A method for preparing vitrified bond grinding wheel by liquid-phase raw material technology

A vitrified bond and raw material technology, applied in the direction of ceramic products, abrasives, manufacturing tools, etc., can solve the problems of inability to fundamentally refine the vitrified bond, uneven mixing, easy agglomeration, etc., and achieve the synchronization of grinding shape and surface Good stability and retention, good uniformity and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049]

[0050] 1) Preparation of multi-component sol: According to the formula shown in the above table, Zn(NO 3 ) 2 ·6H 2 O, LiNO 3 , NaNO 3 , Al(NO 3 ) 3 9H 2 O, ZrOCl 2 ·8H 2 O was dissolved in 43.9 g of deionized water to make a mixed solution; weigh industrial grade SiO 2 Sol, slowly drop into the above mixed solution under the condition of uniform stirring, stir and mix on the constant temperature heating magnetic stirrer, set the temperature at 50 ° C, and dilute with 10% HNO 3 The solution adjusts the pH of the multi-component sol to be 2;

[0051] 2) Add 10vol% N,N-dimethylformamide to the multi-component sol, then add 2.16 grams of polynaphthalene-based superplasticizer, and mix well;

[0052] 3) In the multi-component sol prepared as described in 2, fix the rotating speed at 340r / min, add diamond abrasive (the quality of the abrasive accounts for 70% of the total mass of the forming grinding wheel), stir for 30min, and adjust the pH of the mixed slurry...

Embodiment 2

[0057]

[0058] 1) Preparation of multi-component sol: According to the formula shown in the above table, Zn(NO 3 ) 2 ·6H 2 O, LiNO 3 , NaNO 3 , Al(NO 3 ) 3 9H 2 O, ZrOCl 2 ·8H 2 O was dissolved in 44.2 g of deionized water to make a mixed solution; weigh industrial grade SiO 2 Sol, slowly drop into the above mixed solution under constant stirring conditions, stir and mix on a constant temperature heating magnetic stirrer, set the temperature at 55°C, adjust the pH of the multi-component sol to 2.5 with diluted ammonia solution;

[0059] 2) Add 10vol% N,N-dimethylformamide to the multi-component sol, then add 2.14 grams of naphthalene-based superplasticizer, and mix well;

[0060] 3) In the multi-component sol prepared as described in 2, the fixed speed is 400r / min, add diamond abrasive (the quality of the abrasive accounts for 75% of the total mass of the formed grinding wheel), stir for 30min, and adjust the pH of the mixed slurry to be 4 , Pour the obtained slu...

Embodiment 3

[0065]

[0066] 1) Preparation of multi-component sol: According to the formula shown in the above table, Zn(NO 3 ) 2 ·6H 2 O, LiNO 3 , NaNO 3 , Al(NO 3 ) 3 9H 2 O, ZrOCl 2 ·8H 2 O was dissolved in 45.4 g of deionized water to make a mixed solution; weigh industrial grade SiO 2 Sol, slowly drop into the mixed solution under stirring conditions, stir and mix on a constant temperature heating magnetic stirrer, set the temperature at 60°C, adjust the pH of the multi-component sol to 3 with diluted ammonia solution;

[0067] 2) Add 10vol% N,N-dimethylformamide to the multi-component sol, then add 2.11 grams of naphthalene-based high-efficiency water reducer, and mix well;

[0068] 3) In the multi-component sol prepared as described in 2, the fixed speed is 360r / min, add diamond abrasive (the quality of the abrasive accounts for 80% of the total mass of the formed grinding wheel), stir for 30min, and adjust the pH of the mixed slurry to 5 , Pour the obtained slurry int...

PUM

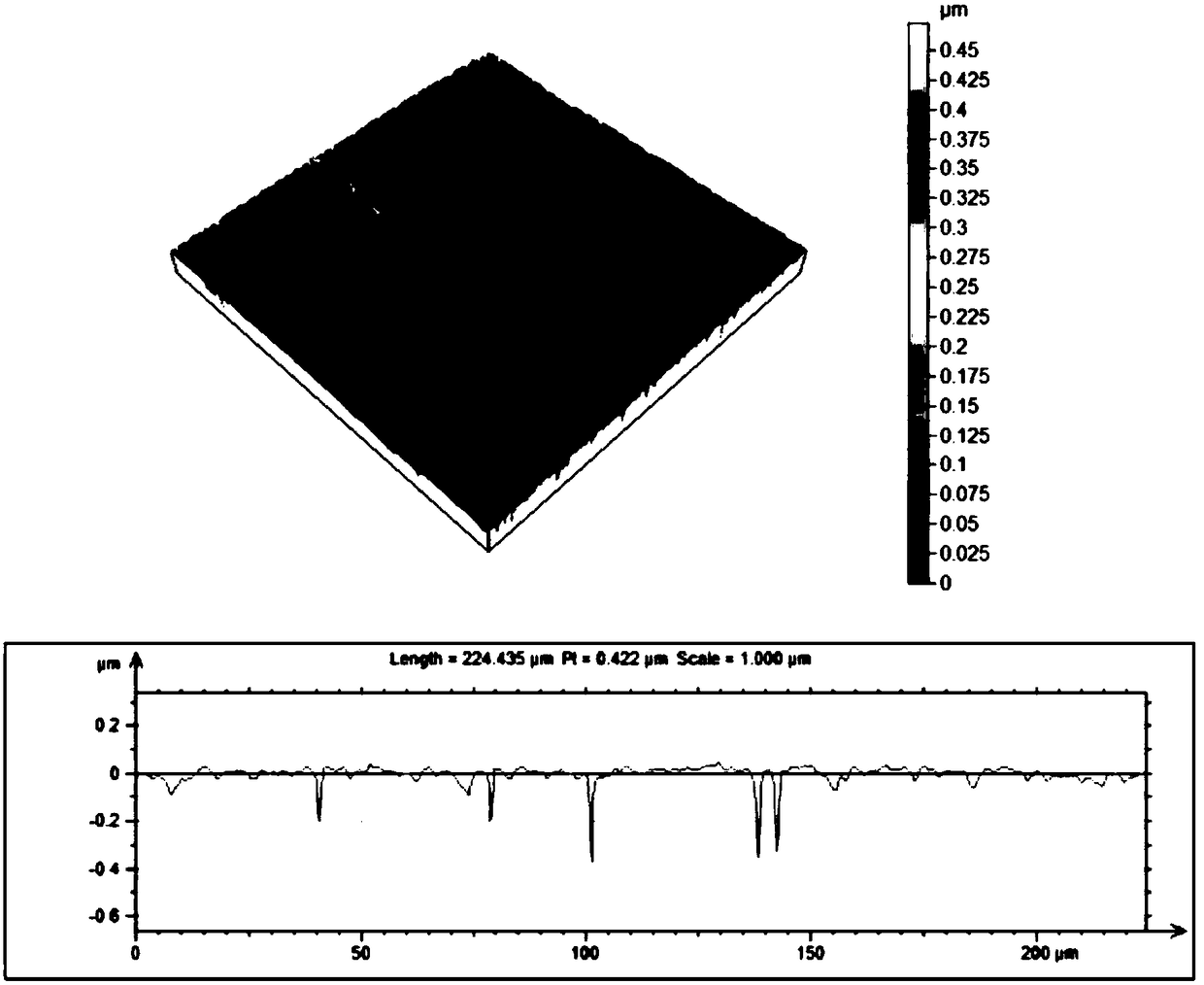

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com