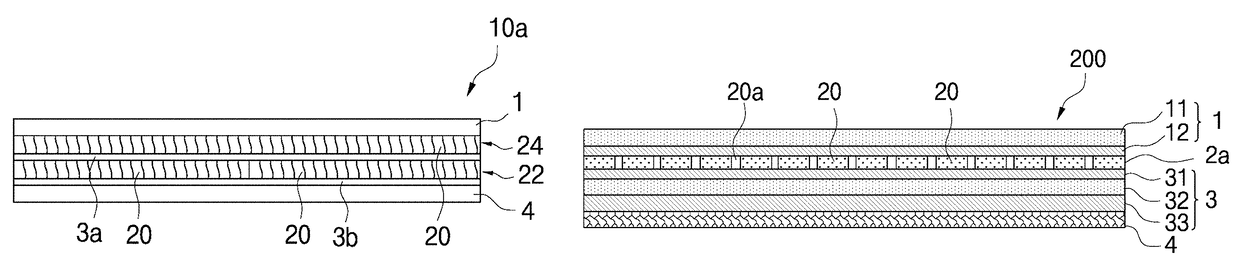

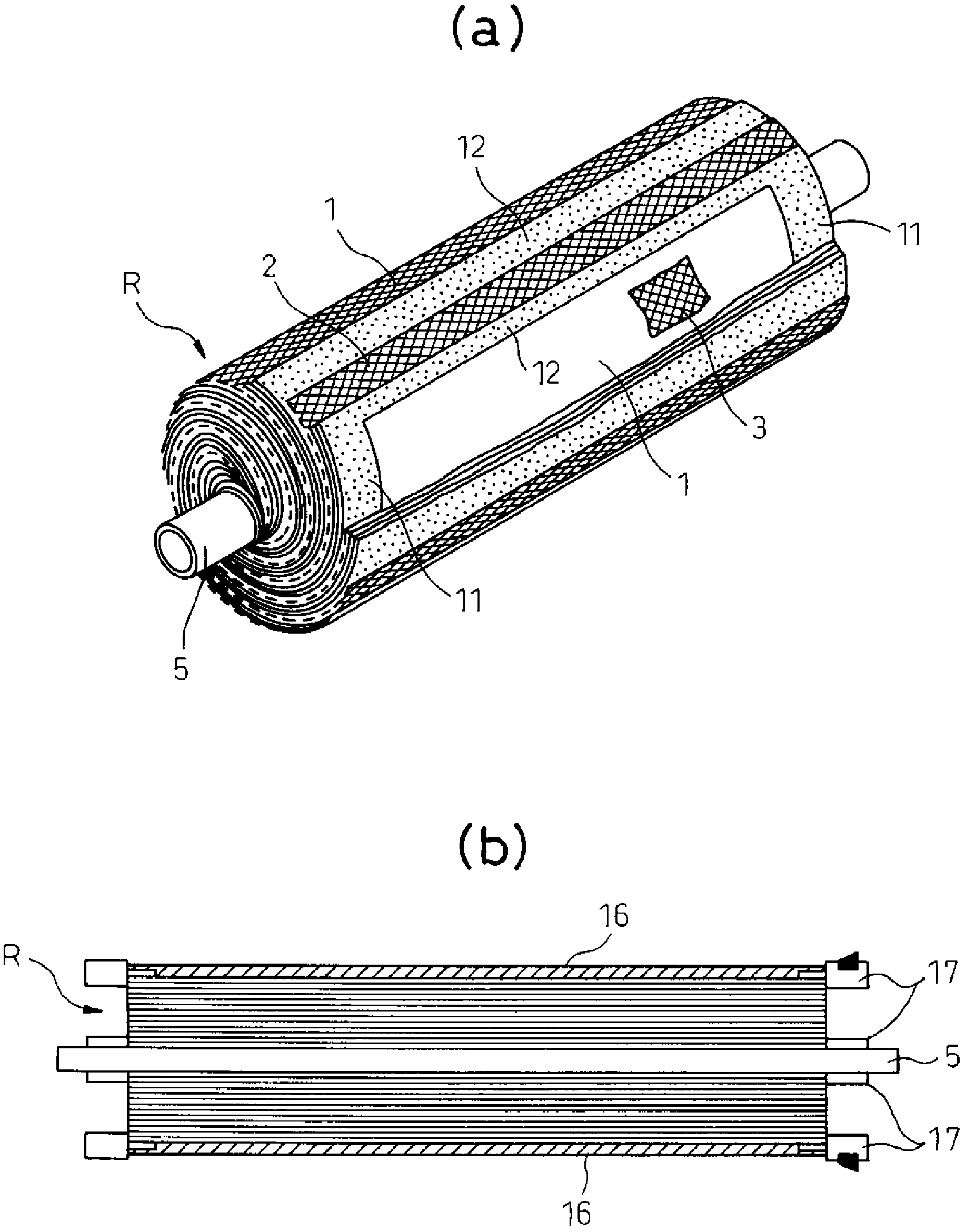

Composite film substrate and composite film using same

InactiveCN102413909AImprove breathabilityImprove barrier propertiesSemi-permeable membranesGeneral water supply conservationComposite filmNonwoven fabric

Disclosed are: a composite film substrate comprising a dry thermoplastic long-fiber nonwoven fabric which has a high uniformity, thereby making it possible to form porous films free from defects such as strike-throughs or pinholes in the course of film formation, which does not generate skin layer defects during the formation of the film layer, and which has a high mechanical strength and a high dimensional stability at high temperatures; and a high-performance composite film and a high-performance composite film element using the same. The composite film substrate, which comprises a layered, dry, thermoplastic, long-fiber nonwoven fabric consisting of three or more layers including at least a melt-blown fiber layer as an intermediate layer and spun-bonded fiber layers on both sides of said intermediate layer, is characterized in that: the average air-flow resistance thereof is 2.0 to 30.0 kPas / m; and a ratio of the average air-flow resistance and the standard deviation is 0.6 or less.

Owner:ASAHI KASEI KK +1

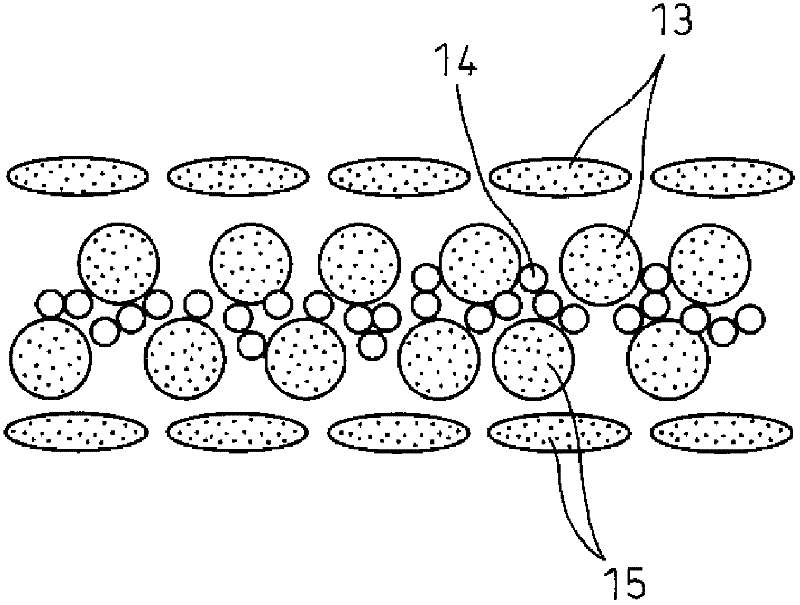

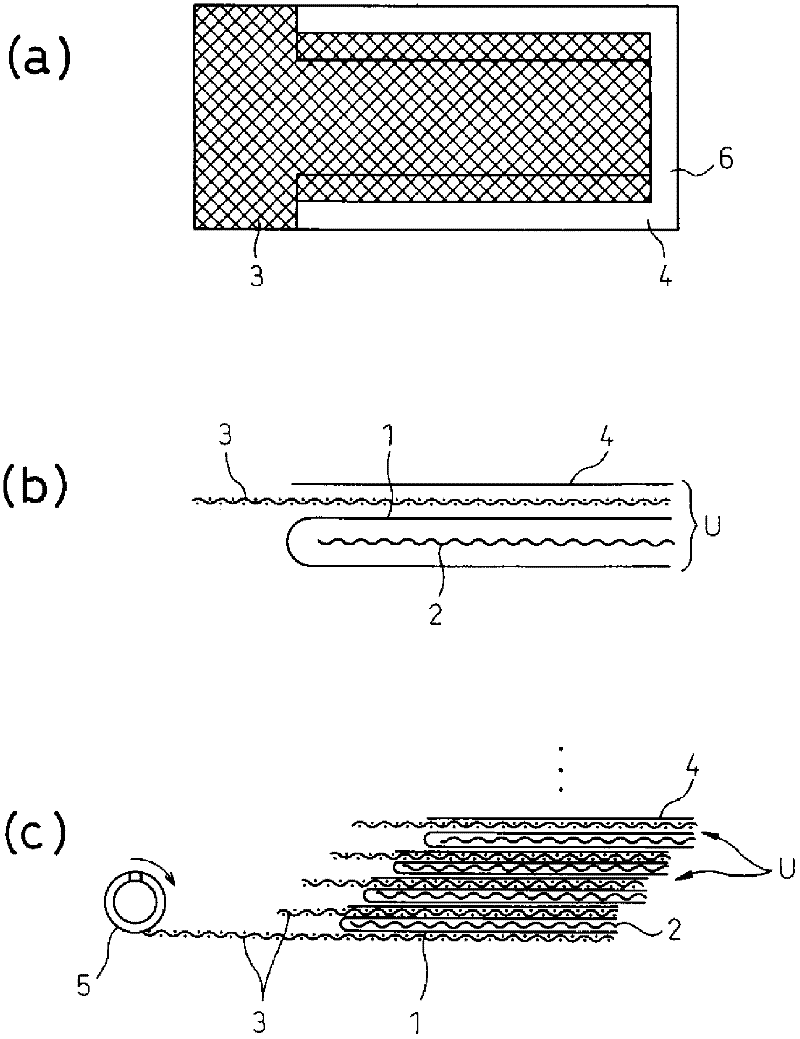

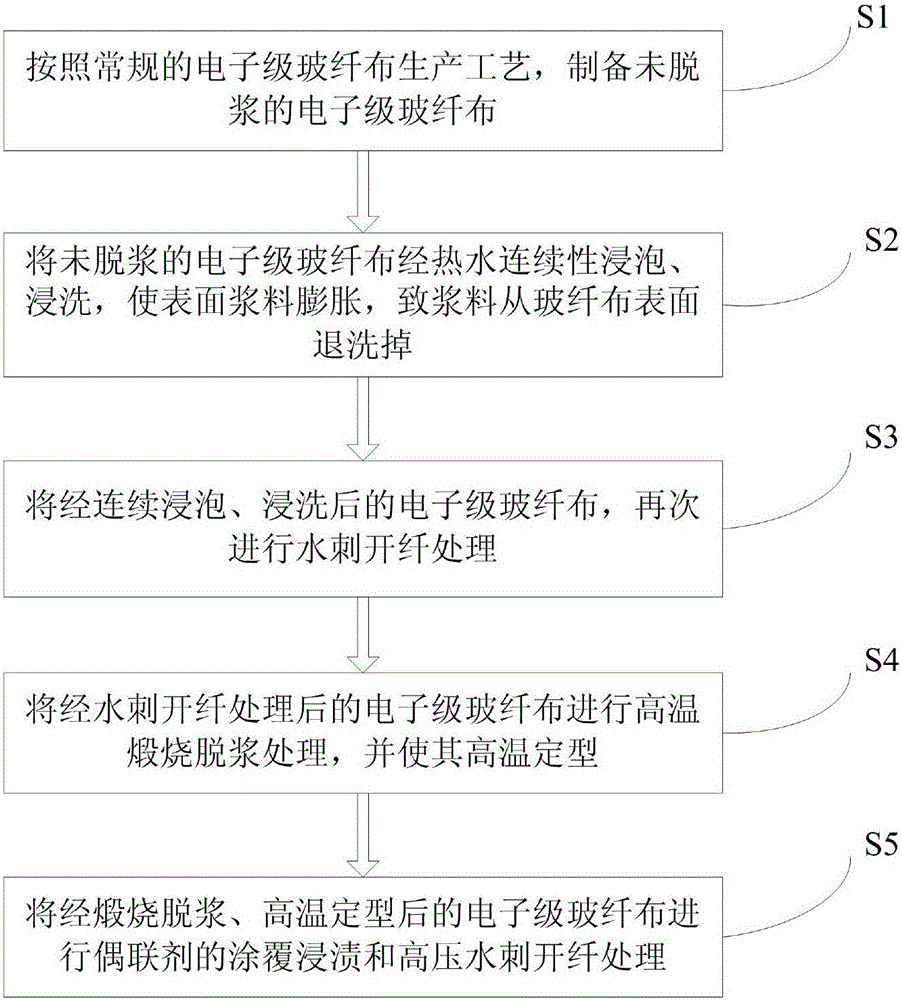

After-treatment processing method and equipment of flat electronic grade glass fiber cloth

InactiveCN105887394AThe overall thickness is thinReduce air permeabilitySucessive textile treatmentsTextile treatment containersGlass fiberYarn

The invention discloses an after-treatment processing method and equipment of flat electronic grade glass fiber cloth. The method comprises the following steps: firstly, soaking and rinsing unwashed electronic grade glass fiber cloth with hot water to enable surface sizing agents to swell until the sizing agents are washed out of the surface of the electronic grade glass fiber cloth; then carrying out spunlacing and splitting treatment on the soaked and rinsed electronic grade glass fiber cloth. According to the after-treatment processing method and equipment of flat electronic grade glass fiber cloth, cloth cover yarns of the treated glass fiber cloth are minimally destroyed, the finally obtained electronic grade glass fiber cloth is thin in thickness, and low and uniform in air permeability, the flatness of the finally obtained electronic grade glass fiber cloth is better than the electronic grade glass fiber cloth treated by a common after-treatment technology.

Owner:建滔(清远)电子材料有限公司

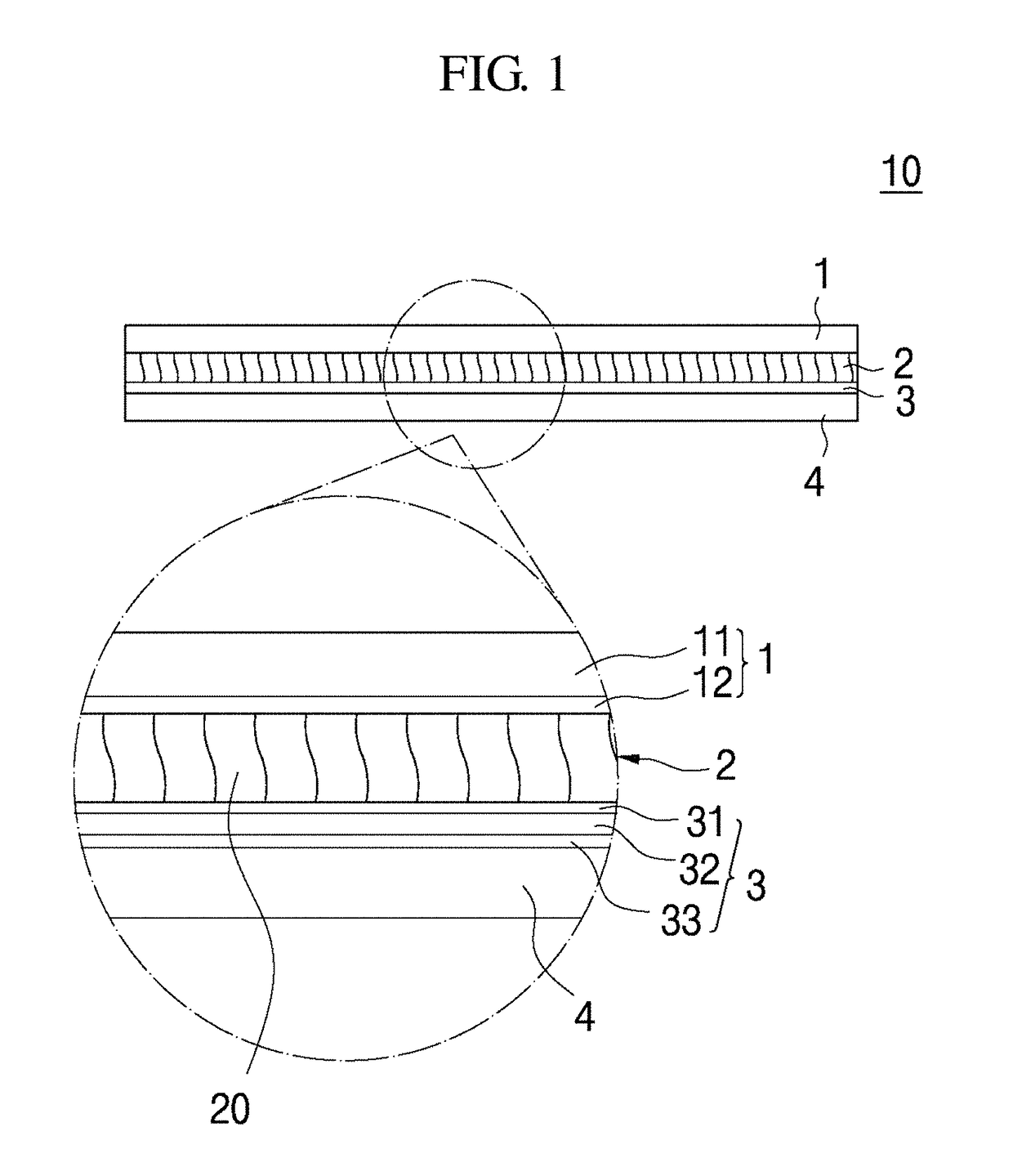

Electromagnetic wave absorbing sheet and method of manufacturing the same and electronic device using the same

ActiveUS9832917B2Good absorption rateComponent with highShielding materialsSynthetic resin layered productsEngineeringElectron

Owner:AMOSENSE

Gas diffusion electrodes, membrane-electrode assembles and method for the production thereof

ActiveUS20060234111A1Uniform permeabilityIncrease useful catalytic surfaceFinal product manufactureElectrode carriers/collectorsChemistryElectrically conductive

A method for forming a patterned noble metal coating on a gas diffusion medium substantially free of ionomeric components comprising subjecting an electrically conductive web with a patterned mask overlaid thereto to a first ion beam having an energy not higher than 500 eV, and to a second beam having an energy of at least 500 eV, containing the ions of at least one noble metal and a gas diffusion electrode.

Owner:BASF FUEL CELL

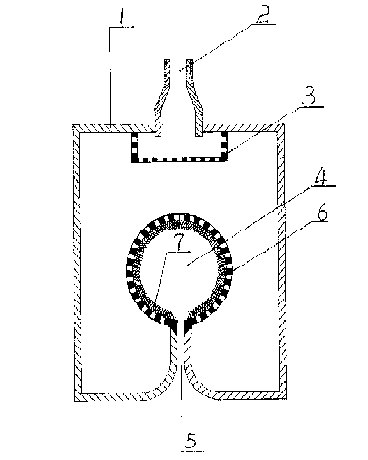

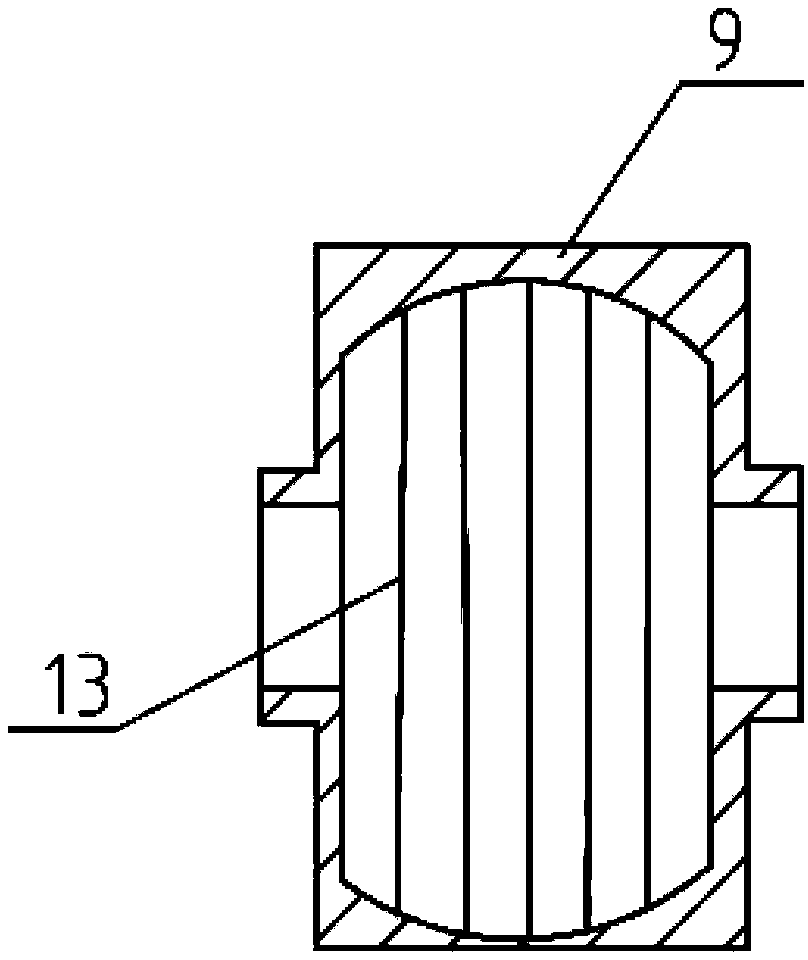

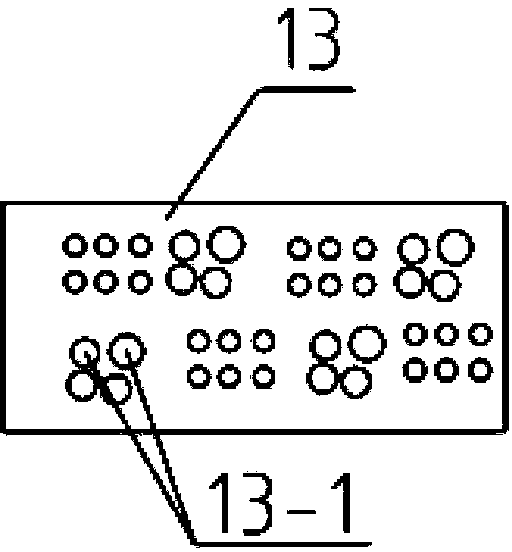

Preparation method for upper nozzle used for continuous casting

The invention discloses a preparation method for an upper nozzle used for continuous casting. The upper nozzle is composed of an inner layer and an outer layer, wherein the inner layer comprises aluminum titanate, silicon nitride and aluminum nitride, and the outer layer comprises a porous mullite ceramic particle, fine mullite powder, fine zirconia mullite powder, fine Cr2O3 powder, fine clay powder and 200-mesh active alpha alumina micro powder. The preparation method comprises the following steps: 1) mixing: a step of respectively and uniformly mixing inner layer raw materials and outer layer raw materials in a mixer with stirring and carrying out granulation; 2) molding: a step of respectively subjecting the inner layer and the outer layer of the upper nozzle to compression molding through isostatic pressing; and 3) sintering: a step of drying a molded green body and sintering the green body in a reducing atmosphere at a temperature of 1460 to 1500 DEG C or in an anoxic environment. The upper nozzle has service life of more than 20 h and good thermal shock resistance and can effectively prevent alumina in molten steel from adhesion and accumulation in the inner cavity of the upper nozzle and prevent obstruction of steel flow.

Owner:WUXI SHENJIA HYDRAULIC TECH

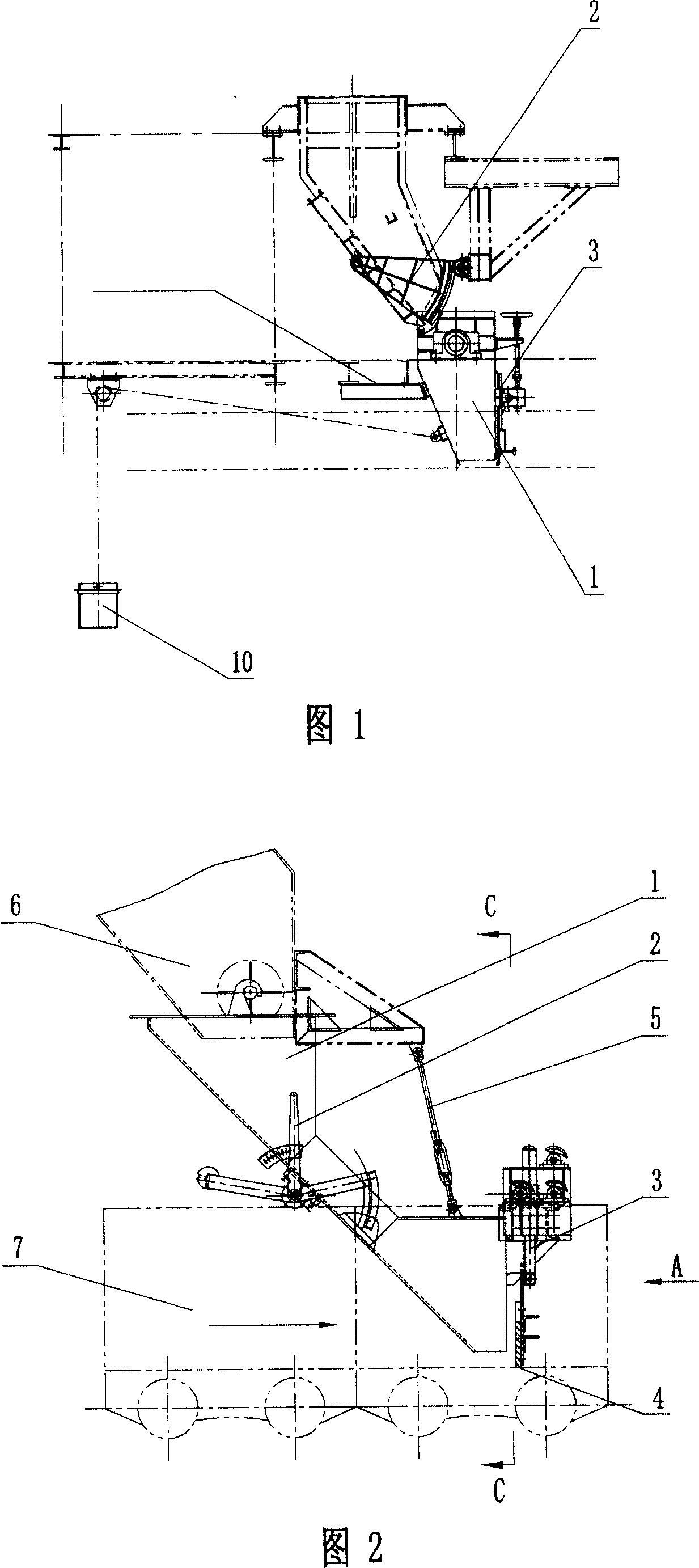

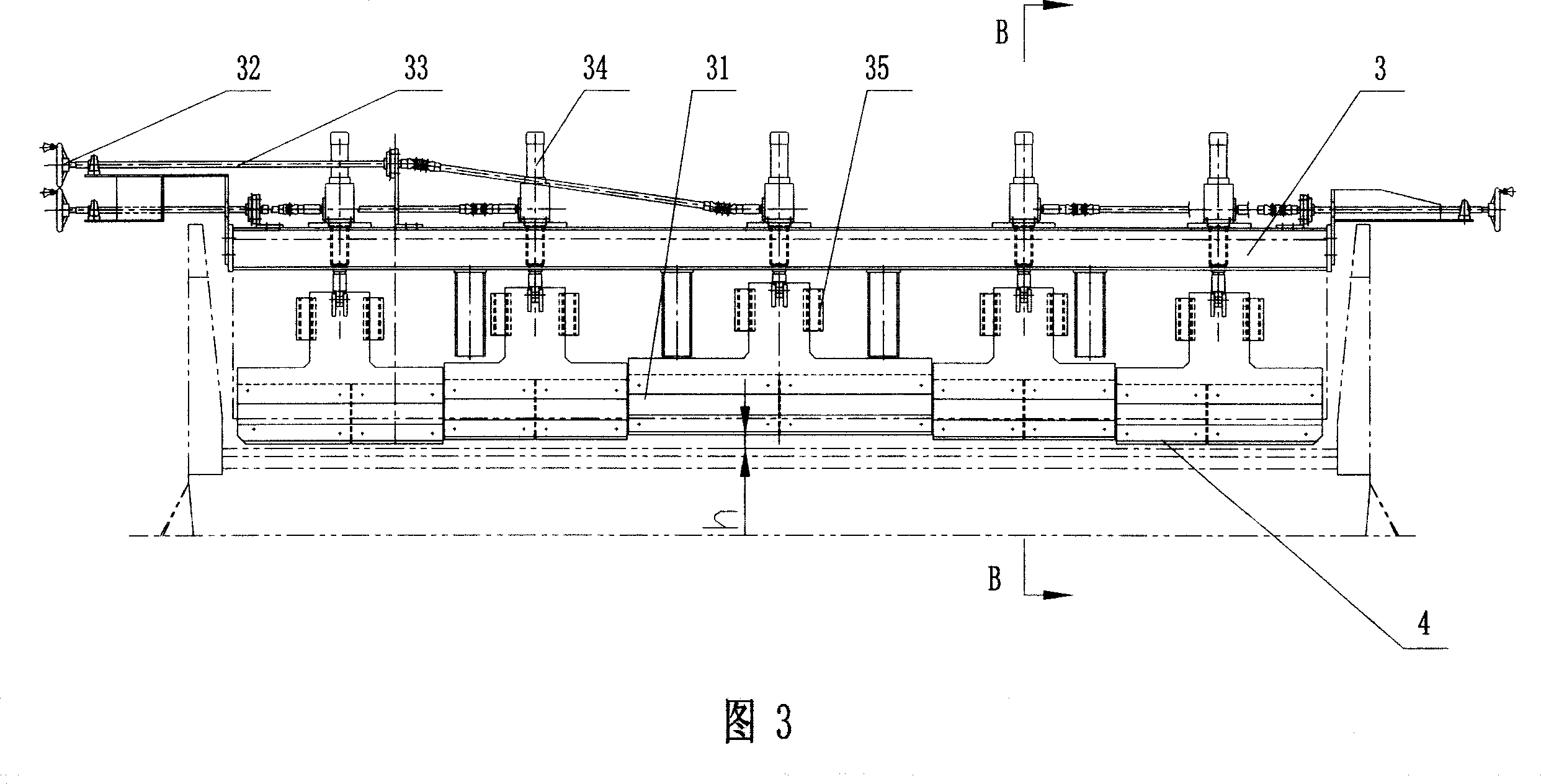

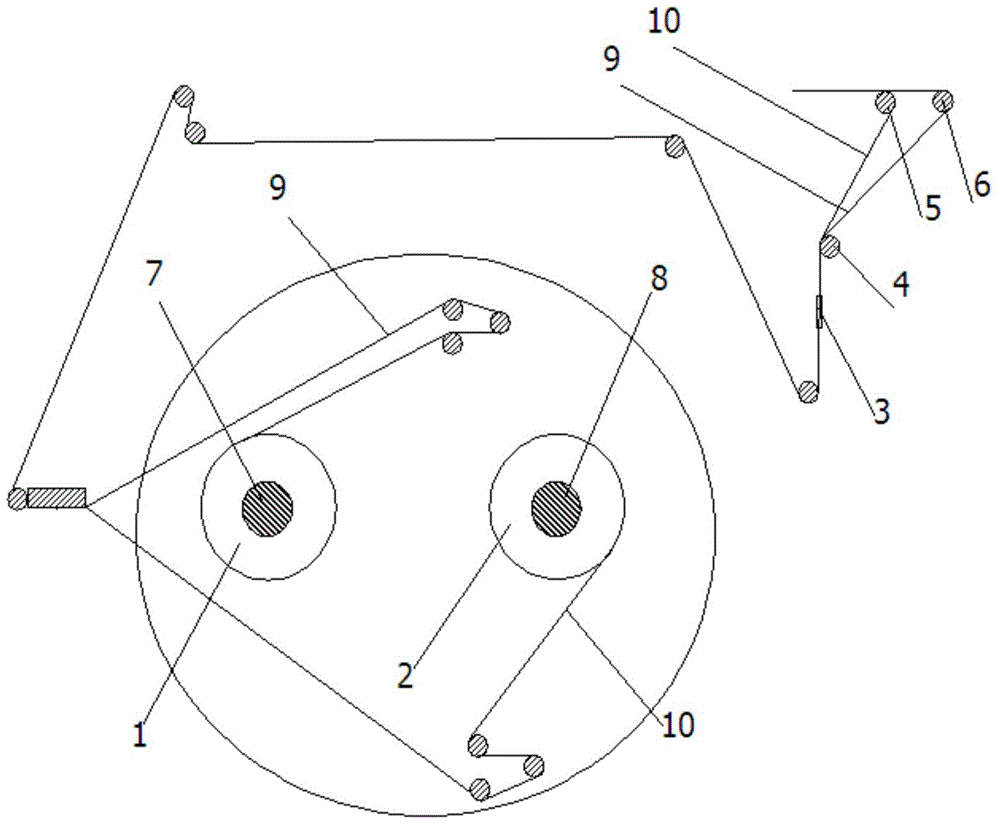

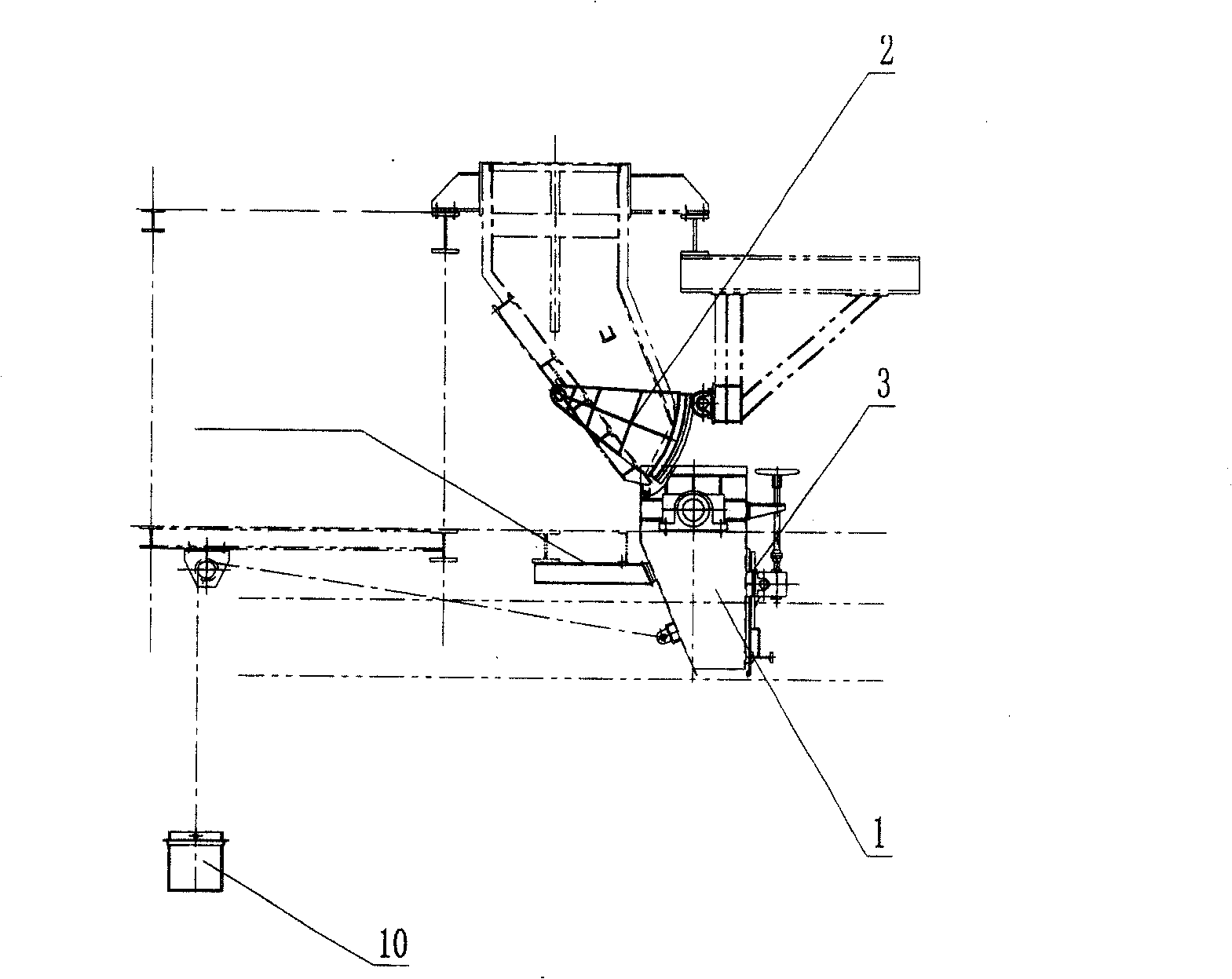

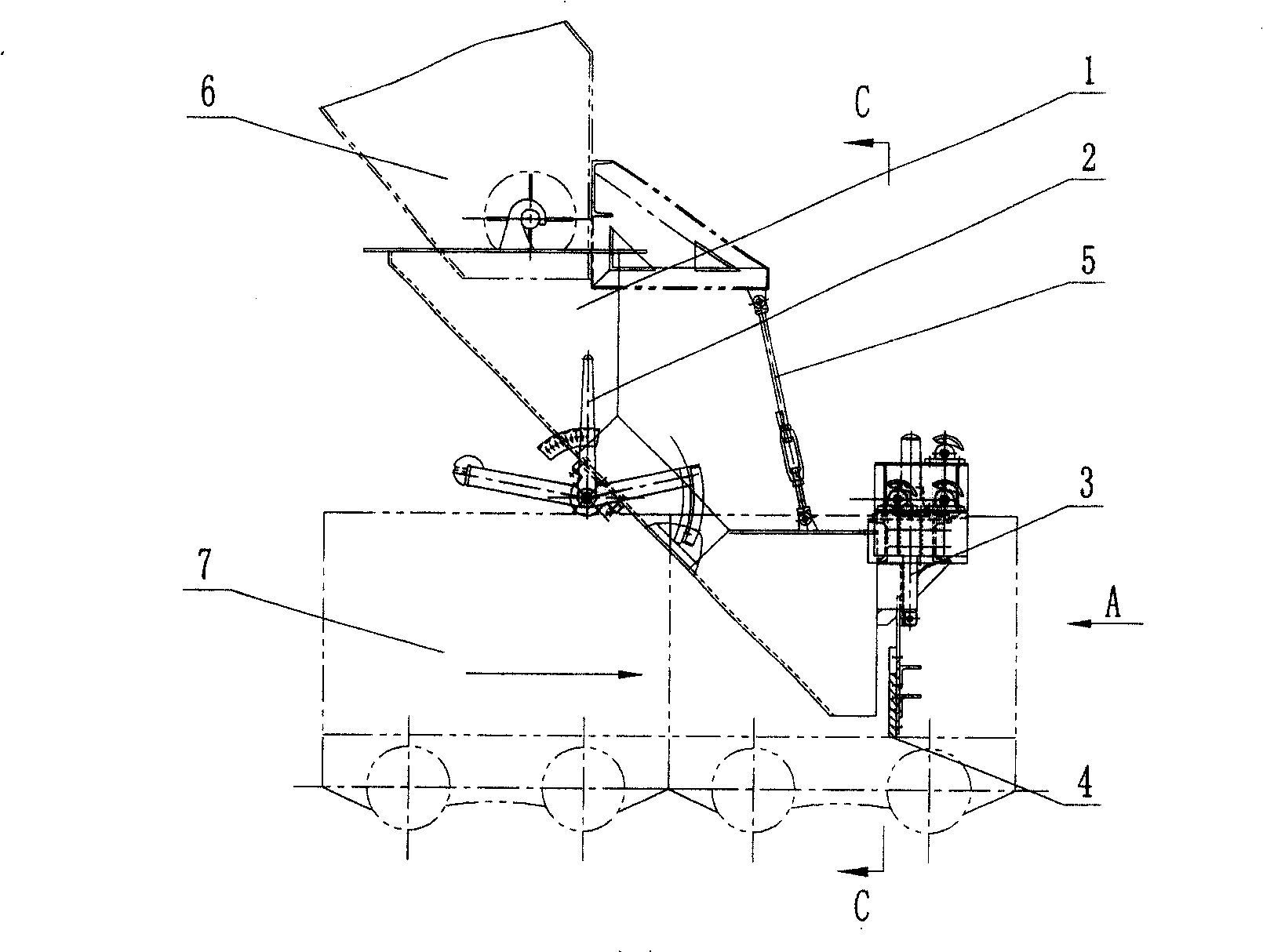

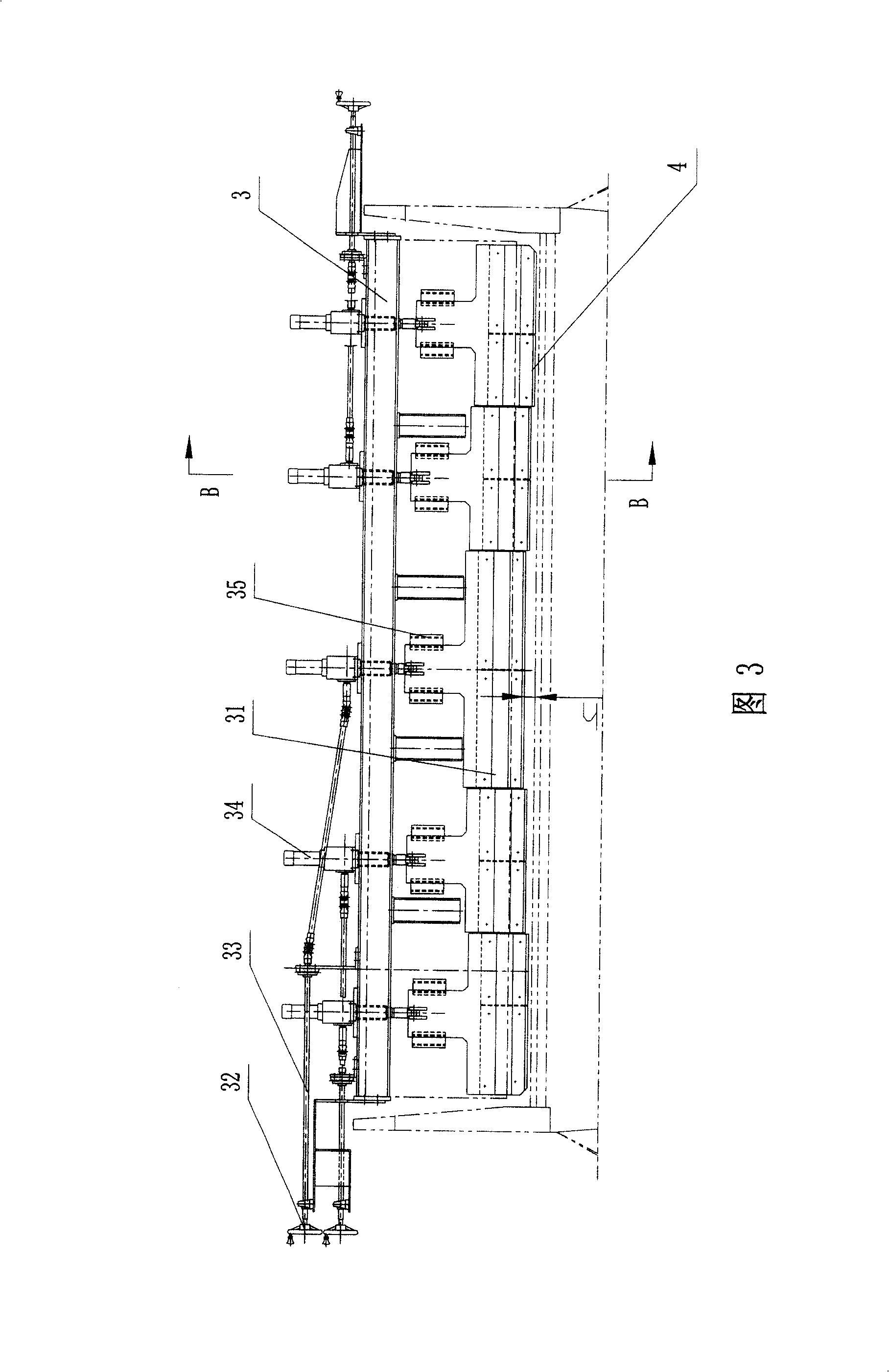

Swinging funnel used for paving bottom flavoring of sintering machine

ActiveCN101017056AUniform air permeabilitySimple structureLighting and heating apparatusAgricultural engineering

The invention discloses a swinging hopper which can segmented adjust the height of sluiceway, reduce edge effect, improve sinter quality and sinter efficiency, with simple structure, small volume, and low cost, for laying bottom material in sinter machine. The invention comprises a body, a rotary sluiceway, and a sluiceway adjuster, wherein the rotary sluiceway is mounted at the middle of the body, the sluiceway adjuster is mounted at the front of the body, and the height of the sluiceway is reduced from middle to two sides.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Composite membrane support and composite membrane using same

InactiveCN102413909BImprove breathabilityImprove barrier propertiesSemi-permeable membranesGeneral water supply conservationComposite filmPorous layer

The purpose of the invention of the present application is to provide a composite membrane support formed by dry thermoplastic long fiber non-woven fabric, and a high-performance composite membrane and composite membrane element using it. The composite membrane support has the ability to be formed on Extremely high uniformity of the porous layer without defects such as offset and pinholes during film formation, no defects in the skin layer when forming the skin layer, and excellent mechanical strength and dimensional stability at high temperatures. The composite film support of the invention of the present application is characterized in that it is a laminated dry thermoplastic long fiber of more than three layers comprising at least a melt-blown fiber layer in the middle layer and a spunbond fiber layer on both sides of the middle layer. For non-woven fabrics, the average value of the air resistance is 2.0 to 30.0 kPa·s / m, and the ratio of the average value to the standard deviation of the air resistance is 0.6 or less.

Owner:ASAHI KASEI KK +1

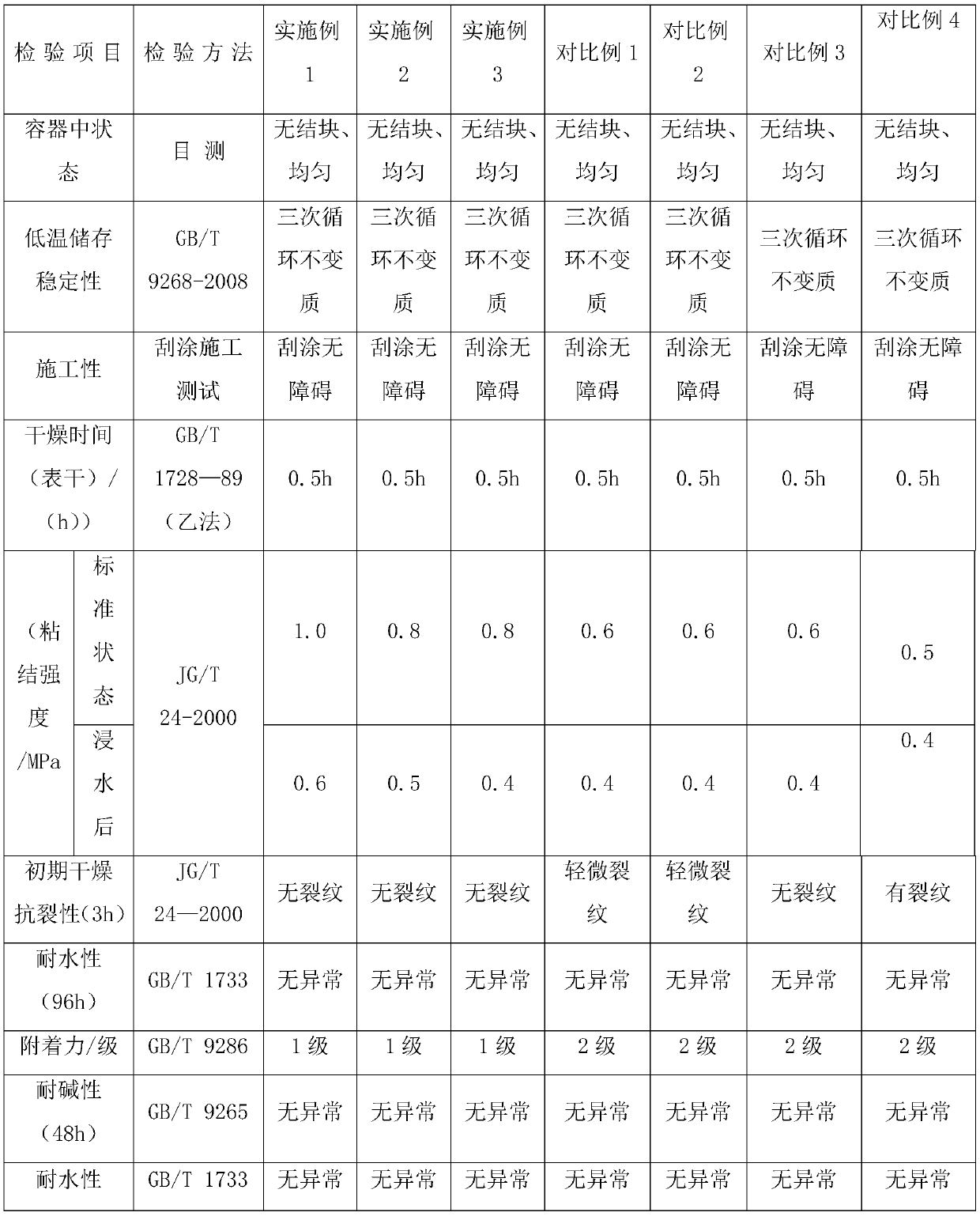

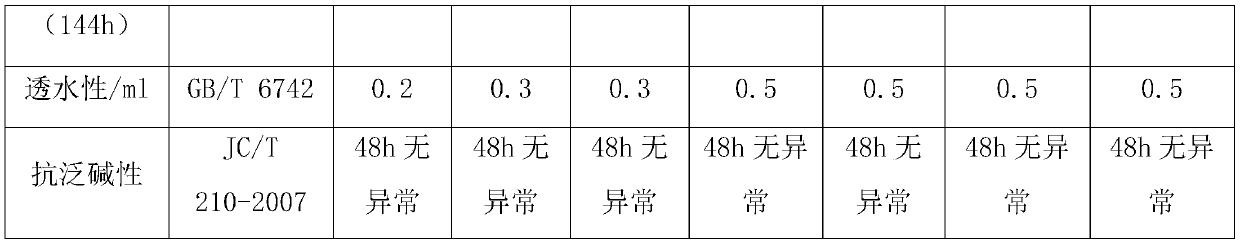

Water-based terrace phase-change epoxy putty coating and preparation method thereof

InactiveCN110964408ARealize the control effectAvoid bulgingEpoxy resin coatingsFiberCrack resistance

The invention discloses a water-based terrace phase-change epoxy putty coating and a preparation method thereof. The water-based terrace phase-change epoxy putty coating is formed by compounding a component A, a component B and a component C; the component A comprises, by weight, 30-50 parts of a waterborne epoxy curing agent, 30-40 parts of deionized water, 0.1-0.3 part of a defoaming agent, 0.1-0.4 part of a dispersing agent, 0.2-0.6 part of a base material wetting agent, 0.8-1.2 parts of a leveling agent and 10-20 parts of a microcapsule phase change material; the component B comprises, byweight, 85-95 parts of waterborne epoxy resin and 5-15 parts of aliphatic glycidyl ether, and the aliphatic glycidyl ether meets the following requirements: (1) the viscosity at 40 DEG C is 3-7 mpa.s,and (2) the epoxy equivalent is 290-310 g / eq; and the component C comprises, by weight, 80-100 parts of 200-mesh quartz powder and 1.5-4.5 parts of a composite fiber. The addition of the microcapsulephase-change material and the composite fiber greatly improves the cracking resistance and adhesive force of the putty coating.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

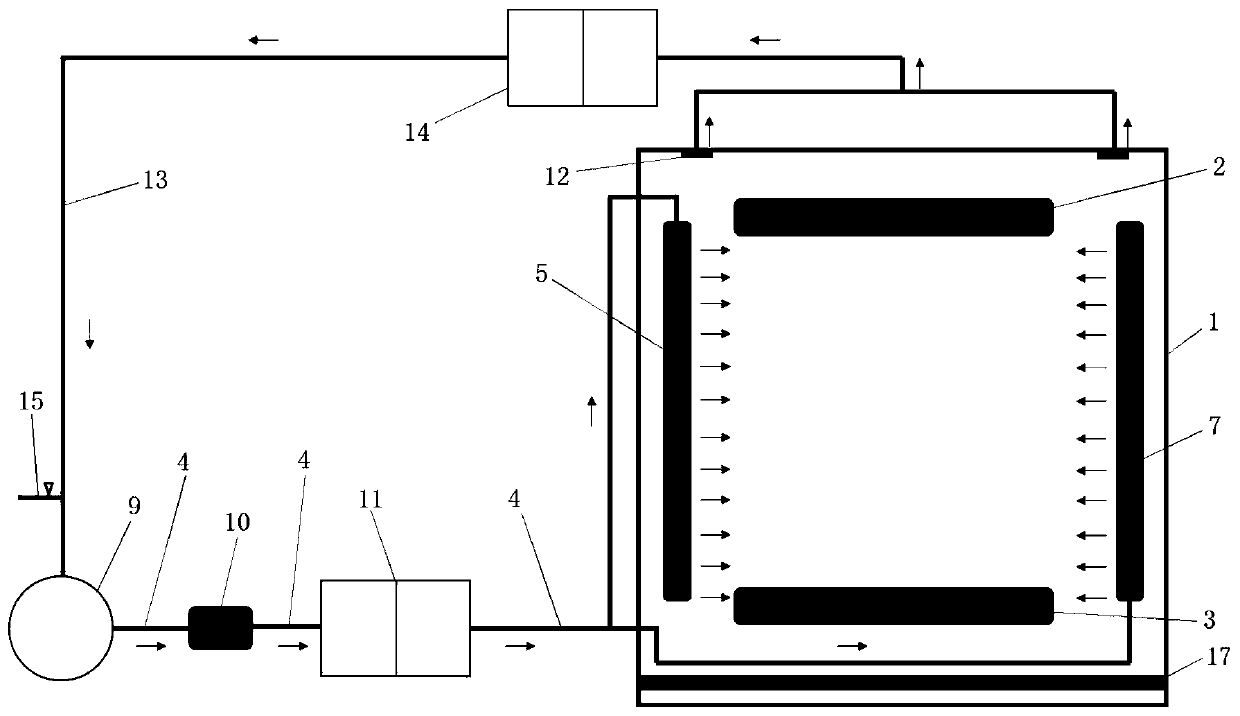

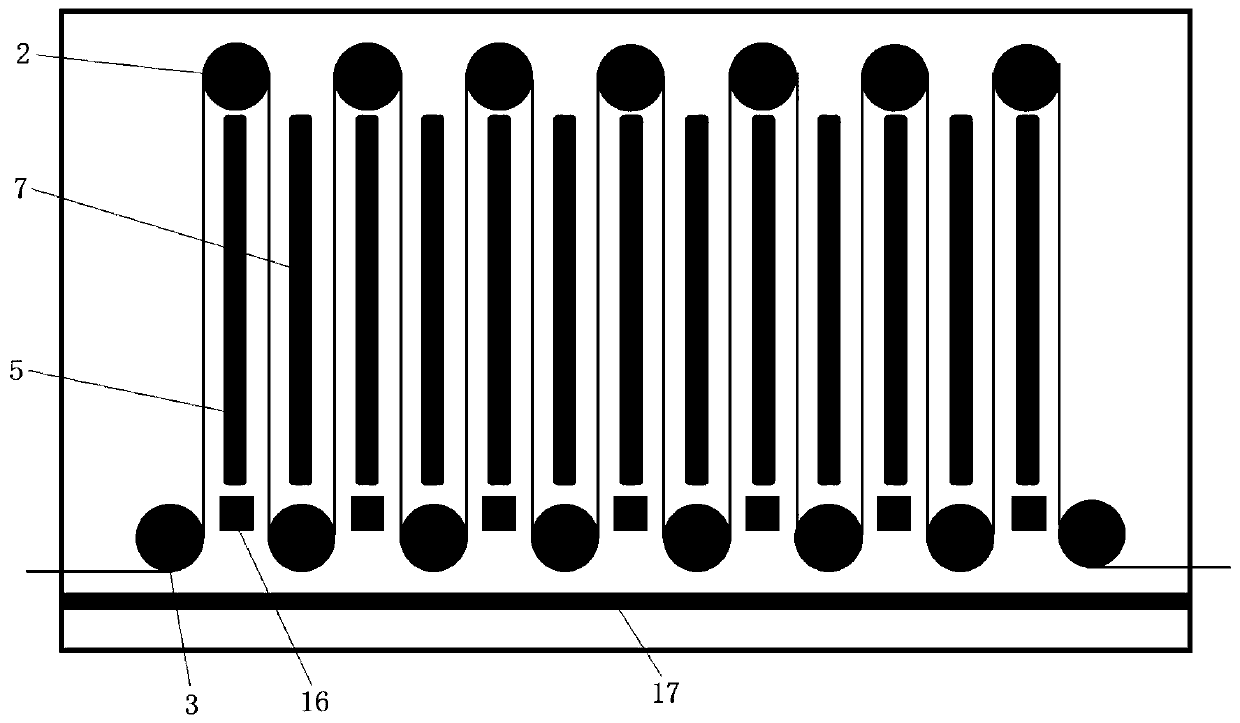

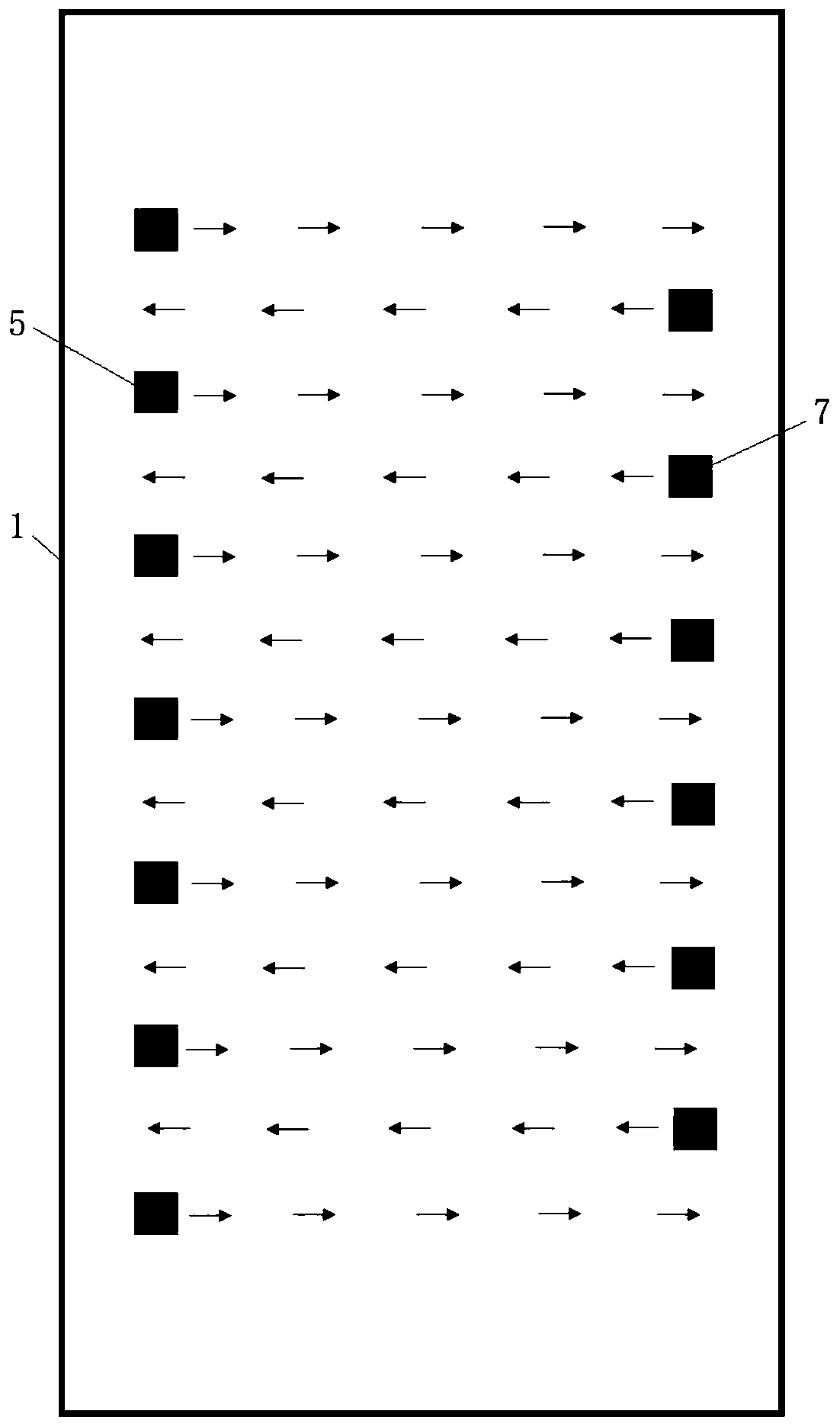

Battery diaphragm drying oven device

PendingCN110202726AHot air and uniform temperatureUniform air permeability and thicknessElectrical batteryWave shape

The invention relates to a battery diaphragm drying oven device which comprises a box body; the front side of the box body is provided with a film inlet; the rear side of the box body is provided witha film outlet; a drying cavity is formed in the box body and is internally provided with a diaphragm conveying device and an air blowing system; the diaphragm conveying device is suitable for conveying a battery diaphragm which enters the drying cavity; and the air blowing system is suitable for blowing air to the battery diaphragm conveyed in the drying cavity. For the battery diaphragm drying oven device, an upper transition roller set and a lower transition roller set of the diaphragm conveying device are arranged in a wave shape at intervals, each left air blowing pipe and each right airblowing pipe oppositely blow the air, and air inlet directions of each left air blowing pipe and the corresponding right air blowing pipe are opposite, so that hot air and temperature received by thesurfaces of the battery diaphragms located at different positions in the drying cavity are uniform; compared with single-side air blowing, the battery diaphragm with more uniform air permeability andthickness can be obtained through double-side air blowing; and through arrangement of a step cross beam, film penetrating operation is facilitated when a film roll is manually replaced, and maintenance of parts in the box body and wiping of the guide roller surface with the worker are facilitated.

Owner:JIANGSU ANREDA NEW MATERIAL

Adjustable high-efficiency sintering machine loosening device and use method

InactiveCN113074554AEasy to controlImprove breathabilityCharge manipulationCharge treatment typeMetallurgyHydraulic ram

The invention discloses an adjustable high-efficiency sintering machine loosening device and a use method, and relates to the technical field of smelting equipment. The adjustable efficient sintering machine loosening device comprises a supporting base, wherein a movable box body is fixedly arranged at the top of the supporting base through a hydraulic oil cylinder, fixed sliding grooves are formed in the two sides of the movable box body, and partition plates and drainage devices are arranged on the fixed sliding grooves. According to the adjustable efficient sintering machine loosening device and the use method, accurate layered control over preheating of a sintering mixture through loosening rods is achieved, so that the layered uniform preheating effect under the action of segregation of a sintering material, different water holding rates of the layers and migration of an over-wet belt is achieved, the air permeability of the sintering material layer can be obviously improved, and relatively reasonable spatial gradient distribution of the loosening rods in the sintering material layer is kept, so that a temperature field in the sintering material layer is more uniform, an over-wet layer is more uniform, and uniform development of a subsequent sintering process is promoted.

Owner:MAANSHAN IRON & STEEL CO LTD

Hot air reshaping and aroma extracting machine

InactiveCN101700083AUniform shapeConsistent moldingPre-extraction tea treatmentPulp and paper industryAir cavity

The invention discloses a hot air reshaping and aroma extracting machine, relating to tea processing machinery. The machine is characterized in that a hot air cavity is arranged on a rack, and a plurality of vent holes are arranged at the top of the hot air cavity and connect the a hot air valve and a hot air stove; therefore, the tea is placed at the top of the hot air cavity and is quickly shaped by the hot air erupted from the vent holes, and heating and ventilating are uniform, thus ensuring the shaped tea to shape up identically. The temperature of the tea can be conveniently controlled by controlling the temperature of the hot air, thus being favorable to ensuring the quality of the tea. As seldom stir-frying is required, the broken tea is reduced. The hot air from the vent hole is favorable to taking away the green smell of the tea, thus enabling the tea to be fragrant but not green and improving the grade of the tea. The machine has low requirements on the technologies of the production personnel and features fast tea shaping, identical shaping, little broken tea, good aroma extracting effect and high production efficiency.

Owner:WUFENG TIANCHI TEA MACHINERY

Gas Diffusion Electrodes, Membrane-Electrode Assemblies and Method for the Production Thereof

InactiveUS20080254342A1Low platinum loadingImprove performanceCell electrodesFinal product manufactureDiffusionIon beam

A method for forming a patterned noble metal coating on a gas diffusion medium substantially free of ionomeric components comprising subjecting an electrically conductive web with a patterned mask overlaid thereto to a first ion beam having an energy not higher than 500 eV, and to a second beam having an energy of at least 500 eV, containing the ions of at least one noble metal and a gas diffusion electrode.

Owner:BASF FUEL CELL

Gas diffusion electrodes, membrane-electrode assemblies and method for the production thereof

ActiveUS7601216B2Low platinum loadingImprove performanceFinal product manufactureElectrode carriers/collectorsIonomerGaseous diffusion

A method for forming a patterned noble metal coating on a gas diffusion medium substantially free of ionomeric components comprising subjecting an electrically conductive web with a patterned mask overlaid thereto to a first ion beam having an energy not higher than 500 eV, and to a second beam having an energy of at least 500 eV, containing the ions of at least one noble metal and a gas diffusion electrode.

Owner:BASF FUEL CELL

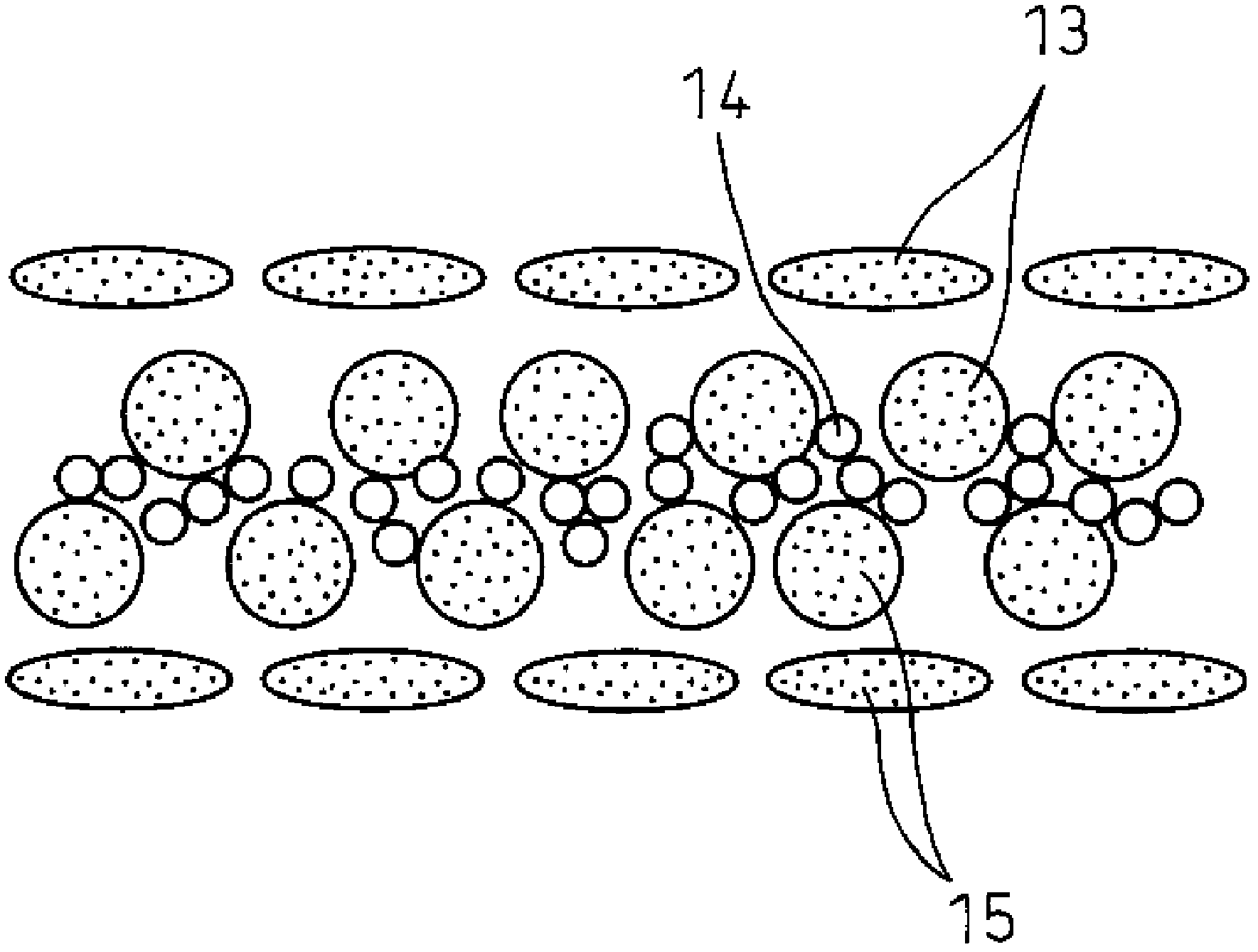

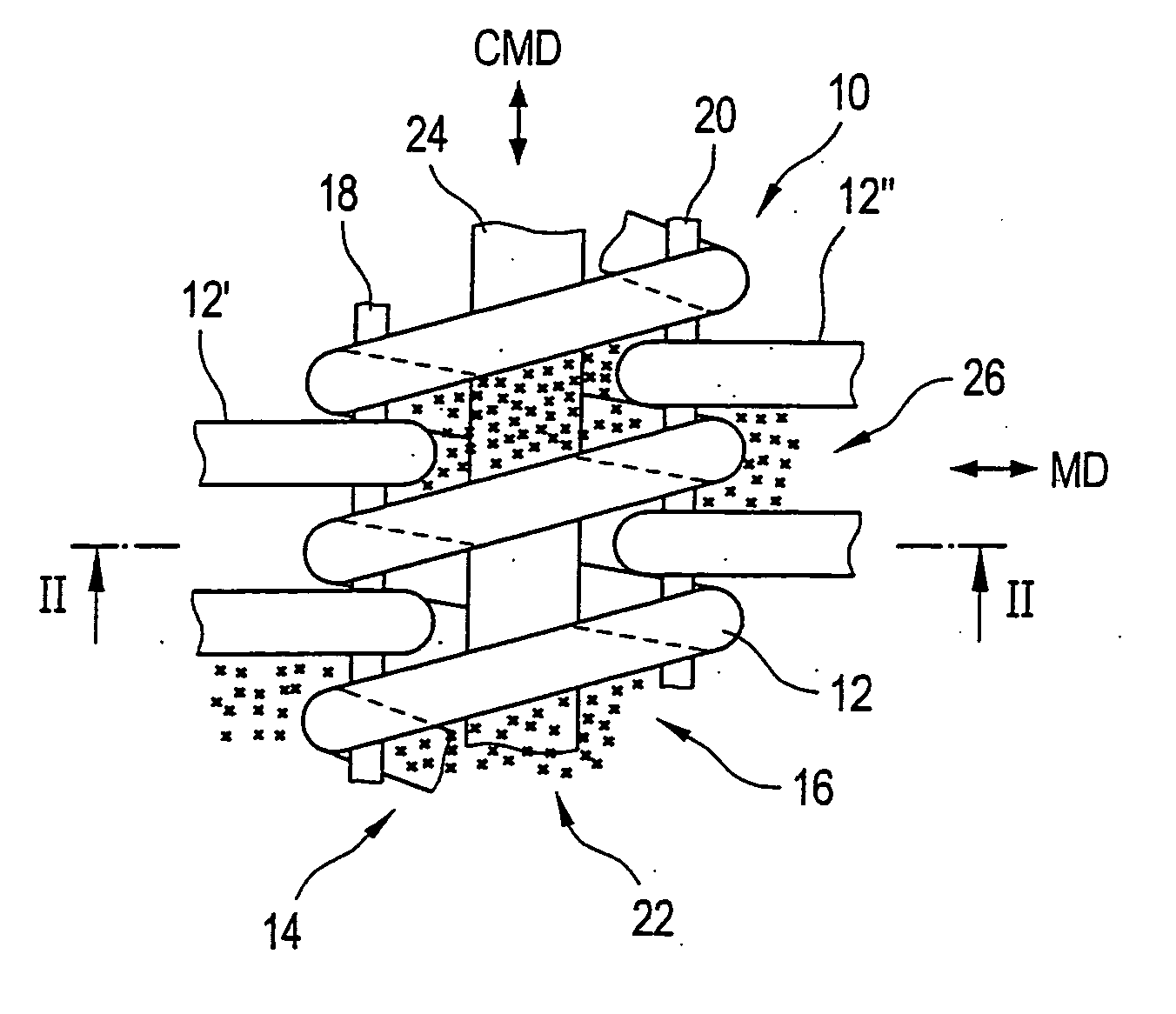

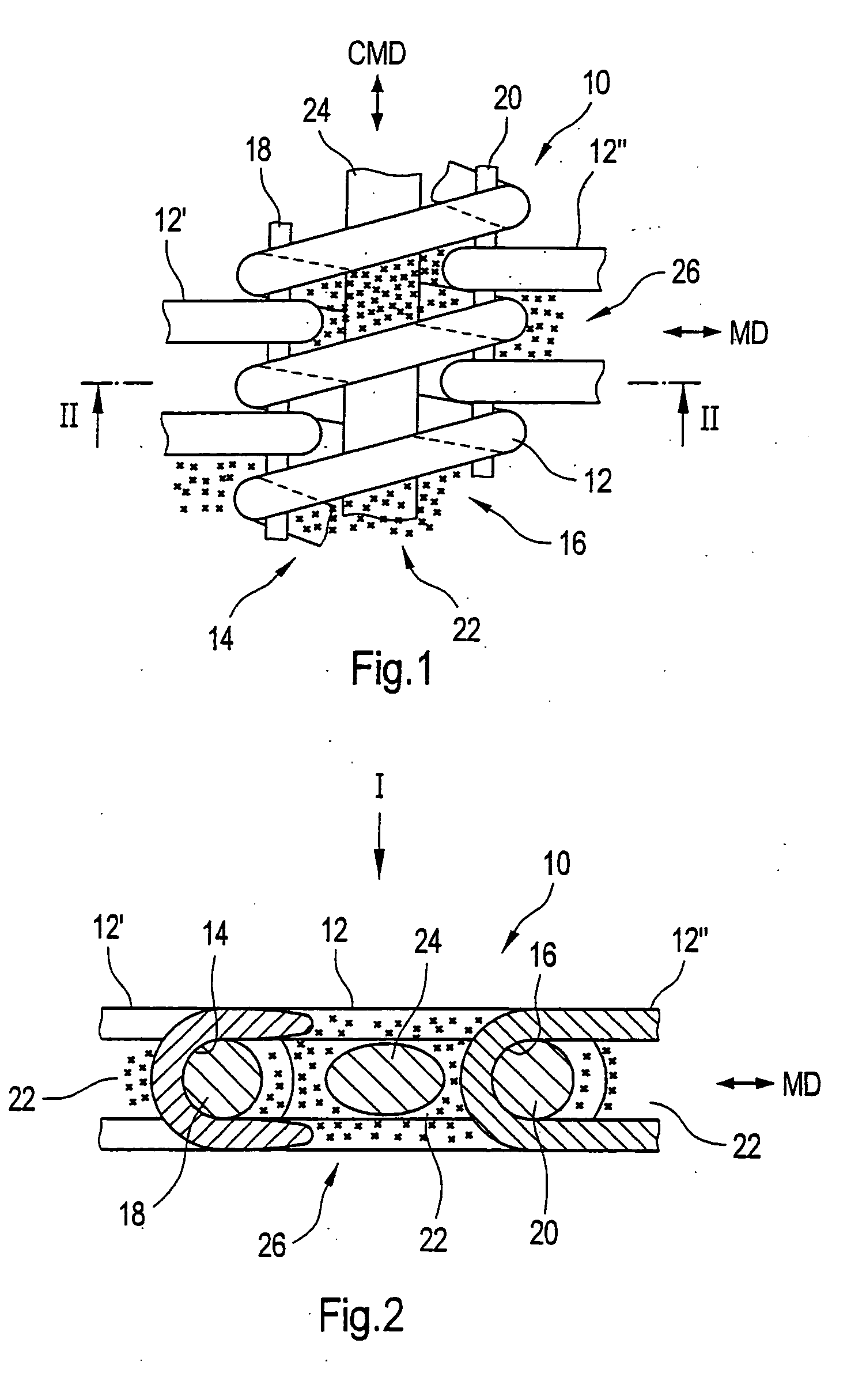

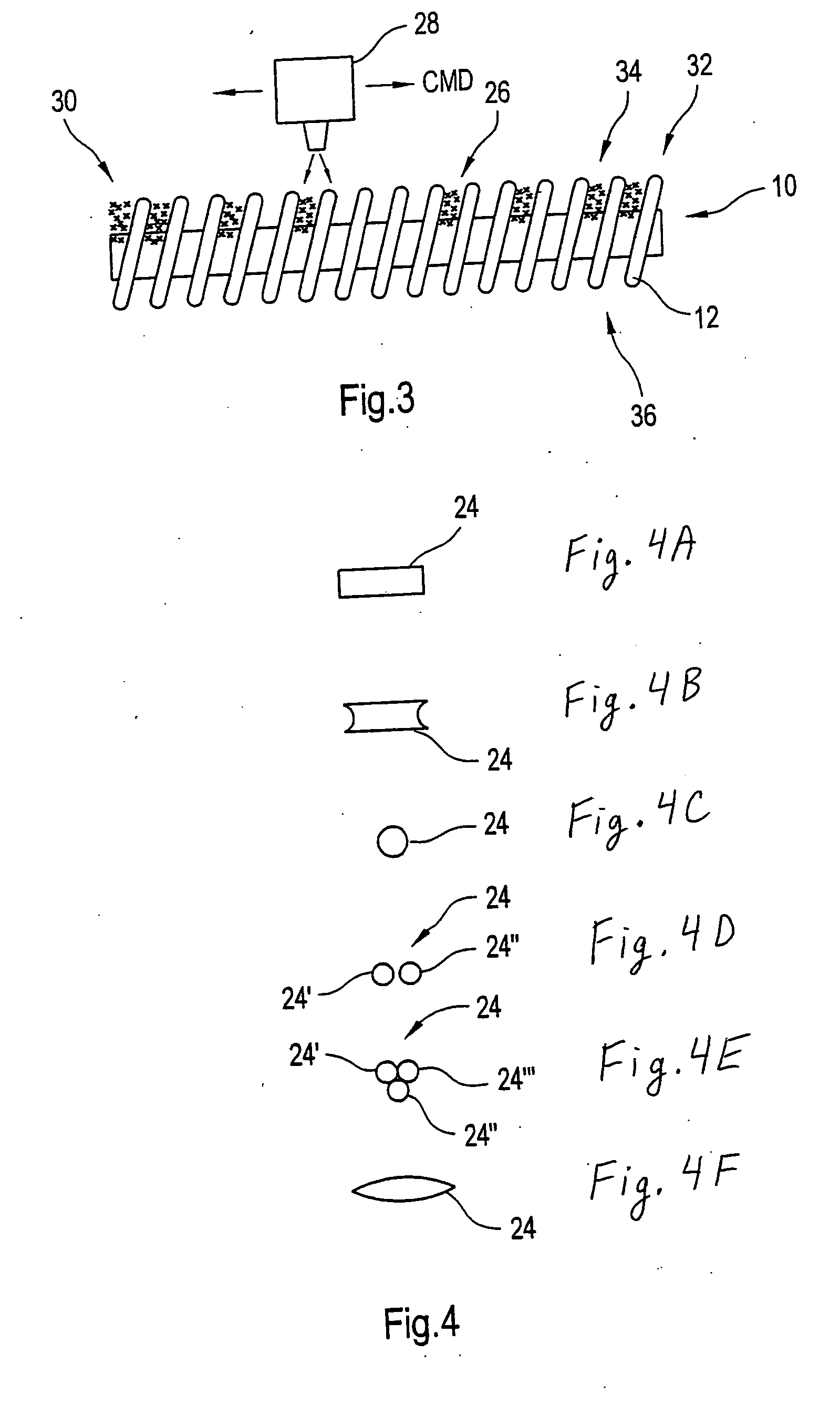

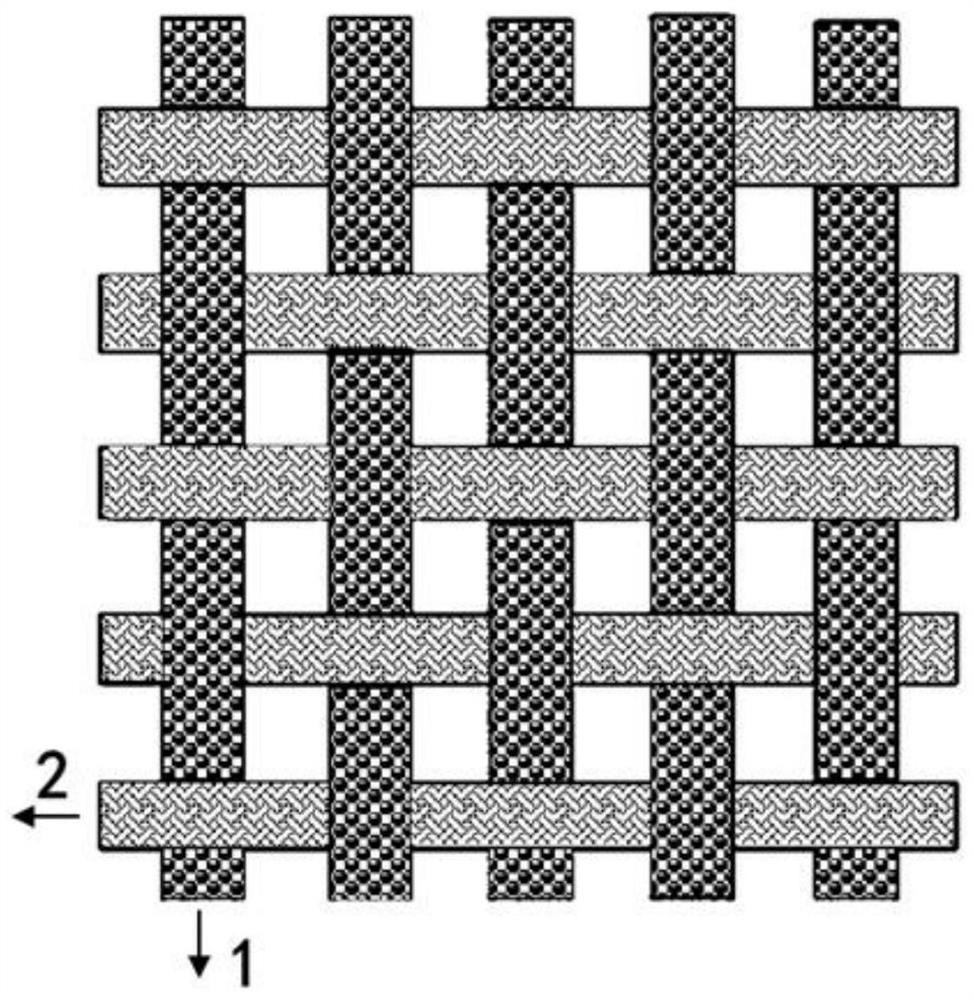

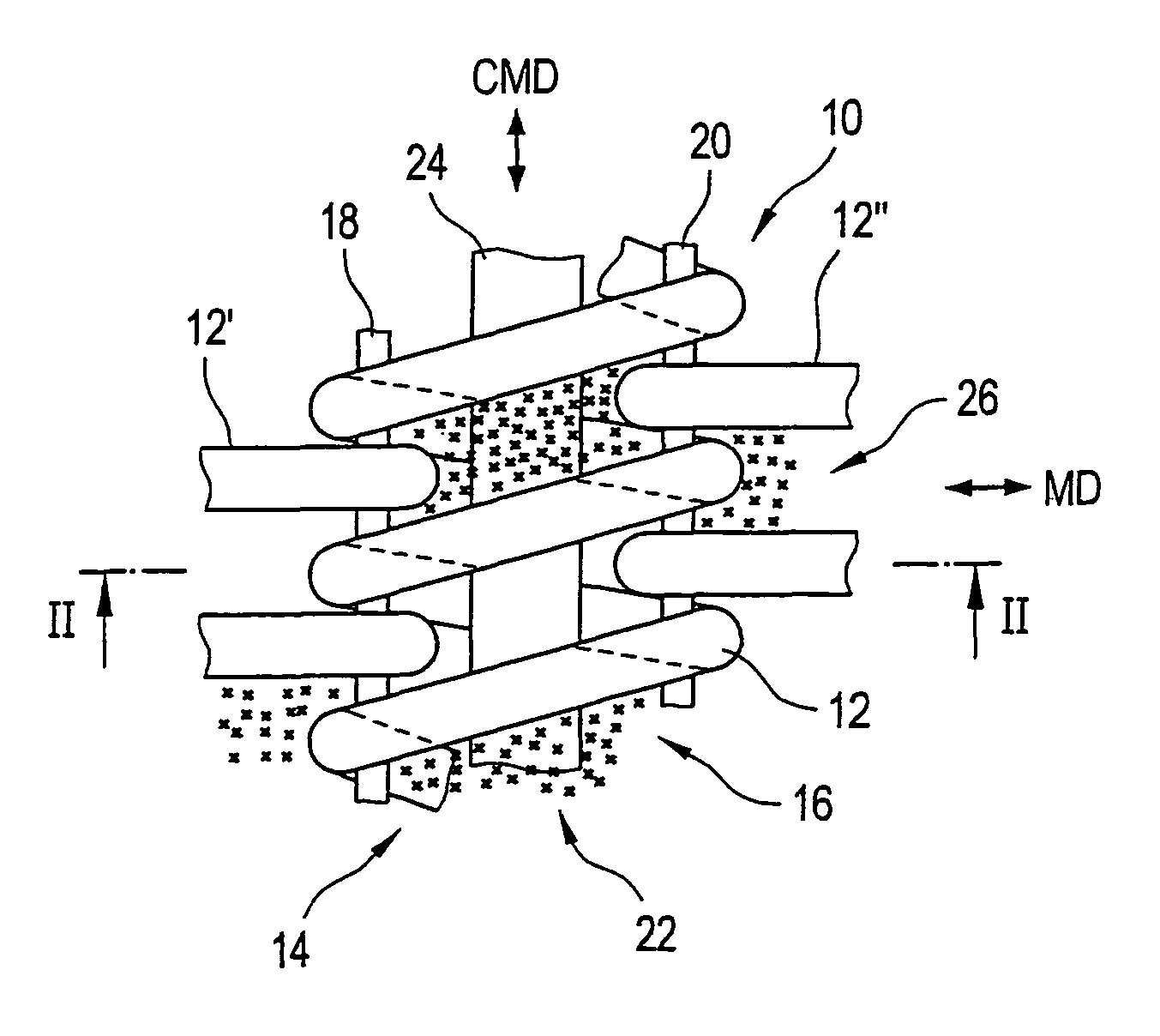

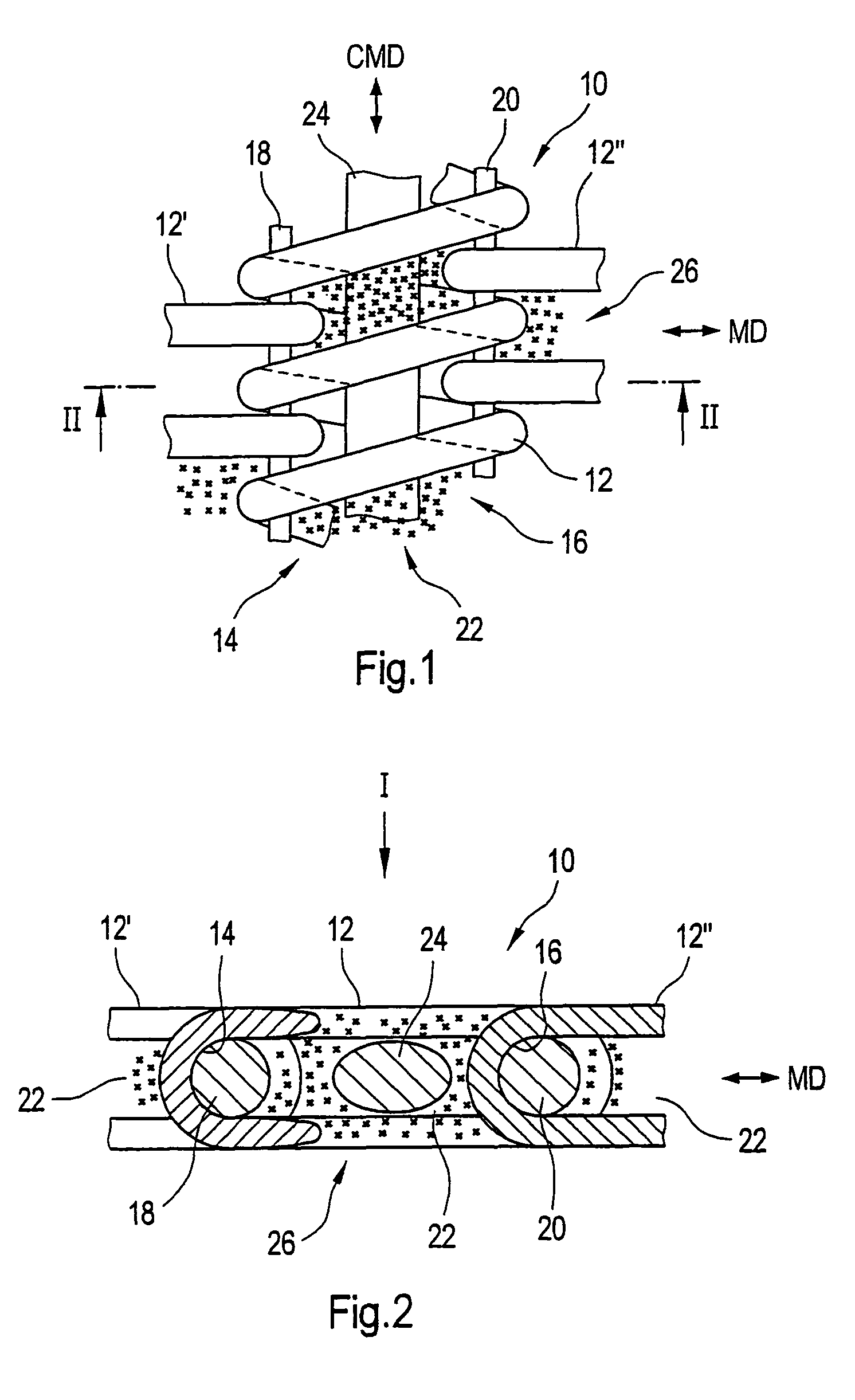

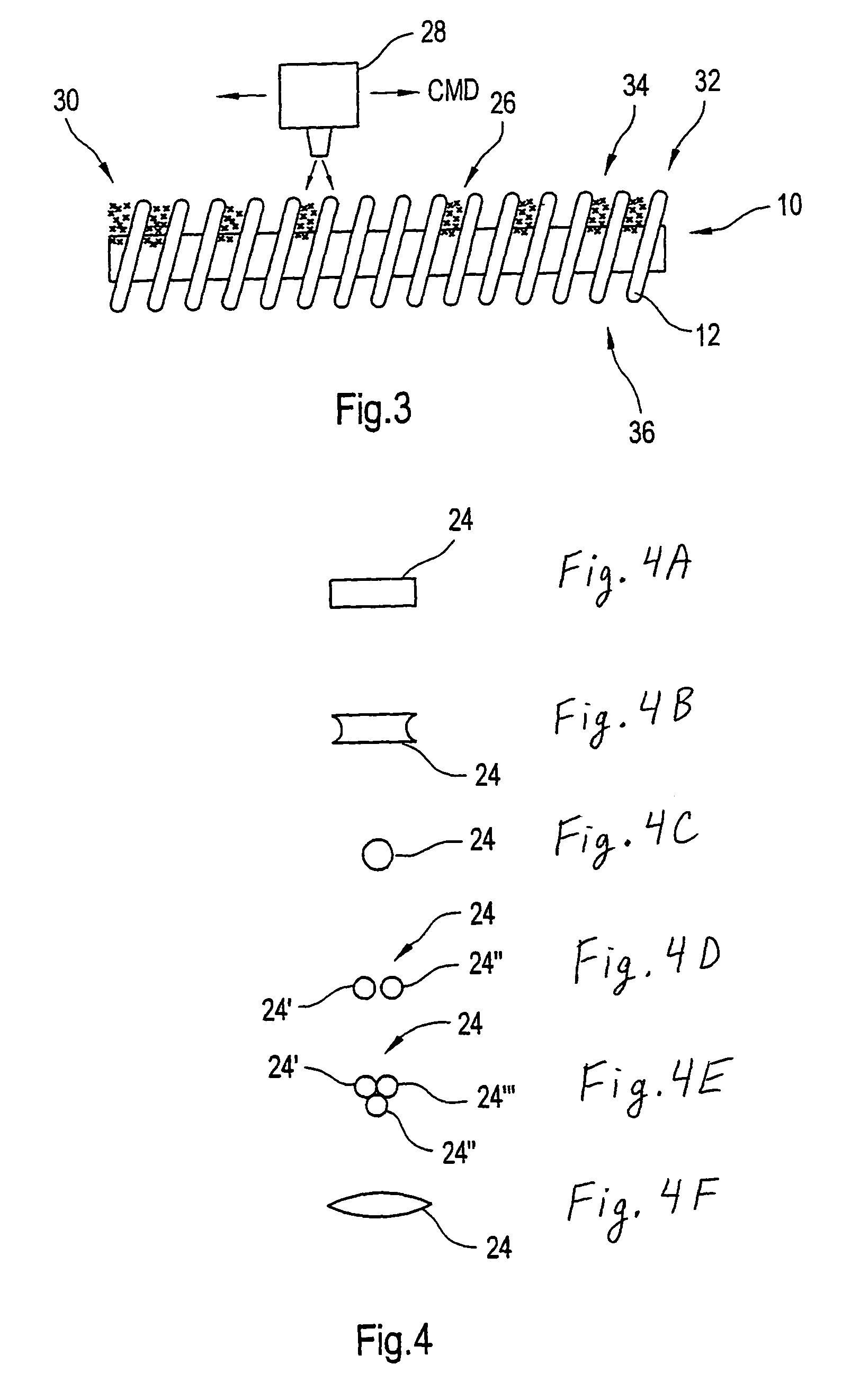

Papermachine clothing

InactiveUS20070066172A1Reduce penetrationReduce riskMachine wet endPaper/cardboardFilling materialsEngineering

A fabric, in particular for a paper making machine, includes a plurality of helically wound coil members arranged side by side with respect to each other in an intermeshing manner, such that connecting channels are formed by adjacent intermeshing coil members, a hinge member being introduced into and extending along each connecting channel for interconnecting adjacent coil members, a stuffer channel being formed within each coil member extending along and between two connecting channels associated to a respective coil member, at least a part of the stuffer channels being filled with stuffer members extending longitudinally within the stuffer channels, a stuffer material being provided at least in regions of the fabric for filling spaces formed within the fabric between the coil members, the hinge members and the stuffer members.

Owner:VOITH PATENT GMBH

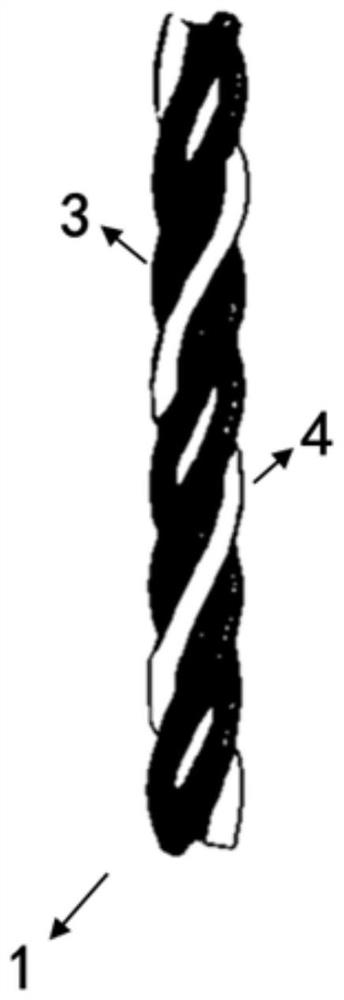

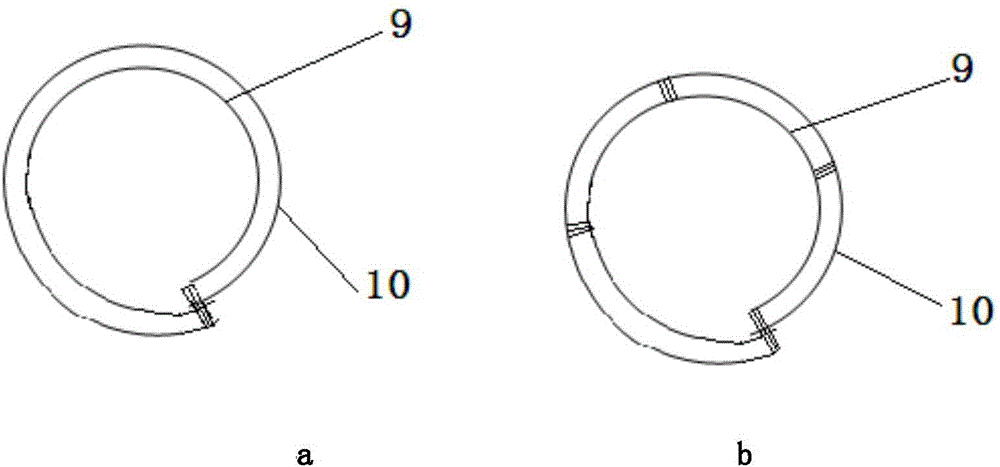

Inner ring type metal fiber infrared radiation combustor for yarn production

The invention relates to the technical fields of textile equipment and metal fiber infrared combustion, and particularly discloses an inner ring type metal fiber infrared radiation combustor for yarn production. The inner ring type metal fiber infrared radiation combustor for yarn production can process yarn in an infrared thermal radiation mode and combust yarn hairness exposed out of the surface of the yarn. The inner ring type metal fiber infrared radiation combustor for yarn production is mainly applied to a production process of the yarn. For yarn finished products prepared through the inner ring type metal fiber infrared radiation combustor, fibers cohere closely, the yarn is smooth, free of the hairness and good in gloss, and textiles are clear in grain and good in wearability.

Owner:新乡市新诚纺织有限公司

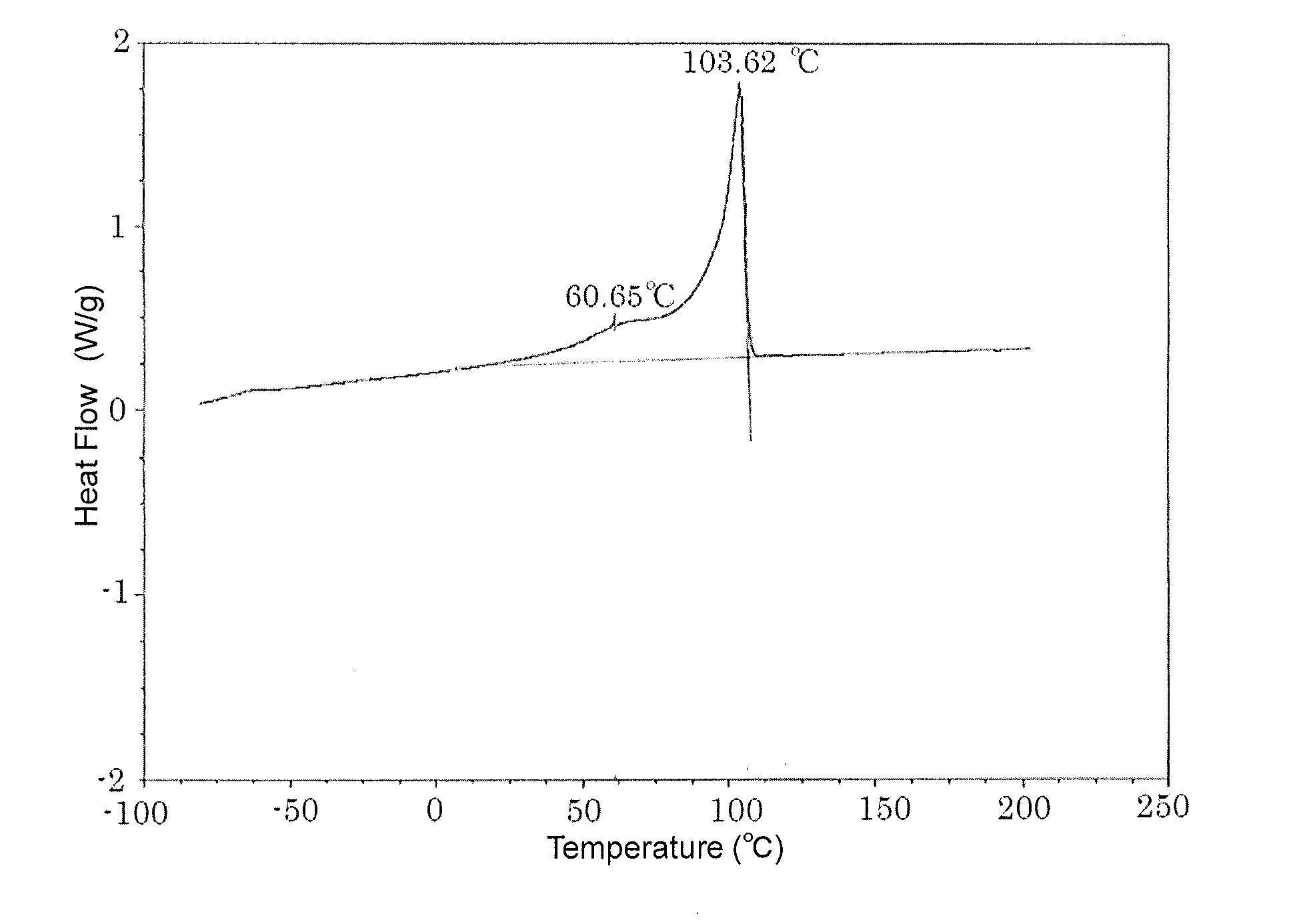

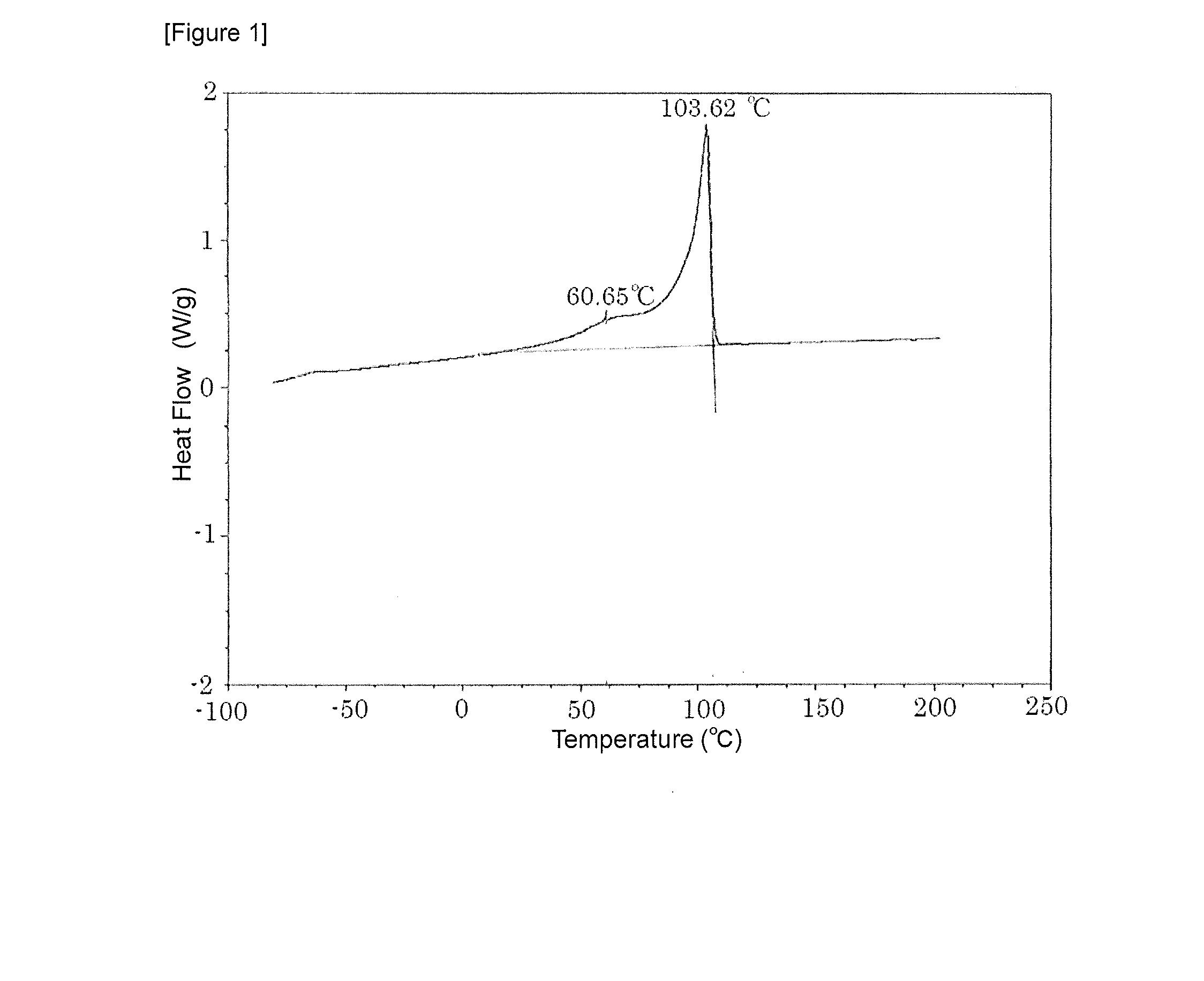

Microporous film, methods for making such film, and use for such film as battery separator film

ActiveUS20130288102A1Low shutdown temperatureImprove breathabilitySemi-permeable membranesCell seperators/membranes/diaphragms/spacersEthylene HomopolymersPolypropylene

A microporous membrane includes a low melting polypropylene, the low melting polypropylene being a polypropylene homopolymer or copolymer having an MFR≧2.0×102, a Tm of 85.0° C. to 130.0° C., and a Te-Tm≦10° C.

Owner:TORAY IND INC

Polylactic acid forming paper and preparation method

ActiveCN102877355BGood compatibilityNon-irritatingPaper/cardboardRetention agents additionPolyesterFiber

Owner:HONGTA TOBACCO GRP +1

Anti-drilling velvet gray fabric and preparation method thereof

ActiveCN112048801BEvenly distributedHigh utilityHeating/cooling textile fabricsDyeing processDisperse dyePolymer science

The invention discloses an anti-drilling velvet gray fabric, which comprises interwoven warp yarns and weft yarns, the warp yarns include cationic dyeable modified polyester staple fibers and cotton fibers dyed with reactive dyes, and the weft yarns include cationic dyeable modified polyester fibers. permanent polyester filaments and polyester filaments dyed with disperse dyes; the warp and weft are treated with cationic windproof softener for anti-drilling finishing. The present invention introduces anion dye bases into the cationic modified fiber molecular structure chain, and through the adsorption of anions and cations, the cationic windproof softener is evenly distributed on the surface of the fabric, and the air permeability of the finished product is uniform, the anti-drilling performance is stable, and the hand feels soft; the fabric is matched with cations Modified fiber can not only produce gray effect, but also ensure the appropriate reduction of warp and weft yarn density of the fabric under the same anti-drilling performance, and the utilization of cationic windproof softener is high, thereby reducing the cost of fabric, and can be widely used in actual production .

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

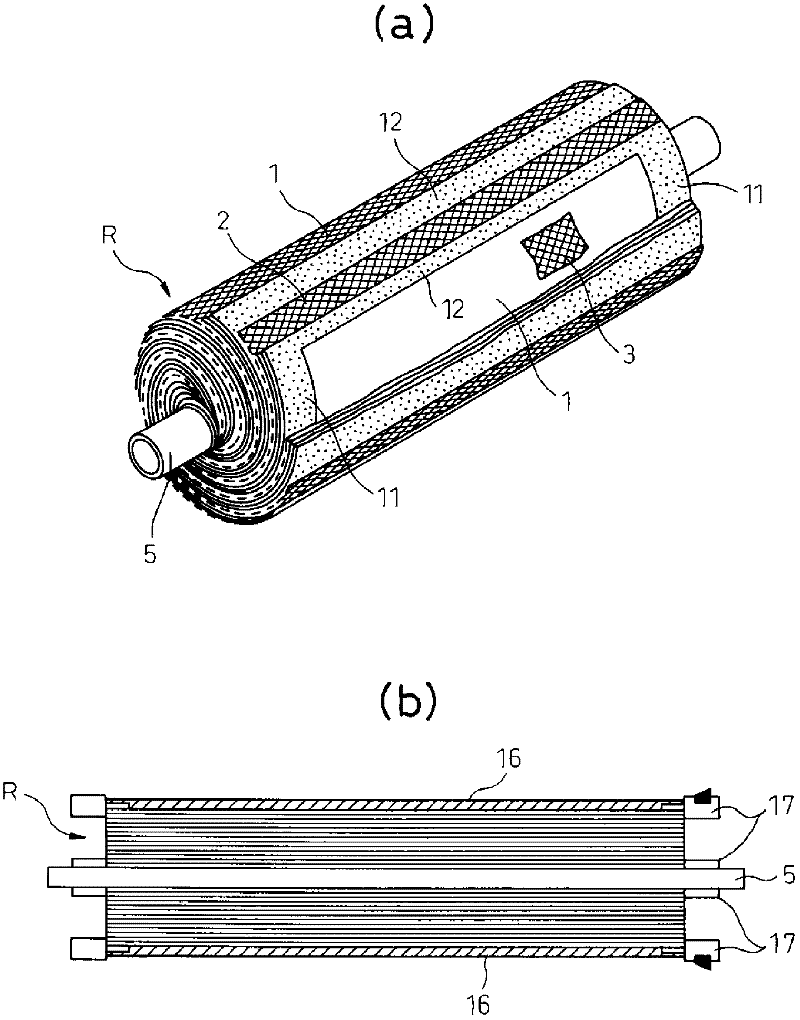

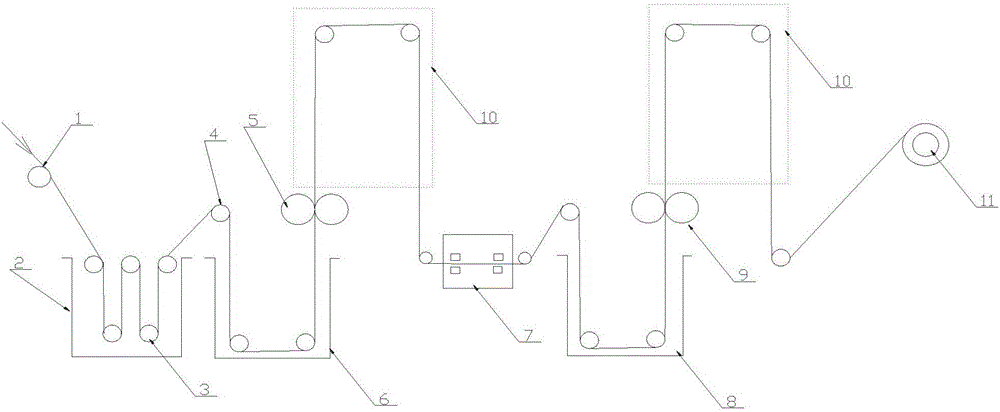

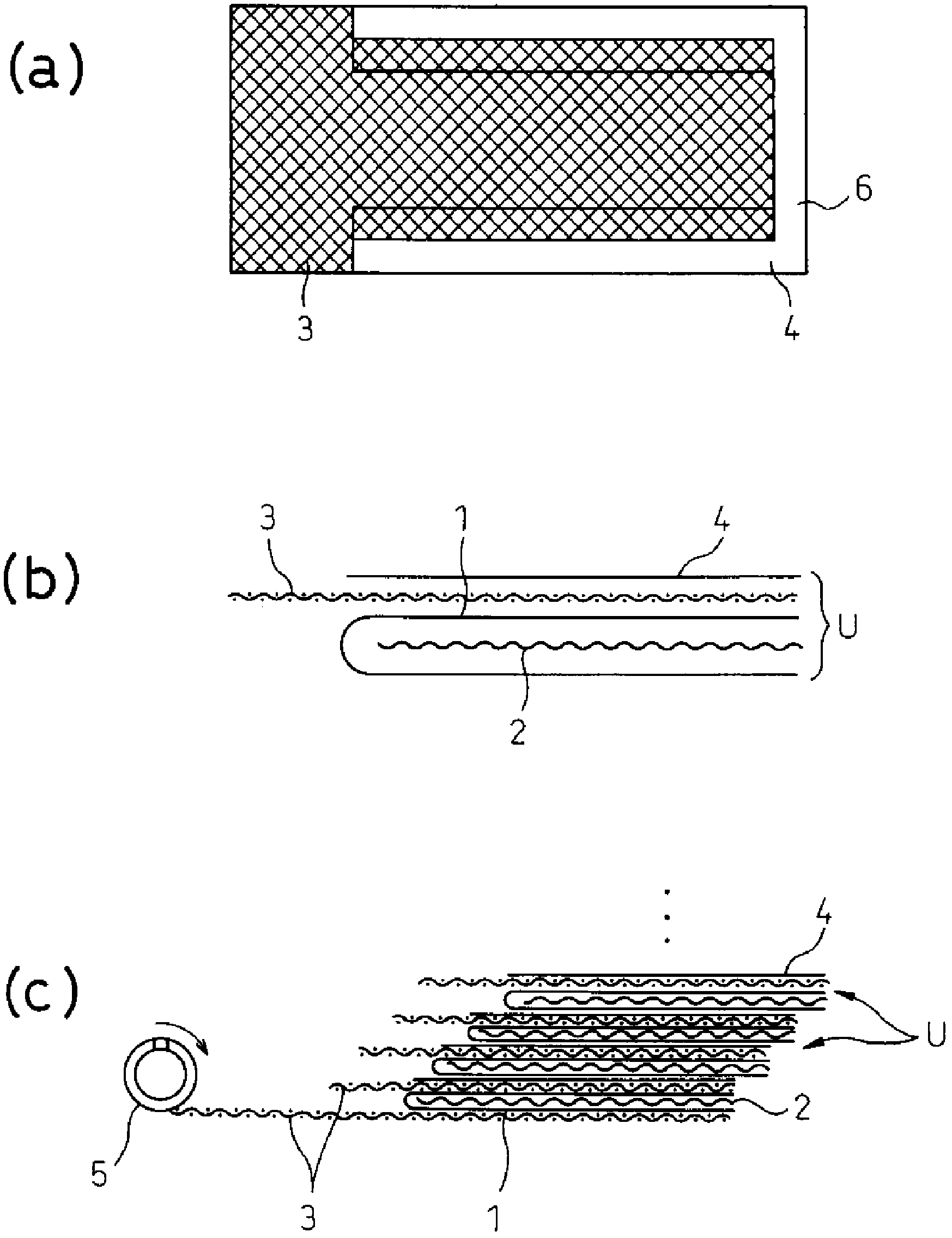

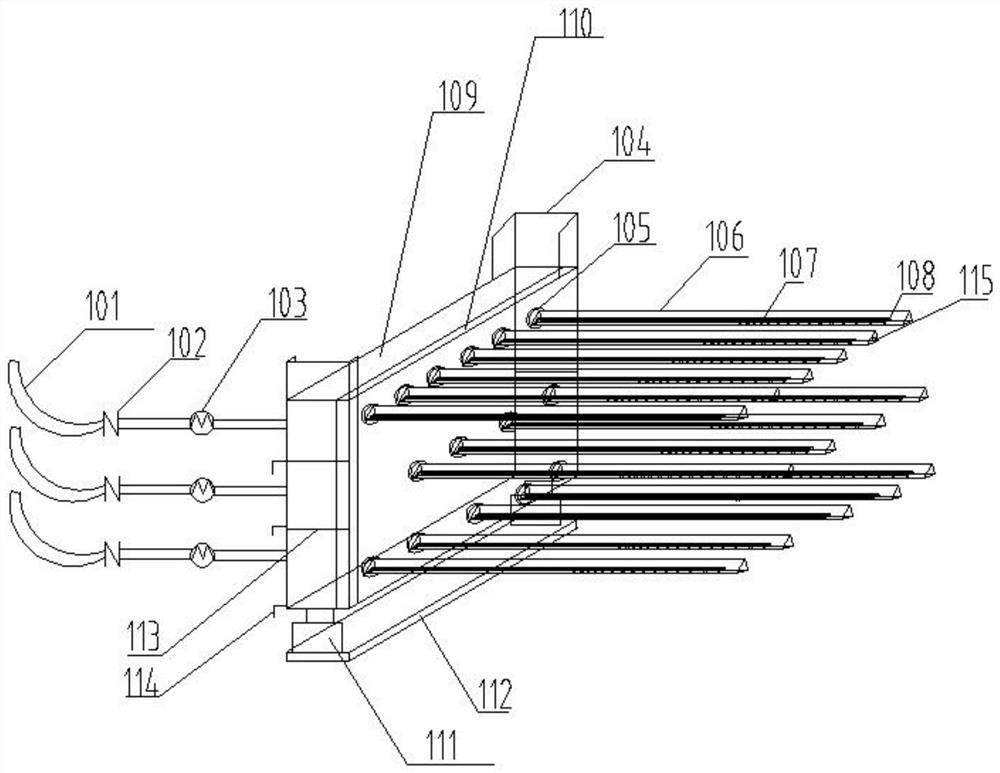

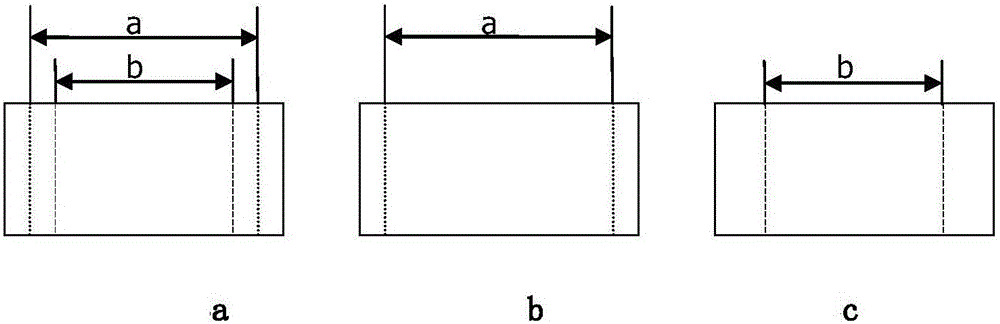

Cigarette paper conveying equipment for simultaneously conveying double-layer cigarette paper and double-layer cigarette paper cigarettes prepared therefrom

ActiveCN104891253BUniform air permeabilityConsistent chemical compositionArticle deliveryBobbinMachine control

The invention relates to cigarette paper conveying equipment capable of conveying double-layered cigarette paper. The equipment comprises two paper retreating machines, namely a left paper retreating machine (1) bearing internal layer cigarette paper bobbin, and a right paper retreating machine (2) bearing external layer cigarette paper bobbin; the left and right paper retreating machines are respectively controlled by a left paper retreating machine control device (1) and a right paper retreating paper control device (8); the equipment further comprises a double-layered cigarette paper neck (3) arranged on the downstreams of the left paper retreating machine (1) and the right paper retreating machine (2); the double-layered cigarette neck is formed by an internal layer cigarette paper neck (11) and an external layer cigarette paper neck (12) and a horizontal position adjusting rotary button (13); and the cigarette paper conveying equipment also comprises a rotating shaft, namely a plurality of conveying path devices arranged along internal layer cigarette paper (9) and external cigarette paper (10). Simple combination between internal and external cigarette paper is smartly utilized in the cigarette paper conveying equipment, so cigarette with double-layered cigarette paper and without bonding parts between the double layers is provided; and cigarette smoking quality can be enhanced.

Owner:CHINA TOBACCO YUNNAN IND

Antibacterial and mildew-proof wallpaper and preparation method thereof

ActiveCN112176776AAvoid bubblingUniform micro-nano surface roughnessCoatings with pigmentsSilicaMicro nanoSilica particle

The invention relates to an antibacterial and mildew-proof wallpaper with excellent performance, and sequentially comprises an adhesive layer, a paper base layer and an antibacterial waterproof layer,the adhesive layer is located on the lower side of the paper base layer and used for stably bonding the wallpaper and a wall to be decorated together, and the antibacterial waterproof layer is located on the upper side of the paper base layer and has antibacterial, waterproof and mildew-proof effects. A proper amount of hollow silicon dioxide particles are added into the paper base layer, and thehollow silicon dioxide particle structure can form an air hole channel penetrating through the two faces of the paper base layer in the paper base layer. The antibacterial waterproof layer is also provided with micro-nano porous structures which are uniformly distributed, and the porous structures can provide channels for a small amount of gas to penetrate through the wallpaper. Through combination, the air permeability of the wallpaper can be effectively guaranteed, and the bubbling problem of the wallpaper is avoided. In addition, the surface of the antibacterial waterproof layer has uniform micro-nano surface roughness, and an excellent hydrophobic surface structure can be provided. The perfluoropolyether emulsion in the antibacterial waterproof layer can provide excellent hydrophobicand oleophobic performance.

Owner:山东奥斯丁装饰材料有限公司

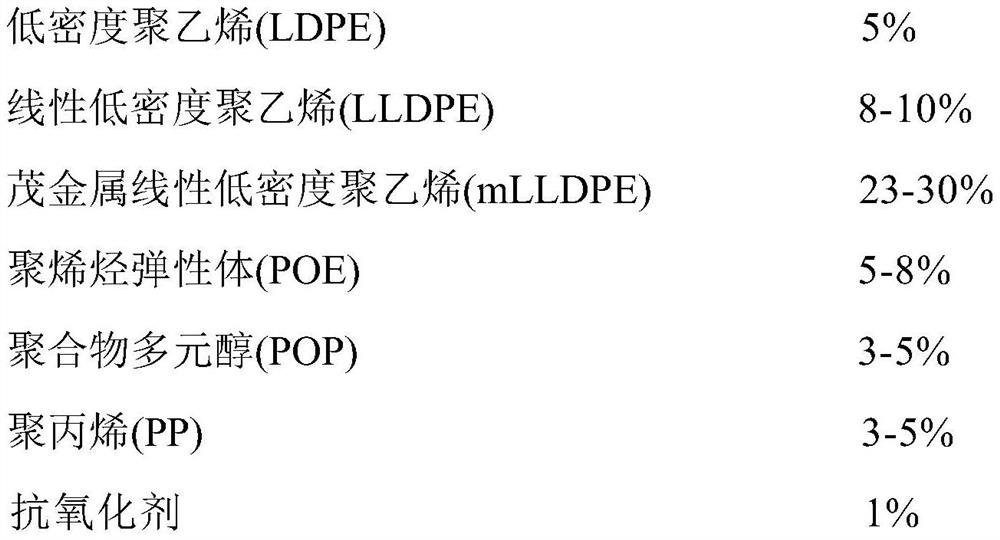

Manufacturing method of resin for polyolefin breathable membrane

ActiveCN110903541BEasy to pullUniform air permeabilityLinear low-density polyethyleneLow-density polyethylene

The present invention relates to a method for producing a resin for a polyolefin gas permeable membrane. Specifically, the present invention discloses a method for manufacturing a resin for a polyolefin breathable film, wherein the resin contains 5% of low density polyethylene, 8-10% of linear low-density polyethylene, and 23-30% of metallocene linear Low-density polyethylene, 30-40% calcium carbonate and other components; first knead calcium carbonate and antioxidants, mix with other components, and then carry out banburying, rolling, pulverization, extrusion, and granulation in turn, so as to obtain the obtained product. The described resin particles for the polyolefin breathable film. The resin prepared by this method has excellent flow properties and can be used for manufacturing disposable heating sheets.

Owner:福建宏科新材料科技有限公司

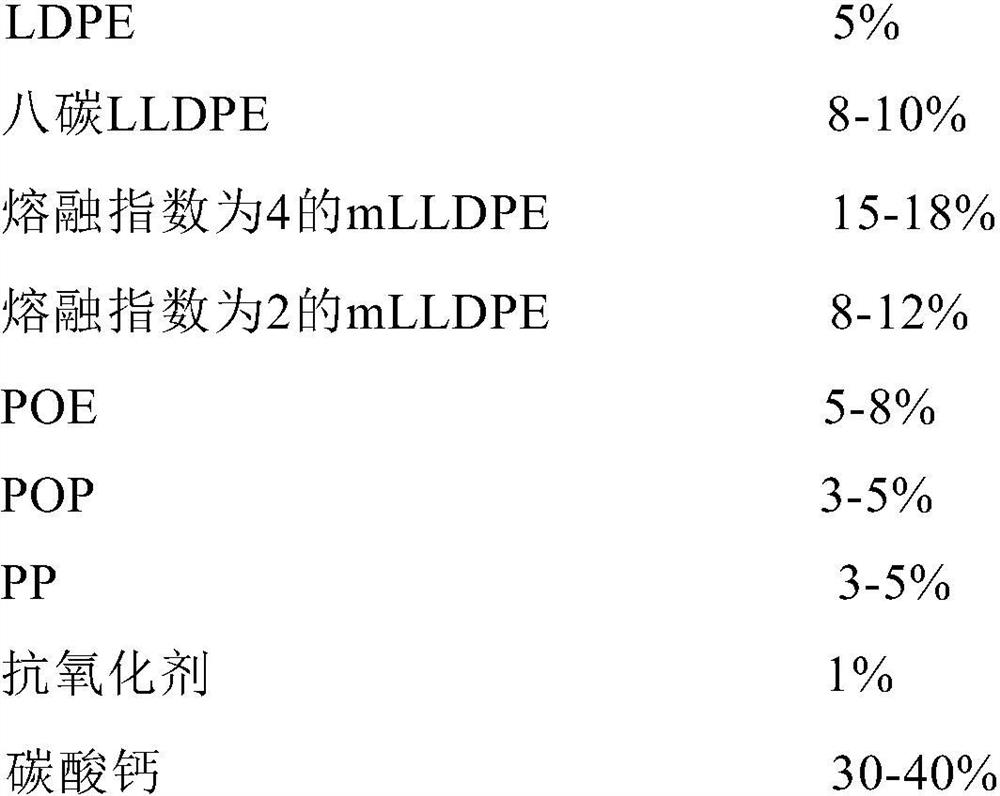

Tape casting machine, and method for producing ventilating waterproofing membrane using same

Owner:合诚技术股份有限公司

Papermachine clothing

InactiveUS7727361B2Reduce penetrationReduce riskWire networkPaper/cardboardFilling materialsPartial filling

A fabric, in particular for a paper making machine, includes a plurality of helically wound coil members arranged side by side with respect to each other in an intermeshing manner, such that connecting channels are formed by adjacent intermeshing coil members, a hinge member being introduced into and extending along each connecting channel for interconnecting adjacent coil members, a stuffer channel being formed within each coil member extending along and between two connecting channels associated to a respective coil member, at least a part of the stuffer channels being filled with stuffer members extending longitudinally within the stuffer channels, a stuffer material being provided at least in regions of the fabric for filling spaces formed within the fabric between the coil members, the hinge members and the stuffer members.

Owner:VOITH PATENT GMBH

Waterproof ventilated microporous membrane, its preparing method and use

The present invention discloses one kind of waterproof and air permeable microporous membrane comprising synthetic resin, inorganic matter powder, plasticizer and lubricant, with the inorganic matter powder being nanometer level inorganic matter powder and / or inorganic matter powder with nanometer level micropores. The waterproof and air permeable microporous membrane has the advantages of even thickness, homogeneous micropore size and distribution and single-way air permeability.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Swinging funnel used for paving bottom flavoring of sintering machine

ActiveCN100449237CUniform air permeabilitySimple structureLighting and heating apparatusAgricultural engineering

The invention discloses a swinging hopper which can segmented adjust the height of sluiceway, reduce edge effect, improve sinter quality and sinter efficiency, with simple structure, small volume, and low cost, for laying bottom material in sinter machine. The invention comprises a body, a rotary sluiceway, and a sluiceway adjuster, wherein the rotary sluiceway is mounted at the middle of the body, the sluiceway adjuster is mounted at the front of the body, and the height of the sluiceway is reduced from middle to two sides.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Preparation method of PBO composite ultra-high temperature filter material

ActiveCN101810971BImprove breathabilityHigh filtration precisionLayered productsFiltration separationFlue gasFilter material

The invention discloses a preparation method of a PBO composite ultra-high temperature filter material, which comprises the following steps that: a plain blanket is formed through an acupuncture and spunlaced composite process, and then soaked in chemical solvent to prepare the ultra-high temperature filter material, the dust facing surface in the prepared filter material comprises PBO and basaltfibers which are blended, wherein the weight proportion of the PBO fibers is 10 to 15 percent; base cloth comprises PBO long filaments and basalt filaments which are interwoven; and a bottom layer adopts 100 percent basalt fibers. The preparation method of the PBO composite ultra-high temperature filter material effectively reduces the damage of the fibers, improves the strong force of the filtermaterial, meets the need of ultra high temperature flue gas treatment, and is applicable to a bag-type dust collector for ultra high temperature flue gas treatment at above 500DEG C.

Owner:南京际华三五二一环保科技有限公司

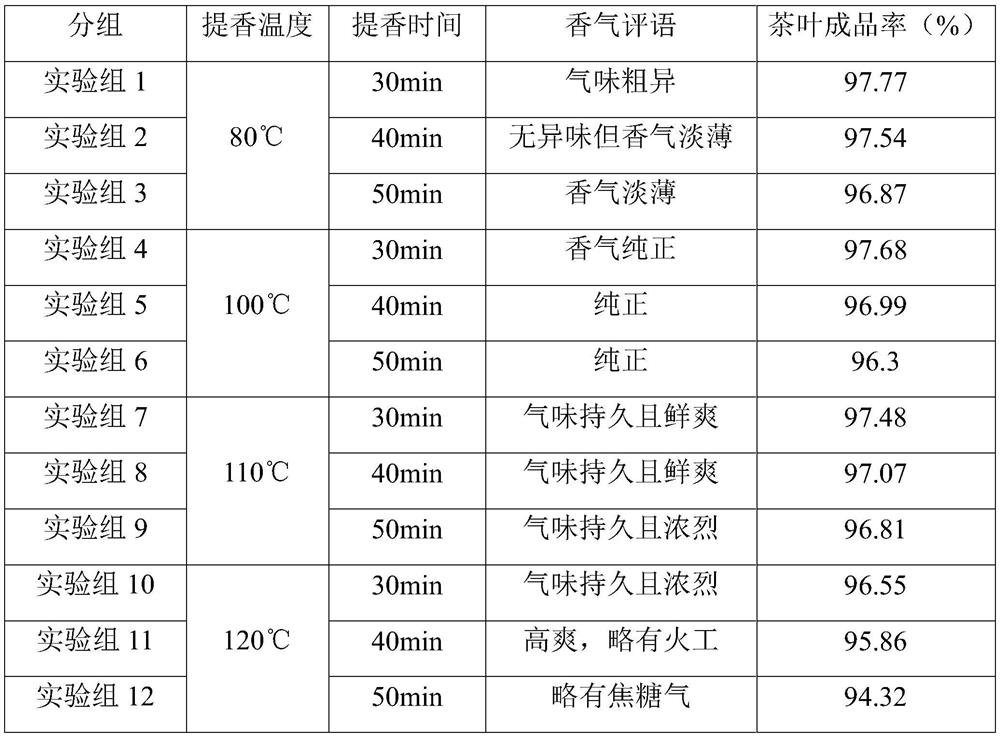

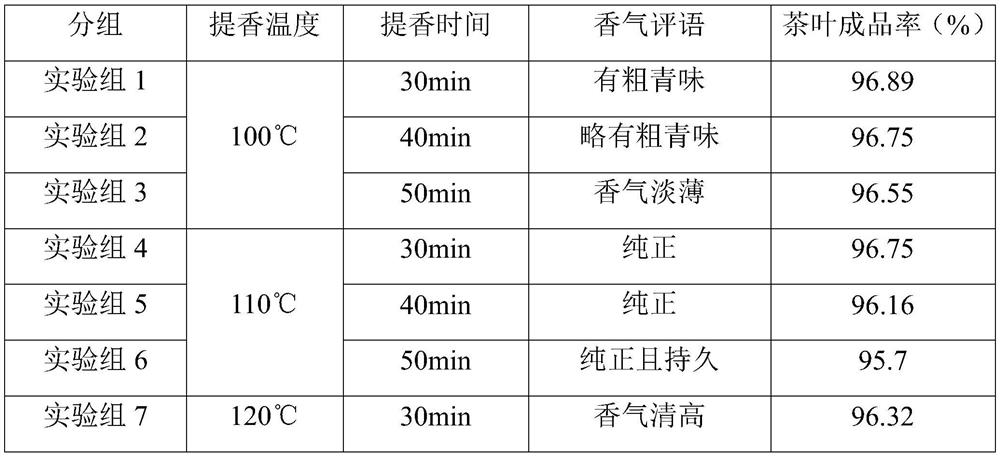

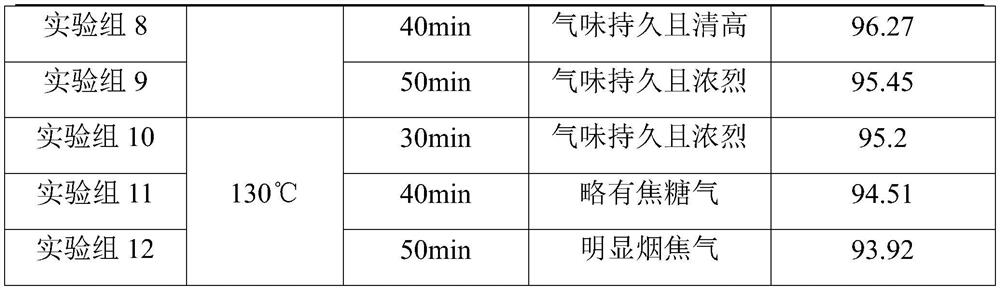

Fermentation process of Pu'er raw materials

InactiveCN112741175AAvoid killing greens that are opaque and have a green smellAvoid burnsPre-extraction tea treatmentBiotechnologyFragrance extraction

The invention provides a fermentation process of Pu'er raw materials, and solves the problems that in the prior art, the final fermentation degrees are different and the tea flavor is influenced due to uneven temperature and different air permeability during fermentation of the Pu'er raw materials. The process comprises the following steps: separating picked Pu'er raw materials in the current year according to bud tips and bud leaves, and respectively cleaning; respectively spreading the cleaned bud tips and bud leaves for water loss; respectively carrying out fixation on the bud tips and the bud leaves; performing fragrance extraction treatment on the bud tips and the bud leaves after fixation; respectively putting the bud tips and the bud leaves subjected to fragrance extraction into a rolling machine for cold rolling, and firstly slightly pressing and then gradually increasing heavy pressing; placing a plurality of silk gauzes in a sealable fermentation room after disinfection and sterilization, then respectively placing the bud tips and the bud leaves on the silk gauzes for pile fermentation, then laying a layer of silk gauzes on the pile fermentation, and sprinkling water for fermentation; and performing low-temperature vacuum drying on the fermented tea leaves to finally obtain a finished product. The fermentation method is uniform in pile fermentation air permeability, can maintain the temperature of tea quality to the maximum extent, improves the taste, and is worthy of popularization.

Owner:尹崇亮

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com