Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "The firing process is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modified calcium oxide type expanding agent with controllable expansion course and preparation method thereof

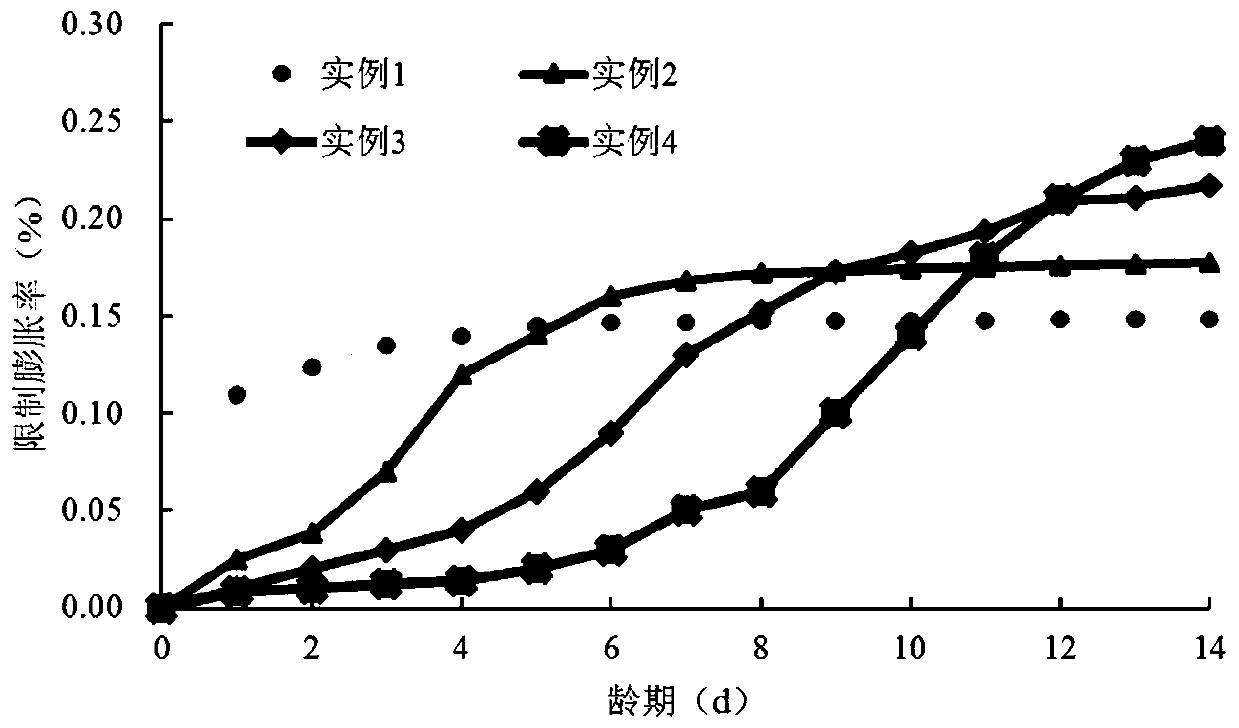

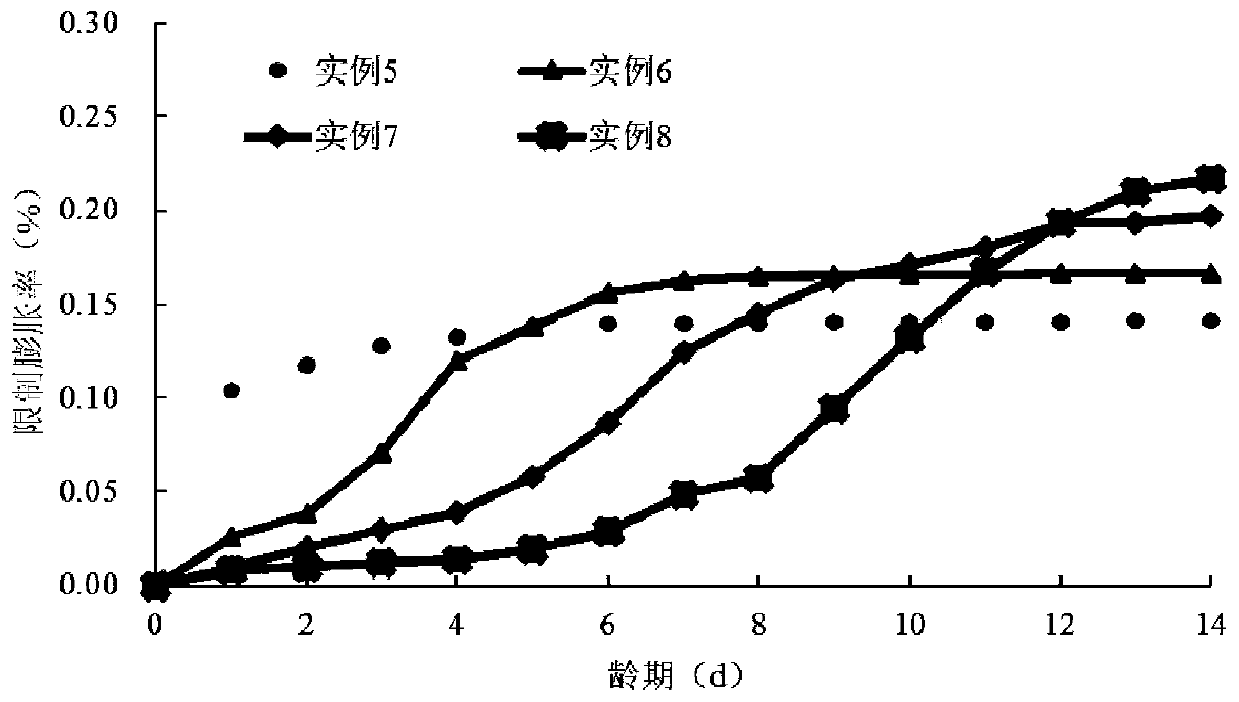

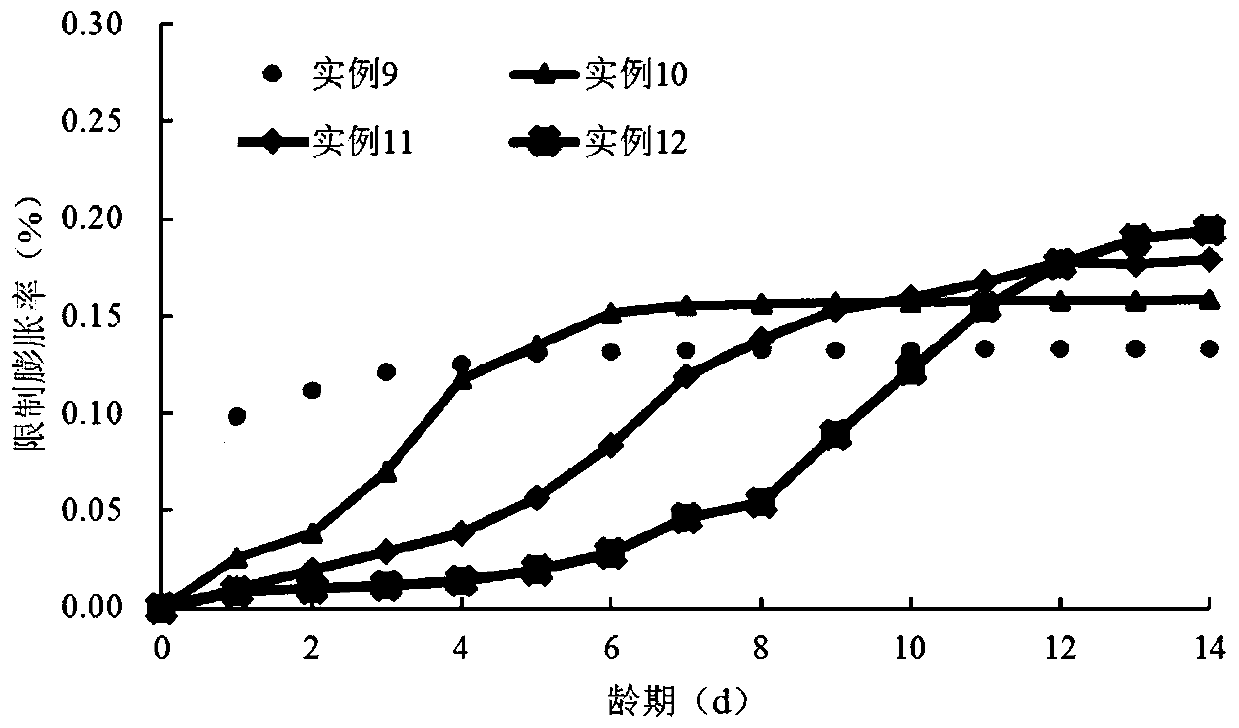

ActiveCN108328961ARegulating the expansion processEnhanced compensating shrinkage effectResin acidRosin

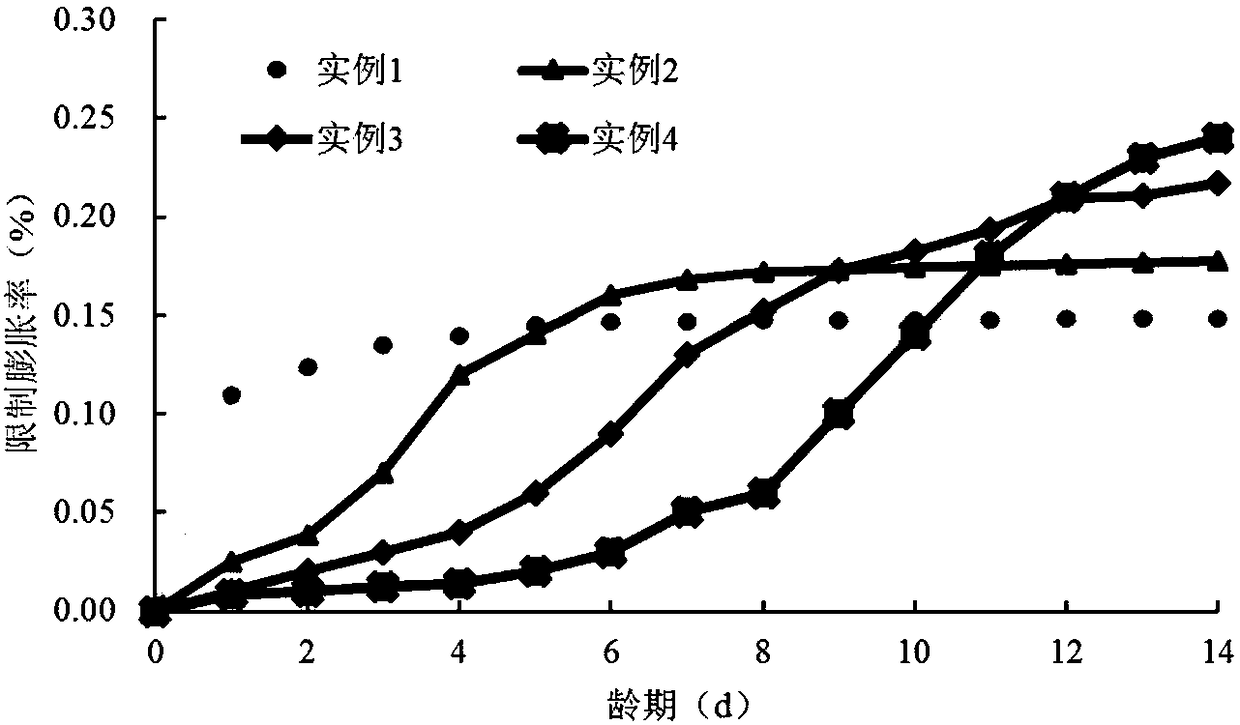

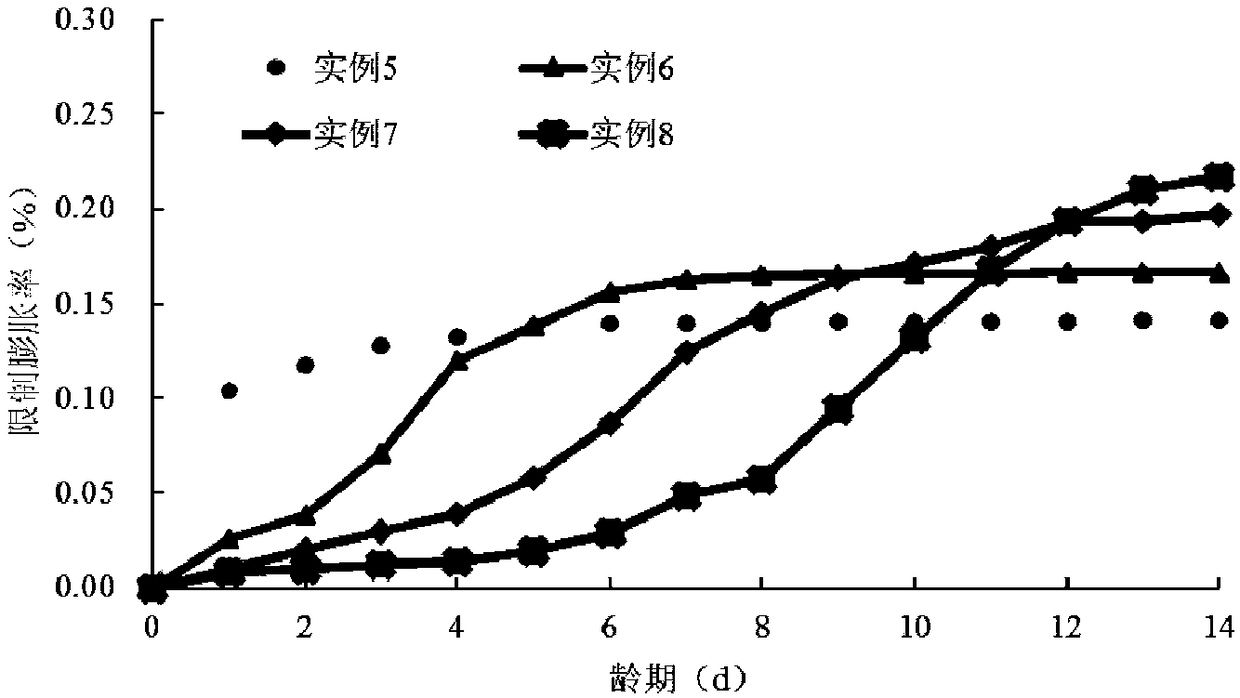

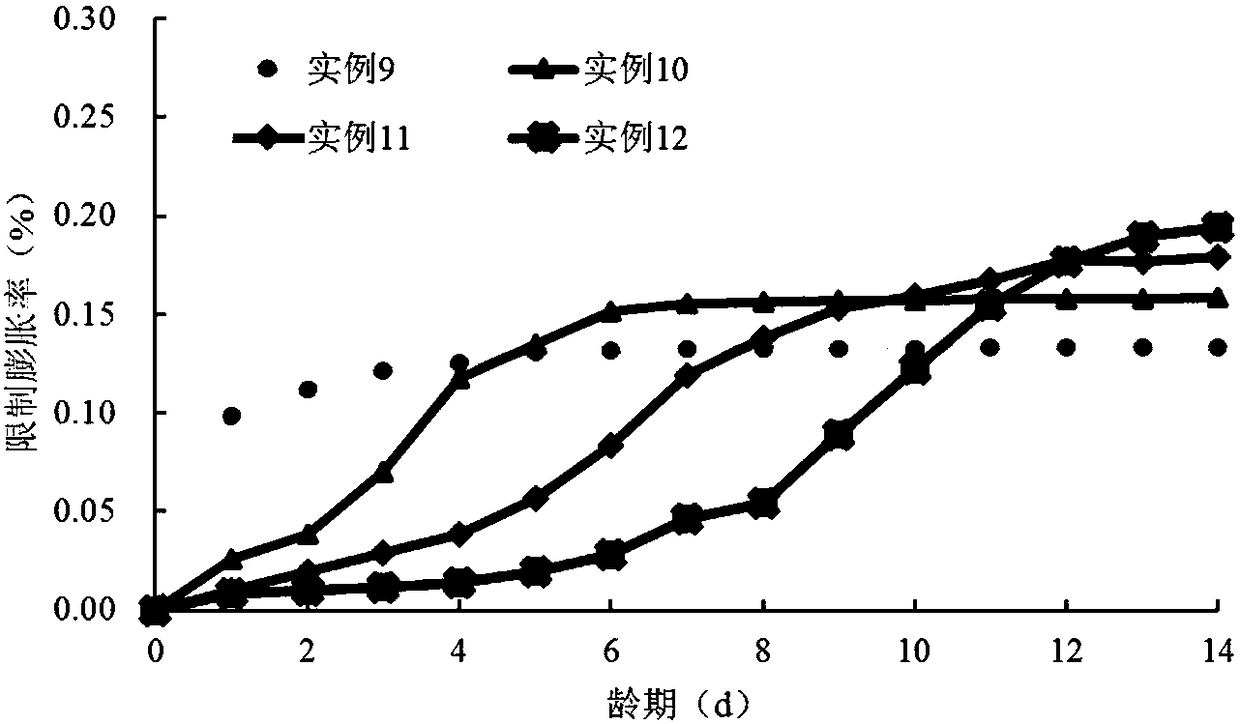

The invention discloses a modified calcium oxide type expanding agent with a controllable expansion course and a preparation method thereof. The specific surface area of the modified calcium oxide type expanding agent is 300m<2> / kg to 500m<2> / kg; the modified calcium oxide type expanding agent is prepared by coating calcium oxide clinker with rosin resin acid and uniformly mixing the calcium oxideclinker with a coagulation regulation component; the mass ratio of the calcium oxide clinker to the rosin resin acid to the coagulation regulation component is (990 to 996) to (2 to 8) to 2. When themodified calcium oxide type expanding agent is applied, the expansion course of the calcium oxide type expanding agent can be remarkably regulated and expansion energy loss of the calcium oxide typeexpanding agent at a concrete plastic stage is reduced; more beneficial expansion is generated in a concrete hardening process and a shrinkage compensating effect of the calcium oxide type expanding agent is efficiently expressed.

Owner:NANJING HYDRAULIC RES INST

High-strength and high-abrasion-resistance brown aluminum oxide ceramic and preparation method thereof

PendingCN108793974ABeautiful and generous colorQuality improvementSilicon dioxideMechanical property

The invention discloses a high-strength and high-abrasion-resistance brown aluminum oxide ceramic and a preparation method thereof and belongs to the technical field of aluminum oxide ceramics and aims to solved the technical problems and remarkably improving the mechanical property of the ceramic under the situation that the firing temperature is not improved, decreasing raw materials, reducing the manufacturing cost and improving the production efficiency. According to the adopted technical scheme, the high-strength and high-abrasion-resistance brown aluminum oxide ceramic is prepared from,by weight, 1-3.5 parts of manganese dioxide, 1-3 parts of iron trioxide, 0.1-0.5 part of magnesium oxide, 0.5-1.5 parts of silicon dioxide, 0.5-2 parts of kaoline, 2-8 parts of calcium oxide, 2-5 parts of zirconium oxide, 0.3-0.8 part of cobaltic oxide, 1-3 parts of barium carbonate, 0.3-0.8 part of chromic oxide and 100 parts of aluminum oxide. The prepared high-aluminum ceramic product has darkand light-toned brown colors due to different ingredient contents and is attractive in appearance.

Owner:河津市锦浩特种陶瓷有限公司

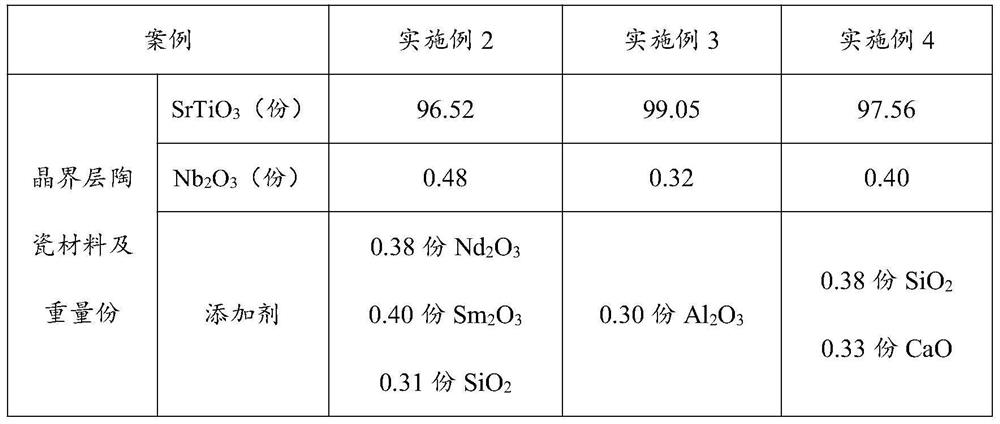

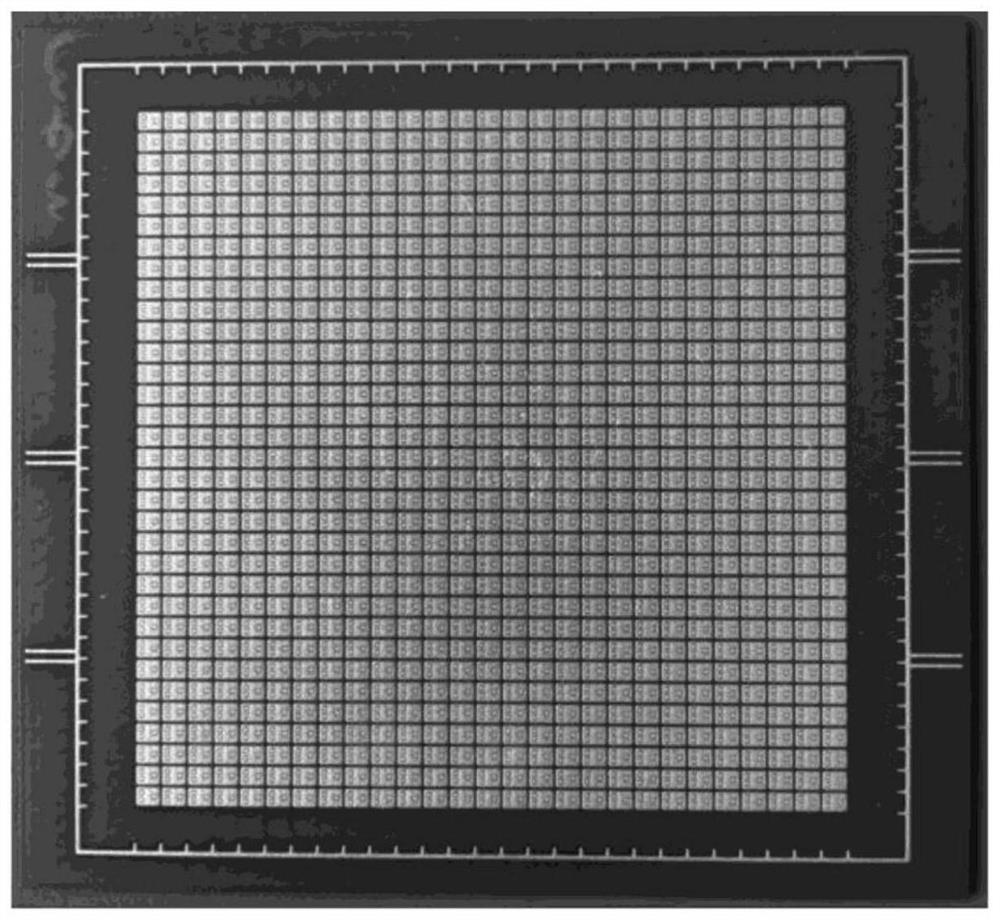

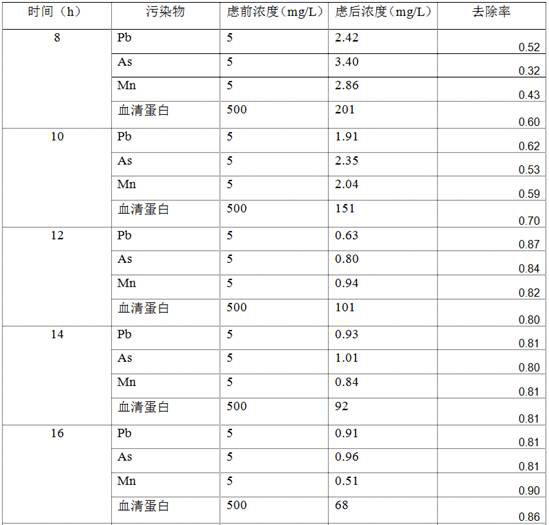

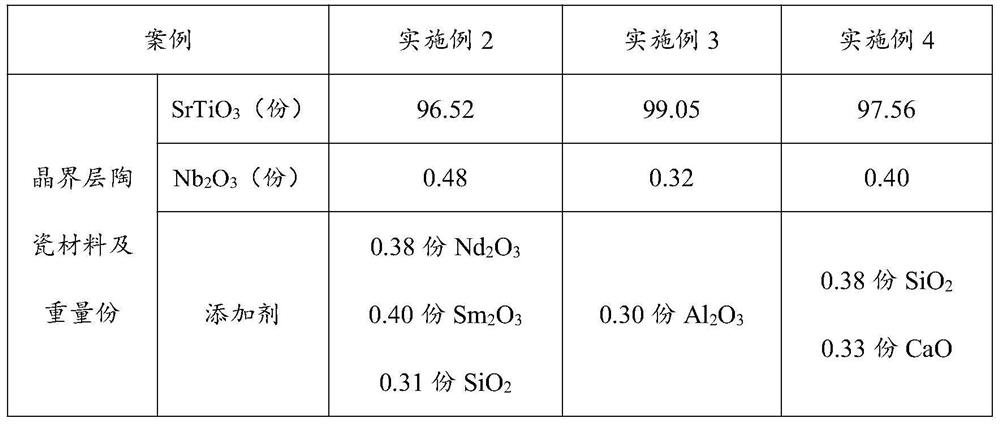

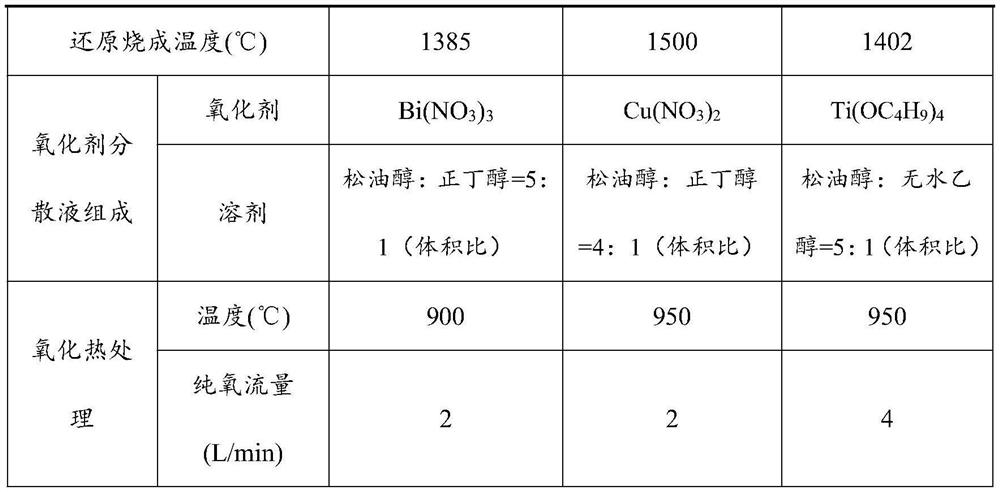

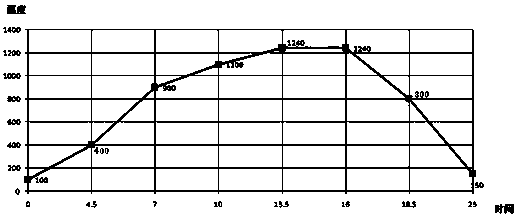

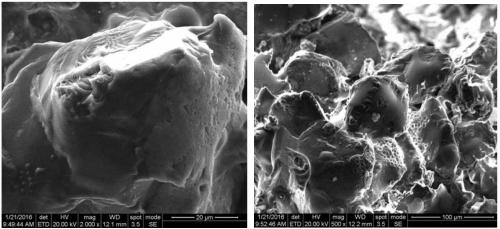

Preparation method and application of grain boundary layer ceramic material and grain boundary layer ceramic substrate

The invention provides a preparation method and application of a grain boundary layer ceramic material and a grain boundary layer ceramic substrate, and belongs to the technical field of chip capacitors. The grain boundary layer ceramic material provided by the invention is prepared from the following preparation raw materials in parts by mass: 95.35 to 99.30 parts of SrTiO3, 0.30 to 0.55 part ofNb2O3 and 0.30 to 5.00 part of a modification additive comprising one or more of BaCO3, Nd2O3, CaO, Sm2O3, Al2O3 and SiO2. The grain boundary layer ceramic material has excellent electrical propertiesand controllability, and a grain boundary layer ceramic substrate prepared from the grain boundary layer ceramic material has excellent repeatability and consistency.

Owner:GUANGZHOU AURORA TECHNOLOGIES CO LTD +1

Tobacco matrix activated carbon and preparation method thereof

InactiveCN111137889ASimple componentsSimple processCarbon compoundsLow-density polyethyleneActivated carbon

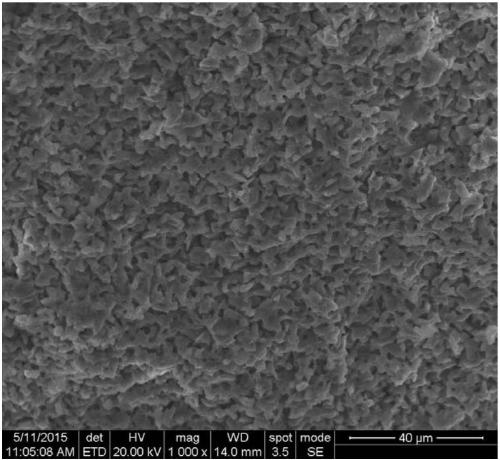

The invention discloses tobacco matrix activated carbon and a preparation method thereof. The tobacco matrix activated carbon is obtained by mixing anhydrous K2CO3, tobacco waste powder and low-density polyethylene powder and performing high-temperature carbonization in a protective gas environment. The methylene blue adsorption capacity of the activated carbon is as high as 806 mg / g and is far higher than the standard methylene blue adsorption capacity of first-grade products. Low-density polyethylene plastic is added, so activation process is more sufficient, activation effect is uniform, and the prepared activated carbon has a more developed pore structure. Potassium carbonate is used as an activating agent, generated K<+> can break a carbon chain to form a complex salt, and the catalytic process of repeated ring opening, cracking and ring opening enriches the microstructure of the activated carbon. CO2 is also a good physical activating agent, so the pore volume and the pore-forming efficiency of the activated carbon can be increased.

Owner:SICHUAN BRANCH OF CHINA TOBACCO +1

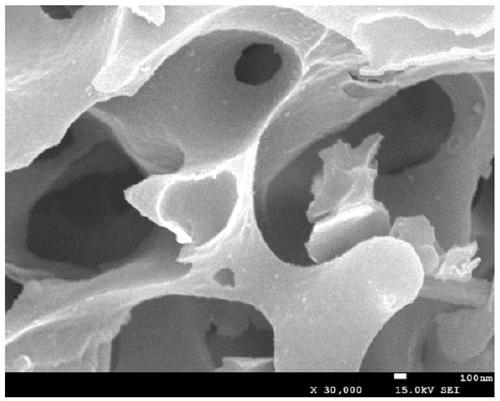

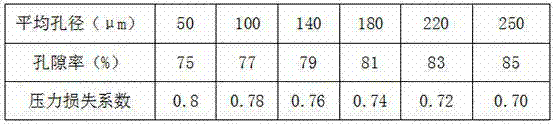

Foamed ceramic high-temperature gas filter pipe and manufacturing technology thereof

InactiveCN102775137AImprove permeabilitySmall pressure lossDispersed particle filtrationFiltration separationPorositySodium Bentonite

The invention relates to the technical field of a filter pipe, and in particular relates to a foamed ceramic high-temperature gas filter pipe and a manufacturing technology thereof. The foamed ceramic high-temperature gas filter pipe comprises 10-30 parts of Al2O3, 10-40 parts of SiO2, 10-30 parts of SiC, 1-3 parts of nano calcium carbonate, 5-10 parts of refractory clay, 1-2 parts of rectorite and 0.5-1.5 parts of sodium bentonite. According to the invention, the average aperture of the filter pipe is 20-250 mu m, the porosity can reach 75-85%, the gas permeability can be improved, and the pressure loss of the filter pipe in work is effectively reduced so that the energy consumption of a draught fan of a dust collector is reduced by 20-30% and the effect of saving energy is achieved; and the manufacturing technology comprises the steps of mixing materials, forming, firing and the like, wherein the firing process is performed under normal pressure, the requirements on equipment and the like are low, the energy consumption is low.

Owner:GUANGDONG SOUTHCHINA INST OF INDAL DESIGN

Zirconium mullite castable for waste incineration kiln and preparation process thereof

InactiveCN110963810AImprove thermal shock resistanceNot easy to crack and deformMulliteWear resistance

The invention belongs to the technical field of castables and particularly relates to a zirconium mullite castable for a waste incineration kiln and a preparation process thereof. According to the invention, a pore-forming agent and a thermal expansion coefficient retarding agent are added into a zirconium mullite system to achieve the effect of outstanding thermal shock resistance of the castable, and the pore-forming agent and the thermal expansion coefficient retarding agent are combined with a proper castable main body material to ensure the basic castable use effect. The castable providedby the invention has good thermal shock resistance, is suitable for the waste incineration kiln, especially kiln mouth flashboard parts, and also has the advantages of basic wear resistance, high temperature resistance and erosion resistance, and the preparation process of the castable and the firing process of precast blocks are simple, effective, energy-saving and efficient.

Owner:长兴兴鹰新型耐火建材有限公司

Firing process of bone-china

InactiveCN104591725AThe firing process is simpleRaw materials are easy to getPotassium feldsparChemistry

The invention relates to a firing process of bone-china. The process comprises the following steps: adding calcium hydroxide and phosphoric acid into a reaction pond, carrying out reaction for 10-15 hours at 60-80 DEG C, filter-pressing, drying and calcining and carrying out magnetic separation to remove iron to obtain synthetic bone meal; adding water into the synthetic bone meal, rock crystal powder, kaolin and potassium feldspar by virtue of a ball mill to obtain powder with the fineness of 250 meshes, filter-pressing the powder to china sheets by a filter press, preparing china sheets into stripes by virtue of a vacuum pug mill, and molding and drying the slurry by machining and molding to obtain a blank; and biscuiting and glaze firing to obtain the bone-china. The process has the advantages that the firing process is simple; raw materials are easily available and low in cost; the product is stable in quality; besides the characteristics of the bone-china fired by common animal bone black, the fired bone-china further has the characteristics of high whiteness, good transparency and high heat stability; the whiteness of the synthetic bone black is greater than or equal to 90 degrees, the transparency is greater than or equal to 45%, and the heat stability is that at 180 DEG G, the bone-china put in water at 20 DEG C for heat exchange three times is not cracked.

Owner:KAZUO YUCHENG PURPLE CLAY PROD

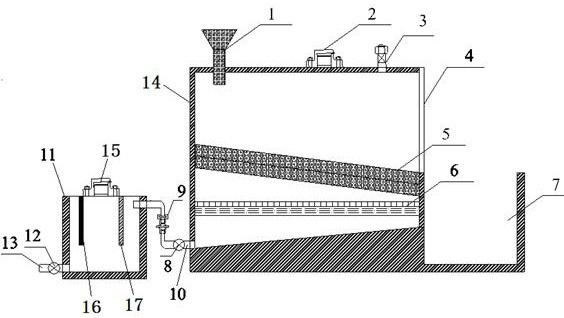

Preparation method of light-weight heat-preservation brick

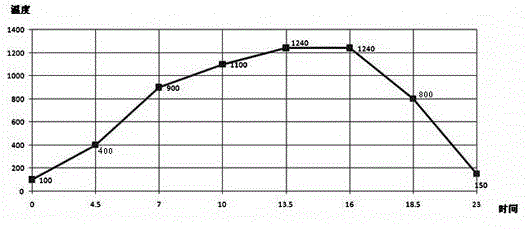

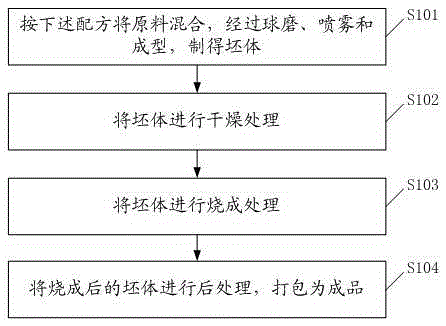

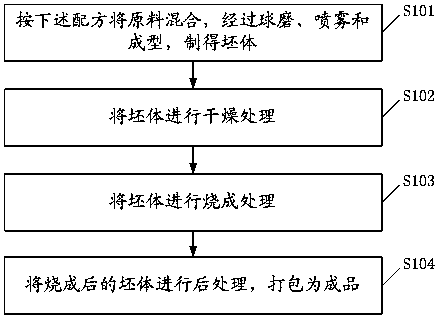

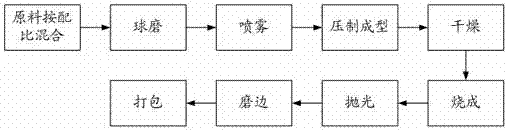

The invention discloses a preparation method of light-weight heat-preservation bricks. The preparation method includes the steps of 1) mixing the following raw materials comprising: 50-76% of industrial coal slag, 6-20% of a mud material, 4-20% of potassium feldspar, 4-20 parts of sodium feldspar, 4-20% of quartz and 0-15% of polishing residue, and performing ball milling, spraying and moulding to produce a green body; (2) drying the green body; (3) sintering the green body; (4) after-treating the sintered green body, and packaging a finish product. The preparation method is simple in step, is short in sintering time and can save energy resources. The produced heat-preservation brick is solid in texture, is low in specific gravity, is high in porosity, is higher than 1000 DEG C in resistance temperature, can easily resist common fire, is low in heat conductivity and high in pressure resistant strength, and is very suitable for heat insulation of outer walls and indoor heat insulation and sound insulation.

Owner:KEDA INDUSTRIAL GROUP CO LTD

A kind of preparation method of lightweight insulation brick

The invention discloses a preparation method of light-weight heat-preservation bricks. The preparation method includes the steps of 1) mixing the following raw materials comprising: 50-76% of industrial coal slag, 6-20% of a mud material, 4-20% of potassium feldspar, 4-20 parts of sodium feldspar, 4-20% of quartz and 0-15% of polishing residue, and performing ball milling, spraying and moulding to produce a green body; (2) drying the green body; (3) sintering the green body; (4) after-treating the sintered green body, and packaging a finish product. The preparation method is simple in step, is short in sintering time and can save energy resources. The produced heat-preservation brick is solid in texture, is low in specific gravity, is high in porosity, is higher than 1000 DEG C in resistance temperature, can easily resist common fire, is low in heat conductivity and high in pressure resistant strength, and is very suitable for heat insulation of outer walls and indoor heat insulation and sound insulation.

Owner:KEDA INDUSTRIAL GROUP CO LTD

A lightweight insulating brick

The invention discloses a light heat insulating brick, which is made of the following main raw materials: 50-76% of industrial cinder, 6-20% of mud material, 4-20% of potassium feldspar, 4-20% of albite feldspar, 4% of quartz ‑20%, polishing slag 0‑15%. The present invention uses industrial coal slag as the main body of the formula, and the addition amount is more than 50%. Moreover, the entire firing time of the present invention can be controlled within 4-7 hours. , The fire resistance temperature exceeds 1000 degrees, can easily resist conventional fires, has small thermal conductivity and high compressive strength, and is very suitable for heat insulation of external walls and indoor heat insulation and sound insulation.

Owner:KEDA INDUSTRIAL GROUP CO LTD

Method for preparing filtering material from copper tailings and application

InactiveCN111760381AHigh economic valueReduce pollutionCeramic materials productionCeramicwareFiberAdhesive

The invention discloses a method for preparing a filtering material from copper tailings. The method comprises the following steps of: mixing pretreated copper tailings, water, a modifier and an adhesive to prepare a raw material with the water content of 10-30%; and performing injection molding and roasting on the raw material so as to obtain the filtering material. The energy-saving and environment-friendly filter material is prepared on the premise of solving the problems of low comprehensive utilization rate of metal tailings and the like, and is applied to filtration and dehydration of mine concentrates and solid-liquid separation in the industries of coal, fine chemical engineering, papermaking, pharmacy, chemical fibers, foods, environmental protection and the like, so that the resource utilization of the tailings is efficiently realized.

Owner:KUNMING UNIV OF SCI & TECH

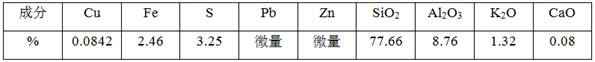

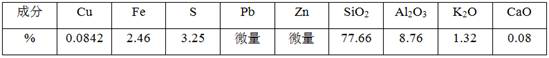

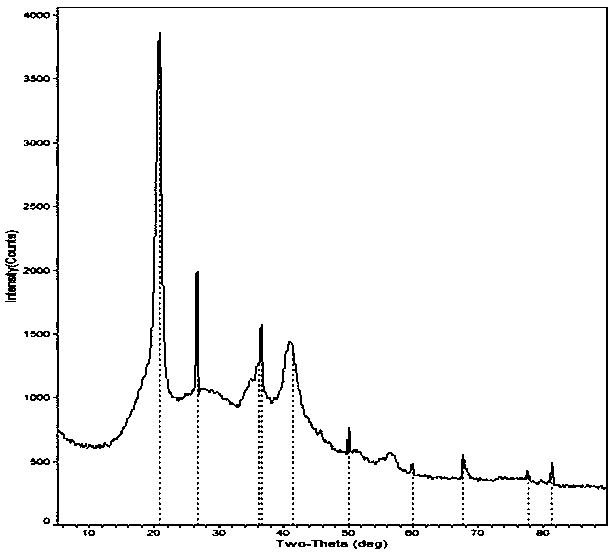

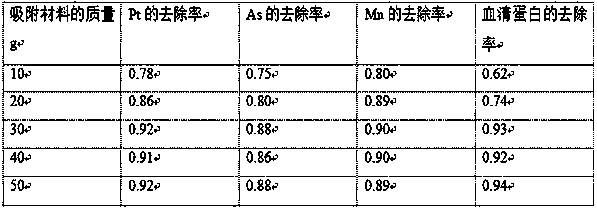

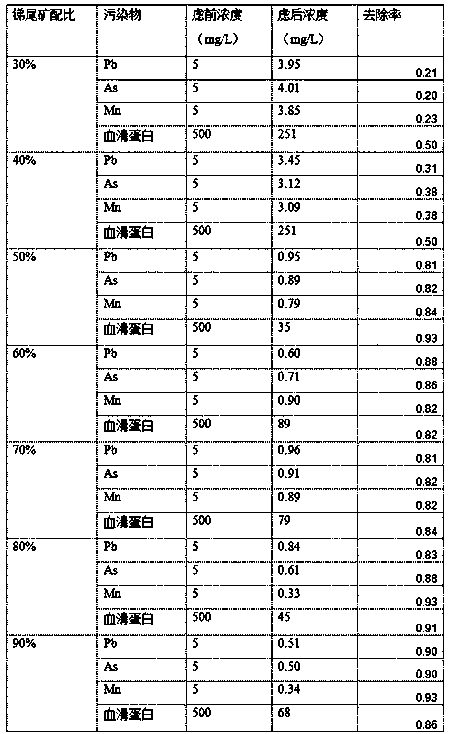

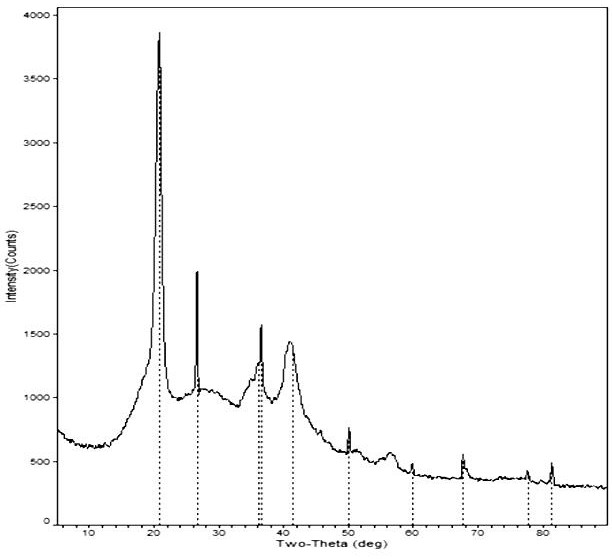

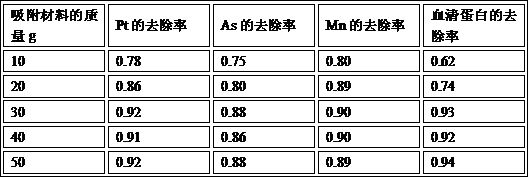

Antimony-based tailing adsorbing material, preparation method and applications thereof

ActiveCN111013526AHigh economic valueReduce pollutionOther chemical processesWater contaminantsHigh concentrationAdhesive

The invention discloses an adsorbing material based on antimony tailings, a preparation method and applications thereof, wherein the adsorbing material is prepared from the following components in percentage by mass: 50-90% of antimony tailings and 50-10% of an adhesive. According to the present invention, the adsorption performance detection results show that the material has high adsorption performance on high-concentration organic emulsification wastewater and heavy metal-containing wastewater, has characteristics of stable chemical property, developed pores, high mechanical strength, high-temperature resistance and the like, and has broad prospects in the fields of waste resource utilization and adsorption materials.

Owner:KUNMING UNIV OF SCI & TECH

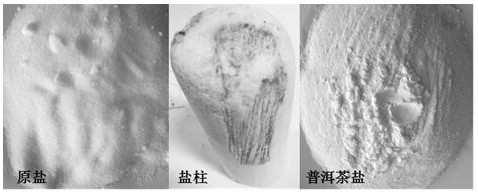

Preparation method of puer tea salt

ActiveCN108095032AIncrease contentThe firing process is simpleFood thermal treatmentAcidic food ingredientsRed mudTrace element

The invention discloses a preparation method of puer tea salt, and belongs to the technical field of health table salt. The preparation method comprises the following steps: putting deep-well raw saltinto a fresh moso bamboo tube with an open end, adding spring water for moistening, and compacting; adding fresh puer tea leaves to the compacted deep-well raw salt, and then sealing the moso bambootube by using red mud; vertically placing the moso bamboo tube in a high temperature-resistant kiln, wherein the red mud end of the moso bamboo tube is downward; heating at a uniform speed till the temperature is 300-320 DEG C, and preserving heat for 2.5-3 hours; when no smoke exists in the kiln, heating at a uniform speed till the temperature is 650-750 DEG C, and preserving heat till the moso bamboo tube and the puer tea leaves are burn out to obtain columnar salt; cooling the columnar salt in the kiln till the temperature is not higher than 300 DEG C to obtain I-stage columnar salt, crushing and grinding the I-stage columnar salt till the particle size is 0.05-0.1 mm to obtain I-stage puer tea salt; and circularly treating the I-stage puer tea salt according to the previous steps for Ntimes to obtain (N+1)-stage puer tea salt. The puer tea salt contains rich minerals and trace elements, and has the health-care effects of natural alkalinity, oxidation resistance, fatigue resistance, blood pressure reduction, blood lipid reduction and the like.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method of Lujun Jun porcelain

The invention discloses a preparation method of Lujun Jun porcelain. According to the preparation method, an unglazed prime tire preparation step, a glaze preparation step, an unglazed prime tire glazing step and a glazed unglazed prime tire firing step are carried out to finish preparation of whole porcelain. The unglazed prime tire preparation step comprises the following steps: taking raw materials in parts by weight: after primarily crushing the raw materials through a crushing machine, filling the crushed raw materials into a ball grinding mill and finely grinding; sieving a fine material, drawing a blank and molding, and firing to obtain an unglazed prime tire finished product. The glaze preparation step comprises the following steps: crushing the raw materials and putting into ballgrinding mill and carrying out ball grinding; sieving wetly-ground material slurry to obtain glaze slurry; preparing a binding agent and a nano-copper ion water solution, and mixing into the glaze slurry; concentrating to obtain the glaze slurry. The unglazed prime tire glazing step comprises the following steps: glazing for two times and blowing air for drying; putting into a kiln furnace and firing. The glazed unglazed prime tire firing step adopts a gradient temperature rising manner to fire, so as to obtain a finished product. The Lujun Jun porcelain disclosed by the invention has the advantages that the appearance has a bright color, and the glaze color is bright and smooth, and is natural but not stiff; the glaze surface strength is high and the porcelain is not easy to damage.

Owner:杨鹏飞

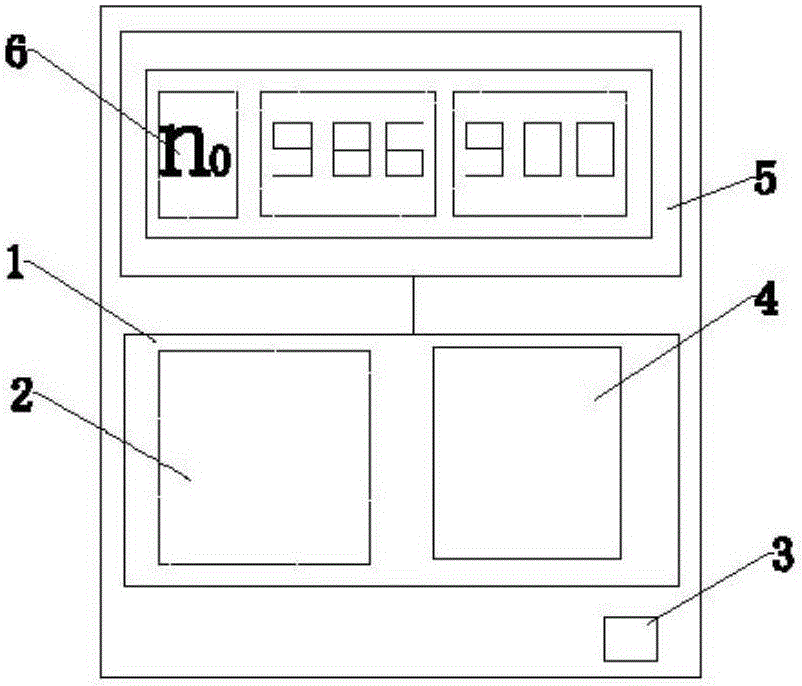

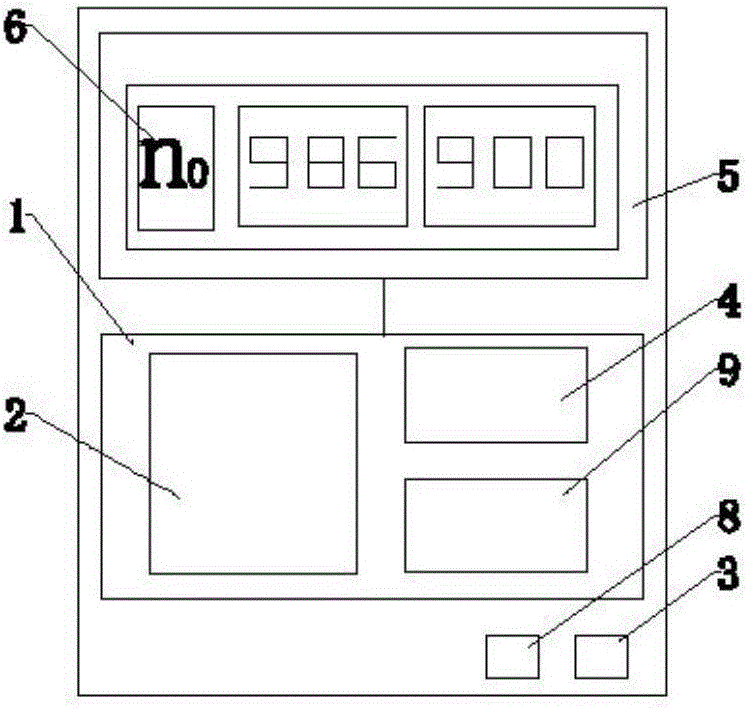

Ceramic firing method and ceramic intelligent firing control device thereof

InactiveCN106045527AImprove firing quality and efficiencyThe firing process is simpleControl devices for furnacesProcess moduleMetallurgy

The invention discloses a ceramic firing method and a ceramic intelligent firing control device thereof. The method comprises the following steps: arranging a firing process module on a system firing master control unit of the ceramic intelligent firing control device; storing corresponding firing processes, firing process curves and firing techniques which correspond to different ceramic products in the firing process module; and starting through an actuating key of the ceramic intelligent firing control device and selecting a corresponding firing process in the firing process module. The ceramic intelligent firing control device comprises a system firing master control unit and a digital display, wherein the system firing master control unit comprises firing process modules of corresponding firing processes corresponding to different ceramic products; and only one actuating key is arranged and corresponds to the system firing master control unit. The method is simple, and the ceramic intelligent firing control device is simple in structure and simple and convenient to operate.

Owner:罗少忠

A kind of mullite lightweight heat insulation brick and preparation method thereof

The invention specifically relates to a mullite lightweight heat-insulating brick and a preparation method thereof. The technical solution is: the raw material and content of the mullite lightweight heat-insulating brick are: 40-48wt% of coke gemstone, 14-38wt% of kyanite, 6-16wt% of clay, α-Al 2 o 3 The micro powder is 14-24wt%; the binder is 15-20wt% of the raw material, and the pore-forming agent is 45-60wt% of the raw material. According to the content of the above-mentioned raw materials, binders and pore-forming agents, the α-Al 2 o 3 Mix micropowder with pore-forming agent, wet mill for 8-10 hours to obtain homogeneous mud; then stir homogeneous mud, burnt gemstone, kyanite, clay and binder evenly, trap material, shape, bake, Keep warm for 3~5h under the condition of ℃ to get mullite lightweight insulation brick. The invention saves resources, has a simple process and is environmentally friendly, and the prepared mullite lightweight heat-insulating brick has good thermal stability, low thermal conductivity, small bulk density, low linear shrinkage after firing, high compressive strength and heat insulation. The effect is good.

Owner:WUHAN UNIV OF SCI & TECH

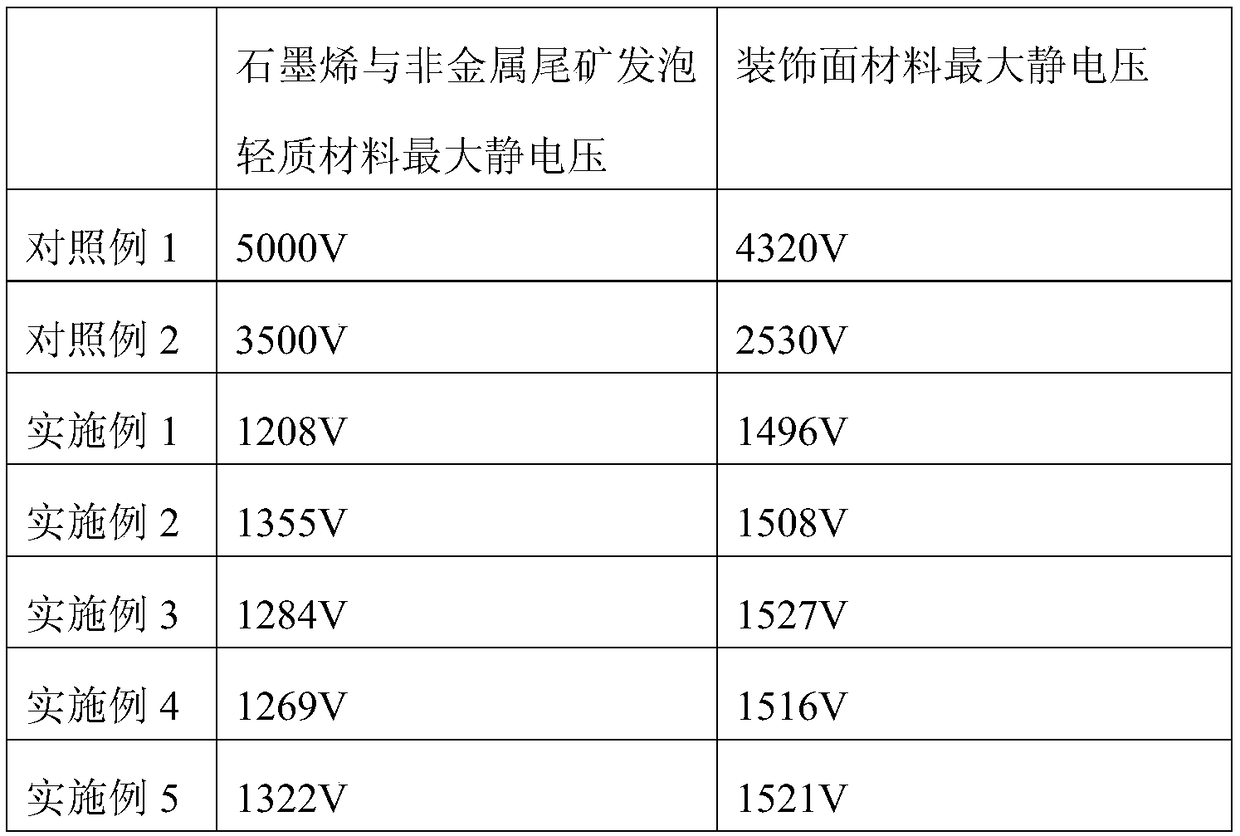

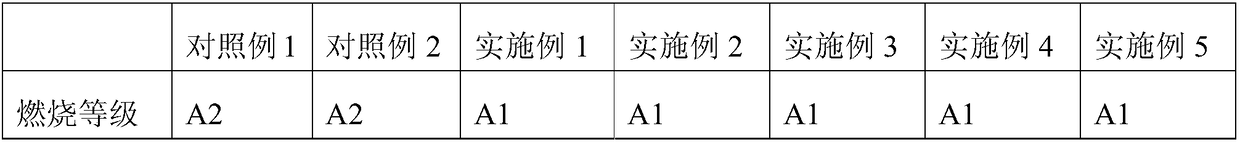

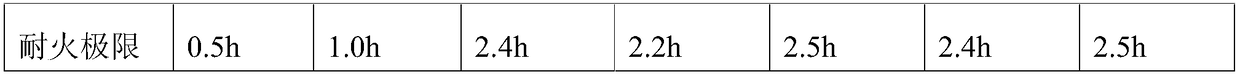

Foamed lightweight decorative integrated board based on graphene and non-metallic tailings and its preparation method

ActiveCN107698238BStable physical propertiesImprove flame retardant performanceCovering/liningsCeramic materials productionGrapheneMetal

The invention discloses a foamed light-weight decorative integrated board based on graphene and non-metallic tailings. The foamed light-weight decorative integrated board comprises a matrix graphene and non-metallic tailings foamed light-weight material layer and a surface decoration face layer which are bonded together through one-time sintering molding after press-molding, wherein the graphene and non-metallic tailings foamed light-weight material layer comprises the following raw materials: non-metallic tailings, graphene, zirconia, a high-temperature fluxing agent, clay, a stabilizer and adispergator. The invention also discloses a preparation method of the foamed light-weight decorative integrated board based on graphene and non-metallic tailings. The foamed light-weight decorative integrated board based on graphene and non-metallic tailings has the advantages of light weight, high strength, high sound, heat and temperature insulation performance, excellent water and seepage resistance, favorable flame retardancy, good corrosion resistance, convenience in installation, low carbon, energy saving, environmental friendliness and the like.

Owner:GUANGXI XUTENG INDUSTRIAL GROUP CO LTD

Modified calcium oxide expansion agent with controllable expansion process and preparation method thereof

The invention discloses a modified calcium oxide type expanding agent with a controllable expansion course and a preparation method thereof. The specific surface area of the modified calcium oxide type expanding agent is 300m<2> / kg to 500m<2> / kg; the modified calcium oxide type expanding agent is prepared by coating calcium oxide clinker with rosin resin acid and uniformly mixing the calcium oxideclinker with a coagulation regulation component; the mass ratio of the calcium oxide clinker to the rosin resin acid to the coagulation regulation component is (990 to 996) to (2 to 8) to 2. When themodified calcium oxide type expanding agent is applied, the expansion course of the calcium oxide type expanding agent can be remarkably regulated and expansion energy loss of the calcium oxide typeexpanding agent at a concrete plastic stage is reduced; more beneficial expansion is generated in a concrete hardening process and a shrinkage compensating effect of the calcium oxide type expanding agent is efficiently expressed.

Owner:NANJING HYDRAULIC RES INST

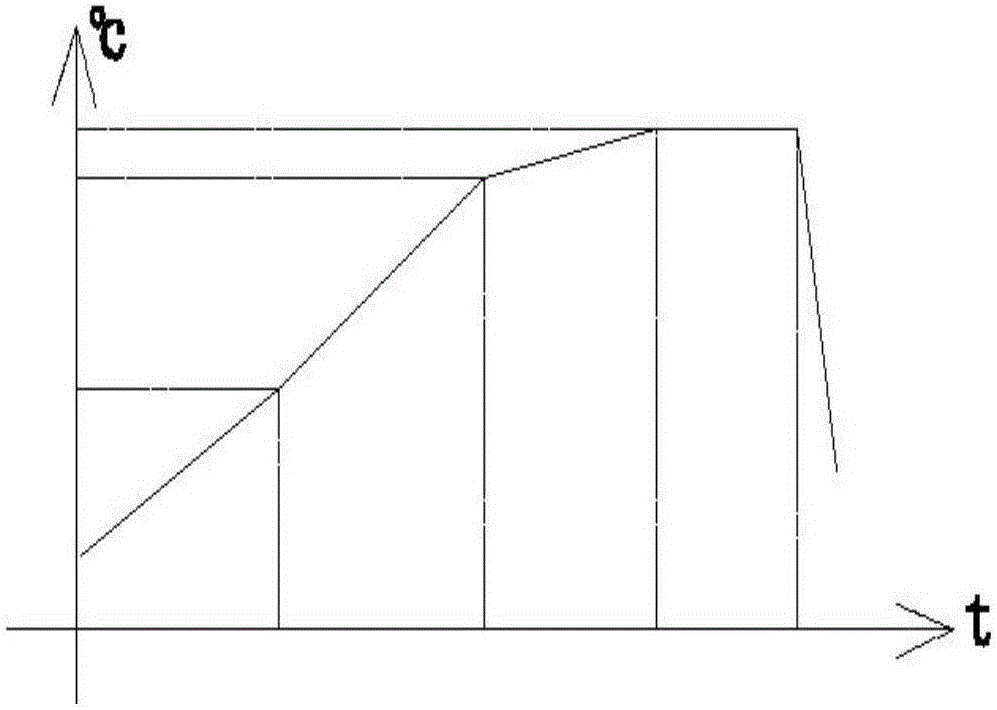

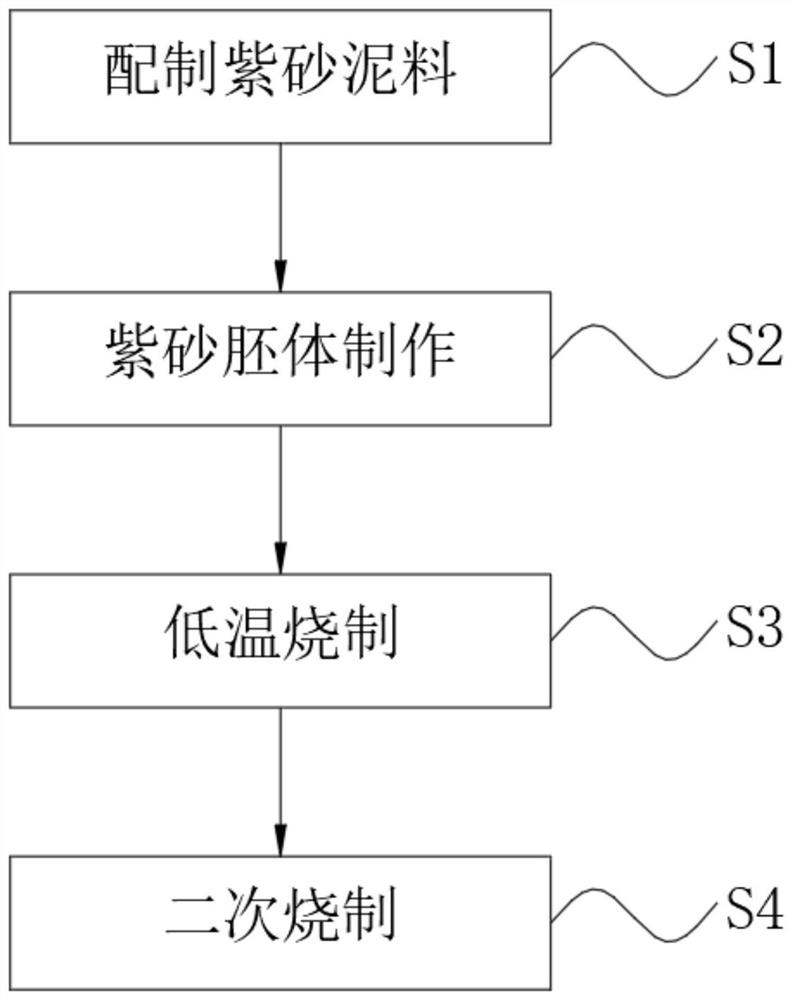

Mixed firing process of gem particles and purple sand raw materials

PendingCN112876215AImprove qualityQuality improvementCeramic materials productionClaywaresPhysical chemistryGemstone

The invention discloses a mixed firing process of jewel particles and purple sand raw materials. The preparation method comprises the following steps: S1, preparing purple sand mud, selecting proper purple sand mineral aggregate as a purple sand pottery firing raw material, stacking the purple sand mineral aggregate, naturally aging for a period of time, grinding the purple sand mineral aggregate through a grinding device to prepare purple sand mineral powder, screening the purple sand mineral powder to obtain purple sand mineral powder; and removing through screening, large-particle purple sand mineral powder; according to the invention, the whole firing process is simple; by treating the purple grit mud, the overall quality of the purple grit mud can be effectively improved, and the quality of purple grit products can be improved; in the firing process, the temperature is regulated and controlled for multiple times, so that the surface glossiness of the purple sand product can be improved, the firing period can be shortened, and the working efficiency of a kiln can be improved; and meanwhile, the gemstone is mixed in the purple sand product, so that the overall ornamental value and the artistic effect can be greatly improved, and the purple sand product is more attractive.

Owner:深圳市信德缘珠宝首饰有限公司

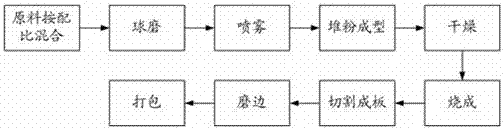

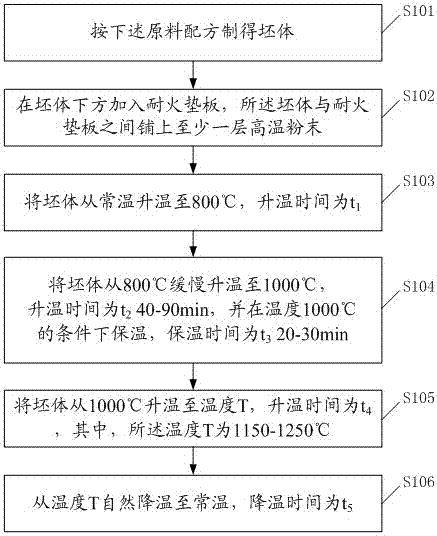

A kind of firing process of light-weight insulating brick

The invention discloses a sintering process for lightweight thermal insulation bricks. %, albite 4-20%, quartz 4-20%, polishing slag 0-15%; (2) A refractory backing plate is added under the green body, and at least one layer is laid between the green body and the refractory backing plate High temperature powder; (3) The green body is heated from normal temperature to 800°C; (4) The green body is slowly heated from 800°C to 1000°C, the heating time is t2 40-90min, and the temperature is kept at 1000°C. The time is t3 20-30min; (5) the green body is heated from 1000 ℃ to the temperature T, and the temperature T is 1150-1250 ℃; (6) the temperature is naturally cooled from the temperature T to the normal temperature. The method of the invention has the advantages of simple firing steps, short firing time, energy saving and good thermal insulation brick performance.

Owner:KEDA INDUSTRIAL GROUP CO LTD

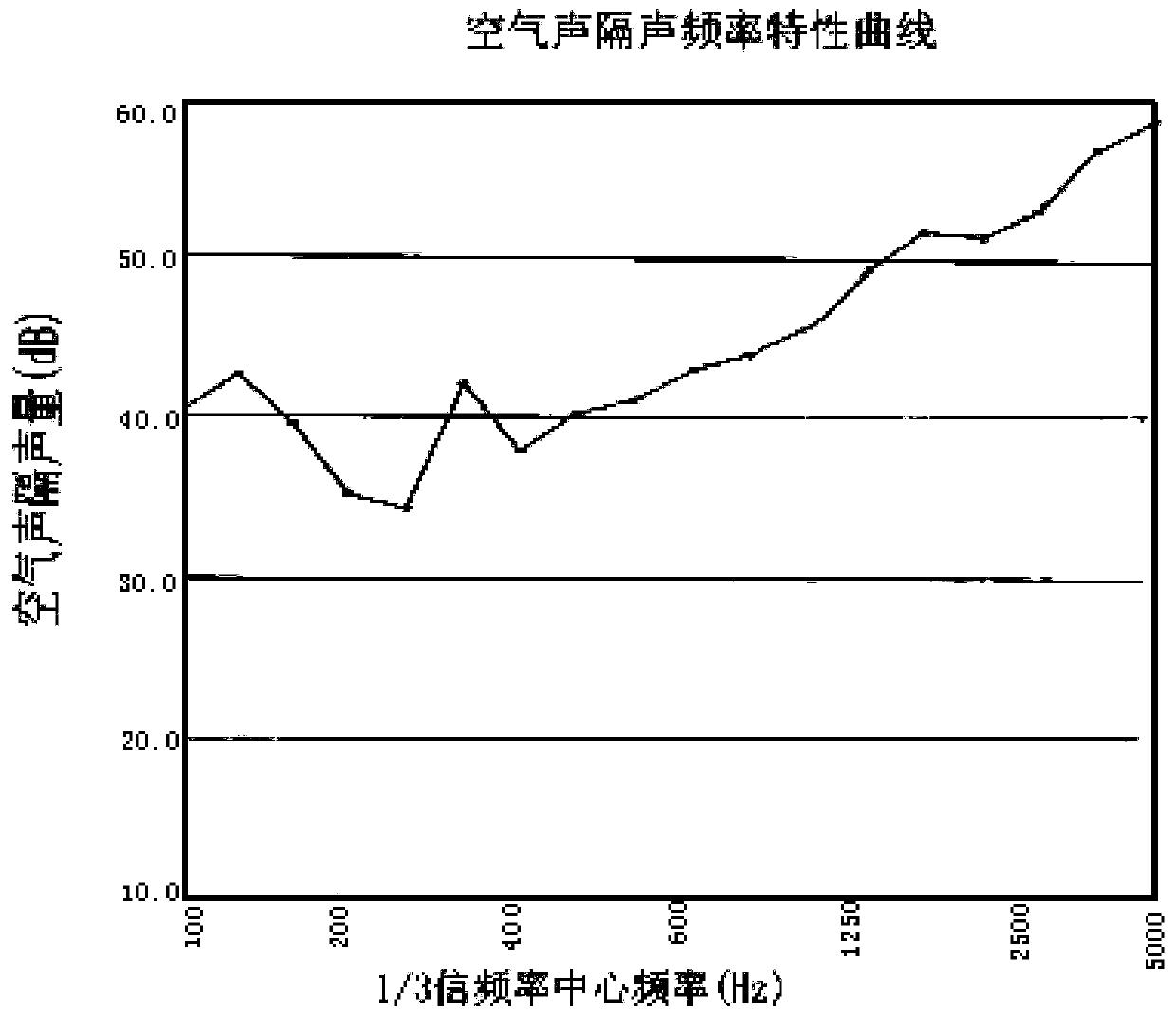

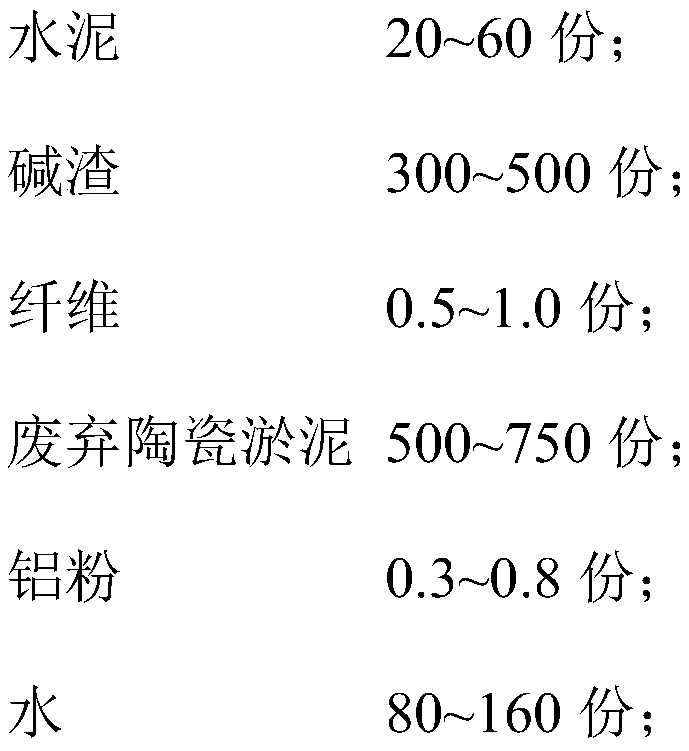

Porous structure material and its preparation method and application

ActiveCN107188535BImprove frost resistanceThe firing process is simpleCeramic materials productionCeramicwareAl powderFiber

The invention discloses a porous structure material, a preparation method and application thereof. The porous structure material comprises the following components by weight: 20-60 parts of cement; 300-500 parts of alkaline residue; 0.5-1.0 part of fiber; 500-750 parts of ceramic waste sludge; 0.3-0.8 part of aluminum powder; and 80-160 parts of water. Specifically the raw materials are fired to form the porous structure material. The material provided by the invention has a volumetric weight of 400-700kg / m<3>, compressive strength of greater than or equal to 8MPa, breaking strength of more than or equal to 3MPa, and thermal conductivity of less than or equal to 0.11W / (m.K), and has good frost resistance, thus being applicable to heat and sound insulation of buildings.

Owner:GUANGDONG GAITEQI NEW MATERIAL TECH CO LTD

A low-temperature sintered alumina black ceramic and its preparation method

Owner:新化县顺达电子陶瓷有限公司

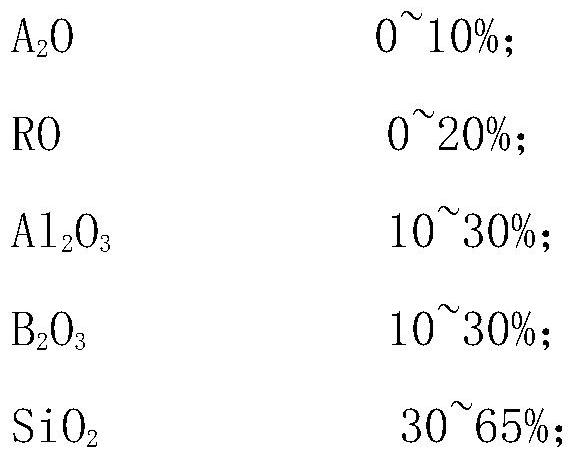

A kind of black low-temperature sintered microwave dielectric ceramic material and its preparation method and application

ActiveCN107500735BMeet the requirements of package light shieldingThe firing process is simpleDielectric ceramicsCeramic substrate

The invention belongs to the field of microwave dielectric ceramics, and relates to a black low-temperature sintered microwave dielectric ceramic material and its preparation method and application. A black low-temperature sintered microwave dielectric ceramic material, the ceramic material includes alumina, aluminoborosilicate glass and black colorant, and the mass percentage is composed of: alumina 40-60%; aluminoborosilicate glass 38-58% ; Black colorant 2 to 10%. The ceramic substrate prepared by using the ceramic material through the LTCC process technology has the characteristics of simple firing process, high mechanical strength, excellent dielectric properties, and light-shielding properties. Can replace HTCC package substrate.

Owner:JIAXING GLEAD ELECTRONICS CO LTD

A kind of preparation method of Pu'er tea salt

ActiveCN108095032BIncrease contentThe firing process is simpleFood thermal treatmentAcidic food ingredientsBlood lipidsMineralogy

The invention discloses a preparation method of puer tea salt, and belongs to the technical field of health table salt. The preparation method comprises the following steps: putting deep-well raw saltinto a fresh moso bamboo tube with an open end, adding spring water for moistening, and compacting; adding fresh puer tea leaves to the compacted deep-well raw salt, and then sealing the moso bambootube by using red mud; vertically placing the moso bamboo tube in a high temperature-resistant kiln, wherein the red mud end of the moso bamboo tube is downward; heating at a uniform speed till the temperature is 300-320 DEG C, and preserving heat for 2.5-3 hours; when no smoke exists in the kiln, heating at a uniform speed till the temperature is 650-750 DEG C, and preserving heat till the moso bamboo tube and the puer tea leaves are burn out to obtain columnar salt; cooling the columnar salt in the kiln till the temperature is not higher than 300 DEG C to obtain I-stage columnar salt, crushing and grinding the I-stage columnar salt till the particle size is 0.05-0.1 mm to obtain I-stage puer tea salt; and circularly treating the I-stage puer tea salt according to the previous steps for Ntimes to obtain (N+1)-stage puer tea salt. The puer tea salt contains rich minerals and trace elements, and has the health-care effects of natural alkalinity, oxidation resistance, fatigue resistance, blood pressure reduction, blood lipid reduction and the like.

Owner:KUNMING UNIV OF SCI & TECH

A kind of adsorption material based on antimony tailings and its preparation method and application

ActiveCN111013526BHigh economic valueReduce pollutionOther chemical processesWater contaminantsHigh concentrationMaterials science

The invention discloses an adsorption material based on antimony tailings and its preparation method and application. The material is prepared from the following composition in mass percentage: 50%-90% of antimony tailings, 50%-10% of viscous agent; the material After the adsorption performance test, the results show that the material has high adsorption performance for high-concentration organic emulsified wastewater and heavy metal-containing wastewater, and has relatively stable chemical properties, developed pores, high mechanical strength, and high temperature resistance. It has broad prospects in the field of chemical utilization and adsorption materials.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method and application of a grain boundary layer ceramic material, grain boundary layer ceramic substrate

The invention provides a grain boundary layer ceramic material, a preparation method of a grain boundary layer ceramic substrate and an application thereof, belonging to the technical field of chip capacitors. The grain boundary layer ceramic material provided by the present invention includes the following preparation raw materials in parts by mass: SrTiO 3 95.35~99.30 parts, Nb 2 o 3 0.30-0.55 parts and 0.30-5.00 parts of modified additive; the modified additive is BaCO 3 、Nd 2 o 3 , CaO, Sm 2 o 3 、Al 2 o 3 and SiO 2 one or more of them. The grain boundary layer ceramic material provided by the invention has excellent electrical properties and controllability, and the grain boundary layer ceramic substrate prepared from the grain boundary layer ceramic material has excellent repeatability and consistency.

Owner:GUANGZHOU AURORA TECHNOLOGIES CO LTD +1

Lead-containing assistant of frit used for preparation of ceramics

The invention discloses a lead-containing assistant of a frit used for preparation of ceramics. The assistant is prepared from the following raw materials by weight: 20-40 parts of SiO2, 5-15 parts of Al2O3, 5-15 parts of an alkali metal, 10-20 parts of PbO, 3-8 parts of acetophenone, and 3-5 parts of a defoaming agent. The lead-containing assistant of the frit used for preparation of ceramics provided by the invention has scientific and reasonable component proportioning, can promote frit fusion, lower fusion temperature, and prevent high temperature volatilization of materials. And the prepared glaze slip has good performance and can be used in a wide range.

Owner:CARLOBBIA GLAZE KUNSHAN

A firing process of bone china

A firing process of bone china. Calcium hydroxide and phosphoric acid are added into a reaction tank, reacted at 60°C to 80°C for 10h to 15h, filter-pressed, dried and calcined, and iron is removed by magnetic separation to obtain synthetic bone powder ;Use synthetic bone meal, crystal quartz powder, kaolin and potassium feldspar, grind with ball mill and water to obtain powder with a fineness of 250 meshes, filter into mud flakes with filter press, and make mud flakes by vacuum mud refining machine After the mud strips are formed, the mud is formed and dried to obtain the embryo body; after bisque firing and glaze firing, bone china is obtained. The advantages are: the firing process is simple, the raw materials are readily available, the cost is low, and the product quality is stable. The fired bone china has the characteristics of ordinary animal bone charcoal fired bone china, and also has high whiteness, good transparency and heat. The characteristics of high stability, the whiteness of synthetic bone char is ≥90°, the transparency is ≥45%, and the thermal stability is placed in water at 180°C and 20°C for three heat exchanges without bursting.

Owner:KAZUO YUCHENG PURPLE CLAY PROD

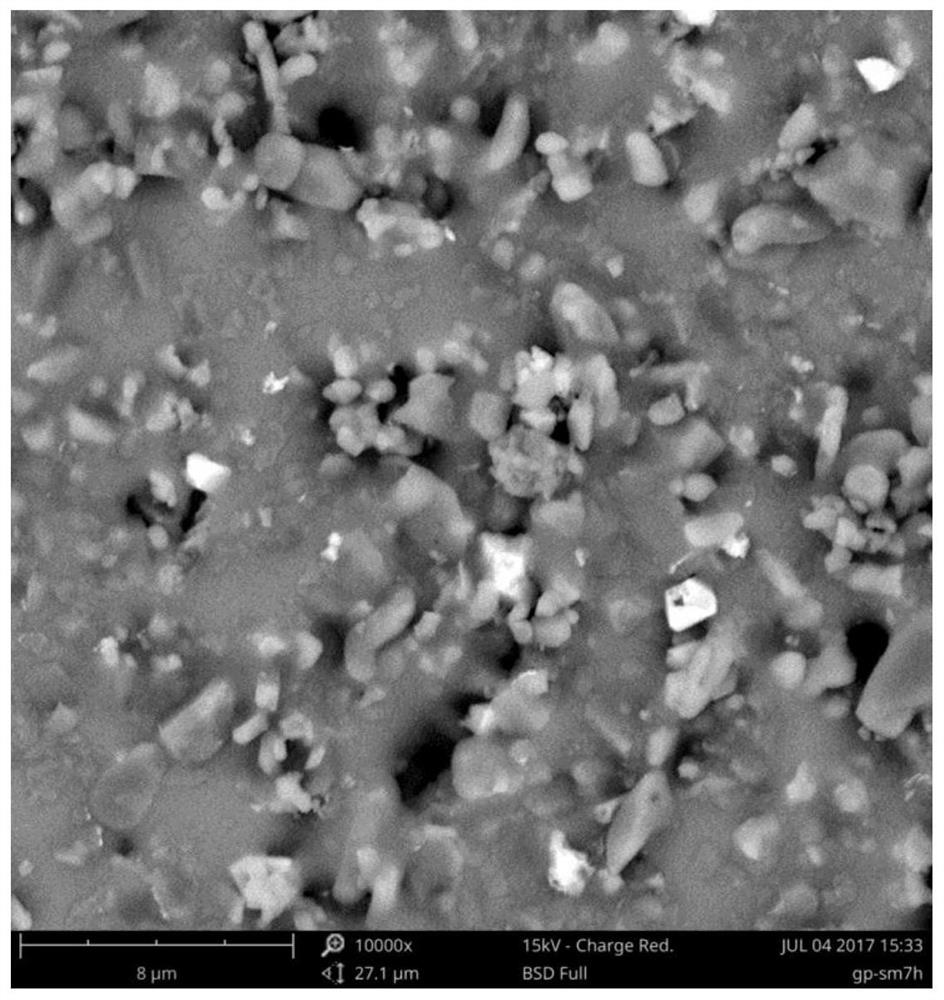

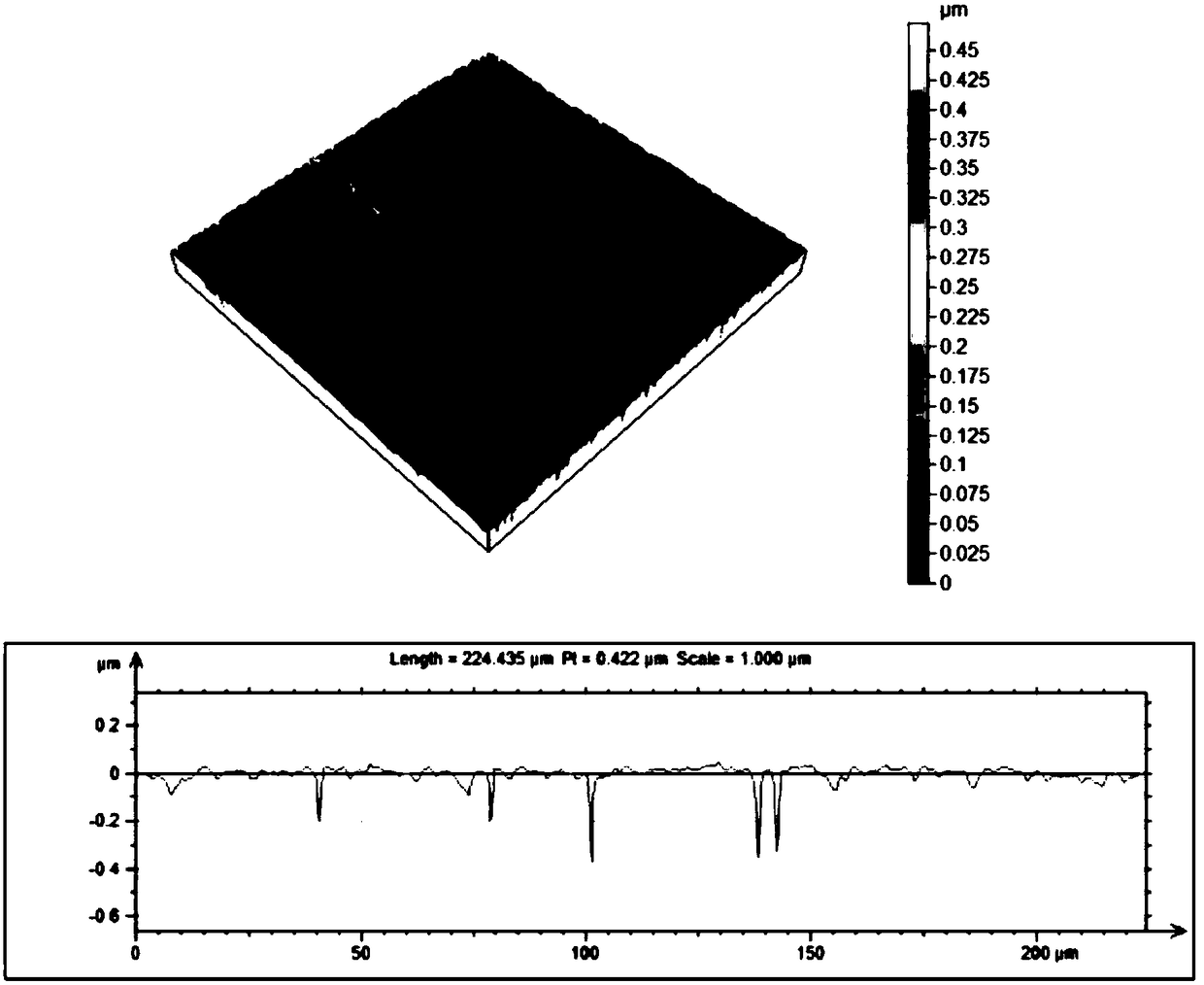

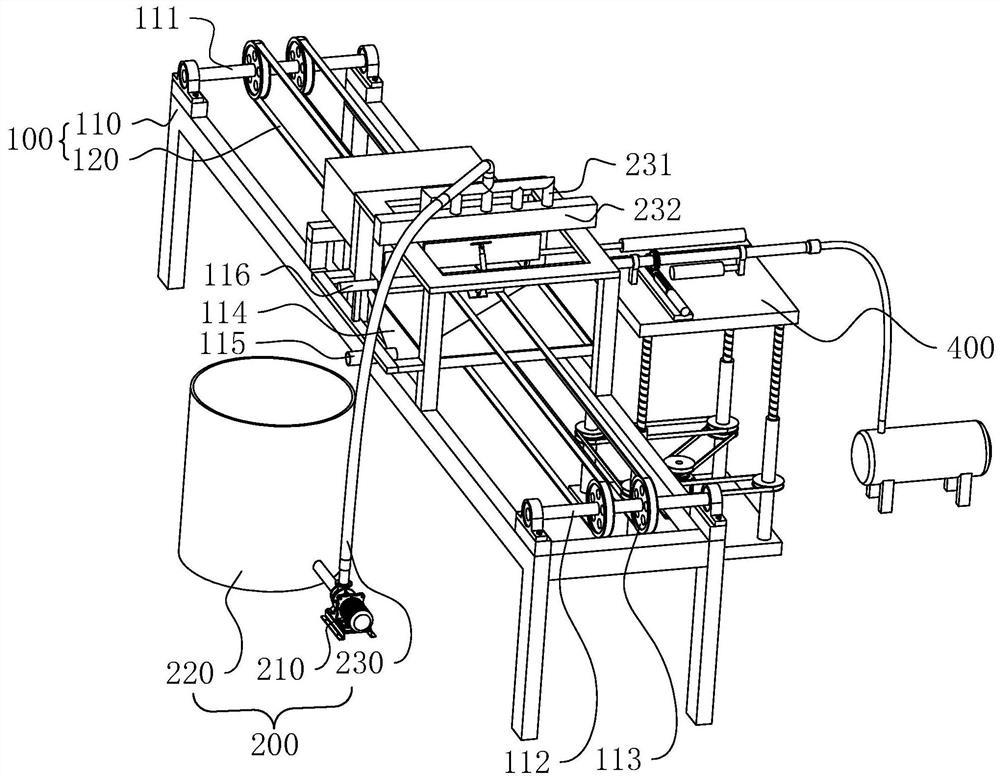

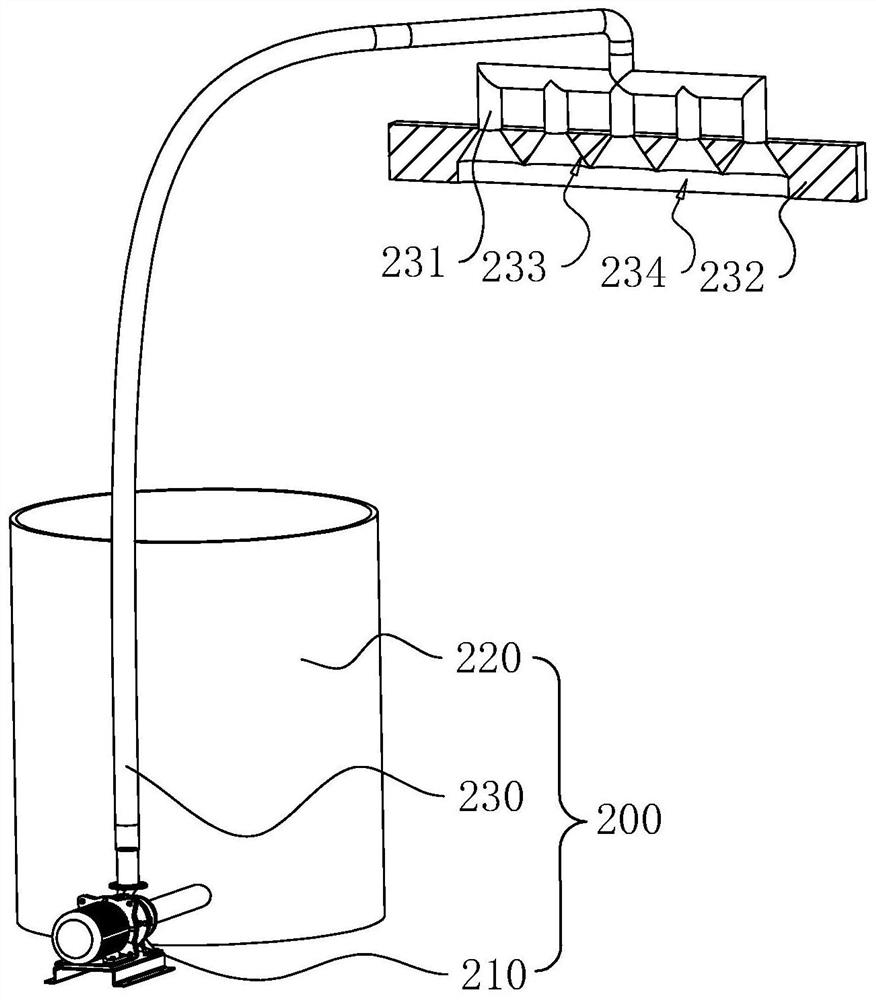

A method for preparing vitrified bond grinding wheel by liquid-phase raw material technology

ActiveCN106145946BCompact structureHigh strengthAbrasion apparatusGrinding devicesSlurryZirconium oxychloride

Owner:HUNAN UNIV

Glazed tile and preparation method thereof

ActiveCN113185262AThe firing process is simpleReduce usageCeramic materials productionClaywaresFritGlaze

The invention relates to the field of ancient building tiles, and particularly discloses a glazed tile and a preparation method thereof. The glazed tile comprises a tile blank and a glaze layer, wherein the glaze layer is laid on the outer side of the tile blank, and the tile blank comprises the following substances in parts by weight: 15-25 parts of Laiyang soil, 50-70 parts of kaolin and 15-25 parts of low bauxite; and the glaze layer comprises the following substances in parts by weight: 15-25 parts of lead frit, 12-17 parts of kaolin, 22-29 parts of glass frit and 35-42 parts of pigment. The glazed tile has the advantage that the firing cost of the glazed tile is reduced. The glazed tile prepared by the preparation method has the advantage of few glaze bubbles.

Owner:邹平宏宇博鹰建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com