Adjustable high-efficiency sintering machine loosening device and use method

A technology of loosening and machine loosening is applied in the field of high-efficiency sintering machine loosening device, which can solve the problems of inability to adapt to the segregation of sintered materials, different water holding rates, inability to accurately preheat the mixture by heat source, and layered control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

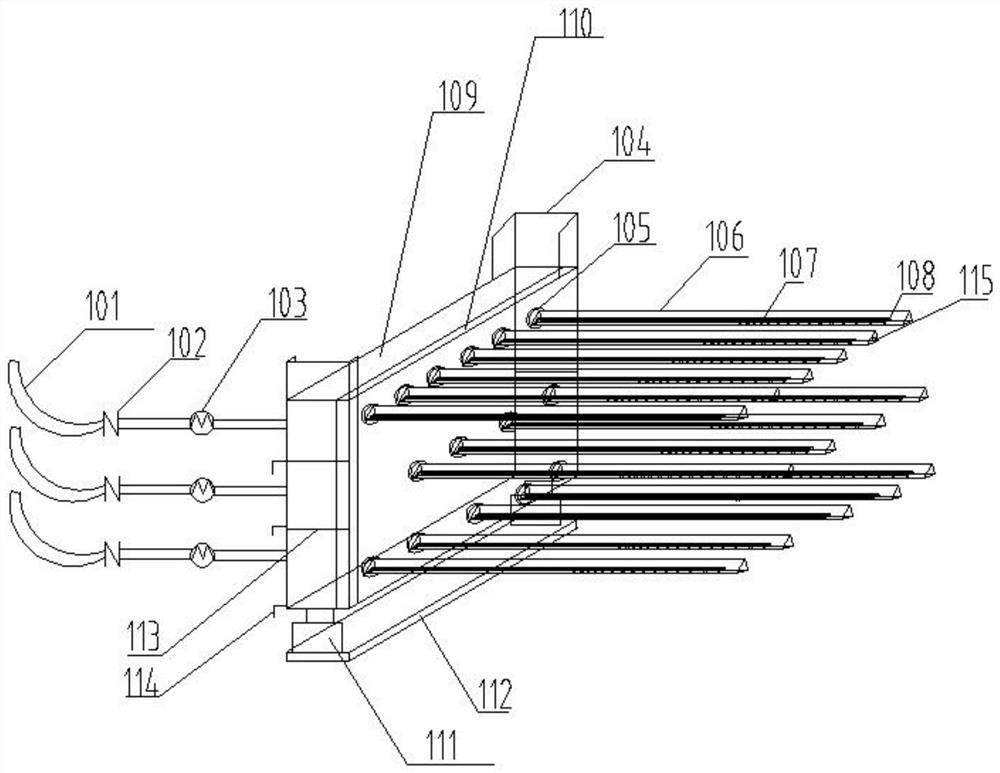

[0036] Taking the sintering of 900mm thick material layer as an example, the height automatic adjustment function of this loosening device is described in detail: the distance between the three layers of loosening rods is set to 200mm between the upper and middle layers, and the distance between the middle and lower layers of loosening rods It is 250mm, and the thickness of the sintered cloth is automatically detected by the layer thickness meter. During normal production, the thickness of the material layer is 900mm, and the distance between the upper loose material rod and the top surface of the material layer is 200mm. At this time, the stroke of the hydraulic cylinder is recorded as L0. When the material layer is reduced from 900mm to 700mm, the cylinder stroke is (h-450) / 2. That is, the displacement of 125mm is retracted, and L1=-125mm at this time, so as to realize the overall movement of the movable box 109 and the loose material rods 106 of each layer. And the distanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com