Anti-drilling velvet gray fabric and preparation method thereof

A technology for fabrics and velvet, which is applied in the field of anti-drilling velvet fabric and its preparation field, can solve the problems of low warp and weft density of yarn, no essential improvement in anti-drilling performance of fabrics, etc., and achieves soft hand feeling and stable anti-drilling performance. , the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

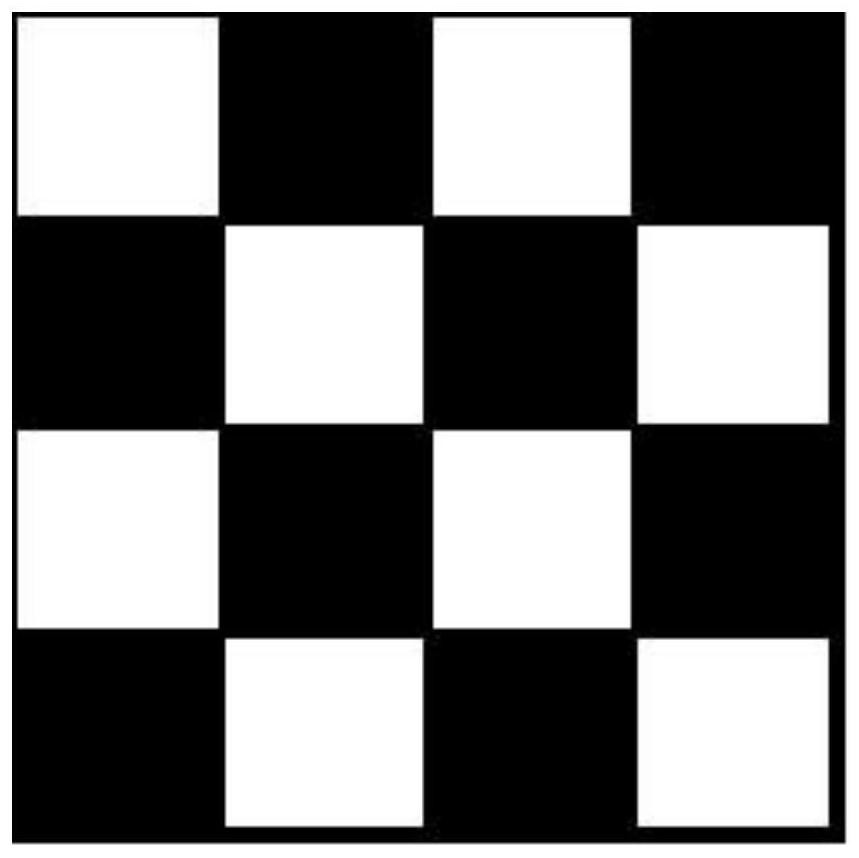

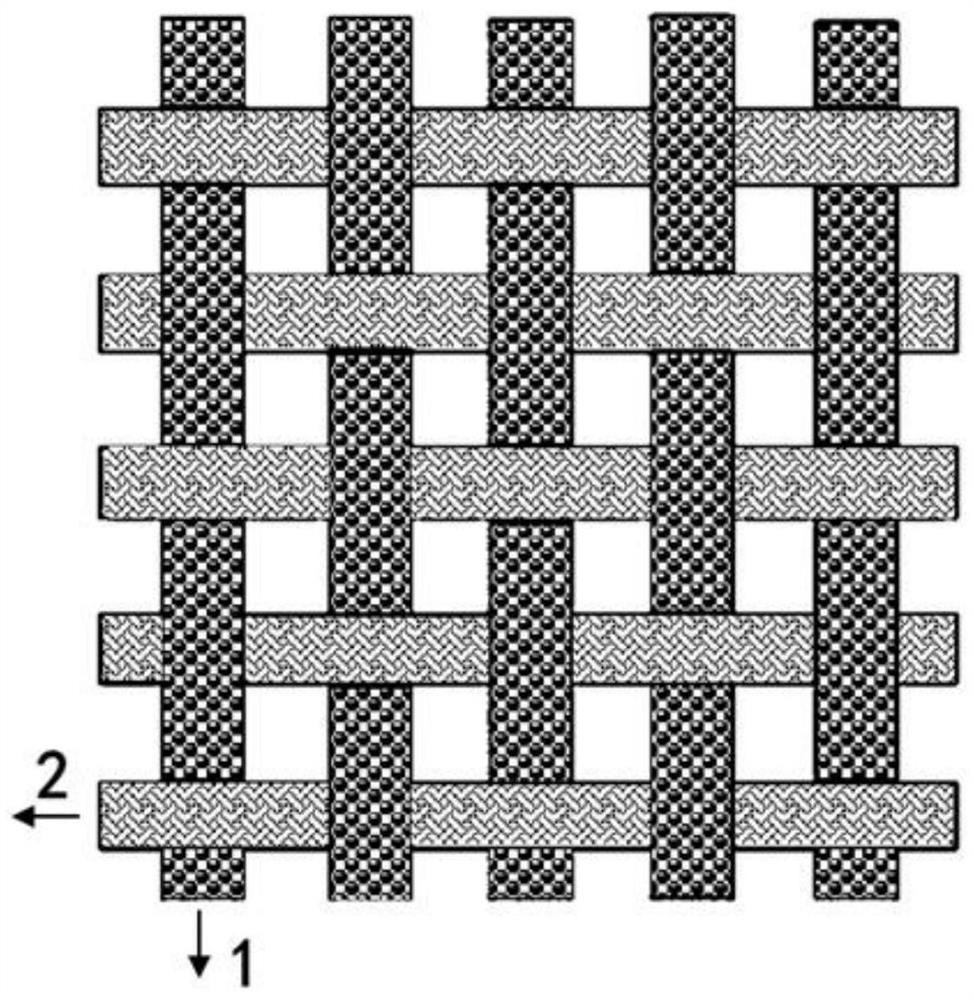

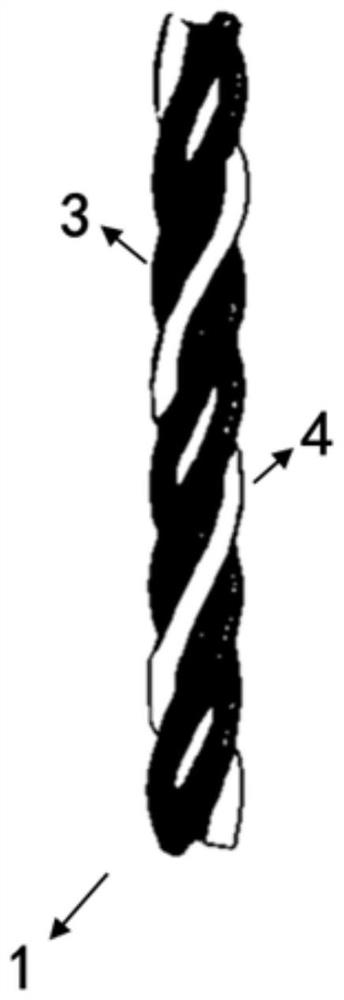

[0028] Step 1, the preparation of gray cloth. The warp yarn is a blended yarn of cationic dyeable modified polyester staple fiber and cotton fiber, the weft yarn is a composite yarn of cationic dyeable modified polyester filament and ordinary polyester filament, and the weave is plain weave, which is machine-woven on an air-jet loom , to obtain gray cloth, and its gray cloth production process includes: warping, sizing, drafting and reeding, and weaving on the machine. The design specifications of the upper machine for the gray fabric are as follows:

[0029] 105″ / (C / YD 60 / 40)40s×(T / YF 40 / 60)130D / 133×90, plain weave.

[0030] Among them, C stands for cotton, YD stands for cationic dyeable modified polyester staple fiber, T stands for ordinary polyester filament, YF stands for cationic dyeable modified polyester filament, 60 / 40 stands for cotton fiber and cationic dyeable dyeable modified The mass percentage of polyester staple fiber in the warp yarn, 40 / 60 represents the mas...

Embodiment 2

[0035] Step 1, the preparation of gray cloth. The warp yarn is a blended yarn of cationic dyeable modified polyester staple fiber and cotton fiber, and the weft yarn is a composite yarn of cationic dyeable modified polyester filament and ordinary polyester filament. Weaving to obtain gray cloth, the gray cloth production process includes: warping, sizing, drafting and reeding, and weaving on the machine. The design specifications of the upper machine for the gray fabric are as follows:

[0036] 105″ / (C / YD 50 / 50)100s×(T / YF 40 / 60)80D / 200×120, plain weave.

[0037] Step 2, the pretreatment of the gray cloth. The gray cloth is sequentially desized, refined and bleached to obtain the fabric processed by the pretreatment process.

[0038] Step 3, the dyeing of the fabric. The above-mentioned pretreated gray cloth is dyed by the method of firstly dyeing ordinary polyester with disperse dyes and then dyeing cotton with reactive dyes to form a fabric with gray effect in both warp a...

Embodiment 3

[0041] Step 1, the preparation of gray cloth. The warp yarn is a blended yarn of cationic dyeable modified polyester staple fiber and cotton fiber, and the weft yarn is a composite yarn of cationic dyeable modified polyester filament and ordinary polyester filament. Weaving to obtain gray cloth, the gray cloth production process includes: warping, sizing, drafting and reeding, and weaving on the machine. The design specifications of the upper machine for the gray fabric are as follows:

[0042] 105″ / (C / YD 50 / 50)100s×(T / YF 40 / 60)80D / 200×120, plain weave.

[0043] Step 2, the pretreatment of the gray cloth. The gray cloth is sequentially desized, refined and bleached to obtain the fabric processed by the pretreatment process.

[0044] Step 3, the dyeing of the fabric. The above-mentioned pretreated gray cloth is dyed by the method of firstly dyeing ordinary polyester with disperse dyes and then dyeing cotton with reactive dyes to form a fabric with gray effect in both warp a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com