Tape casting machine, and method for producing ventilating waterproofing membrane using same

A casting machine and screw technology, which is applied in the field of plastic processing, can solve the problems of large air permeability deviation and uneven film thickness, and achieve the effects of improving thickness uniformity, improving performance, and uniform air permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

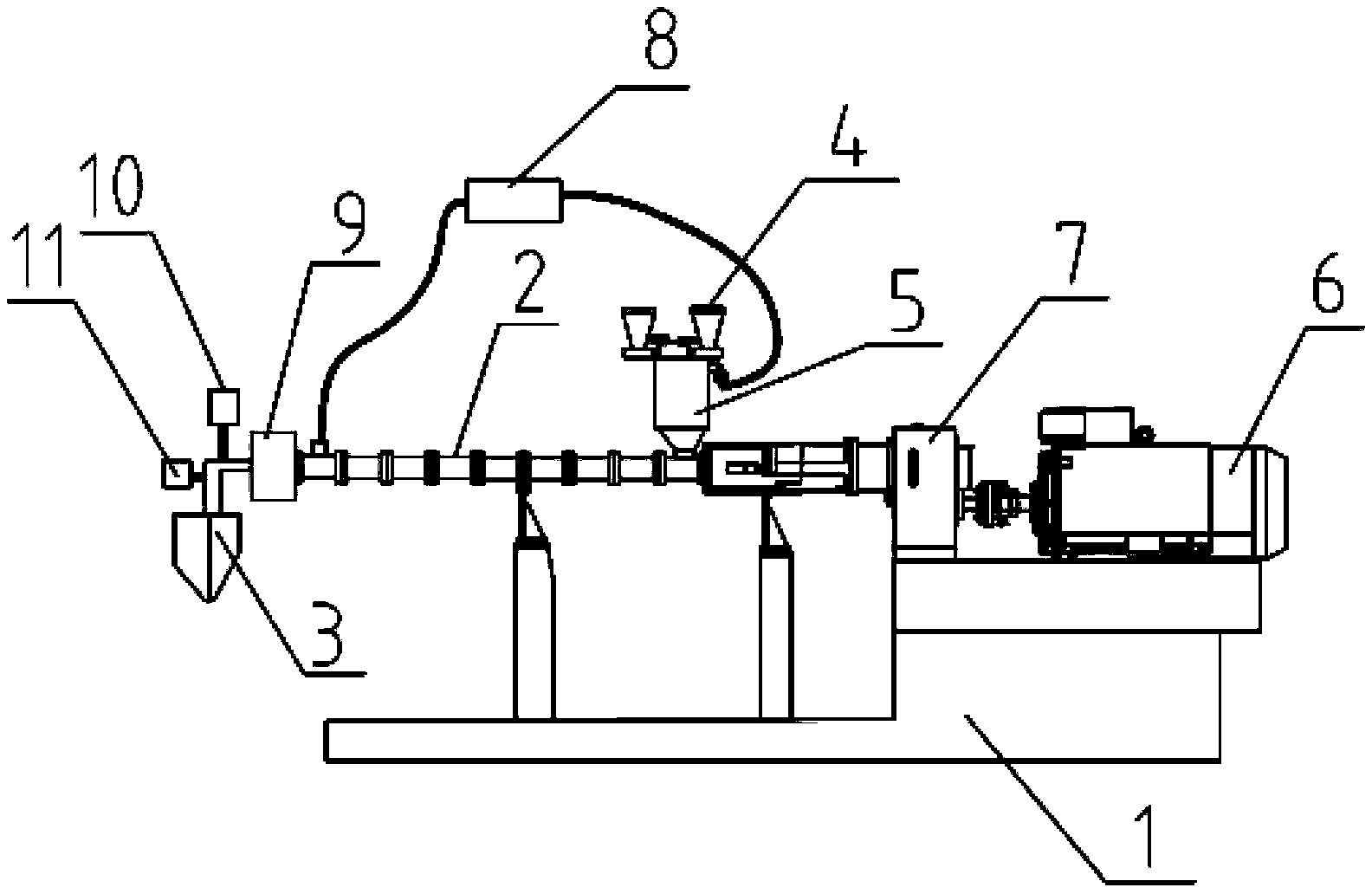

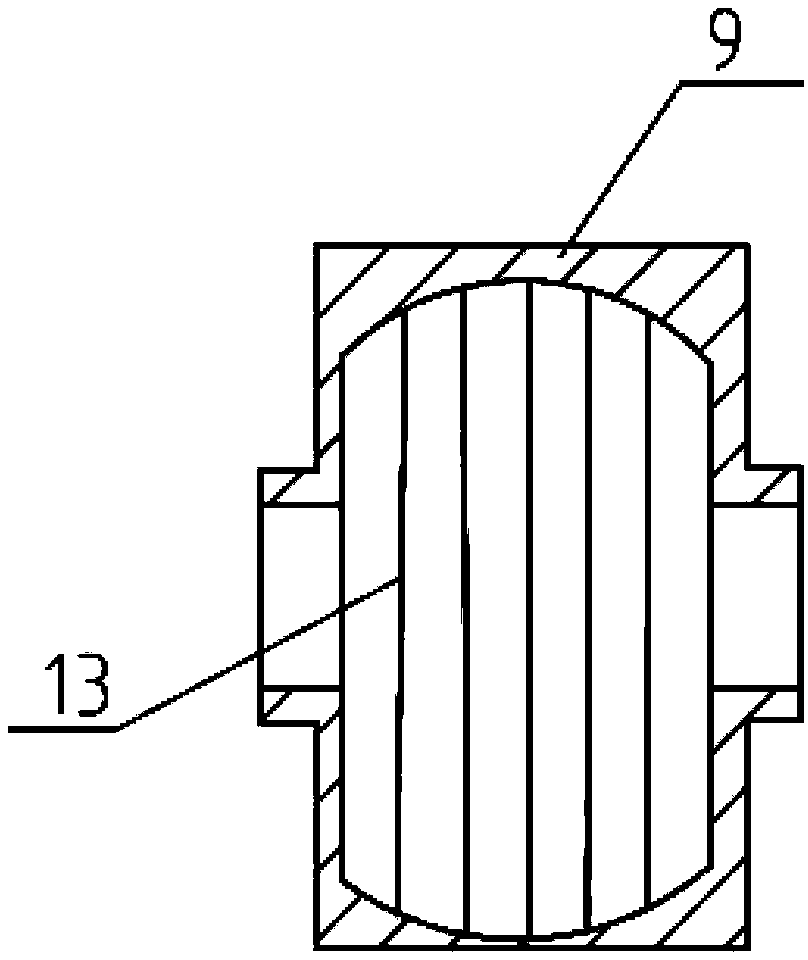

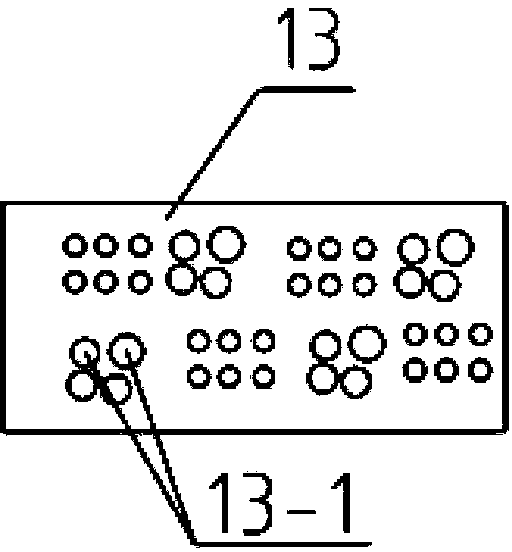

[0032] see figure 1 , the tape casting machine of the present invention is arranged on the machine base, mainly consists of a feeding device, a screw and barrel extrusion device 2, a driving device, a heating device, a die head 3, a melt pressure control device, a melt density control device and a film lip The gap control device consists of a driving device and a feeding device at one end of the screw-and-screw extrusion device 2, a die head 3 at the other end of the screw-and-screw extrusion device 2, and a heating device at the screw-and-screw extrusion device 2 on. The feeding device includes a metering feeding device and a storage hopper 5, the metering feeding device is composed of 2 weighing scales 4, the storage hopper 5 is sealed and connected to the bottom of the weighing scale 4, and the storage hopper 5 is connected with a vacuum device 8, The vacuuming device 8 is a single-stage water ring vacuum pump, and the vacuuming device 8 is also connected to the end of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com