Preparation method of PBO composite ultra-high temperature filter material

A filter material and ultra-high temperature technology, which is applied in the field of preparation of PBO composite ultra-high temperature filter material, can solve the problems of decreased filter material strength, uneven air permeability, poor corrosion resistance, etc., and achieves improved smoothness, high filtration accuracy, Improve the effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

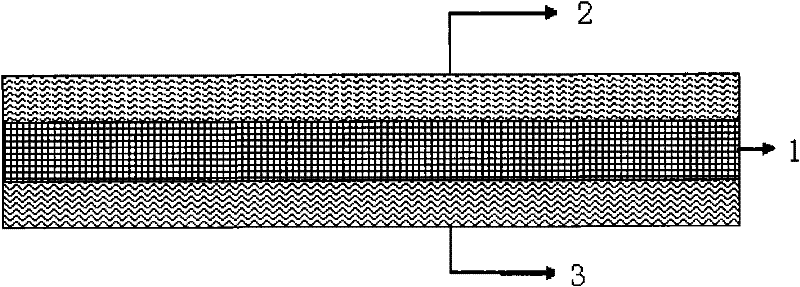

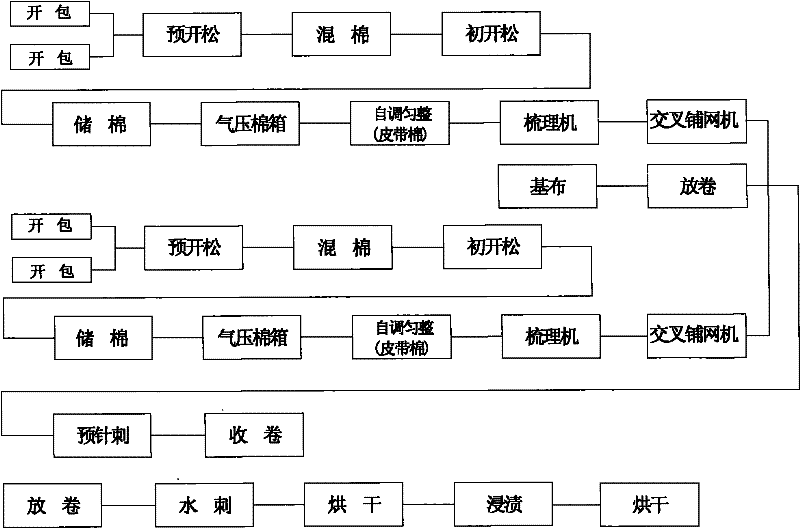

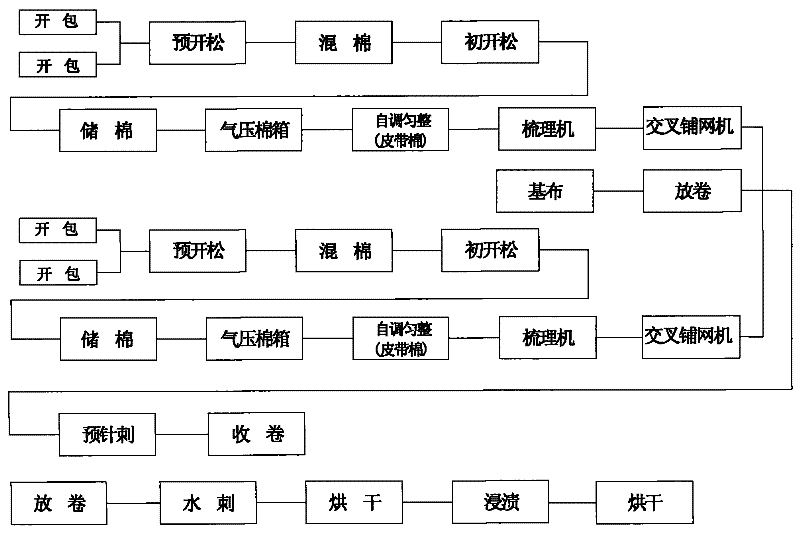

[0017] A kind of preparation method of PBO composite ultra-high temperature filter material of the present invention, see figure 2 , the preparation method forms a plain felt through needle punching and spunlace composite technology, and then impregnates it with a chemical solvent to make an ultra-high temperature filter material. The dust-facing surface of the obtained filter material is blended with PBO fiber and basalt fiber, and the weight of PBO fiber is The ratio is 10-15%; the base fabric is made of mixed PBO filament and basalt filament; the bottom layer is 100% basalt fiber; the specific steps are as follows:

[0018] 1) First, pre-open the PBO fiber and basalt fiber, and then perform the initial opening;

[0019] 2) then combing the opened composite fibers and cross-laying to form a dust-facing surface; the weight ratio of PBO fibers in the dust-facing surface is 10-15%;

[0020] 3) According to the above-mentioned same process, form the bottom layer, the bottom la...

Embodiment 1

[0024] The dust-facing surface is mixed with 2.2dtex PBO fiber and 7μ basalt fiber to obtain a composite fiber, in which the ratio of PBO fiber is 10%; 2 ;The bottom layer is 100% 7μ basalt fiber. according to the above figure 2 It is processed by advanced processing technology to make PBO composite ultra-high temperature filter material.

[0025] Wherein the chemical solvent is prepared from PTFE emulsion and water, the solid content of the PTFE emulsion is 60%, and the weight percentage of PTFE in the solvent is 10%.

[0026] The warp and weft tensile strength of the PBO composite ultra-high temperature filter material prepared by the present invention exceeds 6000N / 5*20cm, which is nearly 2 times higher than that of simple basalt fiber needle felt, and its filtration accuracy reaches 99.999%, and its running resistance is 800Pa about. It can effectively improve the service life, reduce the running resistance of the equipment, and save energy consumption.

Embodiment 2

[0028] The dust facing surface is mixed with 2.2dtex PBO fiber and 7μ basalt fiber to obtain composite fiber, in which the proportion of PBO fiber is 15%; 2 ;The bottom layer is 100% 7μ basalt fiber. according to the above figure 2 It is processed by advanced processing technology to make PBO composite ultra-high temperature filter material.

[0029] Wherein the chemical solvent is prepared from PTFE emulsion and water, the solid content of the PTFE emulsion is 60%, and the weight percentage of PTFE in the solvent is 15%.

[0030] The warp and weft tensile strength of the PBO composite ultra-high temperature filter material prepared by the present invention exceeds 7000N / 5*20cm, which is more than 2 times higher than that of simple basalt fiber needle felt, and its filtration accuracy reaches 99.999%, and its running resistance is 800Pa about. It can effectively improve the service life, reduce the running resistance of the equipment, and save energy consumption.

[0031]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com