Preparation method of PBO composite ultra-high temperature filter material

A filter material and ultra-high temperature technology, which is applied in the field of preparation of PBO composite ultra-high temperature filter material, can solve the problems of decreased filter material strength, poor corrosion resistance, uneven air permeability, etc. The effect of uniform air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

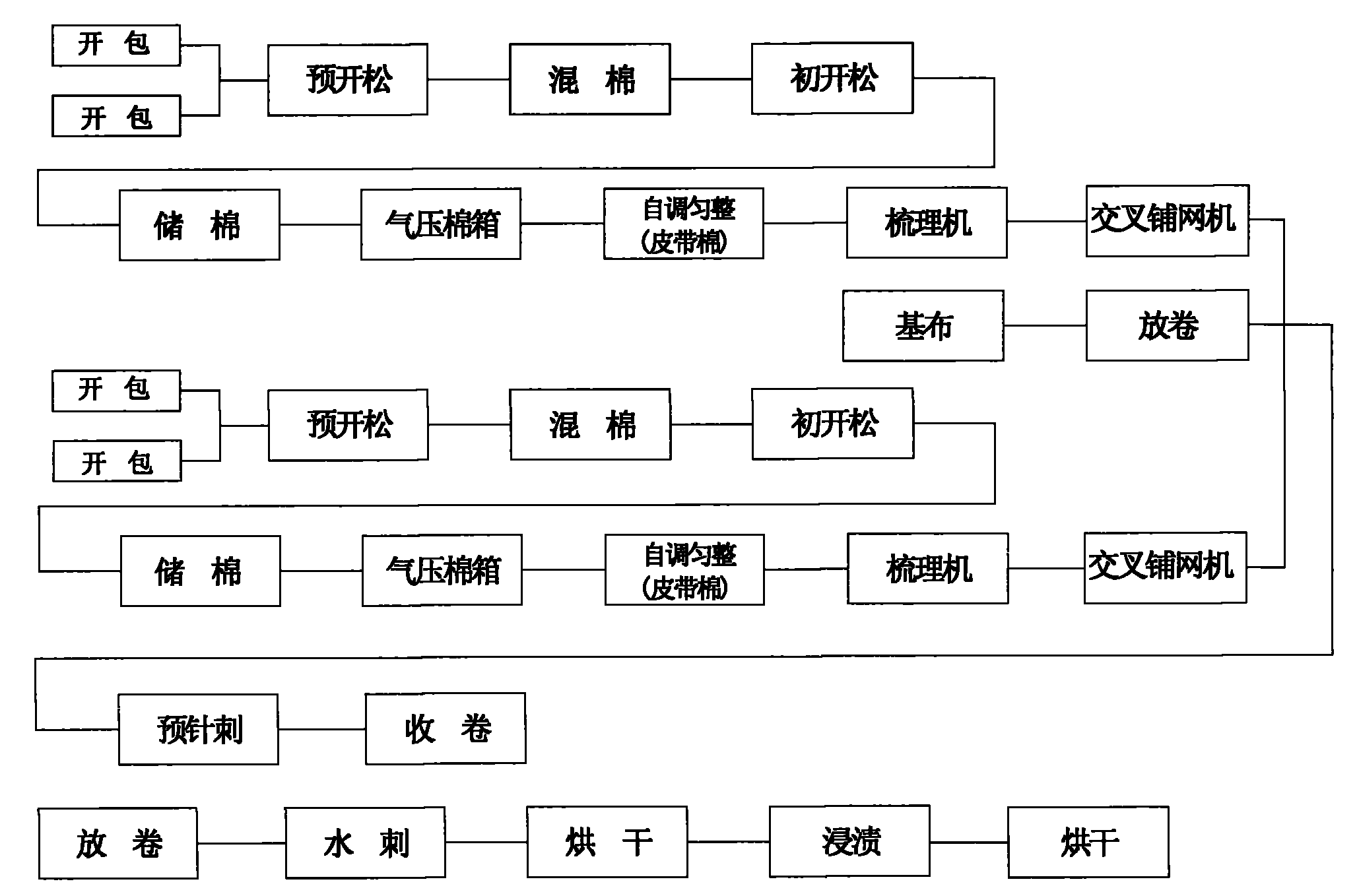

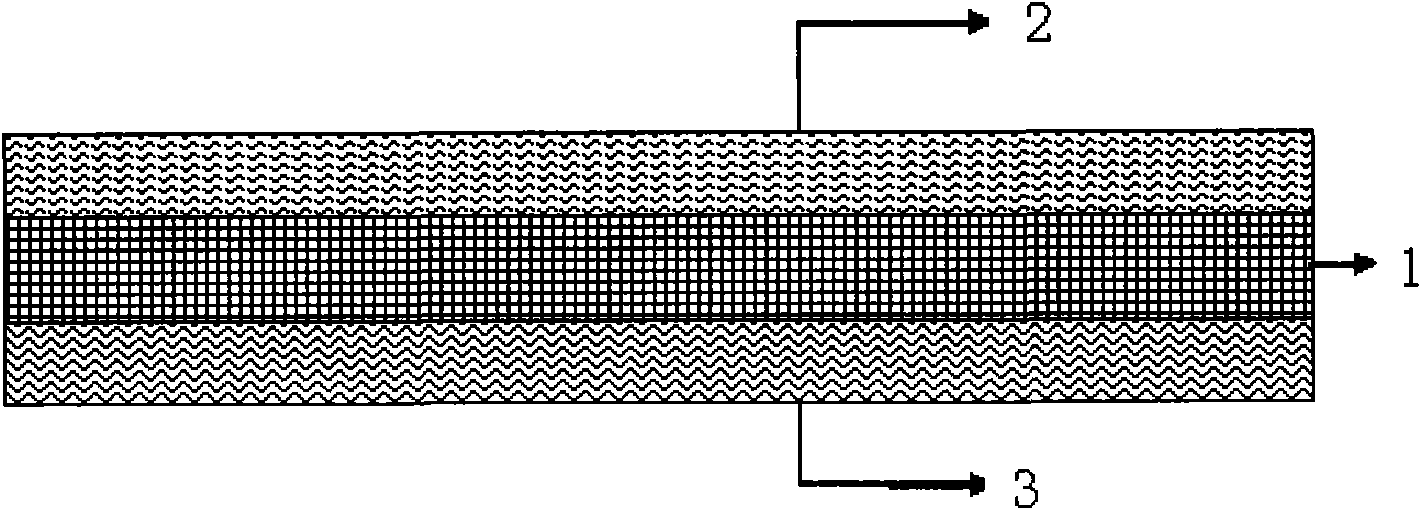

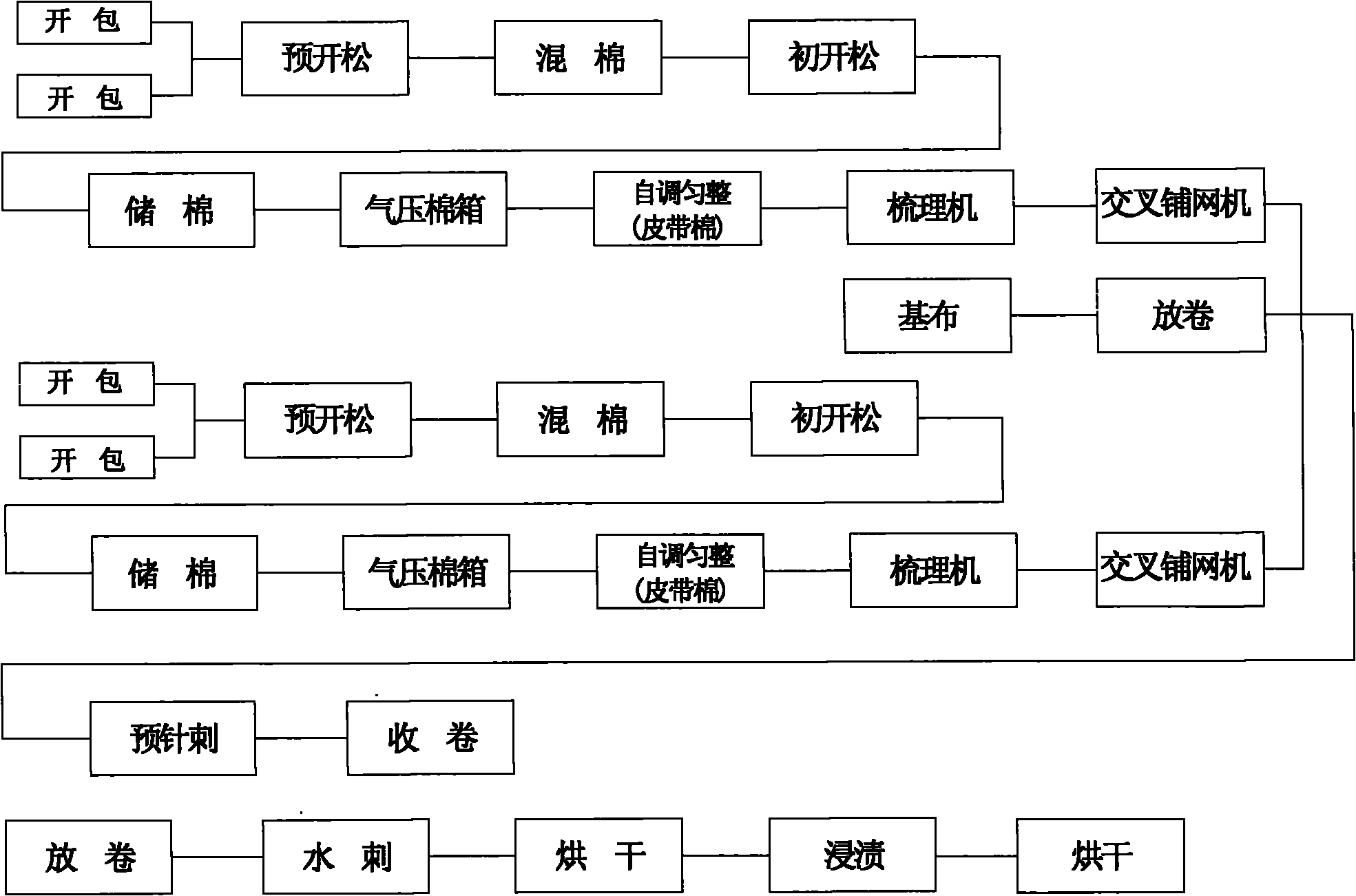

[0017] A preparation method of the PBO composite ultra-high temperature filter material according to the present invention, as shown in Figure 2, the preparation method forms a plain felt through acupuncture and spunlace composite processes, and then undergoes a chemical solvent impregnation treatment to make an ultra-high temperature filter material, The dust-facing surface of the filter material obtained is blended with PBO fiber and basalt fiber, wherein the weight ratio of PBO fiber is 10-15%; the base fabric is made of PBO filament and basalt filament; Proceed as follows:

[0018] 1) First, pre-open the PBO fiber and basalt fiber, and then perform the initial opening;

[0019] 2) then combing the opened composite fibers and cross-laying to form a dust-facing surface; the weight ratio of PBO fibers in the dust-facing surface is 10-15%;

[0020] 3) According to the above-mentioned same process, form the bottom layer, the bottom layer is 100% basalt fiber net;

[0021] 4) ...

Embodiment 1

[0024] The dust-facing surface is mixed with 2.2dtex PBO fiber and 7μ basalt fiber to obtain composite fiber, in which the proportion of PBO fiber is 10%; the base fabric is mixed weaving of 2.2dtex PBO filament and 7μ basalt filament, and the grammage is 120g / m 2 ;The bottom layer is 100% 7μ basalt fiber. It is processed according to the above-mentioned processing technology in Fig. 2 to make PBO composite ultra-high temperature filter material.

[0025] Wherein the chemical solvent is prepared from PTFE emulsion and water, the solid content of the PTFE emulsion is 60%, and the weight percentage of PTFE in the solvent is 10%.

[0026] The warp and weft tensile strength of the PBO composite ultra-high temperature filter material prepared by the present invention exceeds 6000N / 5*20cm, which is nearly 2 times higher than that of simple basalt fiber needle felt, and its filtration accuracy reaches 99.999%, and its running resistance is 800Pa about. It can effectively improve th...

Embodiment 2

[0028] The dust-facing surface is mixed with 2.2dtex PBO fiber and 7μ basalt fiber to obtain composite fiber, in which the proportion of PBO fiber is 15%; 2 ;The bottom layer is 100% 7μ basalt fiber. It is processed according to the above-mentioned processing technology in Fig. 2 to make PBO composite ultra-high temperature filter material.

[0029] Wherein the chemical solvent is prepared from PTFE emulsion and water, the solid content of the PTFE emulsion is 60%, and the weight percentage of PTFE in the solvent is 15%.

[0030] The warp and weft tensile strength of the PBO composite ultra-high temperature filter material prepared by the present invention exceeds 7000N / 5*20cm, which is more than 2 times higher than that of simple basalt fiber needle felt, and its filtration accuracy reaches 99.999%, and its running resistance is 800Pa about. It can effectively improve the service life, reduce the running resistance of the equipment, and save energy consumption.

[0031] Ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com